High Speed Automatic Zipper Bag Premade Doypack Rotary Gummy Packaging Machine

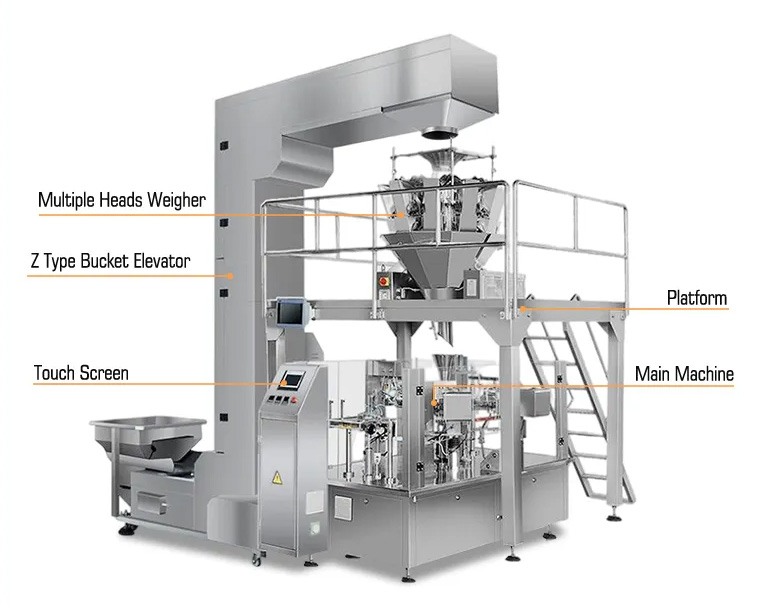

Allpack high-speed zipper bag premade doypack gummy packaging machine can be used for premade bag, stand-up bag with or without zipper. It is suitable for weighing grain, stick, slice, globose, irregular shape products such as candy, chocolate, jelly, pasta, melon seeds, roasted seeds, peanuts, pistachios, almonds, cashews, nuts, coffee bean, chips ,raisins,plum, cereals and other leisure foods, pet food, puffed food, vegetable, dehydrated vegetables ,fruits, sea food, frozen food, small hardware, etc. The gummy packaging machine adopts Z Shape bucket elevator / incline conveyor to raise material to multi weigher which controls the start and stop of the hoister. And the rotary packaging machine for packing pre-made pouch,including get bag,print date,open zipper bag,filling from multihead weigher,option position,hot sealing and cold sealing..

Allpack Gummy Packaging Machine Details:

Allpack Gummy Packaging Machine Application:

Allpack High Speed Automatic Zipper Bag Premade Doypack Rotary Gummy Packaging Machine Features:

1.Automatic rotary packing machine adoptsprecision indexing device and PLC to control each action and working station to makesure the machine operates easily and does accurately.

2.The speed of this machine is adjusted by frequency conversion with the range, and the actual speed depends on type of products and pouch..

3.Automatic checking system can check bag situation, filling and sealing situation.

4.The system shows 1.no bag feeding, no filling and no sealing. 2.no bag opening/opening error, no filling and no sealing 3.no filling, no sealing..

5.The product and pouch contact parts are adopted stainless steel and other advanced material to guarantee the hygiene of products.

Allpack High Speed Automatic Zipper Bag Premade Doypack Rotary Gummy Packaging Machine Technical Specification:

| Model | APKRL-GD-ZK130G | APKRL-GD-ZK160G | APKRL-GD-ZK200G |

| Working Process | 1. Loading bag 2. Opening bag 3. Blanking 4. Adding liquid 5. Reserving 6. Reserving 7. Crossing bag 8. Reserving → (vacuum)

1. Connect the tape 2. Close the cover 3. Primary vacuum 4. Secondary vacuum 5. Tertiary vacuum 6. Fourth vacuum 7. Seal 8. Seal cold cut 9. Vent 10. Open the cover and take out the bag |

||

| Sealing style | Instant heating sealing and instant cold cutting after sealing to ensure beautiful sealing | ||

| Packing speed | 35~60bags/min(By Product Characteristics) | ||

| Packaging Materials | Aluminum foil bags, paper bags, nylon bags and other film coated bags | ||

| Packaging specifications | W:50mm-130mm L:80mm-200mm | W:80mm-160mm L:80mm-210mm | W:130-200mm L:≤300mm |

| Total Power | 5.5KW | ||

| Drive power | 380V 50HZ | ||

| Overall Dimensions | 2100mmx1400mmx1600mm(L*W*H)not include lifter | 2420*1700*1800mm | |

| Weight | 2.2T | ||

| Use environment | Room temperature 10-40 ℃, 30-90% RH, no dew, no corrosive gas, no dust and other harsh environment | ||

Gummy Packaging Machine Related Products