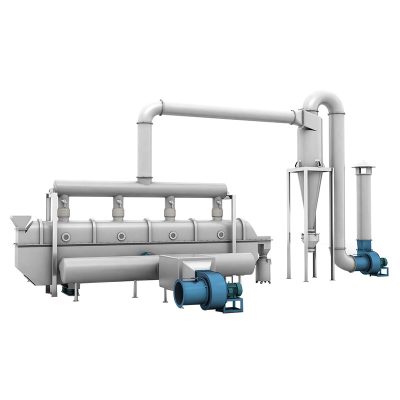

GFG Efficient Boiling Pharmaceutical Dryer

This company produces the boiling dryer for explosion protection and the two, their respective applicable to different production technologies and production requirements can meet different production needs.

Within the machine use centrifugal fan to make the bed form the negative pressure, the cold air suction, cold air by coarse effect, and high efficiency filter to remove tiny dust particles, and then into the heat for heating, air to enter air heated to the desired set temperature (using XMT – 192 temperature control instrument set to the required temperature, ma current signal 0-10 to DQ – 100 type electric converter, a proportional to convert from 20 to 100 kpa pressure of steam film adjusted valve) into the hot air, through the gas distribution plate formation gas column gas velocity dozens of meters per second impact material, between gas column in the formation of negative pressure material entrainment up, make whole layers in boiling state formation, and stir to pluck big materials, make the bed is not easy to form a corner, rising moving through the catcher into the fan exhaust, along with the air currents to rise the fine powder of trapped within the catcher, the machine is suitable for flow better dry particulate materials.

GFG Efficient Boiling Pharmaceutical Dryer Features:

1. The powder granulation improves liquidity and reduces dust emissions.

2. Through the powder granulation improve their dissolving performance.

3. Mixing, granulation, and drying processes accomplished once in the same equipment and improving the thermal efficiency.

4. Frequency Control device is used, Hopper used inflatable seal, sealed and reliable.

5. Excellent speed controlling performance, set up pressure relief hole, the safety of using.

6.No dead angle, material loading and unloading fast, easy cleaning, meeting GMP standards.

GFG Efficient Boiling Pharmaceutical Dryer Technical Specification:

Drier Machine Related Products