Rotary Tablet Press: The Complete Buying Guide In 2025

Tablets are preferred over many other drug delivery modes due to their enhanced stability, longer shelf life, and strong resistance to environmental factors. Similarly, the production of tablets has been prevalent in food, chemical, and other industries. Therefore, producing such large number of tablets with good quality and structure is not a manual task rather it requires an intelligent, sophisticated, and upgraded machine which the the one and only Rotary Tablet Press.

Rotary tablet press is becoming an inevitable equipment to deal with the manufacturing of tablets due to its quick, efficient, and safe functioning. You may be curious to know more about its benefits, working, classification, and installation etc. That's why we have come up with this informative review to answer all of your queries regarding a rotary tablet press. So, let's come to the point and begin exploring these all!

1.What Is A Rotary Tablet Press?

Allpack- Rotary tablet press machine ZP-5B

Rotary tablet press refers to an advanced machine tailored with astonishing features to produce tablets by compressing powder and granules. It uses double punch system to effectively press tablets at relatively high speed. The machine is capable of processing different types of tablets in various industries including pharmaceutical, chemical, and food industry etc.

It works by taking powder from hopper into die cavities after which the compression of upper and lower punch at same speed take place. It resultantly produces uniform and consistent tablets. While pressing tablets, the machine takes care of the hygiene of stuff as being made from quality stainless steel body.

2.Write Down The Features Of A Rotary Tablet Press?

You might be thinking about the features which make a rotary tablet press must have equipment in your business. So, let's know few of the notable ones!

High Throughput

Compared to single punch tablet press, rotary tablet press has extremely high throughput due to its multi-station turret. That's why, it can produce thousands of tablets in an hour.

Automatic Technology

Automatic technology of rotary tablet press- Picture Courtesy: tablettingscience.com

Rotary tablet press has high automation level as a result of which it can perform multiple tasks of powder weighing, tablets pressing, rejection, and formed tablets ejection etc. Hence, it is highly efficient which is why it saves on your time and human labor.

Enclosed Structure

Enclosed structure of rotary tablet press

The machine is a perfect manifestation of quality material. All its contact parts are being made with safe stainless steel which do not allow any adverse reaction even after contacting chemical formulation. Moreover, the transport protection window around the working chamber is allowing user to observe the operation easily while as restricting environmental elements.

High Accuracy

Accurately compressed tablets- Picture Courtesy: Freepik

Rotary tablet press has designed with quality punching tools which is essential for formulating precise tablets. Together with the application of uniform pressure by upper and lower punch, they produce uniform, solid, and smooth tablets by reducing the errors such as sticking, capping, and chipping etc.

User-friendly

This machine is highly user-friendly with its compact body which is easy to mobilize and adjust. In addition to it, the machine has an intuitive human machine interface which simply enable operator to set commands in it and the rest of operation will be carried out by the machine itself.

Versatile

Variety of compressed tablets- Picture Courtesy: icapsulepack.com

Rotary tablet press is versatile enough to process tablets with different particles size and ratio. Moreover, by changing die cavities and punches, you can make tablets of different sizes and shapes by using the same machine.

3.What Type Of Tablets Can Be Made By Using A Rotary Tablet Press?

When it comes to highlight the tablets variety being supported by a rotary tablet press, a long list will be the answer. Since, discussing each of them is not worthwhile, a precise but comprehensive description has been provided to get you to the point:

| Tablet Types | |

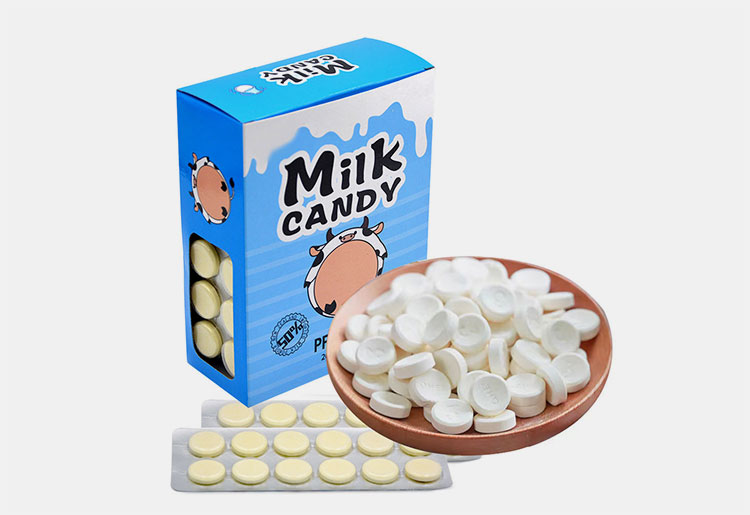

| Candy Tablets

CBD candy boxes- Picture Courtesy: candy-head.com |

Candy tablet is a form of confectionery which is made from enticing flavors along with vibrant colors and sugar as a main ingredient. They are consumed as snacks like gummy and chocolate etc. To Make these candy tablets, a rotary tablet press is perfectly applicable. |

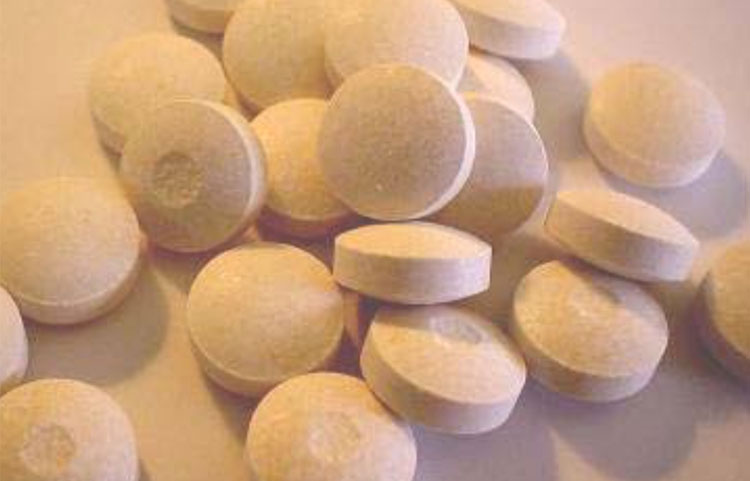

| Medicated Tablets

Six oval white medication pills- Picture Courtesy: wallpaperflare.com |

Tablet is the most popular dosage form being practiced in medical industry. Whether producing pharmaceutical, nutraceucal, or herbal tablets, this machine is suitable to be used. |

| Chlorine Tablets

Drinking water safe chlorine tablets- Picture Courtesy: accepta.com |

Chlorine tablets are disinfectant tablets commonly used for cleaning water and disinfecting the floor of houses and hospitals. They come in small to large size and can be easily made by using a rotary tablet press. |

| Effervescent Tablets

Effervescent tablets- Picture Courtesy: rappler.com |

Effervescent tablets are large size tablets with sodium bicarbonate as a principal ingredient. These tablets release carbon dioxide upon contacting with water to support quick disintegration. Despite their distinct specifications, a rotary tablet press is reliable machine for pressing effervescent tablets. |

| Tablet Layers | |

| Single Layer Tablets

Single layer tablets- Picture Courtesy: medelpharm.com |

Single layer tablet is the common form of tablets which we use in our daily life when suffering from fever or flue etc. Such type of tablets have only single form of mixture. So, you can use this machine to make such tablets. |

| Double Layer Tablets

Bilayer tablets- Picture Courtesy: bioprocessonline.com |

As the title illustrates, double layer tablets consist of two separate formulations being gathered in form of a single tablet by using a rotary tablet press. |

| Triple Layer Tablets

Triple layer tablets- Picture Courtesy: gbu-taganskij.ru |

Triple layer tablets are rare form of tablets with resembling three separate sections each holding a different solution as well as color. They are famous in confectionery and pharmaceutical industry. |

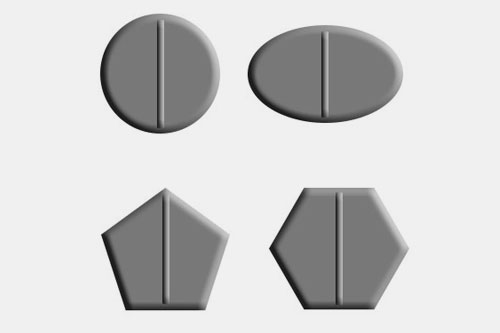

| Tablet Shapes | |

| Multiple Tablet Shapes

Multiple shapes for tablets- Picture Courtesy: wikidoc.org |

Rotary tablet press can make tablets of various shapes including round, oblong, oval, triangle, square, trapezium, and others. |

4.Explain The General Working Principles Of A Rotary Tablet Press?

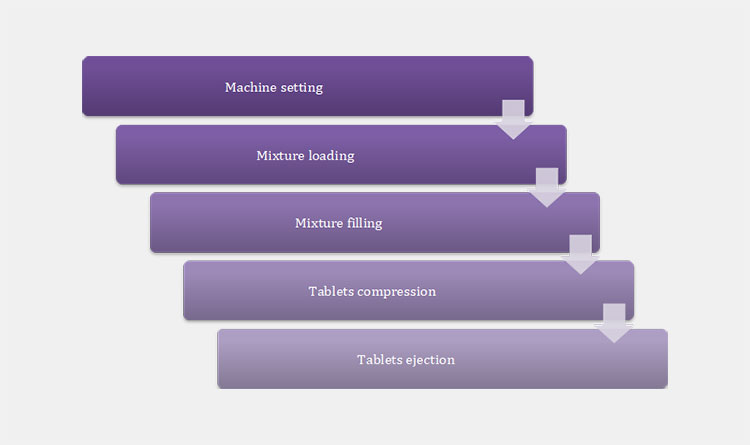

Now, let's talk about the general working principles of a rotary tablet press which are easy to understand and employ practically. These include:

Machine Setting

Before you start your rotary tablet press, it is significant to set its structural tooling as well as the parameters setting. Fix the pressure to be exerted during compression and the amount of powder mixture to be taken for each tablet.

Mixture Loading

Once the setting is done, you can load the hopper of machine with bulk of mixture so as to enable the machine to work smoothly throughout operation. Depending upon the machine type, like in case of bilayer and triple layer tablets, you need to load different mixtures in separate hoppers located in the machine.

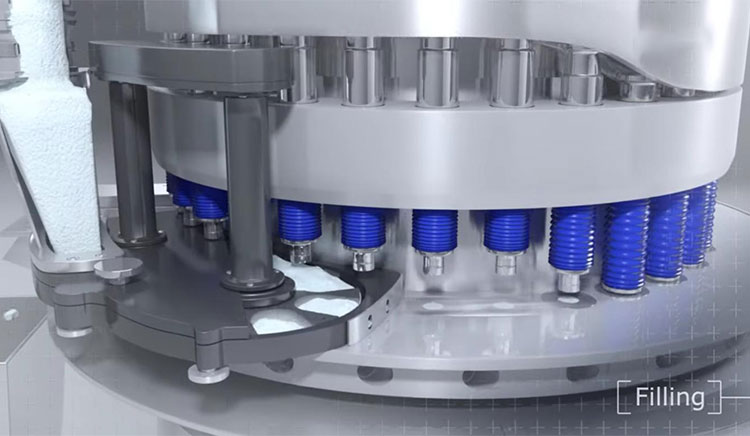

Mixture Filling

Mixture Filling- Picture Courtesy: tablettingscience.com

Now, you can start the machine for the execution of commands you have settled in. After switching it on, the machine will start taking the powder or granulated mixture from hopper towards rotary turret where it is poured into dies. The lower punches move downward and the upper punches move upward to create cavity in dies. In this way, the die cavities are filled with mixture.

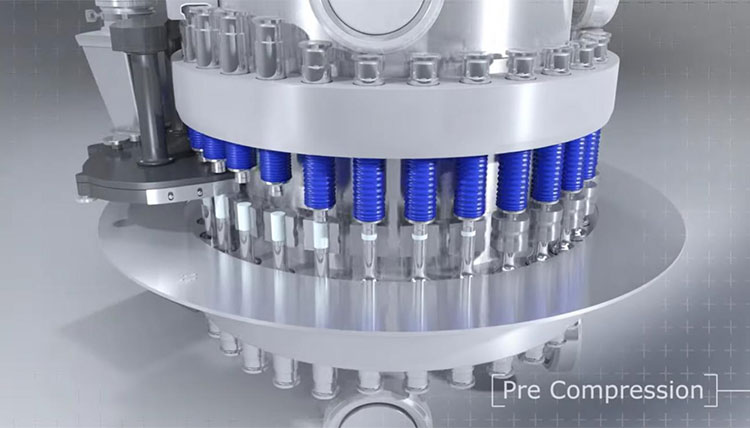

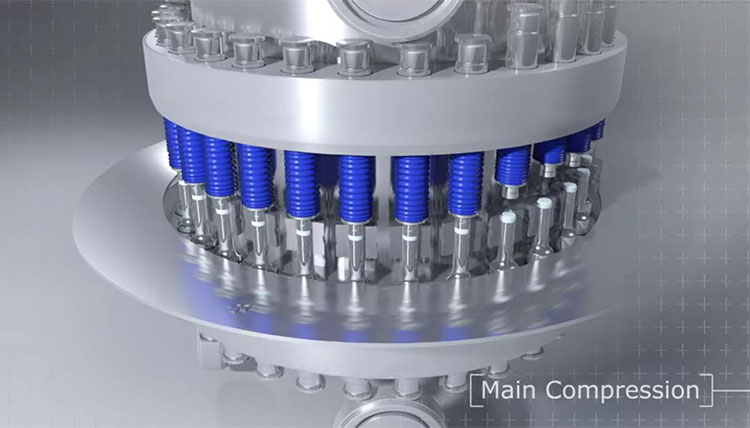

Pre Compression

Pre Compression- Picture Courtesy: tablettingscience.com

Once the filling stage is completed, compression stage begins. The first compression stage is called pre compression where a little pressure by upper punches is applied to the mixture laying in die cavities. Its purpose is to create a slug by removing the presence of void and air pockets in order to make uniform tablets.

Main Compression

Main Compression- Picture Courtesy: tablettingscience.com

After pre compression, the upper punches exert immense force on the slug which result into the creation of hard and uniform tablets. This stage is known as main compression as the mixture is turned into a compact tablet form.

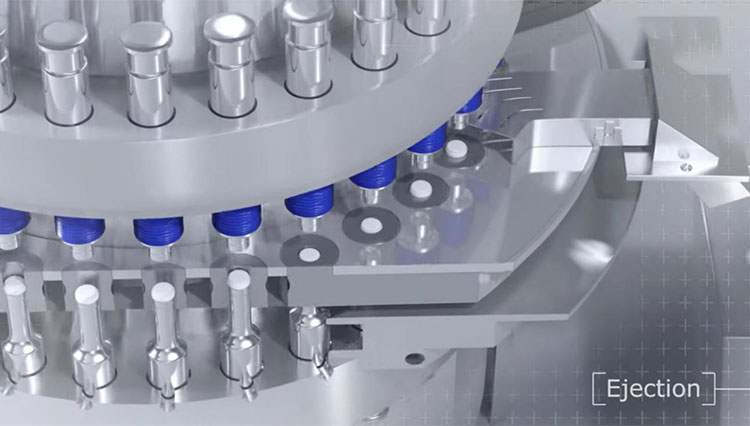

Tablets Ejection

Tablets ejection- Picture Courtesy: tablettingscience.com

At the end, compressed tablets are supposed to be ejected out of the machine. For this, upper punches move backward and lower punches move upward taking the compressed tablets to discharge station. Here, with the help of a scrapper, tablets are one by one discharged through chute.

5.Describe The Structure Of A Rotary Tablet Press?

The structure of a rotary tablet press is compact with multiple components. Together they enable the machine to work smoothly. Some of the core components are described below:

Components of Allpack ZP25 effervescent rotary tablet press machine

Hopper

Hopper is stainless steel container located on the top of rotary tablet press. It is used to hold and supply the machine with powder or granulated mixture required for tablets formulation. Inside hopper has a mechanism to control the flow of material. It can be vibratory or auger depending upon the mixture specifications.

Stainless Steel Body

The body of machine is made up of quality stainless steel which is corrosion resistant to avoid cross contamination. The main frame is also consisting of a stainless steel material and all other components are attached to it.

Rotary Table

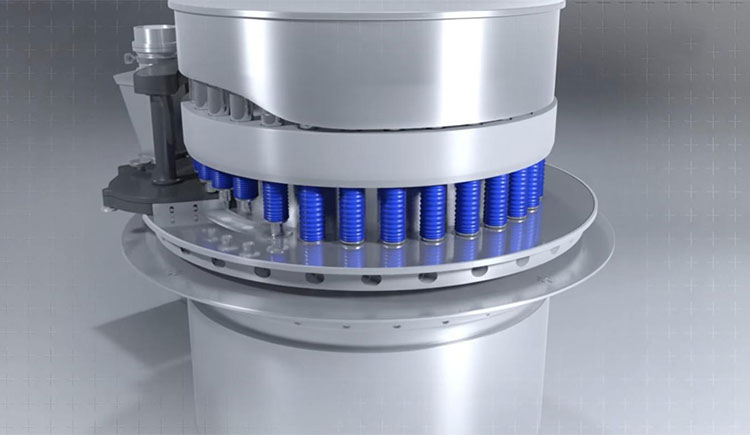

Rotary table or working chamber is the core part of a rotary tablet press. It consists of several other components which enable the machine to perform its actual function. These include:

Punches:Punches are integral part of the rotary tablet press. They are made from durable stainless steel with special tip to meet the tablets' specific shapes and sizes. Each punches set consists of a lower punch and upper punch. Between these two punches, powder is compressed into tablets by use of force.

Dies:Dies are rigid tools having inside them the holes of particular shape where the lower and upper punches meet in order to compress powder. They are instrumental in shaping the structure, size as well as the thickness of tablets. Hence, they require regular maintenance and cleaning.

Cam Tracks:These are small, curved grooves which play their important role in guiding upper and lower punches during tablets compression. For instance, they raise upper punches for allowing mixture to get into die cavity during filling. Similarly, with the help of cam tracks, punches come together for compression and separate apart for ejection.

Turret:Turret is a rotary plate which accommodate punches, dies, and cam tracks. It is considered the invaluable part of rotary tablet press. Moreover, due to its distinct role and round structure, turret carries enable the machine to carry out its function by performing mixture filling, tablets compression, and ejection through taking intervals during operation.

Compression Rolls

Compression rolls are among other important tools. They include pre compression rolls which apply less pressure and main compression rolls for releasing high force to get the desired tablets.

Organic Glass

It refers to the transparent window which surrounds the rotary working table. It is helpful in allowing operator to observe the operation without contacting it and providing safe environment for tablets formulation.

Operation Penal

As the name indicates, operation penal is a part of rotary tablet press where multiple knobs along with intuitive human machine interface are located to control and operate machine.

Emergency Stop

The machine has a large size red color button situated on its front to deal with sudden breakdowns and emergency.

Discharge Chute

It is a stainless steel device attached to the rotary turret for discharging the compressed tablets.

Adjusting Handle

Depending upon the type of rotary tablet press, it has number of adjusting handles which are used for changing the force of compression rolls.

Electric Appliance Box

It is an electric enclosure that encases electrical wires, fuses, and other circuits inside it.

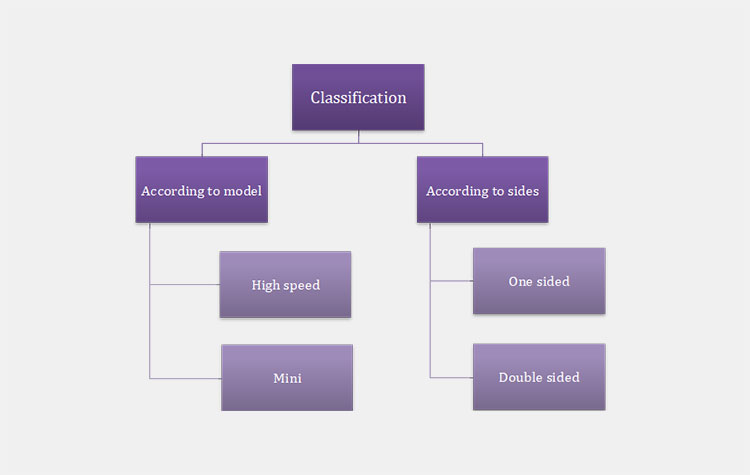

6.What Is The Classification Of A Rotary Tablet Press?

Rotary tablet press can be classified into different types. In this way, details given below will be helpful:

According to Model

High Speed Rotary Tablet Press

Allpack- High speed high capacity GZPS660 series western medicine pill making rotary tablet press machine

This high speed rotary tablet press by Allpack is the most updated model of rotary tablet press with extremely high output ratio up to 675,000 tablets per hour. It has a big touch screen computer display which allows for easy interaction of operator. Moreover, the machine support integration of other machines like tablets deduster, tablets sorting machine, and coating machine etc. It is perfectly suitable for large and extra large industries in every sector.

Components

The body of machine is highly robust and a bit comprehensive which is holding inside its body all the other components. The major parts include a stainless steel body, touch screen penal, light indicators, waste rejector, pressure sensor, impeller type force feeder, and working chamber etc.

Working Principles

It works automatically by taking mixture from hopper and processing it through filling, metering, compression, and ultimately ejection stage.

Mini Rotary Tablet Press

MiniPress II Fully Automated Rotary Tablet Press- Picture Courtesy: pharma-test.de

Mini rotary tablet press is an advanced machine with updated technology to efficiently compress tablets. It is suitable to deal with medium scale production. The machine has good output by producing up to 77,000 tablets in an hour. It is fully automatic in technology and is perfect for laboratories, research centers, and small to medium pharmacies.

Components

The structure of machine is durable and precise with many parts including a robust body, material hopper, operation chamber, control panel, adjustment tools, and electric cabinet etc.

Working Principles

It follows simple working principles by functioning independently once settled by operator. Hence, it carries out task by material filling into dies, compressing them, and ejecting them out of the machine.

According to Sides

Single Side Rotary Tablet Press

Single Sided Square GMP Mini Tablet Press- Picture Courtesy: deepujpharmamachinery.com

As the name display, this type of machine has a single side to form tablets. That's why, it is cost-effective and has simple operational procedure. With single hopper and working chamber, it can compress up to 40,000 tablets in an hour. Hence, it is reliable for medium size volume.

Components

The machine consists of several components including a compact body, control unit, electric cabinet, single hopper, uni turret, adjustment tools, and glass windows etc.

Working Principles

It simply works by using single hopper for filling the die cavities with mixture and then allowing punches to compress the powder. Afterwards, the compressed tablets are discharged from the machine through a chute.

Double Side Rotary Tablet Press

Double Sided High Speed Rotary Tablet Press- Picture Courtesy: deepujpharmamachinery.com

Double sided rotary tablet press is an efficient machine with dual chamber for tablets compression. It can deal with even higher number of tablets that's why its production output reaches up to 3,38,400 per hour. Hence, for excessive workload areas, this machine is the ever-best choice.

Components

The machine has relatively complex structure with dual hopper, dual rotary turret, adjusting handles, control system, and main frame etc.

Working Principles

Its working principles are similar to that of other machines; however, it only differs in a way that it processes two turrets at same time. The upper one gets mixture from hopper location on one side while as the lower turret takes mixture from the hopper of other side. Similarly, both these chambers undergo filling, compression, and ejection stage.

7.Highlight The Applications Of A Rotary Tablet Press?

Rotary tablet press has wide applications in numerous sectors including:

Confectionery Industry

Milk tablets- Picture Courtesy: oemcandy.com

Confectionery industry is constantly engaged in making fruit flavored tablets, milk tablets, sour tablets, and other powder or granulated tablets. For their manufacturing, a rotary tablet press is used by manufacturers on industrial level. It can beautifully create single layer, bilayer, and triple layer colorful tablets.

Pharmaceutical Industry

Pharmaceutical tablets & capsules- Picture Courtesy: medino.com

Another most notable application of a rotary tablet press is pharmaceutical industry where the production and processing of millions of tablets is carried out on daily basis. Hence, meeting such giant production target is only the ability of a rotary tablet press.

Supplement Industry

Supplement tablets- Picture Courtesy: nutrifactor.com.pk

The time has gone when people used to rely only on conventional medication for their treatment. Now, with advancements in technology and growing concern about health has shifted the focus more on taking nutraceutical supplements for being rich in protein, vitamin, and minerals with almost no side effects. Hence, they are often delivered in form of tablets and pills for which this machine is employed.

Pet Care Industry

Doctor holding pets in hand- Picture Courtesy: petcareins.com

The use of drugs especially tablets is not also rare in pet care industry. Similarly, to treat the vary illnesses of animals, medication is often enclosed in tablets for which the help of a rotary tablet press is taken.

Chemical Industry

Jumbo chlorine tablets- Picture Courtesy: lesliespool.com

The use of a rotary tablet press can also be found in chemical sector where pesticides, detergent, and disinfectants are delivered in form of tablets. Hence, to reduce their negative effects while producing, the enclosed structure of this machine is worthwhile.

8.What Quality Standards Should A Rotary Tablet Press Meet With?

As a rotary tablet press is made for the processing of tablets, it must be the product of highest quality material. Now, you may be thinking how to confirm whether a rotary tablet press is of quality material or not. For this, you need to check its certifications by certain quality standards including:

ISO quality standard- Picture Courtesy: arenasolutions.com

International Organization for Standardization (ISO)

ISO is an international organization established for ensuring that all the goods and equipment which are made for food and drugs should be safe. Therefore, it is obligatory for every rotary tablet press to be certified by ISO.

Good Manufacturing Practices (GMP)

GMP is another notable quality standard formed for controlling the manufacturing and processing of products to make sure they are made from good material. 304, 314, and 316 stainless steel are among the GMP's regulations for making rotary tablet press.

Food and Drug Administration (FDA)

FDA is American agency created for the purpose of ensuring public health and safety by establishing principles for industries to meet while producing their machines. Thus, a rotary tablet press should meet its standards.

Conformate European (CE)

CE is the certification mark of European Union. Therefore, if any country wants to sell their products in European Union countries or if the member state aim to produce their own machine, then they must possess this mark which comes with adhering their health and environmental safety policies.

9.What Are The Future Trends For A Rotary Tablet Press?

Future trends illustration- Picture Courtesy: startupsmagazine.co.uk

The future trends for rotary tablet press are prosperous for the reason that tablets have not been replaced by any other dosage form up till now. Despite the growing popularity of gummies, oral strips, and softgels, tablets are still the most convenient and cost-effective dosage form.

Its significance can also be seen by the introduction of updated rotary tablet presses and the expected growth of rotary tablet press market to reach XX.X USD billion by 2031. Moreover, the available customization options, wide applications, and updated technology has enhanced its appeal which is becoming the reason why producers from different sectors are looking forward for its use.

10.How To Maintain Your Rotary Tablet Press For Effective Working?

Once bring into operation, rotary tablet press must be maintained on regular basis for ensuring its fluent and non-stop functioning. The underlying explanation will help you in conducting sound maintenance of your rotary tablet press:

Maintenance program icon- Picture Courtesy: gesrepair.com

Cleaning:Cleaning is very important for rotary tablet press as it has to deal with mixture of different nature. So, each time when you are done with one type of tablets compression make sure to clean your machine. Remove out all the debris, dust, and pollution accumulated on the vary parts of machine.

Parts Replacement:In case of parts damage or wear and tear, it is eminent to take notice of them and timely replace them with new ones to avoid material damage and machine performance.

Greasing:Add lubrication oil to the moving parts of machine as it will reduce the chances of parts breakdown and possible friction which might cause inefficiencies of machine.

Adjustment:Inspect your machine on regular basis. In case you notice unusual voice or abnormal part then quickly stop machine and adjust the parts to be on right place. In addition to it, setting of parameters like dwell time, mixture amount, and tablets size must be modified before starting operation.

11.Diagnose The Spontaneous Errors Of A Rotary Tablet Press?

Like any other machine, rotary tablet press may also display some sudden errors. So, no need to worry about that. Just follow the upcoming guidelines to tackle these issues easily by your own!

Tablets capping

Tablets capping- Picture Courtesy: scientistlive.com

It occurs when the compression phase has just completed, and the formed tablet gets stick to upper punch and get cracked.

Cause:

It may be due to air which is trapped inside the die cavity.

The mixture is not prepared well or mixed.

Lack of binding agent cause dryness in mixture causing tablets to fall apart.

Solution:

It can be solved by extending the dwell timing of pre compression phase.

Prepare the mixture properly before using it for compression.

Add binders to the mixture and process it in fluid bed dryer to create adhesiveness in mixture.

Tablets sticking and picking

Tablets sticking

It refers to situation when the top of tablets usually logo place get stick to punches.

Cause:

It happens when the mixture is not dried properly due to which it sticks to punch tip.

Another reason can be a minor issue in punches head.

Solution:

Make sure to give proper timing to mixture for drying during preparation.

To avoid sticking and picking, polish the punch head.

Tablets lamination

Tablets lamination- Picture Courtesy: bosch-wn.at

Tablets lamination occurs when tablets get cracked other than top.

Cause:

Mostly, this is due to the over compression which restrict particles of mixture to bind together.

The shallower depth of punches also causes tablets lamination.

Solution:

Reduce the compression force to resolve the issue.

Change the punches and use ones with relatively even surface and different shapes like square and circle etc.

Tablets breakage

Tablets breakage- Picture Courtesy: singlecare.com

It means that tablets are extremely friable and prone to breakage causing problems in handling.

Cause:

First reason is the low amount of stabilizers and emulsifiers.

Second cause is the too much pressure being exerted during compression.

Third reason is the large particles in mixture.

Solution:

Add sufficient amount of binders to make uniform tablets formula.

Reduce the pressure to suitable level to avoid tablets breakage.

Make sure to breakdown the particles and granules of mixture where they can easily stick together when pressure is applied.

12.Factors To Consider When Buying A Rotary Tablet Press?

When buying a rotary tablet press you may get puzzled in multiple questions and get confused to opt for which one. Hence, we have come up with this question to address your queries and present some valuable factors for making sound purchase. These are as follows:

Production Volume

First you need to examine your current production volume and then decide what machine will be suitable for your. If you are running medium size production facility then single side rotary tablet press or mini rotary tablet press will be a better choice. However, in case of large industry, going for advanced high speed rotary tablet press will help you increase your production.

Type of Tooling

Rotary tablet press dies & punches tooling- Picture Courtesy: indiantoolsengineering.co.in

As rotary tablet press has a set of tooling, die and punches, which is its integral part, it is crucial to have awareness about each type. Similarly, you need to choose the right tooling system for your rotary tablet press among B, D, BB, and DB tooling.

Specific Features

Features icon- Picture Courtesy: depositphotos.com

Each machine has specific features like fun extraction mechanism, safety guards, and controlling system. So, if you want to have all the safety features available in your rotary tablet press then opt for the most updated machine. Otherwise, choosing ordinary model will have a low economic burden.

Quality Assurance

Quality assurance icon- Picture Courtesy: blog.pbbg.com

Quality assurance is a factor that must be paid heed. After all you are spending your good amount of money and that's your right as well as responsibility to choose the supplier with expertise in the field, customer support and warranty policy for the machine you are going to purchase.

Conclusion

The bottom line is that a Rotary Tablet Press is a fundamental equipment of pharmaceutical industry and now food as well as chemical industry. Clear understanding of its features, working process, tooling system, and structure are valuable to make the best use of it. All these simply require your attention and eagerness to gain relevant information which has been provided above. Now, when you have known almost everything about a rotary tablet press, what is your next step? Are you planning to buy the machine? If yes! Then contact us now to present you top class machines offered by Allpack!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide