Drum Filling Machine Barrel Grease Engine Lubricant Lube Oil Weighing Filling Capping Machine Automatic liquid filling line

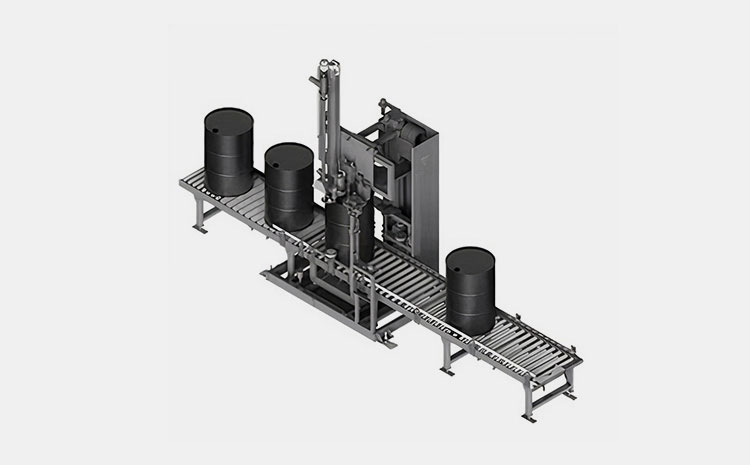

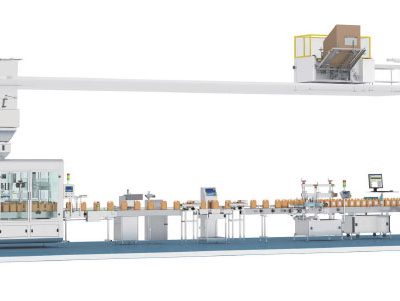

Allpack drum filling machine automatic liquid filling line is used for all kinds of scale liquid filling.It can finish a series of operations automatically, such as drum inlet, weight filling,and drum outlet.Especially for edible oil and lube oil.It is a nice choice for foodstuff and chemical industries.The drum filling machine adopt PLC control,touch screen control panel,convenient to adjust.Each filling head has the weight and feedback system. Each filling head can be regulated.With photoelectric sensor, approximate switch and other electric elements are the international famous brand. No container no filling. The main host can trigger the alarm if there is any container blocked.

Allpack Drum Filling Machine Features:

1.The whole line finish the process of drum incoming,drum distinguish, aiming, falling down.And slowly rising according to the filling quantity add,to prevent the bubble.

2.After the filling automatically out of drum, it is put the caps around the barrel outlet, through the pneumatic capping head screw.After the whole process ending, through the forklift or human handling of materials.

3.This machine uses PLC to control, touch screen operation.It has characteristics like convenient operation, high efficiency,wide range of application.

4.This machine electric equipment control part is made by PLC, adjust speed channel,it had strong control ability, high automatically.

5.It has function of no drum no filling, no aiming to drum outlet no filling,which avoid material waste and pollution.

Allpack Drum Filling Machine Technical Specification:

|

Type

|

Suitable bottles

|

Capacity

|

Machine Size

|

Power

|

Power supply

|

Precise

|

|

2 Heads

|

length:160-3600mm

width:100-300mmheight:250-500mmneck diameter:≥Φ40mm(can be customized) |

30kg:200BPH

|

2000*1700*2300mm

|

2kw

|

AC220/380V 50/60Hz |

≤±0.5%

|

|

4 Heads

|

30kg:350BPH

|

2500*1700*2300mm

|

2kw

|

|||

|

6 Heads

|

30kg:520BPH

|

3500*1700*2300mm

|

2kw

|

|||

|

8 Heads

|

30kg:600BPH

|

4500*1700*2300mm

|

2.5kw

|

The Buyer's Guide

Drum Filling Machine: The Complete Buying Guide in 2024

Large shipping containers need specialized filling systems that can handle heavy loads and bulk filling. For this purpose, a drum filling machine is employed in a drum processing line. This equipment is designed keeping in mind the special filling needs of both foaming and non-foaming liquids.

The drum filling machine serves every single industry since these industries usually involve large-volume liquid loading for shipment and transport.

Now let’s discuss all the useful aspects and many more about this versatile and robust equipment.

1.How to Define a Drum Filling Machine?

Drum Filling Machine: Photo Courtesy Direct Industry

This is a robust and heavy-duty machine, specifically designed and calibrated to fill large-load containers such as drums or barrels. It is also called a tote filling machine as it also loads inside IBCs or other pallets. It can fill one or more drums or tote simultaneously.

This equipment has an automatic bunging arrangement as well as a cap-sealing device. It is perfect for bulk dispensing solutions, suspensions, coatings, and other fluids for shipment and transportation of shipment.

The drum filling machine is equipped with conveyor systems, photo-eye detection, and a lance height adjustment system. The components of this machine are supported by sturdy solid construction and a leveling stand.

2.What Advantages Does Drum Filling Machine Bring?

This equipment is sturdy, robust, and efficient. A drum filling machine is an ideal solution for every industrial bulk loading of liquids and powders. It has a huge range of advantages including:

Boost Production Speed

Faster Speed with Drum Filling Machine

Manual filling consumes much time and effort. However, switching to a drum filling machine brings the advantage of faster speeds. This machine is furnished with high-load motors and pumps that displace products quickly in drum containers consequently boosting your production capacity.

Accuracy and Precision

Accuracy with Drum Filling Machine: Photo Courtesy Joint Tank Services FZCO.

There should be higher accuracy and precision while drum filling as otherwise, it would result in the loss of valuable products. The drum filling machine has highly accurate weight detection sensors and scales that aid in accurate fill.

Safety

Drum filling machine is offered with different safety features such as safety interlocks, antistatic devices, and ventilation systems that eliminate the risk of accidents and other hazardous situations. Moreover, these are enclosed systems that prevent the chance of operation injuries.

Ease of Handling

Ease of Handling with Drum Filling Machine: Photo Courtesy Crank Software Blog

An advanced drum filling machine has cutting-edge electronic, engineering, and computerized parts that make it easy to program and operate this equipment. With the aid of HMI and PLC systems, users can change and alter machine settings without needing special training.

Cut off Operation Expenses

Low Operational Expenses with Drum Filling Machine: Photo Courtesy Mobus

Since the drum filling machine minimizes product loss, therefore, it helps in saving money on formulating more products. This machine requires only one operator for managing it which further cut down your operational cost.

3.In What Kind of Industries, a Drum Filling Machine is Used?

Drum filling machine is used in every industry where liquids products are prepared and packaged inside the drums for mass-scale shipment and storage. Some of the industrial applications are:

Food Industry

Drum Filling Machine in Food Industry: Photo Courtesy KTC Edibles

Food packaging requires hygiene and precision. A drum filling machine is useful in this regard as it fills corn syrup, maple syrup, cooking oils, food additives, coloring, etc. in bulk-sized containers with higher efficiency and accuracy.

Dairy Industry

Drum Filling Machine in Milk Industry: Photo Courtesy kkcans

Milk, creams, yogurt, cheese, etc are loaded inside the plastic or steel drums by the drum filling machine for ease of storage and transportation. This machine accurately dispenses dairy products in large-volume drum containers.

Beverage Industry

Drum Filling Machine in Beverage Industry: Photo Courtesy World Atlas

Since the beverage industry requires high filling volumes, thus drum filling machine is employed in the beverage processing line to load tons of liquids products such as water, alcohols, juices, and vinegar ale, in drums or barrels.

Chemical Industry

Drum Filling Machine in Petroleum Industry: Photo Courtesy Pulsair Systems

In the chemical industry, the processing of hazardous chemicals takes place so, drum filling machine is predominately utilized in the chemical industry for loading paints, coatings, emulsions, acids, glues, bleaches, inks, grease, etc in the drum or IBCs.

Petroleum Industry

Drum Filling Machine in Petroleum Industry: Photo Courtesy Pond5

Petroleum products such as gasoline, diesel, turbine fuel, fuel oil, paraffin, etc are filled inside the heavy-duty drum containers. Drum filling machine loads bulk quantity of crude oils and other petroleum fuels inside drums for storage and transportation.

Automotive Industry

Drum Filling Machine in Automotive Industry: Photo Courtesy Top Gear

In this industry, drum filling machine is part of automotive manufacturing and packaging. This machine fills heavy amounts of automotive fuel, battery oils, lubricants, anti-freeze, resins, etc in drum containers.

Agriculture Industry

Drum Filling Machine in Agriculture Industry: Photo Courtesy ReAgent

In the agriculture industry, this machine doses accurate volumes of chemicals such as pesticides, insecticides, germicides, weedicides, and liquid fertilizers by weighing and vibration. It is equipped with anti-drip filling systems that reduce the wastage of agricultural products.

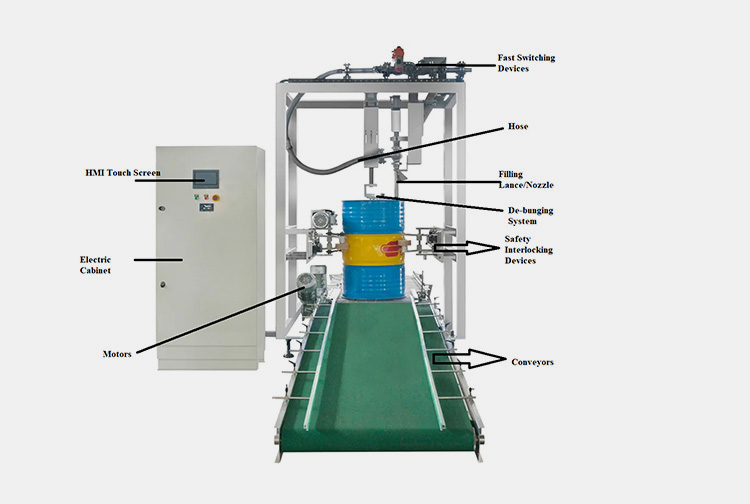

4.What are the Key Components of a Drum Filling Machine?

This heavy-duty drum filling machine consists of several parts that work together to achieve low-error filling. Some of these parts are:

Drum Filling Machine

HMI Touch Screen

It is an intelligent and smart touchscreen on which operators program filling parameters. It displays the progress of the filling operation and also outputs machine troubleshooting tips.

Electric Cabinet

The fuse, switches, relays, etc. are present in the electric cabinet for powering different parts of the machine. It is made of explosion-proof materials to avoid electric accidents.

Motors

They are mechanical parts that drive the filling process. It provides energy for moving conveyors, rollers, bearings, and other mobile parts.

Fast Filling Device

This part is used for changing the filling rate from slow to fast and vice versa to acquire accuracy and precision in each fill.

Hose

These are the pipes that connect the filling lance to the product tank. It provides a passageway for the movement of liquids.

Filling Lance or Nozzle

It has a tube-like device and is equipped with infeed valves that open and close the filling lance. It is a long cylindrical device that is often lowered in drums for filling.

De-bunging System

It is equipped with a laser scanner and color sensors that detect the precise location of the bung and removes it to expose the opening of the drum for filling.

Safety Interlocking Device

This component rotates and locks the drums in the right position. If the drum is not oriented properly then filling lance cannot go inside the bung.

Conveyors

These are equipped with rollers and drive belts and transport containers through different stations.

5.What are the Types of a Drum Filling Machine?

Drum filling machine is classified in a variety of ways such as automation and design. These classification types are detailed below:

Classification Based on Automation

There are two types of drum filling machines when classified based on the level of automation.

Semi-Automatic Drum Filling Machine

Semiautomatic Drum Filling Machine

This type of drum filling machine has both manual and automatic functionalities. It has a smaller footprint and is ideal for small and medium-sized productions. It has a PLC system that coordinates the filling process while the loading and unloading of containers is performed manually. In this machine, operators manually align the filling lance with the bung of the drum.

It has lower throughput as well as a more filling error rate.

Automatic Drum Filling Machine

Automatic Drum Filling Machine

This machine is equipped with cutting-edge technology, sensors, weighing systems, laser systems, and de-bunging systems to achieve higher production efficiency as well as accuracy. It has a larger footprint and is well-matched for industries with higher production volumes.

Container loading to filling and everything in between is performed by this machine independently. However, this machine is quite costly.

Classification Based on Design Configuration

There are three different drum filling machine types based on design configuration.

Pivot Style Drum Filling Machine

Pivot-Style Drum Filling Machine: Photo Courtesy Ideal Phase

The machine has a pivot-style lance arm that can lengthen outwards and withdraw backward. This machine design assists in filling multiple drum pallets, IBCs, as well as various-sized drum containers because the height and XY positioning of the lance column is easily changed.

Swing Arm Style Drum Filling Machine

Swing-Style Drum Filling Machine: Photo Courtesy Ideal Phase

It is a semi-automatic kind of drum filling machine in which the lance arm moves to and fro to locate the bung of the drum. It is usually employed for filling a single drum, pallets, or tote.

Gantry-Style Drum Filling Machine

Gantry Style Drums in Drum Filling Machine: Photo Courtesy Feige

In this type of drum filling machine, the machine structure is supported by the overhead bridge construction and side frames that are present on the parallel side of the conveyors. This drum filling machine can handle heavy loads and the gantry structure helps in the stability of the machine.

6.What Can You Tell About Working of Drum Filling Machine?

Since the drum filling machine is designed for heavy product fill, therefore, each step included in its working must be carried out accurately. Different stages of its working are detailed below:

Loading of Drums

Loading of Drums in Drum Filling Machine: Photo Courtesy Feige

First, the container or drum is placed on the drum tilter that automatically positions the drums on the conveyors. This container is automatically sensed by the container detection sensors present in the equipment. The next step is de-bunging the opening of the drums for filling.

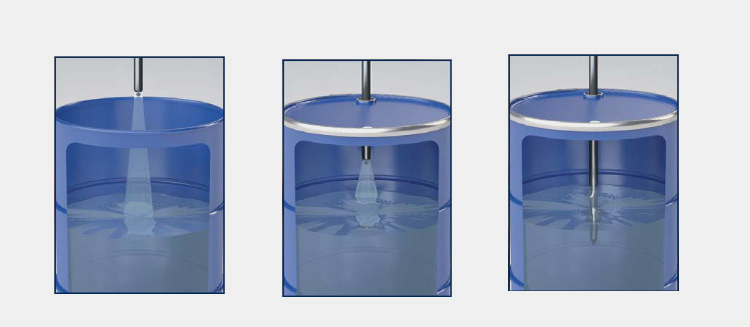

Product Filling

Filling of Drums in Drum Filling Machine

The drums are transported to the filling station. These drums are passed to the feeding unit as a single drum or a pallet. First, the drum bung is detected by the automatic bunging unit and then the filling lance is lowered in the drum for filling. The fill is according to the preset fill level programmed by the operators.

The filling lance is raised out of the drum gradually, as the products are dispensed inside it. Once the weighing scale senses that preprogrammed fill tolerance is reached, the filling stops.

Discharging

Drum Filling Machine: Photo Courtesy Direct Industry

As soon as the drum is filled, the conveyors are switched on and the filled drums are moved to the cap sealing or bunging unit.

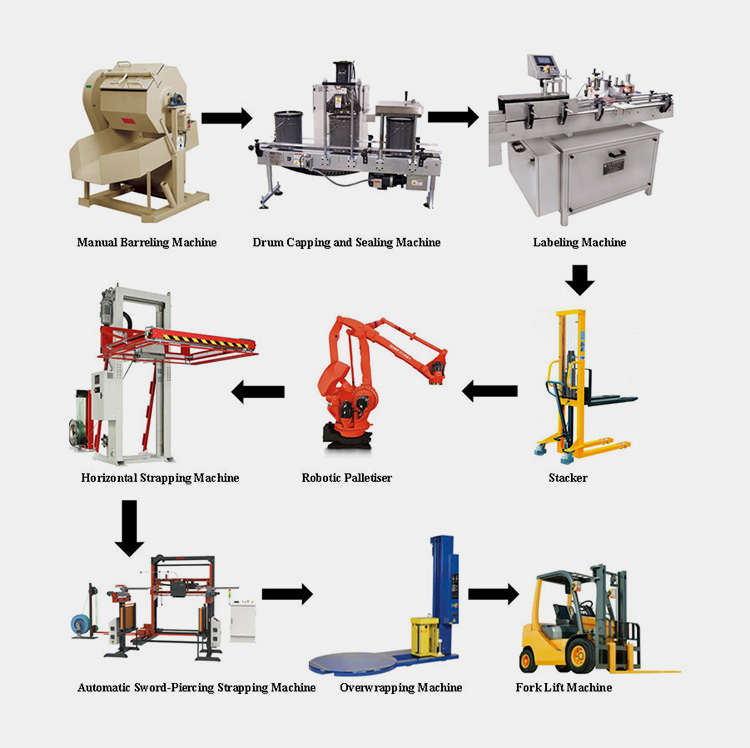

7.What is the Other Equipment Besides the Drum Filling Machine in the Production Line?

The drum filling and processing line is customized with cutting-edge and state-of-the-art equipment that are integrated for synchronized and coordinated packaging of drum containers.

Besides the drum filling machine, the following instruments are also present in the drum filling machine.

| Manual Barreling Machine | This machine has a tumbling device in which reused drum containers are placed for polishing, cleaning, scratch removing as well as fixing dents. |

| Drum Capping and Closing Machine | It has bunging units, capping unit, as well as lidding units that permanently closes the drum containers to prevent the leakage of inner contents as well as their contamination and damage. This equipment put bungs inside the drum opening as well as put press-on lids over drums for sealing |

| Automatic Labeling Machine | For identification of products as well as informing user about the inner contents of drum containers, automatic labeling machine stick and apply sticker labels or overwraps on the body of drums. |

| Stacker | Since drums are heavy containers, so, for their lifting and stacking, a stacker machine is used. This machine is an electric or hydraulic lifting device that carries and piles them over one another. |

| Robotic Palletiser | For palletizing the drum stacks on the wooden pallet construction, a robotic palletizer is utilized. This machine has a robotic arm capable of lifting heavy loads and placing them on pallets for secure shipping. |

| Horizontal Strapping Machine | After palletizing drum containers, their tight bundling is done using the horizontal strapping machine. This machine compresses and compacts the pallets and ties them together using heavy-duty tapes or cables. It carries out sideways strapping of pallets. |

| Automatic Sword-Piercing Machine | It has a sword-like component that is used for tying the pallet bundle from the bottom. An automatic sword-piercing strapping machine straps the bundles vertically to prevent the scattering of drums during shipment. |

| Automatic Overwrapping Machine | This machine wraps the tied pallet bundles with a plastic stretch film. This film fully covers the pallets and eliminates the chances of impairment to containers during shipment. |

| Drum Fork Lifter Machine | It is a lifting machine that carries drum pallets from the packaging area and moves them to the product shipment area. |

8.What Type of Containers Does the Drum Filling Machine Fill?

A drum filling machine is a sturdy machine with a reinforced structure and normally fills large containers having higher dimensions. Some types of containers filled by drum filling machine are:

| Drum | These are cylindrical containers that are flat at the top and bottom. The center of the drum bulges out which results in a fatter look in the middle. They are sealed with bungs. Drums are also known as barrels or casks. |

| Kegs | These are cylindrical containers that often come with sprouts for taps or pouring of liquids. They are employed for the transportation of liquids such as alcoholic beverages. |

| IBCs | These are rigid containers that have a wooden base. They are stackable and reused. Since they have storage capacity in between drum and tank containers that is why they are known as intermediatory bulk containers. |

| Bucket | It is a cone-shaped container with a flat base and opening that is lidded for sealing the container. It is also known as pails and is usually used in the food industry for bulk packaging of materials. |

| Jerrycans | These are rectangular, square, or oval-shaped devices that are equipped with handles for ease of carrying. It stores fluids such as motor oils, water, sealants, etc. |

9.How Much Volume Does Drum Filling Machine Load?

Drums are large containers with high load capacity than other types of containers such as bottles, buckets, or jerrycans. So, the drum filling machine dispenses large volumes of liquid products. A typical drum filling machine can fill about 10 liters to 200 liters of fluids inside the drum containers.

However, if this equipment is used for filling IBCs, then it can load 1,250 liters of liquids. The drum filling machine’s filling capacity is generally dependent upon business needs.

10.How Does Drum Filling Machine Ensure Accuracy?

Drum Filling Machine: Photo Courtesy Ideal Pase

Accuracy is a central component that determines the quality of the filling. Therefore, a drum filling machine must be accurate and precise to decrease the filling error and prevents underfilling and overfilling of products.

Modern drum filling machine is provided with highly sensitive weighing scales, flowmeters, and load cells that measure the correct amounts of liquids for dispensing. This equipment has tare check, flow rate control, as well as fill monitoring systems that ensure high precision in the fill.

11.What are the Filling Modes of Drum Filling Machine?

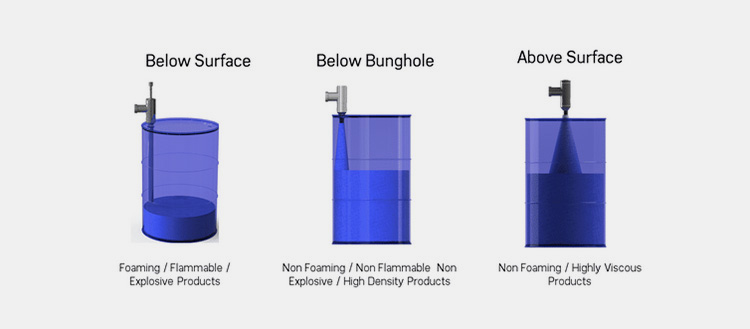

There are three filling modes of the drum filling machine which are:

Above-Product Surface Filling

Modes of Drum Filling: Photo Courtesy Feige

This type of filling is done for non-hazardous liquids in the open drum containers. It is used for filling thin viscosity, non-foamy liquids that do not drip. This filling lance does not enter the containers and dispense liquids from the top into the container.

This is employed for filling paints, adhesives, suspensions, etc.

Below Product Surface Filling

Modes of Drum Filling: Photo Courtesy PRECIA MOLEN

In this filling, the filling lance is fully lowered to the container bottom and slowly dispenses liquids. the plunging of the lance averts the chance of liquid splashes and is advantageous for filling foamy and hazardous chemicals.

This filling usually starts at dribble mode because at the beginning liquids are filled at a very slow pace to eliminate early foaming. As soon as the lance is immersed in the liquids, the drum filling machine increases the filling speed.

Below Bunghole Filling

In this type of filling, the filling lance is lowered to the bottom of the containers but stays above the filling level. The filling starts at the bottom of the container and the lance is gradually lifted upward.

It is employed for filling coarse, fine, as well as high-viscosity liquids. The benefit of below-bunghole filling is that there is no product dripping.

12.What are the Pump Types in Drum Filling Machine?

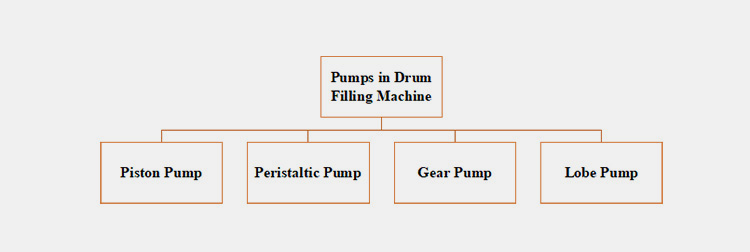

There are different kinds of pumps in the drum filling machine, each is discussed one by one.

Piston Pump

It has a piston that is enclosed in the cylinder. The forward and backward movement of the piston generates pressure that draws liquids inside the filling lance. Since the piston travels the same distance every day, it gives highly accurate fill.

A piston pump is used in various industries like food, pharmaceutical, beverage, diagnostic, etc.

Peristaltic Pump

It has rollers that compress tubing for the movements of liquids. It is perfect for sterile and sanitary fill as this pump is not in direct contact with the products. Only liquids move in the tubing which prevents contamination of products.

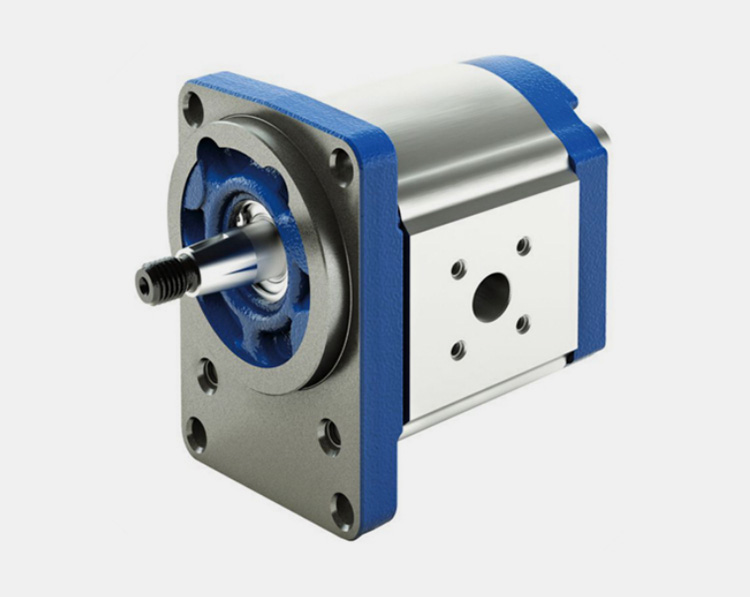

Gear Pump

It has teethed gears that trap the products on the rotation of gears. On the other turn, the products are forced from the teeth to the pump outlet.

A gear pump loads thicker as well as free-flowing liquid and is ideal for loading higher filling volumes easily.

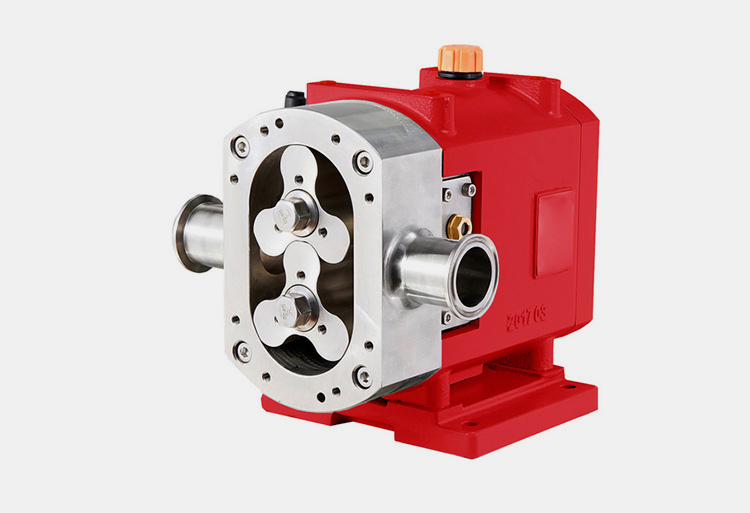

Lobe Pump

This pump works similarly to gear pumps but instead of teeth, it has lobes that trap the fluids between them upon rotation of the lobe pump. This pump is ideal for pumping particulate materials since it has a small space between lobes.

It is employed for dairy products, cosmetics, and personal care products.

13.What Kinds of Conveyors Are Present in a Drum Filling Machine?

There are different kinds of conveyors furnished inside the drum filling machines. Some of these conveyor types are detailed below.

Drive Belt Conveyors

These conveyors have cylindrical rollers present at the ends of the conveyors while drive belts are looped around these rollers for container transportation. This type of conveyor is lifted or lowered for drum or pallet filling. Roller conveyors are connected to motors that power these conveyor systems.

Chain Conveyor

This moves the containers to different stations using chains that act like a pulley system for stabilizing moving containers. These chains are fixed to sprockets located at the ends of the conveyors. These conveyors have one to two chain configurations.

Drum Roller Conveyor

As the name suggests, this type of conveyor uses a series of cylindrical devices or rollers located perpendicular to track walls for transferring containers down the drum filling machine. These drum rollers are placed in succession to construct large areas for object transportation.

14.What Drum Materials are Processed by Drum Filling Machine?

A drum filling machine is a versatile piece of equipment and can process a variety of different drum materials such as:

- Aluminum

- Carbon steel

- Plastic (HDPE)

- Wooden

- Composite (plastic and steel)

- Dense paperboard

15.What are the Safety Features of a Drum Filling Machine?

Since the drum filling machine fills hazardous and critical chemicals and liquids. there are several safety features in this machine to ensure the safety of working staff and environment as well as to prevent equipment damage.

Explosion-Proof Devices

The drum filling machine is equipped with explosion-proof devices such as motors, electric cabinets, sensors, alarms, conveyors, and electric cabinets. These devices are made with explosion-resistant materials.

Anti-Corrosive Construction

Drum Filling Machine: Photo Courtesy vkpak

The frame, filling lance, and hose are constructed using strong anti-corrosive materials such as stainless steel 316, Teflon, titanium, nickel, PVDF, and PTFE. This ensures that machine components can withstand high temperatures as well as harsh chemicals.

Plus, for fire and explosion aversion, inserting or nitrogen blanketing is employed. This is done by introducing inert gas to a machine for preventing the flammability of oxygen. Moreover, this machine is also offered with a fume hood.

Moreover, this machine is equipped with anti-static devices that inhibit the upsurging of electrostatic discharge.

16.What is the Difference between Drum Filling Machine and Bottle Filling Machine?

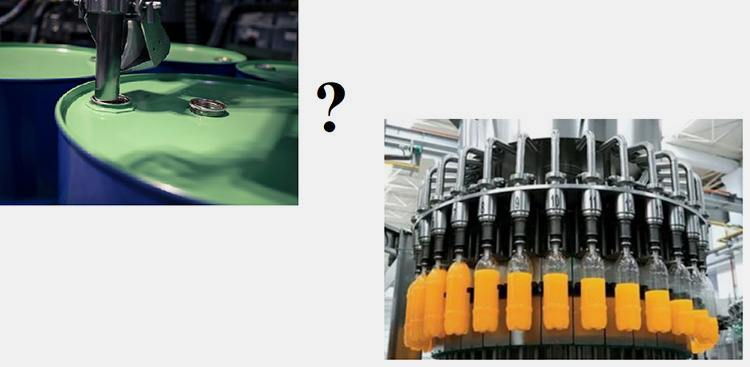

Both the drum filling machine and the bottle filling machine are employed for filling fluids, powders, etc. However, these machines are quite different from each other. Some of these differences are discussed below:

| Feature | Drum Filling Machine | Bottle Filling Machine |

| Container Type | As the name indicates, this machine is employed for filling bulk-capacity containers such as drums, barrels, totes, and buckets. | This machine is generally employed for filling small containers such as bottles, jars, ampoules, vials, etc. |

| Location of Conveyor Systems | Since it accommodates large-sized containers hence the conveyor systems are usually located at knee level. | As bottles have less height so conveyor systems in the bottle filling machine are located at the waist level. |

| FootPrint | This machine has a larger footprint than a bottle filling machine. | It has a smaller footprint as compared to a drum filling machine. |

| Filling Nozzles | The drum filling machine has larger-sized and more capacity nozzles. Moreover, these nozzles have larger orifices for bulk filling. | It has smaller-sized nozzles suitable for filling smaller-capacity containers. |

| Conveyor Systems | This machine usually has a drum roller conveyor for the transportation of heavy loads. | This machine has drive-belt conveyors. |

| Number of Containers | It fills single or multiple containers at a time. Moreover, it is also used for filling drum pallets having four drums. | It loads single or multiple containers at a time. |

| Filling Volume | It can fill 10 liters to 1250 liters of liquids. | It can fill 1ml to 10 liters of liquids. |

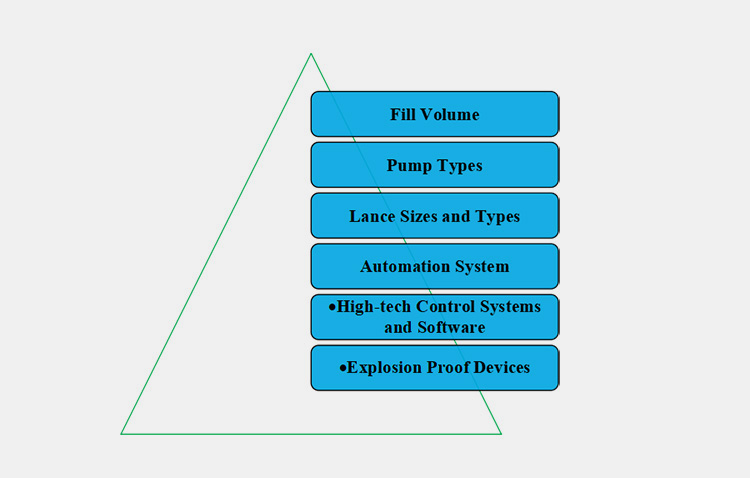

17.Can You Customize the Drum Filling Machine As Per Your Specific Needs?

The simple answer is yes, you can customize the drum filling machine as per your needs by following approaches.

Fill Volume

Different containers have different fill volumes and you can easily change the fill setting on the touchscreen display.

Pump Types

There are different kinds of pumps, each suitable for the specific nature of products as well as filling volume. For instance, if you are dealing with dairy products, it is best to go for lobe pumps. Furthermore, each pump has different filling accuracy thus selecting the pump right for your application will bring you maximum benefits.

Lance Sizes and Types

There are different types of fill lance sizes and types available in the market. You can easily select the right kind of lance depending on the type of product and container you are handling.

Automation System

Production efficiency can be enhanced by customizing the drum filling machine with robotics, automatic de-bunging systems, ultrasensitive sensors as well as weighing scales.

High-tech Control Systems and Software

By installing advanced control systems and software in the drum filling machine, you can achieve precise filling, diagnostic troubleshooting as well component failure warnings.

Explosion Proof Devices

Since hazardous chemicals and powders often generate dust and fumes that could ignite on charging. Thus, by setting up an explosion-proof device in your drum filling machine, you can avoid the risk of explosion.

18.What are the Technical Problems and Remedies of a Drum Filling Machine?

Technical problems are quite prevalent in the drum filling machine. But there are some remedies by which these problems can be easily resolved, including:

| Technical Problem | Cause | Remedy |

| Inconsistent Filling in Drum Containers

|

Defects in the Flow meter or load cell

Incorrect programming of fill volume and time on HMI The filling lance is clogged or jammed |

Repair the flow meter and load cell

Adjust the setting of fill time and volume on the touchscreen Properly rinse the filling lance to remove debris or product buildup |

| Leakage or Product Spillage

|

The linkage between pipes and hose is loose

Drums are not properly positioned under the filling lance Old seals and gaskets |

Fix the connection between pipes and hose and tightened them

Align the drum opening with the head of the filling lance Replace old seals and gaskets |

| Failure in Motor Function

|

Fluctuating voltage

Overheating of motor Misarrangement of drive shafts Worn out bearings |

Fix the fluctuation in voltage

Turn off the machine to lower the temperature of the motor Properly align drive shaft parts Place old bearings |

| Blocked Filling Lance or Pumps

|

Dust or debris buildup

Inadequate cleaning |

Properly flush out the filling lance

Install CIP systems for high-quality cleaning. |

| Conveyor Systems Does Not Move

|

Worn-out rollers and idlers

Misalignment of belt part causing belt spillage Jammed or seized rollers |

Replace the old rollers and idlers

Properly align drive belts Install new rollers if they are damaged beyond repair |

Conclusion

The drum filling machine has become a necessity in every industry for bulk packaging, storage, transport, and export shipment of various products such as fuel oils, and chemicals, water, beverages, milk, etc. This machine is different from other machines in various ways-design, filling capacity, and filling speed. To boost your filling accuracy and efficiency, integrate this machine into your plants since it is not only capable of handling dangerous chemicals but also creates a secure work environment. For additional inquiries, you are more than welcome to call and email our customer service.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Automatic liquid filling line Related Products