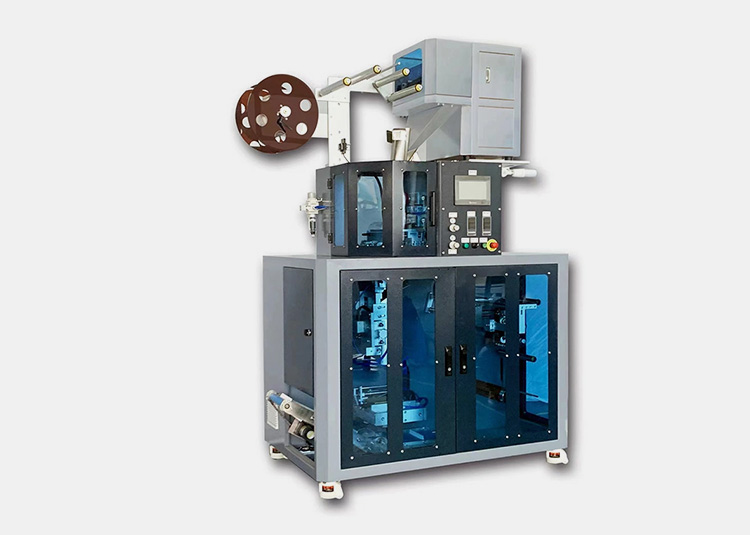

High-speed drip tea coffee bag packing machine inner and outer tea bag machine

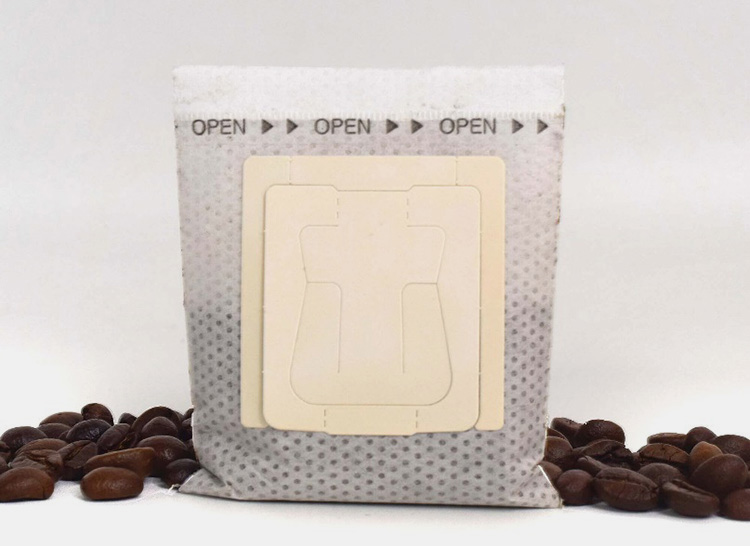

Allpack high-speed drip tea coffee bag packing machine is suitable for all kinds of tea,ground coffee and small particulate packaging.Adopt the special drip filter bag with three-sides sealing, the packed tea bag can be directly hung against the cup edge,which make you have a better brewing effect, moreover, the neat bag shape could be more popular among nowadays’ market.This drip coffee bag packing machine integrates automatic function, such as bag making, measuring, filling, sealing cutting, counting, batch number printing and other functions.The inner drip bag is made of non-woven fabric, guarantees convenient and hygienic brewing. The sealing adopts the advanced ultrasonic sealing, perfect sealing and beautiful bag type.The packing material could be filter paper, composite membrane, nylon, corn fiber(Food grade),drip fitter bag.

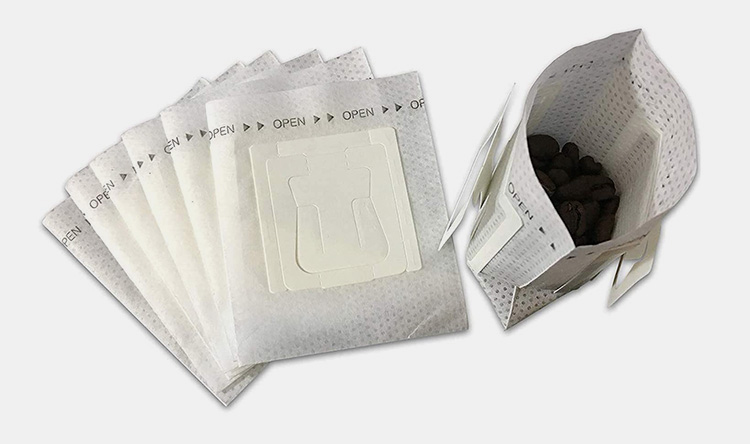

Product Sample of Allpack Drip Tea Bag Machine:

Allpack High-speed Drip Tea Coffee Inner And Outer Tea Bag Machine Features:

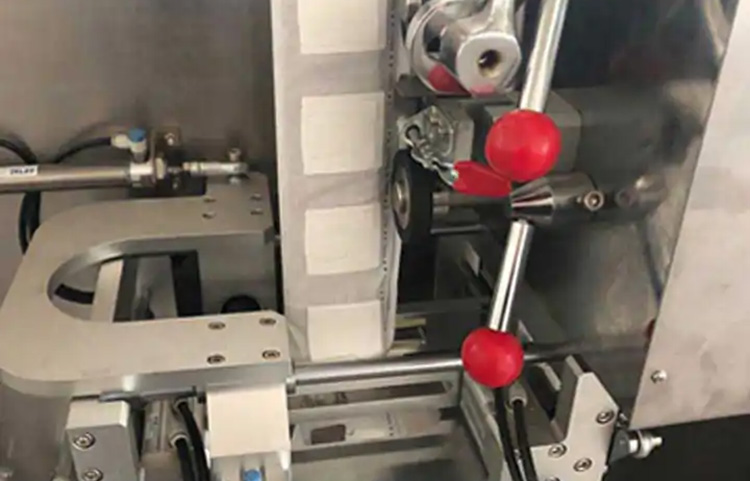

1.The outer sealing paper is controlled by a stepper motor, ensuring stable bag length and accurate positioning.

2.Adopting a PID temperature controller for more accurate temperature control.

3.PLC is used to control the operation of the entire machine, with human-machine interface display and convenient operation.

4.All accessible materials are made of SUS304 stainless steel to ensure the hygiene and reliability of the product.

5.Some working cylinders use original imported parts to ensure their accurate and stable operation.

6.The additional device of this machine can complete functions such as flat cutting, date printing, and easy tearing.

7.The ultrasonic and heat sealing forms can achieve a linear incision, saving the filling space inside the ear and reaching a packaging capacity of 10g.

8.Ultrasonic sealing is suitable for cutting all non-woven packaging materials, with a success rate of nearly 100%.

9.This equipment can be equipped with nitrogen filling devices, date printing devices, and mixing devices.

Allpack High-speed Drip Tea Coffee Inner And Outer Tea Bag Machine Technical Specification:

| Model | APK-188X |

| Sealing Type | 3-sides sealing |

| Measuring Scope | 5 - 10 g |

| Inner bag size | 90 mm( W ) :90 mm |

| Outer bag size | 120 mm( W ) :100 mm |

| Packing Speed | 60-80 bags/min |

| Dimension ( L * W * H ) | 1210 * 832 * 2141 mm |

| Weight | 660 kg |

| Total Power | AC220V / 50Hz / 3.7kw |

| Gas source | ≥0.6m³/ min |

The Buyer's Guide

Drip Coffee Bag Packing Machine: The Complete Buying Guide in 2024

Coffee packaging is a booming market and one important machine that played a major role in its expansion is the drip coffee bag packing machine. It is the choice of brand for seamless and automated coffee packaging.

It surpasses other coffee packaging machines because it can package tea, and herbal powders in addition to coffee. Flexibility and versatility are the vital benefits of a drip coffee bag packing machine. Its efficiency and reliable performance are the features that make this machine a great addition to production lines.

Are you looking to install a drip coffee bag packing machine in the plant or interested in upgrading your existing unit, then carefully read this guide to learn about significant and useful aspects of a drip coffee bag packing machine.

1.What is Meant by a Drip Coffee Bag Packing Machine?

Drip Coffee Bag Packing Machine

This machine is dominating the coffee industry because it packs one of the popular coffee packaging styles called drip coffee bags. It usually handles non-woven fibres, PET, nylon, Bio mesh, filter paper, food-grade plastics, and aluminium foil for wrapping the coffee powders.

It packages coffee in two bags-outer and inner. The inner bag is the drip coffee bag while the outer one is the envelope bag. Drip coffee bags are filled with coffee and are small-sized size single-serving bags, popular among coffee lovers. It is one of the easiest means of brewing coffee without creating a mess.

The drip coffee bag machine adds freshly ground coffee inside the compact bag without further additional processing steps. It is routinely employed in coffee production for the protection and convenience of end-users.

2.What are the Key Benefits of a Drip Coffee Bag Packing Machine?

Integration of a drip coffee bag packing machine generates huge revenue for the business because of its fast automation and efficient working. Here is a list of benefits of a drip coffee bag packing machine:

Safe and Hygienic Processing

Safe and Hygienic Processing

Stainless steel, a corrosion and rust-resistant material is used for making the exterior and interior of the machine. This machine has a clean design and it ensures safe and hygienic packing of coffee. Furthermore, this machine is ISO and cGMP certified which makes it perfect for processing coffee.

Batch-to-Batch Consistency

This machine is designed with highly accurate auger filler that allows to achieve batch-to-batch consistency. Accuracy and precision are two key features that increase brand profitability. Moreover, there is consistency in bag formation as servo-drives of a drip coffee bag packing machine regulate the bag length, hence, there is minimal error in filling and forming bags.

Easy Handling

Easy Handling- Picture Courtesy: KEBA

The drip coffee bag packing machine is tailored with easy controls that require zero skill on the operator's end. It is customized with intelligent software that offers quick operation programming. Also, this machine is easily maintained, cleaned, set up, and dismantled, reducing the need for high human supervision.

High Output Rate

High Output Rate

Speed is one of the major concerns of the brands, therefore, this machine is featured with advanced technological controls that boost the machine's efficiency. Automated parts allow this machine to package drip coffee bags in the shortest time imaginable. Due to its seamless and fast operations, the drip coffee bag machine can output thousands of bags per hour.

Cost-effectivity

Cost-effectivity

As businesses want to earn more profits with the smallest investment, so drip coffee bag packaging machine aids them in this endeavor. This machine has little-to-no human supervision, in turn cutting down the labour wages. Furthermore, it uses minimal packaging material which further eases up on operational expenses due to less purchase of packing film.

Branding and Product Communication

Branding and Product Communication- Picture Courtesy: Dieline

This machine also aids in product promotion by attaching a label or tag to the inner coffee bag. This tag is small cardboard attached with a string that is glued or stapled to the coffee bag. It creates an attractive product display and also communicates useful information, for example, expiry date, usage instructions, etc.

3.In What Packaging Industries Drip Coffee Bag Packing Machine is Used?

The drip coffee bag packing machine maintains the freshness of coffee by packaging it in small and stylish drip coffee bags. Different industry utilizes this machine due to its clean packaging. The industrial uses of this equipment are discussed below:

Coffee Industry

Application of Drip Coffee Bag Packing Machine in Coffee Industry: Picture Courtesy: Paradox Coffee Roasters

As the main indicates, drip coffee bag packing machine is mainly utilized in the coffee industry for packing ground coffee in bags. It packs single-serve coffee for home-based applications, retail stores, and E-commerce businesses. Its efficiency and high throughput make it a vital unit in the coffee industry.

Tea Industry

Application of Drip Coffee Bag Packing Machine in Tea Industry- Picture Courtesy: Pinkoi

After the coffee industry, the tea industry has a second place for the utility of the drip coffee bag packing machine. This machine loads a one-time serving of tea leaves inside the tea bags for instant preparation of tea. Quick processing and clean operation are the key features due to which this machine has acquired traction in the tea industry.

Herbal Industry

Application of Drip Coffee Bag Packing Machine in Herbal Industry- Picture Courtesy: KKH Tea Collective

In the herbal industry, a drip coffee bag packing machine is employed for loading herbal medicines, spices, powder brews, infusions, plant extract, botanical powders etc in one-use bags for treatment purposes. This industry uses a drip coffee bag packing machine because of its contamination-free processing and clean protocols.

Spice and Curry Industry

Application of Drip Coffee Bag Packing Machine in Spice and Curry Industry- Picture Courtesy: Hello Kitchen & Home

Yes, this industry also uses a drip coffee bag packing machine for loading individual loose herbs and spices in a small bag. It also loads herbs spices blends and curry mixes into compact regular bags. These bags are utilized for convenient meal preparation.

Snack and Soup Industry

Application of Drip Coffee Bag Packing Machine in Scack and Soup Industry- Picture Courtesy: Brod & Taylor

Snack and soup powder mixes as well as dehydrated vegetables are also fed inside the instant bags by a drip coffee bag packing machine. These bags usually include pre-prepared dehydrated full meals and small snacks that are made by adding hot and cold water.

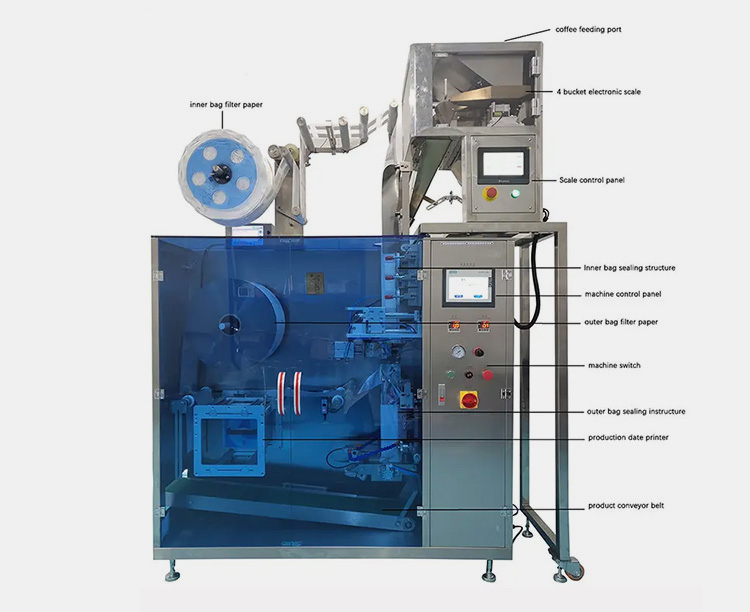

4.What are the Principal Components of a Drip Coffee Bag Packing Machine?

The drip coffee bag machine consists of different mechanical, electronic, and computerized parts for outclass and seamless drip coffee bag packing. Here is the list of a few principal parts of the drip coffee bag packing machine:

Parts of Drip Coffee Bag Packing Machine

| Product Feeding Port | It is a conical or square-shaped bowl located at the top of the equipment. A bulk quantity of ground coffee is stored in the hopper for continuous and fast feeding of products in coffee bags. |

| Scale Control Panel | It intelligent and interactive control display that is more easily programmed than a toggle button panel. With this system, every operator input can be easily adjusted and it aids in checking the operational performance of the machine. |

| 4 Bucket Electronic Scale | This unit helps in measuring accurate amount of coffee to be dispensed in coffee bags. |

| Inner Bag Filter Paper | This film holder is found at the bottom of the machine and houses the film for the fabrication of the inner coffee bag. |

| Inner bag sealing structure | This unit is responsible for sealing inner bag to maintain freshness of coffee. |

| Machine Control Unit | The unit is meant to regulate machine important tasks via easy accessible keys. This part regulates the functioning of the tag dispenser. When pressed, it controls the attachment of a pre-printed label tag or string to the inner drip coffee bag. It is useful for branding and product communication |

| Outer Bag Packaging instructure | This part houses the packaging film used for forming the outer coffee bag. This film protects the inner coffee bags from environmental and physical damage. |

| Cutting Clutch | It is used for activating the function of the cutting blade after the formation and sealing of the bag. It allows the machine to generate bags having uniform lengths. |

| Production Date Printer | This part holds the labelling film that is employed for tagging the inner drip coffee bag. |

| Coffee Bag Conveyor | This part of the machine is like a conveyor system for filled and sealed drip coffee bags. |

5.How to Classify a Drip Coffee Bag Packing Machine?

With technological innovation, different types of drip coffee bag machines are seen in the market different in configuration, filling, and sealing mechanism. These classes of drip coffee bag machines are:

Aguer Drip Coffee Bag Packing Machine

Aguer Drip Coffee Bag Packing Machine

In this type of drip coffee bag packing machine, an auger auger-filling device is widely employed for packing various powders. The magnetic clutch rotates auger screws and ground coffee gradually trickles down from auger plates into the inner drip coffee bag. This allows brands to achieve accuracy in the filling.

This machine is expensive than other volumetric fillers and due to its closed structure, it is difficult to clean and maintain it.

Vibratory Plate Drip Coffee Bag Packing Machine

Vibratory Plate Drip Coffee Bag Packing Machine- Picture Courtesy: King Victor Machine

As the name indicates, this type of drip coffee bag packing machine has a vibratory plate for uniformly packing ground coffee into the inner drip coffee bag. The ground coffee flows from the hopper into the bag via slotted plates via the vibration. It is usually employed for dispensing delicate powders that may lose their structural integrity by other kinds of drip coffee bag packing machines.

It also lowers the agglomeration of coffee powders. However, this machine is slower than its counterparts.

Piston Drip Coffee Bag Packing Machine

Piston Drip Coffee Bag Packing Machine

It is a machine housing a piston cylinder for dosing exact quantities of coffee into the inner drip coffee bag. The movement of a piston in the cylinder hauls the coffee powder from the top hopper and pushes it into the inner drip coffee bag. It is an extremely precise drip coffee bag packing machine but comes at a high price.

It is ideal for packing fragile and expensive coffee powders.

Volumetric Cup Drip Coffee Bag Packing Machine

Volumetric Cup Drip Coffee Bag Packing Machine

It is the most common type of drip coffee bag packing machine usually seen in almost every coffee packaging industry. It has a straightforward working and it is a fairly affordable unit. It is easily operated, requiring minimal training. It features a rotating cup that rotates to load a pre-measured amount of coffee powders inside the inner drip coffee bag.

It is less accurate than other drip coffee bag packing machines and is prone to fill errors.

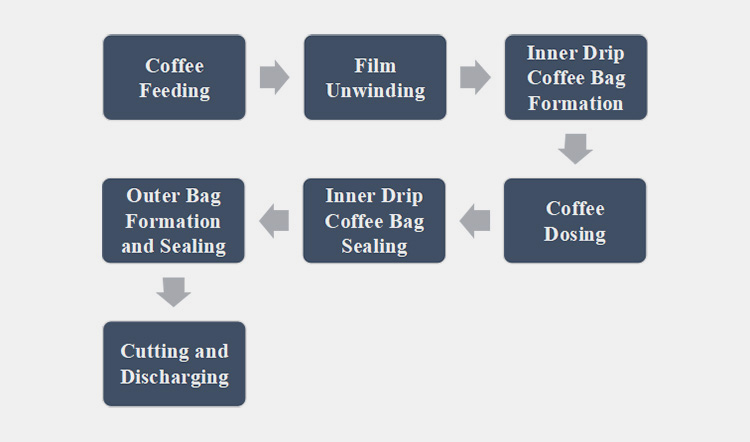

6.How Does the Drip Coffee Bag Packing Machine Work?

The drip coffee bag packing machine is a modern and sophisticated unit that changes ground coffee powders into small compact coffee packets. This is only possible by harmonious working of different machine parts. The working steps are detailed below for your understanding.

Coffee Feeding and Film Unwinding

Coffee Feeding and Film Unwinding

At the start, the bulk quantity of coffee powders is stored in the large product hopper, found at the top of the equipment. this hopper gradually feeds the filling devices once the operation starts.

The inner and outer bag packaging films are put on their respective holder. Once the packaging operation starts, these films unwind by the revolution of the unwinding disks. These films are guided over the roller to go to the forming tube.

Inner Drip Coffee Bag Formation

Inner Drip Coffee Bag Formation

In the next step, the forming tube present in the machine transforms the inner drip coffee bag film into the tubular pouch. Ultrasonic or heat sealer vertical sealer fuses the lower and side seams of the inner drip coffee bag.

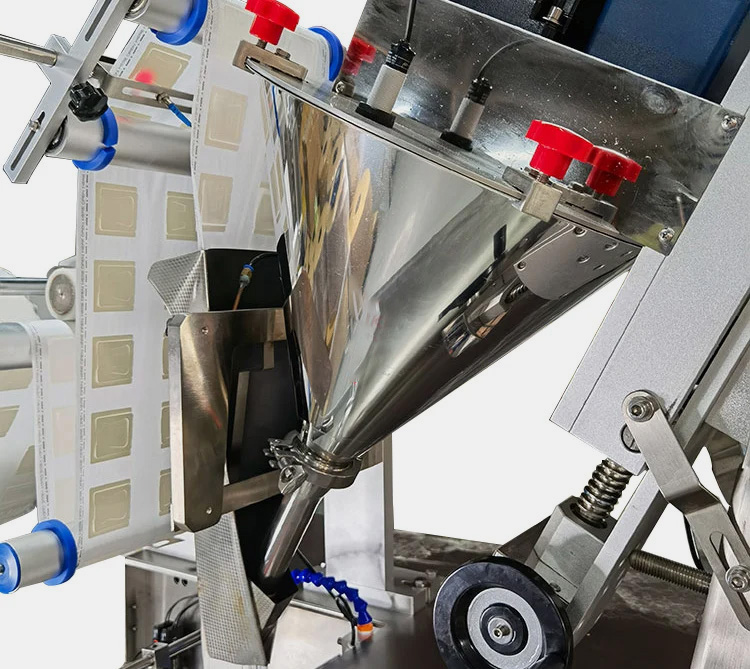

Coffee Dosing

Coffee Dosing

Afterwards, the ground coffee powders are fed inside the inner drip coffee bag by diverse filling devices, for instance, an auger, a vibratory plate, and a piston. These filling devices act by different mechanisms to dose accurate pre-measured quantity of coffee.

Inner Drip Coffee Bag Sealing

Inner Drip Coffee Bag Sealing

Upon coffee feeding, the topside of one inner drip coffee bag and the bottom seam of the other inner drip coffee bag are tightly closed using horizontal sealers. These sealers also employ ultrasonic waves or heat to form a secure seal that is integral in maintaining coffee freshness.

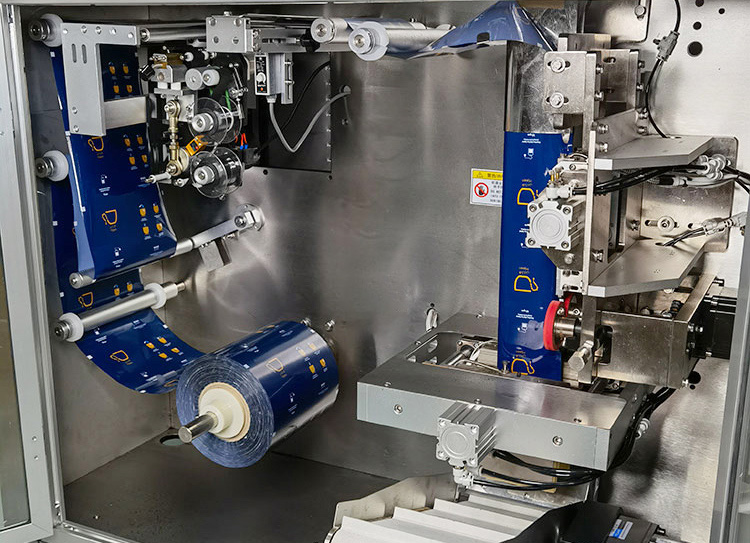

Outer Bag Formation and Sealing

Outer Bag Formation and Sealing

It is the optional step occurring in various models of drip coffee bag packing machines. In this step, the outer or envelop bag is formed by outer bag packaging film. This bag is formed by the same working steps that are executed to make an inner drip coffee bag. The inner bag is introduced to the outer bag and then the latter is closed using heat.

Cutting and Discharging

Cutting and Discharging

In the last step, the outer bag is cut by the sharp knife from the film roll and is discharged into the product outfeed for collection and further packaging.

7.What are the Materials Processed by Drip Coffee Bag Packing Machine?

Drip coffee bag packing is distinct from other pouch packaging machines as it processes other materials besides plastic and aluminium foil for creating inner drip bags and outer envelope bags. These materials are listed below:

| Nylon

Nylon |

These are multi-layered polymers created synthetically and are used for fabricating inner drip coffee bags. It is well-known for its sturdiness and robustness. |

| Bio Mesh

Bio Mesh- Picture Courtesy: Ever Green Cloth |

With increasing demands of consumers for sustainable packaging, bio mesh materials are employed for creating inner drip coffee bags. These are compostable materials and are biologically degraded by microbes. |

| Filter Paper

Filter Paper |

It is routinely utilized for creating an inner drip bag because it has micro-perforations and this increases water permeability for brewing coffee. It acts like a typical filter paper as it does not allow ground coffee to seep through it. |

| Aluminium Foil

Aluminium Foil |

It is mostly used for making outer bags. It is a sturdy and mealable material and is easily moulded into diverse shapes. Its basic aim is to protect the inner drip bag from environmental elements. |

| Non-Woven Fibers

Non-Woven Fibers- Picture Courtesy: www.biononwoven.com |

These are yet another popular materials and are alternatively used instead of typical filter paper. They are used for manufacturing inner drip coffee bags. These are created synthetically by the chemical reaction. Non-woven fibres also hold milled coffee and allow the entry of water to brew coffee. |

8.What are the Bag Shapes Created by Drip Coffee Bag Packing Machine?

The drip coffee bag packing machine is tailored to produce diverse bag shapes, for instance,

Rectangular and Square

Rectangular or Square Shape Drip Coffee Bag- Picture Courtesy: Tasty Decaf

It is one of the most commonly created bag shapes. Rectangular and square bags are designed with four sides and they have four distinct round or straight corners They are simple and classy bag shapes.

Round

Round Shape Drip Coffee Bag- Picture Courtesy: Xhteapack

It is a circular shape that is easily fitted in the opening of a mug. This style is more convenient than traditional square or rectangular shapes.

Diamond

Diamond Shape Drip Coffee Bag- Picture Courtesy: Tea bags manufacturer

It is a pentagon or diamond-shaped inner drip coffee bag and its distinct shape offers a unique marketability opportunity, as it entices customers more than regular shape.

Cone

V Cone Shape Drip Coffee Bag- Picture Courtesy: Temu

It is like a v or cone-shaped drip coffee bag and is snugly attached inside the mug. Water is poured into this shape for rapid and convenient brewing.

9.What are Add-on Features in a Drip Coffee Bag Processed by a Drip Coffee Bag Packing Machine?

Besides, packaging ground coffee in two bags, this machine is also customized to include different add-on features on the drip coffee bags such as:

String and Tag

String and Tag- Picture Courtesy: spackmachine

The drip coffee bag packing machine can attach a string and tag on the inner drip coffee bag for ease of use. A tagged label is glued to the inner drip bag to inform users about the usage of coffee and the brand.

Tear Notch

Tear Notch

Sometimes, the drip coffee bag packing machine is programmed to create tear-away notches in the envelope coffee bag. It is a small cut section in the bag for ease of opening the outer bag.

Hanging Hole

Hanging Hole

The hanging hold is added to the inner drip bag for ease of putting them onto the mug. They behave this a cloth hanger.

Window Patch

Window Patch- Picture Courtesy: World of Coffee-Café

It is an add-on feature that allows users to view the inside content of drip coffee bags. The drip coffee bag machine can be adjusted to add a small window patch from where users can see the state of ground coffee.

10.What are the Technical Problems and their Remedies for the Drip Coffee Bag Packing Machine?

Even the automated drip coffee bag packing machine faces unexpected technical problems that could lead to significant loss of money if left untreated. Hence, we are giving some tips and tricks to remedy these problems.

| Cause | Remedy | Image |

| Non-uniformity in Bag Length | ||

| Defective forming and sealing components

Inadequate film tension |

Repair and replace worn-out forming components and sealing jaws

Adjust the film tension |

Non-uniformity in Bag Length |

| Leakage from the Inner Drip Coffee Bag | ||

| Low and inaccurate pressure while sealing

Defective sealers Unclean and dirty sealers |

Fix the sealing pressure

Check the sealers and replace them if needed. Maintain proper cleaning schedule for accurate working of sealing jaws. |

Leakage from the Inner Drip Coffee Bag |

| Packaging Film Get Struck in the Equipment | ||

| Faulty cutting knife

Improper alignment of film over rollers High film tension |

Replace old and defective cutting knife

Realign film over the rollers. Reduce film tension |

Packaging Film Get Struck in the Equipment |

| Inaccuracy in Coffee Volumes | ||

| Out-of-order filling devices

Faulty input for the filling process Non-uniformity in coffee powder particles |

Replace defective filling devices

Reprogram the filling parameter Regrind coffee particles |

Inaccuracy in Coffee Volumes- Picture Courtesy: Rovii |

| Bags have Incomplete Seals | ||

| Low temperature and pressure darting bag sealing

Dirty exterior of sealing jaws Damaged and old sealers |

Fix the seal temperature and pressure

Thoroughly clean the surfaces of sealing jaws with a clean cloth Change old sealers |

Bags have Incomplete Seals |

| Packaging Film Get Burnt | ||

| High seal temperature and pressure

Incompatibility of film material with machine Inaccurate film alignment |

Lower the seal temperature and pressure

Use the right film material as recommended by the manufacturer Realign film over the rollers |

Packaging Film Get Burnt- Picture Courtesy: Gala Fabrics |

11.What are Buying Consideration for the Drip Coffee Bag Packing Machine?

When investing in adding the drip coffee bag packing machine to the production plant, carefully consider the various aspects and specifications of this equipment. Meticulous planning will come in handy over time. Hence, here are some best buying tips just for you.

Measure Floor Space- Picture Courtesy: Allpack

Different types of drip coffee bag packaging machines are different in their footprint. When planning to buy a new machine first, measure your floor space and the area in which you will set up your drip coffee bag packaging machine. This will help in procuring the right-sized equipment that is adjusted in the existing space.

Output Rate

Output Rate of drip coffee bag packaging machine

The output rate of the machine is its packaging capacity which is the number of packaged drip coffee bags per hour or minute. Determining the output rate of the production allows you to select a drip coffee bag packaging machine that matches your calculated production volume.

Coffee Type

Coffee Type

The filling devices in the drip coffee bag packaging machine can process specific coffee grinds. Thus, before selecting a specific machine, first choose the type of coffee grind that you will process. It aids in picking a machine that is well-aligned with your required packaging needs.

Ease of Usability

Ease of Usability- Picture Courtesy: Packaging Strategies

A machine will advanced electronics and technology comes with a high price tag. But it will prove its worth in the long run. It needs only one to two operators to program the machine because of its ease of use. Therefore, do not compromise on technology and opt machine with state-of-the-art controls.

Accuracy

Accuracy of Drip Coffee Bag Packing Machine

The accuracy and precision of the drip coffee bag packaging machine are listed in its specifications. Advanced and automated equipment have more accuracy and minimal filling error but they are more pricey. Nevertheless, the selection of this drip coffee bag packaging machine will generate more than the initial investment in a few months.

Conclusion

Drip coffee bag is the latest innovation in coffee packaging and a drip coffee bag packing machine processes this style of coffee packaging. It is different from other coffee packaging machines because it envelops coffee in two bags- outer and inner. The addition of this machine in the coffee packaging industry is a fruitful investment, generating tons of money for businesses. This is because the drip coffee bag packing machine has a streamlined operation and high efficiency. Branding, convenience, speed, and accuracy are a few of the many benefits of a drip coffee bag packing machine. Now are you convinced to purchase a drip coffee bag packing machine and do not know where to look? Then click on our main Allpack website because we are renowned for manufacturing the best of the best machines

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Allpack Drip Tea Coffee Bag Packing Machine Related Products