video:

Introduction:

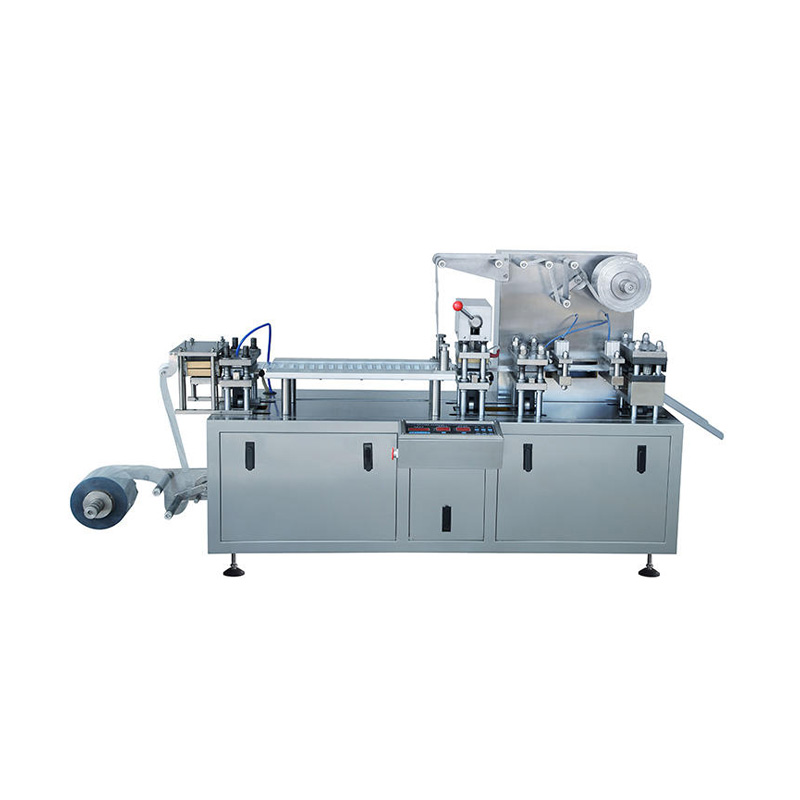

DPP-120H multifunctional automatic blister packing machine, the machine is the company comprehensive domestic and foreign aluminum plastic packaging machine has the advantages of innovative design, my company a number of innovative technology is used in the key parts, the contact part of the drug and the stainless steel and high-grade aluminum alloy material production, applicable to the pharmaceutical, food, health care products industry packing element piece, sugar coated tablets, capsules also packaging small food and metal parts, electronic components. The machine set coil uncoiling, aluminum (AL) feeding, blister forming, filling, waste recycling, heat sealing, print a batch number, reticulate indentation, edition piece rushed cut, display finished counting and ten functions in one, goods packaging sealing good, safe and sanitary.

Feature:

- The spindle locating devices with gear racks are equipped in the devices of forming, thermal sealing, batch No. printing, impressing and cutting, etc, and when the handle is rotated, all these devices can move flexibly in the spindle. There is a ruler, with which it’s convenient to position fast and correctly.

- There are double oscillating rods in the manipulator, the puling travel’s range is increased to 180mm, so the blister package with all kinds of size can be satisfied. Operations of blister sheet correcting & heating, the pressing & forming, the face/back surface pattern impressing, the cylinder’s thermal sealing, the automatic feeding, the automatic batch No. printing and automatic cutting can all be completed by this machine, and it’s easy and reliable to operate.

- With the pressing & air forming device and the mechanical punch, the blister shapes are homogeneous and strong, and it is specially used for the packing of big honey pill or medical machinery, etc, whose size is bigger or whose shape is irregular. When the special automatic charging device is equipped, this machine can also be used for the packing of ampoule, syringe or vials, etc.

- The helical-gear reducing box with parallel shaft is adopted for the main transmission part, the pin positioning is adopted for the dies of forming, thermal sealing and the impressing, the pressing plate is tight, the positioning is accurate, and it’s convenient to change dies.

- As to user’s requirement, the machine can be made by several parts, which is convenient to move the machine into the workshop.

Specification:

| PROJECT | PARAMETERS |

| Cutting Ffequency | Al-plastic:10-40Times/min |

| Al-Al:10-30Times/min | |

| Travel Range | 30-100mm (Adjustable) |

| Max forming area | 120×90mm |

| Max Forming Depth | 20mm( customized according to customer requirements) |

| Main motor power | 0.75kw |

| Upper heating power | 0.5kw |

| Lower heating power | 0.5kw |

| Heat sealing heating power | 0.5kw |

| Air volume flow | ≥0.2m2/min |

| Air pump pressure | 0.4-0.6Mpa |

| PVC | 0.25-0.5×130mm |

| PTP | 0.02-0.035×130mm |

| Dialysis paper | 50-100g×130mm |

| Overall dimensions | 2070×650×1060 mm |

Reviews

There are no reviews yet.