Protein Powder Filling Machine: The Complete Buying Guide In 2025

Protein powders are nutritional supplements obtained from natural sources such as animals, plants and vegetables etc. They are highly beneficial for physical as well as mental growth of humans, due to which most of the people around globe prefer using protein powders in their daily diet. Are you also fond of taking protein powders? Or are you among the manufacturers contributing to reach the market of protein powders up to 22.3 billion worth? If yes! You must be looking forward to get the best protein powder filling machine to keep the pace of your production.

Therefore, Allpack brings you an excellent protein powder filling machine with substantial benefits which can ultimately give you high throughput with easy handling and cost-effective price. This and lots of other information about applications, production line and process of protein powder filling machine has been mentioned below. So, let's take a look towards them!

1.What Is A Protein Powder Filling Machine?

Protein Powder Filling Machine-Allpack

Protein powder filling machine is a packaging machine that is employed to undertake the function of filling precise amount of protein powders and similar stuff in different containers. The machine is made up of antibacterial and corrosion resistant stainless to preserve the hygiene of powders during operation.

By adopting innovative high powder transmission mechanism, the machine works by continuously rotating agitator inside protein filled hopper to avoid jamming. Similarly, the powder is dispensed into containers through nozzles. While performing its function, the machine remains stable and shows strict adherence to set parameters in order to gain optimum results.

2.What Are The Advantages Of A Protein Powder Filling Machine?

A protein powder filling machine is designed in such a way that its use can give your business immeasurable incentives including:

High Productivity

Various powder filled bottles-Picture Courtesy: Byrdie

Featured with intelligent inspection system, high power filling mechanism and multi-stations, protein powder filling machine gives exceptional performance in terms of production.

Adaptable

Various containers with multiple protein powders-Picture Courtesy: fedandfit.com

Protein powder filling machine is resilient enough to fill any type of powder in range of small to large containers such as bottles, bags and cans etc. For instance, the machine can be easily adjusted for processing multiple objects through structural and operational modification.

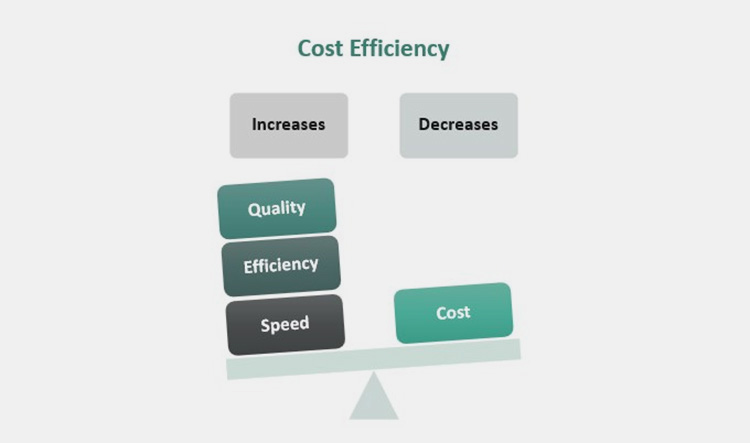

Cost-effective

Cost-effective idea-Picture Courtesy: wallstreetmojo.com

Protein powder filling machine is a cost-effective solution for the reason that it eliminates the need for labors to fill powder. Moreover, its compact structure saves space and ensures waste free filling.

High Accuracy

Protein powder bottle display-Picture Courtesy: Vital Proteins

The machine is well known for its high accuracy and precision for the reason that it is regulated by electric sensor due to which containers are filled with accurate amount of powder.

Easy Usability

Protein powder filling machine is equipped with advance features such as intuitive control panel, automatic detection system and fast changeover which together makes it easy for operator to regulate the machine.

3.Enumerate The Different Types Of Protein Powders Filled By A Protein Powder Filling Machine?

Protein powders are available in range of forms depending upon the type of ingredients used in them. Some of the common protein powders filled by this machine are as follows:

Whey Protein Powder

Whey protein bottle display-Picture Courtesy: Designer Wellness

Whey is the most common protein powder derived from animal milk and is great source of muscle recovery. It has fast digestion power that's why most of the people with sensitive stomachs prefer using it.

Casein Protein Powder

Casein protein powder bottle-Picture Courtesy: allmaxnutrition

Another type of protein powder which is filled by a protein powder filling machine is casein powder. Similar to whey, it is also obtained from cow's milk, however, its rate of absorption in your body is slower than that of former due to providing steadier effects which stay for longer.

Egg Protein Powder

Eggs and powder display-Picture Courtesy: nakednutrition.com

Egg protein powder is the most popular one among animal protein powders. It is mostly used by athletes for losing calories but preserving proteins for stimulating muscles growth.

Pea Protein Powder

healthline.com

Pea protein powder is the best alternative for vegans who avoid animal derived proteins. It contains nine effective amino acids which your body may not create. In addition, pea protein powder is the rapidly absorbable powder among other plant based protein.

Hemp Protein Powder

Hemp seeds & powder display-Picture Courtesy: thehempshop.co.uk

Hemp is another plant based protein powder available in form of seeds. It is the best natural protein for the reason of being consumed in its natural form. It also contains multiple minerals and vitamins. Therefore, it can be filled by a protein powder filling machine.

Brown Rice Protein Powder

Brown rice protein bag-Picture Courtesy:de.myprotein.com

Rice protein powder is rich in amino acids which is a great source of protecting your body from too much sugar in the blood. In this way, it de-risk the body from blood pressure and blood fats.

4.What Other Products Does A Protein Powder Filling Machine Process?

Apart from protein powders, there are range of other products which can be filled by this machine. They are highlighted below:

Flour

Wheat flour presentation idea-Picture Courtesy: 4burner.studio

All types of flour including wheat flour, peanut flour, pastry flour and bread flour etc., are packed in bags and containers where protein powder filling machine is used.

Milk Powder

Dry milk cans-Picture Courtesy: epicurious.con

With advancement in technology, people become more reliant on dry milk powder to fulfill their spontaneous need of milk. Hence, milk powders are among other products which are filled by a protein powder filling machine.

Coffee Powder

Coffee beans & powder display-Picture Courtesy: closetcooking.com

Coffee powder is obtained from roasted coffee beans for easy usability. It is packed in different containers, jars and bags where need for a protein powder filling machine is realized.

Condiments

Spices presentation idea-Picture Courtesy: Tasty Food Lovers

Condiments are herbs used as additives in food for bringing new taste and aroma. As they are dangerous for eyes, their packaging is done through a protein powder filling machine.

Dyes

Food color powder display-Picture Courtesy: Suncore Foods

Dyes and colorants are powdered substances which are used to impart colors to objects. These objects may be food where dyes are used for flavors and colors, while, non-food matter for vibrant look. Therefore , they are also eligible to be processed by a protein powder filling machine.

5.Write Down The Containers Which Are Supported By A Protein Powder Filling Machine?

It is pertinent to mention here, that protein powder filling machine is not restricted to the single type of packaging container, rather it is applicable to different types of containers including those mentioned below:

| No | Containers | Description | Pictures |

| 1 | Bags | Bags are popularly used for packaging protein powders due to flexible nature which can be molded in different styles and designs. Moreover, plastic bags are cost-effective and good for low volume products. Hence, they can be filled by protein powder filling machine. |

Food color powder packaging idea-Picture Courtesy: Suncore Foods |

| 2 | Cups | Most of the protein powder packaging cups are made from paper. They are highly environmental friendly and cheap in price. For this reason, manufacturers eagerly use cups for filling protein and other powder substances through a protein powder filling machine. |

Coffee powder in cup-Picture Courtesy: mudwtr.com |

| 3 | Bottles | Bottles are highly durable and easy to carry due to which most of the powder proteins are packed in glass or plastic bottles. Therefore, these bottles can be filled by a protein powder filling machine. |

Matcha in bottle & spoon-Picture Courtesy: minimalistbaker.com |

| 4 | Jars | Jars are sustainable and eco-friendly storage containers with strong resistance to bacteria and moisture. These qualities often attract manufacturers to supply their quality protein powders in jars and gain valuable customer satisfaction. Ergo, these are also processed by a protein powder filling machine. |

Protein powder in jar-Picture Courtesy: simplegreensmoothies.com |

| 5 | Cans | Cans are made from thin metal often stainless steel or aluminum. They are lightweight and 100% recyclable as a result most of the time cans are processed by a protein powder filling machine to fill them with sufficient volume of protein or other powders. |

Square packaging cans-Picture Courtesy: AliExpress |

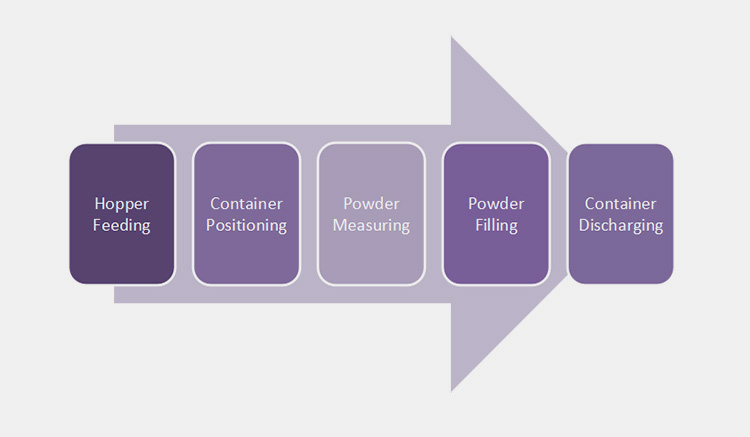

6.Explain The Working Procedure Of A Protein Powder Filling Machine?

The working procedure of a protein powder filling machine is as simple as any layman can easily operate it after knowing the working parameters once. Below is the description of operation of a protein powder filling machine:

Hopper Feeding

Hopper with an agitator-Picture Courtesy: Allpack

The first step required for operating a protein powder filling machine is to supply the hopper of machine with adequate volume of protein or other powders. It can be done automatically by attaching feeding station with hopper or manually loading bulk powder into hopper.

Container Positioning

Bottles during filling process-Picture Courtesy- JDAProgres-Canada

In second step, it is necessary to make sure that you have supplied the protein powder filling machine with sufficient number of containers to be filled. For automatic accurate positioning, bottle unscrambler may be used to assist the machine during operation.

Powder Measuring

Now, user can turn the machine on after setting essential parameters such as volume of powder to be filled in each container and speed of agitator or conveyor etc. Right after the machine is switched on, agitator will start rotary movement inside the hopper to avoid jamming of powder. At the same time, machine will measure volume of powder which comes from the outlet of hopper into auger filler.

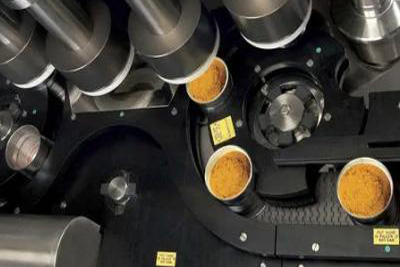

Powder Filling

Glass jar filling-Picture Courtesy: JDAProgres-Canada

After the realization of powder measurement, precise volume of powder will be filled in containers under the filling nozzles one after another.

Container Discharging

Finally, with the help of conveyor, all the filled containers will be discharged from protein powder filling machine to other machines for further packaging.

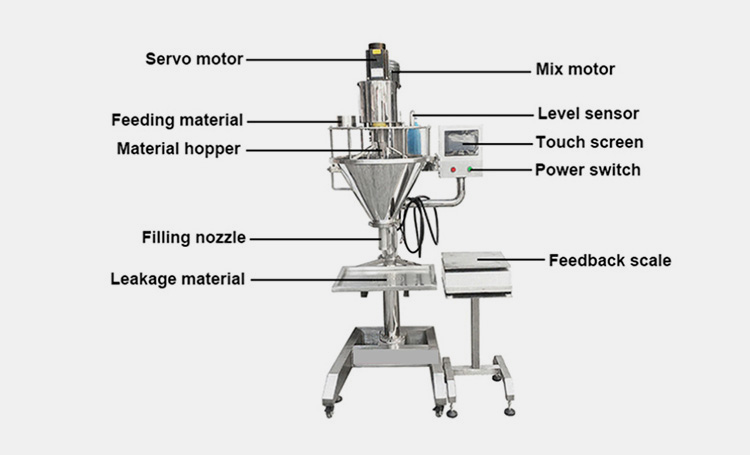

7.Describe The Structure Of A Protein Powder Filling Machine?

Structure of protein powder filling machine-Picture Courtesy: szhxmachine.com

A protein powder filling machine is composed of small to large parts, each contributing to the completion of machine's task. These components are made up of corrosion resistant stainless steel to avoid cross contamination. In following paragraphs, the structure of a protein powder filling machine will be clearly described:

Servo Motor

Servo motor is the significant part of a protein powder filling machine located on the top of machine to facilitate the movement of agitator inside hopper.

Mix Motor

Mix motor is a universal motor integrated in machine to drive other motors or machine such as servo motor and aid the magnitude of mixing

Level Sensor

Level sensor is the core component of protein powder filling machine with assigned task of measuring the level inside of containers which are filled with powder. Fundamentally, the sensor uses an electric eye to measure and monitor the volume of powder.

Feeding Material

Feeding material valve is situated on the upper side of feed hopper through which powder is supplied from feeding station into the hopper during operation.

Material Hopper

Material hopper is large size container located on the top of machine. Before starting operation, it is obligatory to supply the material hopper with enough volume of protein powder.

Touch Screen

Touch screen display is the outside manifestation of control system of machine. There are multiple icons displayed over the touch screen panel through which user set the parameters in machine for proper execution.

Power Switch

Power switch is large size green colored button which can be seen on the front of machine. When operator fix the setting of machine, power switch is used for final starting of machine.

Filling Nozzle

Filling nozzles are long narrow stainless steel tubes through which protein powder is conveyed into containers from hopper.

Feedback Scale

It is an apparatus integrated with machine to sequentially check the weight of filled containers.

Leakage Tray

Leakage tray is stainless steel flat plate over which containers are placed for filling. In case of product leakage or over filling, this tray saves the powders from being wasted.

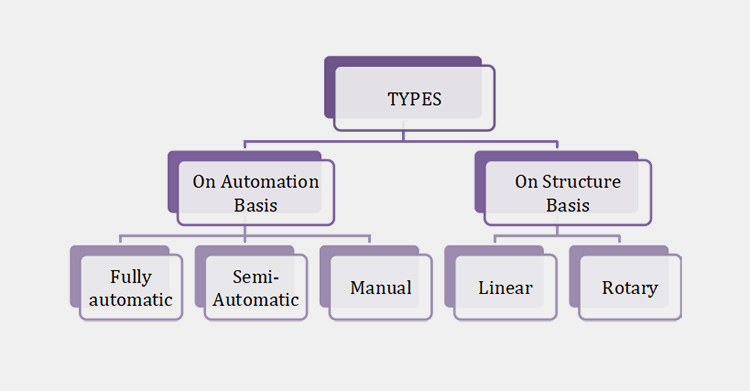

8.Explain The Various Types Of A Protein Powder Filling Machine?

Protein powder filling machine comes in various types on several basis to facilitate the broad range production of different industries. These types are enlisted below:

Fully Automatic Protein Powder Filling Machine

Fully Automatic Protein Powder Filling Machine-Allpack

Fully automatic protein powder filling machine is standalone device that can independently accomplish the task of processing, measuring, detecting and filling of protein powders. It consists of a hopper, mixer, servo motor, mixing motor, electric sensor, filling nozzle and mainframe. Allpack's fully automatic powder filling machine is capable of filling up to 50 cans per minute by a single filling nozzle. It is the best suitable device for large scale industries including food, herbal, medical and cosmetic industry etc.

Semi-Automatic Protein Powder Filling Machine

Semi-Automatic Powder Filling Machine-Allpack

Semi-automatic powder filling machine is compact structured machine which requires minimal operator intervention in achieving the filling of protein powders into bottles or bags. It is mainly composed of a hopper, control system, leakage tray and a foot pedal. With simple operational procedure, the user simply press the foot pedal for filling each container. The rest process of measuring and filling powder is done by the machine. By filling up to 10-30 bags or bottles per minute, Allpack's semi-automatic protein powder filling machine is the best suitable for medium scale production in different industries.

Manual Protein Powder Filling Machine

Manual Protein Powder Filling Machine-Allpack

Manual protein powder filling machine is cost-effective machine with reasonable price and small footprint. The machine is made with GMP's standard 304 quality stainless steel. It is composed of few parts comprising hopper, casters and a handle. The operator pushes the handle for filling each container. Same process goes on until the user realizes completion of desired number of containers. This compact machine is good for laboratories, markets and home based businesses.

Linear Protein Powder Filling Machine

Linear Protein Powder Filling Machine-Allpack

Linear protein powder filling follows straight path for filling powders into containers. There are different types of linear protein powder filling machine in terms of filling head such as single head, double head or multi head protein powder filling machine. It fills the bottles in a serialized manner. Similarly, the bottles are discharged by linear conveyor towards other machines.

Rotary Protein Powder Filling Machine

Rotary protein powder filling machine-Picture Courtesy: cvctechnologies.com

Rotary protein powder filling machine is multi head filling machine integrated with automatic features. It consists of a buffer hopper, nitrogen purging device, auger filler, agitators, filling nozzles and conveying system. The machine works by continuously moving agitators inside powder hopper. Similarly, bottles are pushed ahead towards rotary filling station by plastic bottle positioning device. These bottles are then filled by multiple filling nozzles with powder. At the end, all filled bottles are discharged through conveyor.

9.What Are The Applications Of A Protein Powder Filling Machine?

Protein powder filling machine has extensive uses in range of industries including those which are particularly mentioned below:

Food Industry

Multiple spices bags-Picture Courtesy- track-fiver.com

Food industry is the most prominent sector where the use of a protein powder filling machine is undeniable. All types of food powder including spices, coffee powder, milk powder, flour and custard powder are measured and filled by this machine.

Healthcare Industry

Pea protein powder display-Picture Courtesy: urbanplatter.in

Healthcare industry is among top sectors where this machine is has a popular demand. For instance, protein powders made for childcare, mothers and nutritional growth are all processed by a protein powder filling machine.

Pharmaceutical Industry

Herbal powder-Picture Courtesy: naturerestore.com

Pharmaceutical industry is known for producing and packaging of medicinal powders where the need of a protein powder filling machine has been realized.

Chemical Industry

Chemical powder presentation idea-Picture Courtesy: amazon.ca

Chemical industry is another area where different types of chemical substances are processed and filled by a protein powder filling machine on daily basis.

Agricultural Industry

Husk powder bucket-Picture Courtesy: ozdingo.com.au

Protein powder filling machine can be also used in agriculture industry for the filling of granules and powders of different nature.

Cosmetic Industry

Various protein powder bottles-Picture Courtesy: bonappetite.com

Most of the protein powders used for skin and hair beauty are manufactured by specialized and authorized cosmetic industries. Therefore, they use protein powder filling machine for its packaging.

10.Which Other Machines Can Be Integrated With A Protein Powder Filling Machine?

Production line for protein powder filling machine-Allpack

Protein powder filling machine is perfectly capable for integration with several other machines in order to make a whole production line. In this way, Allpack's production line for protein powder filling machine has been taken into account:

Bottle Unscrambler

Bottle unscrambler is an important machine of the protein powder filling machine production line. It is designed to feed the protein powder filling machine with glass or plastic bottles sequentially.

Protein Powder Filling Machine

Protein powder filling machine is used for filling the precise volume of protein powder or other powders into containers of various sizes and shapes.

Bottle Capping Machine

Bottle capping machine is a vital machine in bottling automation. It carries bulk of caps in hopper and apply them over plastic or glass bottles in a serialized way.

Induction Sealer

Induction sealer is intelligent machine employed to undertake the crucial task of sealing bottles with an aluminum foil. It uses electromagnetic energy to perform this responsible task of sealing which eventually produce airtight sealing

Labeling Machine

Labeling machine is the assembly of several components including labeling roller, servo motor, label applicator and main frame etc. Collectively, these components make the machine able to apply adhesive labels over bottles, jars and containers in a beautiful and neat way.

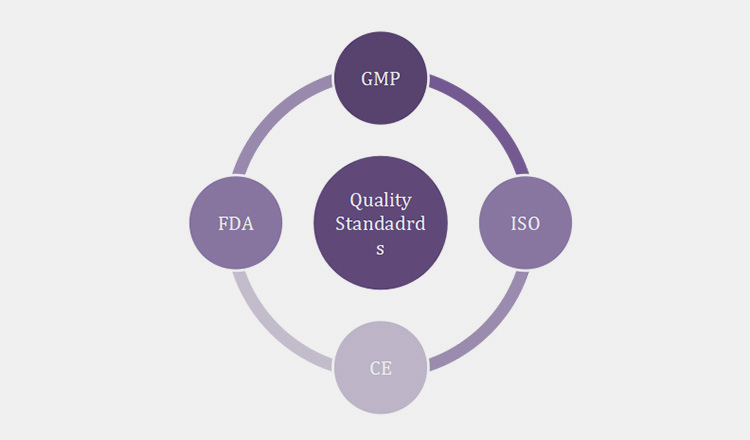

11.What Quality Standards Are Required For Assessing The Quality Of A Protein Powder Filling Machine?

Quality standard icon-Picture Courtesy: onlineresize.club

To ensure the quality of products manufactured across the globe, international community has established certain quality standards whose compliance is obligatory for all types of goods and materials. Therefore, to assess the quality of a protein powder filling machine, following standards must be checked:

GMP

Good Manufacturing Practices is an international aspect of quality assurance which works under the auspices of World Health Organization. GMP's compliance assures that products and machines which are associated with drugs and food materials are fully safe.

ISO

International Organization for Standardization is non-governmental organization working as a worldwide federation to regulate standards for the efficiency and quality of various goods and services.

CE

CE is the quality certification adopted by European Union countries. It aims at maintaining consumer safety by establishing certain strict rules for products. Hence, a country who want to sell their products in European Union countries must adhere these regulations.

FDA

Another quality standard required for assessing the quality of a protein powder filling machine is Food and Drug Administration which is responsible for protecting the human and animal life by assuring the efficacy and security of all drugs and associated machines.

12.What Is The Preventive Maintenance Of A Protein Powder Filling Machine?

Operator fixing machine-Picture Courtesy: nsflow.com

To keep your machine in a safe condition and avoid mismanagement, following instructions can be used:

Regular Maintenance: It is necessary to maintain your protein powder filling machine on regular basis. It may include the structural adjustment, configuration setting and routine maintenance.

Cleaning: Cleaning is an inevitable for maintaining your machine. Make sure, to wash and clean your protein powder filling machine after daily task to remove out all the debris and residues left in machine.

Parts Changeover: Operating your machine for long term may damage any parts whose timely changeover is necessary for smooth operation of machine. Hence, it must be ensured to examine the parts of machine regularly.

Lubrication:Protein powder filling machine is an assembly of several movable parts including agitator, servo motor and conveyor etc. These components should be well lubricated to avoid possible friction caused by lack of lubrication.

13.Troubleshoot The Malfunctions Of A Protein Powder Filling Machine?

You might face difficulty in operating a protein powder filling machine due to unexpected malfunctions which occur during process. Therefore, the table below will enable you to get ready for tackling these minor issues:

| No | Malfunctions | Possible Causes | Troubleshooting | Pictures |

| 1 | Inappropriate powder flow in hopper | The slow speed of agitator or the moistened powder may create powder bridging and result in irregular flow pattern. | It can be solved by increasing agitator speed, using dry powder and that the con of hopper is steep to avoid jamming |

Hopper-Picture Courtesy: Allpack |

| 2 | Startup failure of machine | The cord may be damaged, or the fuse is burnout | Change the power cord recheck again. Also replace the fuse if damaged |

Control system-Picture Courtesy: Allpack |

| 3 | Inaccurate level sensing | The sensor may be polluted which causes inaccurate detection | Clean the sensor for accurate measurement and control |

Powder cans filling-Picture Courtesy: directindustry |

| 4 | Unnecessary vibration and noise | It only happens when the components of a machine is either loose, damaged or misaligned | For its correction, make sure to examine the machine: tight all the loose parts and replace damaged ones |

Erroneous protein powder filling machine-Picture Courtesy: bellatrx.com |

| 5 | Inaccurate filling | Wrong calibration and clogged nozzles often lead to inaccurate filling | To solve the issue, adjust the machine calibration and clean the nozzles |

Protein powder filling-Picture Courtesy: directindustry |

Conclusion

To conclude, protein powder filling machine is efficacious equipment made with innovative technology of filling various types of protein powder filling machine into different containers while at the same time ensuring accuracy and hygiene. Besides, Allpack has brought for you an amazing line of protein powder filling machine as a standalone and entire production line protein powder filling machine facility. If you are interested in getting further knowledge about it, feel free to ask your queries.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide