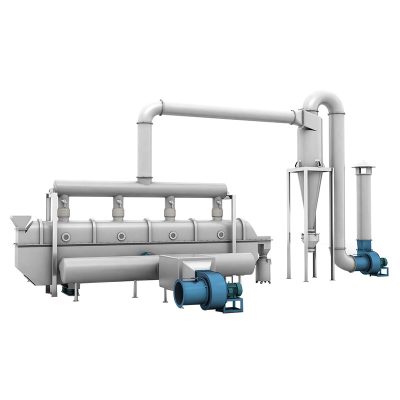

GF Series High Efficiency Fluidized Bed Dryer

This machine is used for boiled drying of granulate material with a site of 0.16mm and is applicable for quick drying of wet granulate and powdery material of finished products and intermediate(semi-finished products) in such trades as pharmacy, foodstuff, light industry, and chemical, etc.

Under the draught of the fan, natural air passes through the purification cabinet and heater, and forms high-speed airflow in the small hole of the material bed board, which makes the material boiled(fluidized)status and then makes the moisture(or solvent)in material vaporized(or volatilized)quickly, thus realizing the purpose of drying. The stirrer is designed inside the hopper, material boiling is free of dead angle, with uniform and quick drying, drying time can be set up freely according to material characteristics, and normally at 10-30min.

GF Series High Efficiency Fluidized Bed Dryer Features:

1. Adopts double-screw type air compressor and low-temperature condensation technique for dehydration.

2. Small and light, easy to operate, energy-saving, safe and reliable.

3. Combined with the advantages of refrigerated air dryer, desiccant air dryer, and ultrahigh precision filtration technique to produce high-quality low dew point dry air.

4. The machine has with integrated design and automatic PLC control is available to check running parameters automatically. It has a compact and reasonable structure and good performance with low consumption and a long lifetime. The composite desiccant adopted has a better effect and is about 3 times longer in lifetime than that of common desiccant.

5. The machine adopts absorption dehydrate and regeneration technique, high precision coalescence dehydration filters, and 0.01μm ultra high precision filters to keep cleanliness of air clean. It’s easy to operate, energy-saving, safe, and reliable.

GF Series High Efficiency Fluidized Bed Dryer Technical Specification:

Drier Machine Related Products