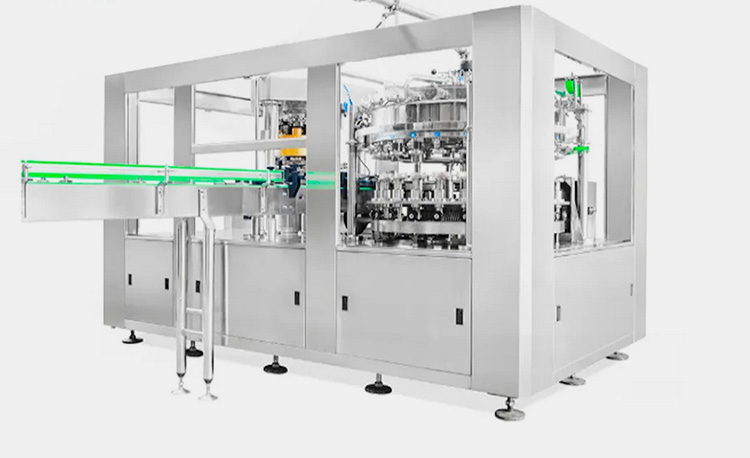

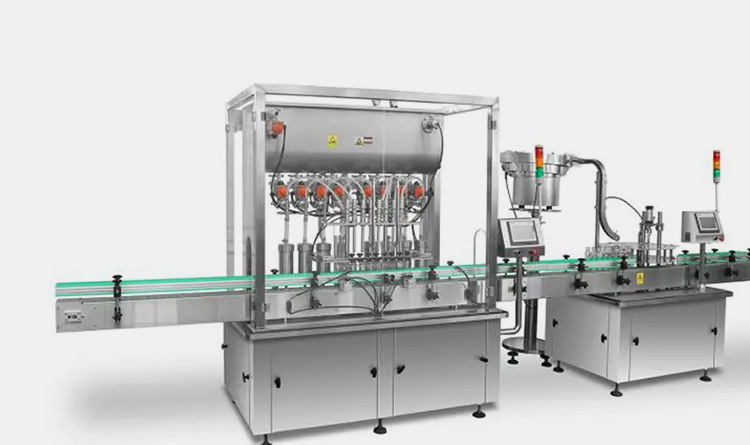

Curing Agent Can Filling Machine Automatic liquid filling line

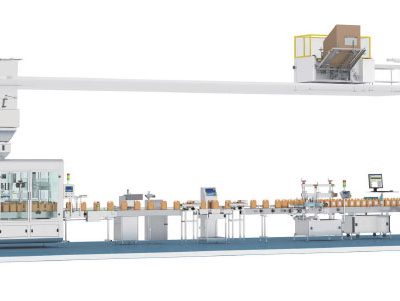

Allpack curing agent automatic liquid filling line is suitable for filling 5-1000L by weight,and automatically completes a series of operations such as counting into barrel,filling by weight,and conveying out barrels.It is especially suitable for quantitative filling of water agent and raw materials.The curing agent automatic liquid filling line is an ideal production line for petrochemical,paint,pharmaceutical,chemical and other industries.The whole machine adopts programmable logic controller(PLC) and touch screen for operation control,which is convenient to use and adjust.

Allpack Curing Agent Can Filling Machine Features:

1.The equipment has strong compatibility, and can quickly adjust and replace bottles of different shapes and specificationswithout replacing parts, which can meet the production requirements of multiple varieties and

specifications

2.PLC control ,touch bottle operatation ,simple and convenient operation.

3.The use of internatioal famouse brand electrical components, performance and stability.

4.User can adjust filling range, the materials is not enough in hopper, the computer will give the feeding pump signal to addmaterial by level sensor. When the material is full, the pump will stop automatically.

5.Machine body is made by 304 stainless steel, easy to clean, machine is full compliance with GMP requirements.

6.Peristaltic pump or piston pump filling system, measuring precision, convenient manipulation

Allpack Curing Agent Can Filling Machine Technical Specification:

| Filling capacity | 400-2200barrels/hour |

| Number of filling heads | 4/6/8/10 |

| Applicable Specifications | 10-1000L square barrel, round barrel |

| Filling accuracy | ±0.1% |

| mains power | 380V/50Hz;12KW |

| Air pressure | 0.6MPa |

| Scope of application | Precise filling of liquid products such as coatings, chemicals, paints, etc. |

The Buyer's Guide

Can Filling Machine: The Complete Buying Guide in 2024

Do you want to package your products in aesthetically pleasing and durable containers, if yes, then use a Can Filling Machine.

It is seamless and high-speed equipment that fills your containers in no time. This machine is the answer to all your filling problems. It is a versatile machine capable of handling various products with the toolless changeover. Furthermore, can filling machine is integrated into production lines without much effort on your part.

If you are planning to buy this useful equipment, then it is recommended to go through this guide to discover various characteristics, advantages, applications, classifications, etc. of a can filling machine.

1.What is Meant by Can Filling Machine?

A can filling machine is a robust and efficient piece of equipment usually employed in production plants for filling bulk-capacity containers such as jerrycans, pails, buckets, and large gallon barrels.This machine is equipped with various types of fillers that play an essential role in loading liquids with great accuracy and precision.

It has quick change-over with helps in dispensing several different products in a short time. It is equipped with conveyor systems, filling units, sensors, etc to aid in bulk low-error dispensing.

2.How Can Filling Machine Benefit Your Productions?

Can filling machine boasts a huge range of advances and also enhance your production capability. It has become a go-to equipment for the filling of larger loads. Some of the important benefits of a can filling machine are detailed below for your understanding.

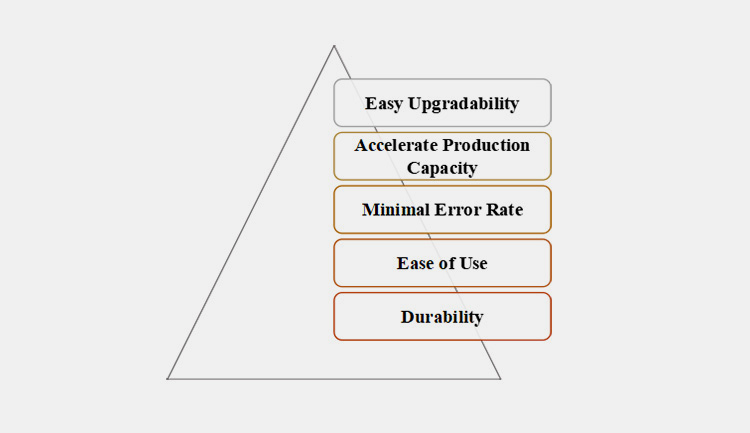

Easy Upgradability

Filling Nozzle Addition to Upgrade Can Filling Machine: Photo Courtesy ASG

If you are unable to meet your evolving filling demands, you can easily upgrade your existing can filling machine by installing additional filling nozzles in it without going to market to buy a new can filling machine of high cost.

Accelerate Production Capacity

Accelerate Production Capacity with Can Filling Machine: Photo Courtesy ASG

A can filling machine is an automated and independent system capable of working at high speed. By using this handy equipment in your production lines, you can get rid of slow manual filling often requiring more time.

Minimal Error Rate

Can Filling Machine Photo Courtesy: Levapack

This machine not only increases your production volume but also offers you filling with high accuracy and precision. There is a minimal batch-to-batch variation using this system because it is equipped with highly sensitive sensors and scales. These components detect minute errors in filling and assist in refilling containers with meticulousness.

Ease of Use

Ease of Use in Can Filling Machine: Photo Courtesy UID

Users can easily operate and supervise this system without needing any special skills and training. HMI and other computerized devices make it easy to supervise machine operation without going down the line. Remote connectivity aids in monitoring a can filling machine from the comfort of offices and homes.

Durability

Can Filling Machine- Picture Courtesy: Sidel

This machine is made up of durable stainless-steel materials and heavy-duty and robust components that run for a long time without any significant wear and tear. This feature extends the machine working life by decades.

3.In What Type of Industries Can Filling Machine Employed?

Can filling machine is used in various industries to automate the filling of containers. It is designed to accurately dispense and package a wide range of substances including liquids, fluids, suspensions, solutions, etc. This is a list of industries in which can filling machine is commonly employed.

Food and Beverage Industry

Can Filling Machine in Food and Beverage Industry: Photo Courtesy- Word Press

In the food and beverage industry, the can filling machine is widely employed for packaging liquids, such as water, juices, milk, sauces, oils, and carbonated drinks. It is extensively utilized in the beverage and brewing industry to fill beer, wine, spirits, and other alcoholic and non-alcoholic beverages in bottles, cans, and kegs.

Cosmetics and Personal Care Industry

Can Filling Machine in Automotive Industry: Photo Courtesy Maharastra

Can filling machine is used to fill a variety of pesticide and agriculture products, including pesticide in viscous and non-viscous form.

Chemical and Petrochemical Industry

In chemical and petrochemical industries, this machine is employed to manage and fill a variety of chemical products, including solvents, cleaning agents, lubricants, adhesives, and industrial chemicals, into drums, barrels, canisters, and other containers. It is also recurrently used to precisely fill paint, varnish, stains, and other coatings in cans, pails, and drums.

Automotive Industry

In the automotive industry, it is employed to fill containers, cans, and other large-capacity containers with fluids, such as engine oils, lubricants, coolants, brake oils, and windshield washer fluids.

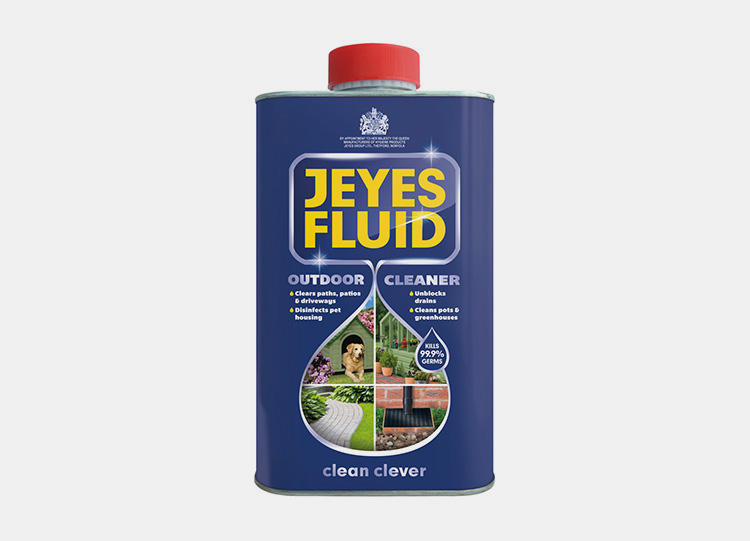

Household and Cleaning Products Industry

Can Filling Machine in House-Hold Industry: Photo Courtesy- Dettol

Cleaning and household items, including detergents, soaps, disinfectants, and fabric softeners are packaged into cans., using can filling machine. This machine ensures safe and secure packaging.

4.What are the Various Ways by Which a Can Filling Machine is Classified?

There are several ways to classify can filling machine, some of which are detailed below:

Classification Based on Automation

Three types of can filling machines are available in the market when classified depending upon the level of automation.

Semi-automatic Can Filling Machine

It is a step up to the manual can filling machine. As the name suggests, this machine is capable of carrying out different functions both automatically and with the help of operators. Human intervention is needed to operate this type of machine for loading and unloading containers.

It is usually employed in medium-scale productions.

Automatic Can Filling Machine

This type of can filling machine is completely autonomous as it is equipped with modern technological controls, sensors, alarm systems, and PLC units. It has more costly than its other counterparts, however; this equipment demands little to no human supervision.

Operations just have no program filling protocols and the automatic can filling machine fills containers with great precision due to its error-correction systems.

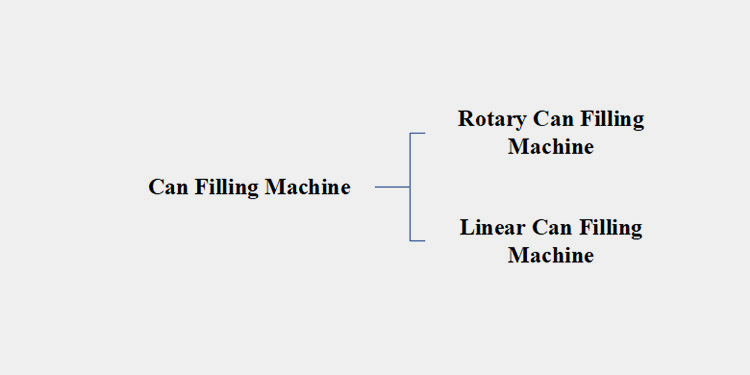

Classification Based on Design Configuration

Modern can filling machine comes in two design configuration which is detailed below:

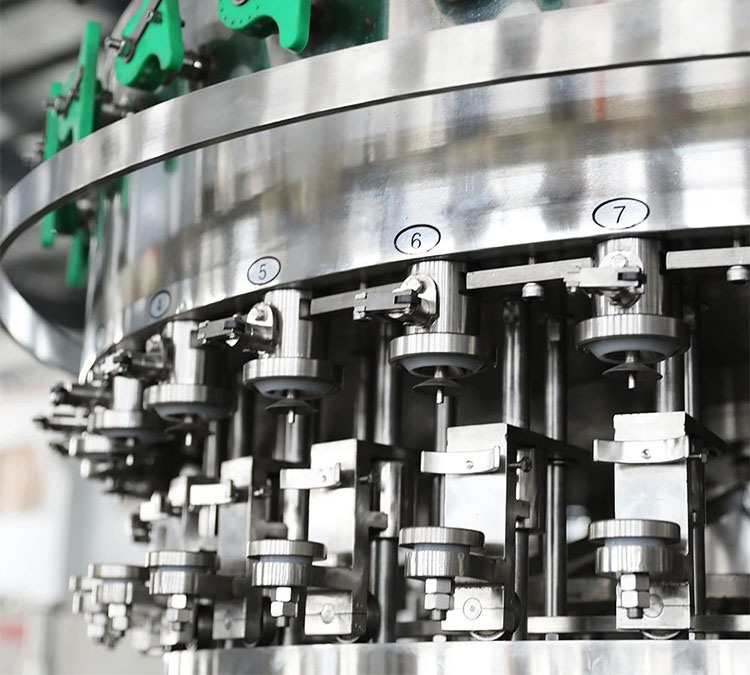

| Rotary Can Filling Machine | This type of machine opts for a circular type of configuration because it has a rotary star wheel. This component has many filling heads and is involved in continuous filling operations. Rotary can filling machine has higher productivity than its linear counterpart and can fill containers without pause. This machine is excellent for higher production. |

| Linear Can Filling Machine | This machine is available in Z, L, U, and S types of designs. It sequentially fills containers. The transport of containers stops while the machine is dispensing liquids in containers. It is easy to upgrade a linear can filling machine than a rotary can filling machine. But this equipment has less production capacity. |

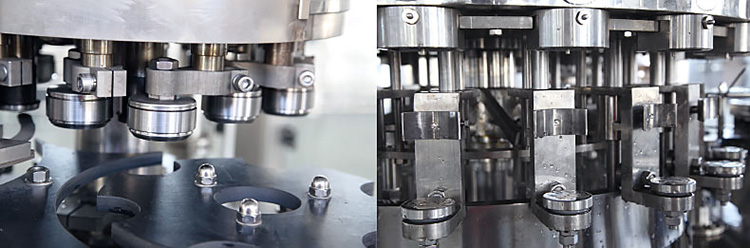

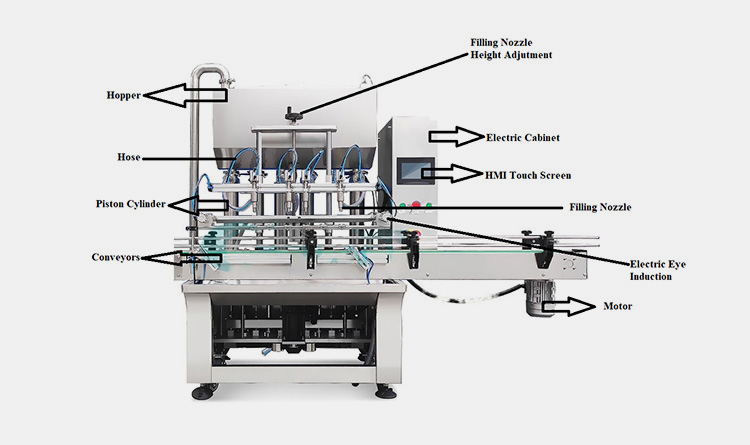

5.What are the Main Parts of a Can Filling Machine?

Can filling machine has various technologically advanced parts and each has its particular role in efficient and fast filling. Some of these important components are detailed below for your understanding.

Hopper

This is the topmost part of the can filling machine and the bulk quantity of liquid products is loaded in this device before the start of operation. It is normally like a trough shape.

Hose

It is a pipeline that links the hopper and the filling nozzles. The liquids move from the hopper to this passageway. It is made of PVDF and PTFE for resisting harsh chemicals.

Piston Cylinder

A piston cylinder is a type of filling device. It is a cylindrical component enclosed within a larger cylinder for drawing the liquids from the hoppers. The to and fro movement of the piston moves the liquids into the filling cylinder and filling nozzle respectively.

Conveyors

These are made of drum rollers, chains, and drive belts and are employed for moving cans or drum containers to the filling station and machine discharge area.

Filling Nozzle Height Adjustment

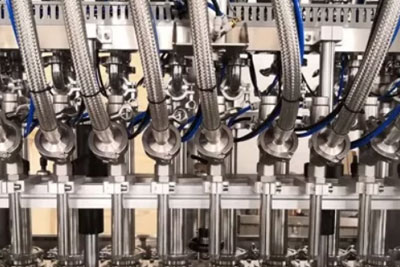

It is a hand crank or valve that is used for tightening of spring connected with filling nozzles and to achieve steady fills. In the automatic can filling machine, this device is powered electrically. This raises as well as lowers the nozzles for filling.

Electric Cabinet

It is an electric board having different kinds of relays, fuses, switches, wires, etc for powering the system and its components. These switches are present inside the fireproof cabinet for safety concerns.

HMI Touch Screen

The intuitive and intelligent smart screen that helps in programming and modifying filling parameters is HMI. It is a touch interface that is employed for displaying the progress of filling as well as for recording operation recipes,

Filling Nozzle

These are tube devices having different types of valves as well as orifices for dispensing liquids. The diameter of the orifice is usually depended upon the type of filling containers.

Electric Eye Induction

It is a photo-eye container detection system for automatically pausing the filling process if no container is detected under the filling nozzle. It is essential in preventing the wastage of liquid products.

Motor

It is a powerhouse of the can filling machine and is capable of transforming electric energy into mechanical energy for moving conveyors, pumps, filling nozzles, etc.

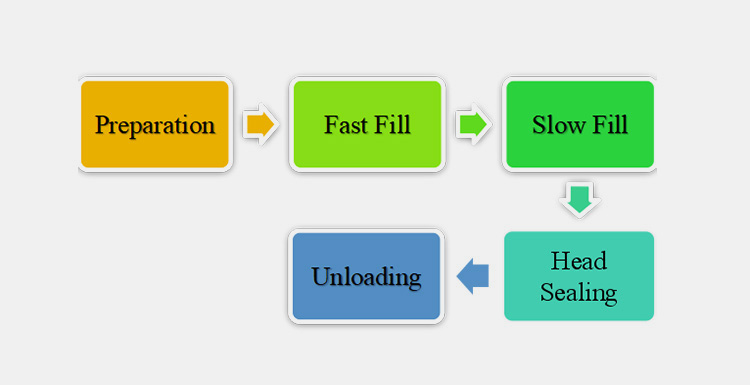

6.What Can You Tell About the Working of Can Filling Machine?

Understanding the inner working of the can filling machine assists in programming, troubleshooting, and repairing this equipment. Moreover, this helps you to customize the machine according to your filling requirements. Some facts regarding the working of can filling machine are:

Preparation

First, the empty containers are lined on the conveyors for uninterpreted fill by the operators. These conveyors transport the empty containers under the filling nozzles. Moreover, bulk amounts of liquids are also stored in the product tank or hoppers.

Fast Fill

Immediately, after the container moves under the filling head, the PLC system activates product dispensing. At first, nozzles are opened to maximum capacity for fast filling.

Slow Fill

When a capacity threshold is nearby, a slow filling mode is activated and the nozzle orifice is reduced to limit the product flow. This is done to acquire precision in the filling.

Head Sealing

When cans are filled they’re transported toward head sealing section for induction sealing.

Unloading

After the container is filled to a required set limit, the filling stops, and nozzles close. The conveyors then move the filled containers to the capping or labeling area.

7.What are Different Equipment Integrated With a Can Filling Machine in Production Lines?

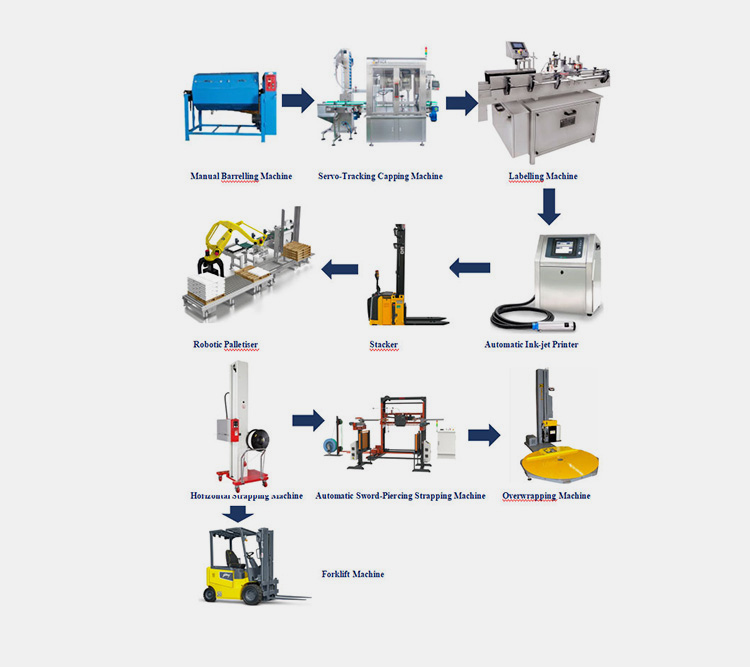

To ensure the effective and prompt packing of chemicals, the chemical filling production line is made up of several connected machineries. Some of these machines are penned below:

Manual Barreling Machine

The technology uses cylindrical tumblers to thoroughly clean, polish, and remove dust from reusable transport containers including drums and intermediate bulk containers (IBCs). While lowering the chance of cross-contamination, this approach seeks to improve their visual impact.

Capping Machine

To safeguard the contents of shipping chemical containers, a large-volume capping machine was developed. It comes after the can filling machine in the order of events. With a capping machine, jerrycans, pails, and drums are typically securely sealed.

Labelling Machine

On chemical storage containers, add-on stickers, overwraps, and other labels are applied and glued using a bulk-capacity labeling machine. These bulk labels increase the conspicuousness of products on merchandising shelves, aid to distinguish their contents, and provide information on proper container management throughout transportation.

Stacker

Large-capacity storage containers can be challenging to transport, which is why stackers like the hydraulic lift or electric walkie machine are used. The containers are simply lifted and arranged horizontally.

Robotic Palletizer

When compared to traditional palletizer equipment, a robotic pelletizer is a unique and automated device with a greater palletizing speed and efficiency. For simpler palletizing, it features a robotic arm and a lifter that automatically arranges the container stacks on a wooden pallet structure.

Horizontal Strapping Machine

Pallets of chemicals are laterally strapped using a horizontal strapping machine. Before binding the pallets together at the sides, this machine compresses and compacts the pallets. For pallets to be shipped safely, this strapping is necessary.

Automatic Sword-Piercing Strapping Machine

It is a kind of strapping device that fastens the pallets by slicing through the bottom of the pallet bundle with its sword-like elements. Heavy-duty PP or PET steel cable is strapped to the bundle using the automated sword-piercing strapping equipment. Pallets are less likely to escape during shipping as a result.

Automatic Wrapping Machine

Stretch film is entirely wrapped around chemical pallets by this final equipment in the chemical processing line. It features a robotic arm or turntable for completely encasing pellets in film, keeping pallets stable and safe. Additionally, doing so lessens the possibility of pallet damage during transportation.

Forklift Unload Bucket

A forklift picks up the completely packed pallets at the end of the processing line and transports them to a storage location while awaiting shipping.

8.What Type of Products a Can Filling Machine Fill?

There is a variety of products packaged by the can filling machines, some examples are given below:

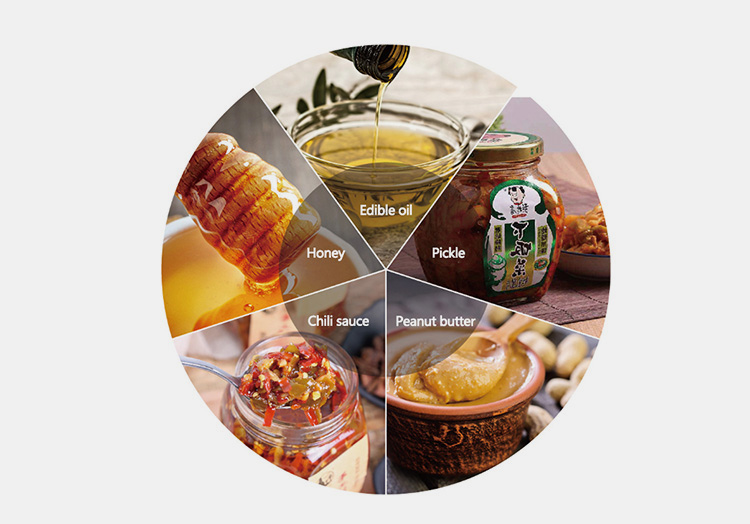

Viscous Products

These products have some resistance in their flowability These include honey, grease, maple syrup, peanut butter, etc.

Free-Flowing Products

They have no hindrance in their flow. Water, acids, alcohols, etc. are the example of free-flowing products.

Foamy Products

These liquids have trapped gas areas that generate foam. Foamy liquids include whipped cream, soap bubbles, alcohol, shampoos, fire retardants, etc.

Oily Products

These liquids have small quantities of oil molecules or are completely enveloped with oils. These comprise petroleum, crude oils, motor fuel, lubricating oils, etc.

9.Is Can Filling Machine Different From Traditional Bottle Filling Machine?

Yes, a can filling machine and a traditional bottle-filling machine are quite dissimilar to one another based on design and filling productions. Some differences in these machines are:

| Features | Can Filling Machine | Traditional Bottle Filling Machine |

| Filling Containers | This machine dispenses liquid feed in large containers which can accommodate higher product volume. | It fills liquid materials in small containers usually bottles and jars. |

| Structure | Can filling machine is a large construction requiring more space. | Traditional bottle filling machine is smaller with lower floor space. |

| Type of Fillers | Mostly net weigh fillers are installed in this machine for precise fill. But it also employs pump and piston fillers for dispensing viscous feed. | It mostly uses gravity, overflow, and pneumatic fillers for loading liquids. |

| Conveyor Design | Conveyor systems are long and wide to process bulk-capacity containers. Moreover, drum roller conveyors are installed in these machines for stability. | The conveyor systems in this machine are shorter and narrow for handling bottles. Drive-belt conveyors are installed in traditional bottle-filling machines. |

| Fill Volume | It is mostly for bulk filling with a maximum range of 1000 liters in the case of IBCs. | It is usually employed for small-scale fill ranging from 1 ml to 10 liters. |

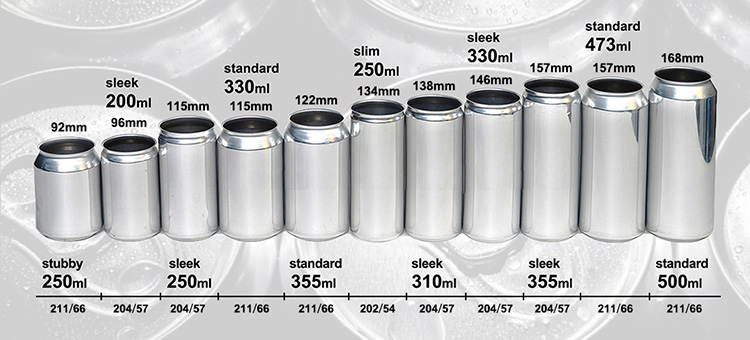

10.Can You Use the Can Filling Machine For Different Container Sizes?

Since liquid feeds come in different-sized containers, therefore, a can filling machine is also employed for loading products in containers varying in dimensions. Some examples of different-sized containers are:

| IBCIt is the largest container filled by the can filling machine. It is an industrial storage container usually available in rectangular or cubic form. IBC comes with a wooden pallet that provides ease of carrying. It is also referred to as a tote. | DrumIt is a cylindrical container often called a barrel. The drum is available in different designs and is sealed by lids or bungs. It is the second largest container processed by the can filling machine. |

| BucketsThese are rectangular, oval, or round containers with flat bases. The buckets are equipped with handles and lids for carrying and closing the containers. | JerrycansThey are the rectangular container usually employed for storing motor fuel. It has a rectangular or oval-type shape. Jerrycans and buckets generally have the same sizes and filling range. |

11.What is the Filling Capacity Range of the Can Filling Machine?

As mentioned above, can filling machine dispense containers of different sizes. So, the filling range of the can filling machine is also diverse for each of the product containers. Typically, the filling range of this machine is about 10 liters to 200 liters.

However, if it is employed for dispensing products in IBCs container then its filling range is increased to about 1250 liters.

12.What are Different Types of Filling Devices in Can Filling Machine?

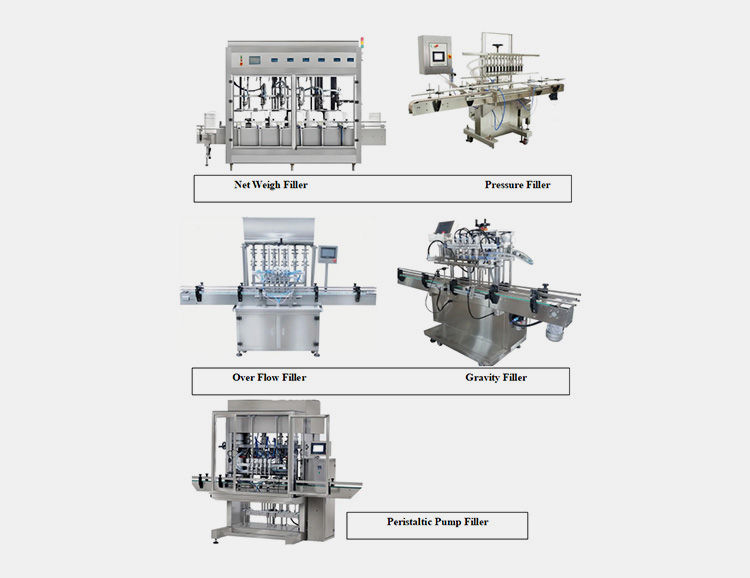

There are several different types of filling devices in the can filling machine, that are responsible for the smooth and reliable filling of liquid products in various containers. These are detailed below.

| Gravity Fillers | Gravity fillers consist of hoppers, filling hose, and nozzles. The filling nozzles have solenoid valves that open and close in response to liquid flow. The liquids flow from the hopper into the filling nozzles upon opening of valves. Fill volume is dependent upon the filling time. Multi-head filling nozzles are only used in this filler if the flow of liquids is identical. |

| Net Weigh Fillers | As opposed to other volume fillers, these fillers consider the weight of the products for filling. These fillers are best suited for loading bulk-capacity containers. They are comprised of photoelectric sensors, sensitive weighing scales as well as filling devices for precise filling. |

| Pressure Fillers | In these types of filler devices, the storage tank is located below the containers. Using pressure generated by centrifugal or other positive displacement pumps, the liquids move directly into the containers. They have more speed than other fillers and fill viscous products. |

| Overflow Fillers | It is a liquid leveling filler that is employed for filling containers to the same level. It uses overflow nozzles and pressure to quickly fill the container. The anti-drip nozzles are submerged in the containers and raised on the increasing product level. This filler is employed for loading clear containers and products “seem” to have identical volumes but there are variations in filling volume in each container. |

| Peristaltic Pump Fillers | This filler type is widely employed in the industries where processing of hazardous and pharmaceutical products is involved. This is because the product does not get in contact with the environment and moves directly into the hose. Moreover, some types of pumps in these fillers have extremely accurate filling that is down to 1 microliter. The pumps- rollers, lobes, wipes- are employed for moving products in tubing hose. |

13.How a Can Filling Machine Achieve Different Filling Speed For Different Products?

Servo-driven Filling Nozzles in Can Filling Machine

Can filling machine is capable of filling a wide range of containers with some easy adjustments. Moreover, different containers require different filling speeds. Generally, at first, containers are loaded at high speeds by the can filling machine then on the last leg, the filling speed is decreased to attain high accuracy.

Different filling velocities are obtained due to the component of can filling machine- servo-driven motor assemblies. These motors control different filling rates by filling nozzles. Moreover, these synchronize the nozzle withdrawal to increase in fill level for preventing liquid overflow.

14.What are Different Buying Considerations For Can Filling Machine?

Several considerations should be made when buying a can filling machine. It is crucial to keep in mind that these factors may change depending on the company’s particular demands and specifications. The following are a few key factors to consider when purchasing a can-filling machine:

Production Potential

The output capacity of the can filling machine is one of the most important elements to consider. Determine how many cans you need to fill each minute or hour by analyzing the production needs. This enables the selection of a machine that can efficiently manage the specified production volume.

Can Size and Compatibility

Consider the sizes and types of cans you plan to fill. Some can filling machine is designed for specific can sizes, whereas others offer flexibility to handle various can sizes and shapes.

Safety Features and Compliance

Safety in Can Filling Machine

Safety comes first in all industrial settings. The can filling machine must comply with all applicable safety guidelines and aspects, such as safety guarding, emergency stop buttons, and certification for electrical and safety compliance.

After-sales Service

After-Sale Service: Photo Courtesy- Dr.Fried

Consider the quality of the manufacturer's or supplier's after-sales service and also elements such as warranty protection, technological support, and accessibility of service professionals. The response time and dependability of assistance may save downtime and guarantee the effective operation of the filling machine.

15.How Can You Extend the Shelf Life of a Can Filling Machine?

By following these guidelines, the shelf life of a can filling machine can be extended significantly.

Regular Maintenance and Cleaning

Maintaining Can Filling Machine: Photo Courtesy- Sapli

A can filling machine requires routine maintenance and cleaning to last longer. This includes looking for signs of wear and tear on the equipment, tightening any loose parts, and lubricating any moving parts. Furthermore, careful washing after each usage keeps residue from building up and guarantees optimal performance.

Proper Calibration

Calibrating Can Filling Machine: Photo Courtesy- Beverage Filling

To preserve the consistency and effectiveness of the filling process, a can filling machine must be calibrated precisely. To maintain precise filling levels, the machine’s sensors, timers, and measuring systems were regularly checked and calibrated. This reduces product waste and enhances overall efficiency by preventing the cans from being overfilled or underfilled.

Quality Control

A strong quality control system must be put in place if the can filling machine is to last longer. Conduct routine testing and inspections to identify and fix any possible problems early.

Training and Operator Knowledge

Training Workforce: Photo Courtesy- Metalboss

The best way to extend the life of a machine is through appropriate training and operator knowledge. Ensure that users have received adequate training to operate and maintain the can-filling equipment.

To avoid unnecessary damage or downtime, they should be informed of the proper processes, safety precautions, and troubleshooting strategies.

Timely Replacement of Wearable Parts

Gaskets, O-rings, and seals are examples of parts of can-filling machines that are susceptible to wear over time. To avoid leaks, guarantee good sealing, preserve the machine's lifespan, regularly examine these components, and replace them as necessary.

The likelihood of failure is reduced, and the machine's lifespan is increased by maintaining a supply of spare parts and quickly replacing damaged or worn-out parts.

16.How Would You Troubleshoot Can Filling Machine?

Problems and technical faults are the part of routine process in a can filling machine and are the major source of headache and tension for operators as well as brand owners. However, these could be resolved by some simple steps including:

| Problem | Reason | Solution |

| Motors Do Not Start

|

Drive shafts in motors are improperly alignedDamaged bearingsA high temperature of motorsVarying voltage | Correctly arrange driveshaftsReplace faulty bearingsSwitch off the machine to lower the motor temperatureUse UPS to accommodate fluctuating voltage |

| Immovable Head Dive

|

Airpipes are disconnectedLeakage in the airlinesImproper compressed air supplyFaulty settings of the head dive | Tightly connect the airpipes.Inspect airpipes for leakage and replace themEnsure proper compressed air supply to equipmentInput correct settings of head dive |

| Liquids are Not Dispensed in the Container Even Tough Machine is Switched On

|

The valve in the filling nozzles is shut.Improper compressed-gas pressureThe fuel injection cylinder is dripping | Switch on the machine again for opening the valves in the nozzlesFix the compressed-gas pressureReseal or replace the fuel injection cylinder |

| Container Tipping and Liquid Spillage

|

Unstable containers due to uneven baseWorn-out conveyor beltsDamaged drum rollers in conveyors | Use neck grippers for container supportReplace old conveyor beltsRepair damaged drum rollers |

| Blocked Nozzles

|

Accumulation of debris due to improper and irregular cleaningLiquid residue sticks to the nozzle and fill the tubing | Maintain a proper and regular cleaning scheduleCompletely wash the fill tube and nozzles with soapy water after every shift |

Conclusion

For efficiency, accuracy, and high speed in your bulk filling, it is best to opt for a can filling machine. This machine is versatile and processes a wide variety of liquids as well as filling containers. Furthermore, by using this machine, you can avoid problems related to overfills and underfills. Hope this blog aids you in selecting the right kind of can filling machine for your business. However, if you have some confusion related to this machine, you can contact our customer care support,.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Automatic liquid filling line Related Products