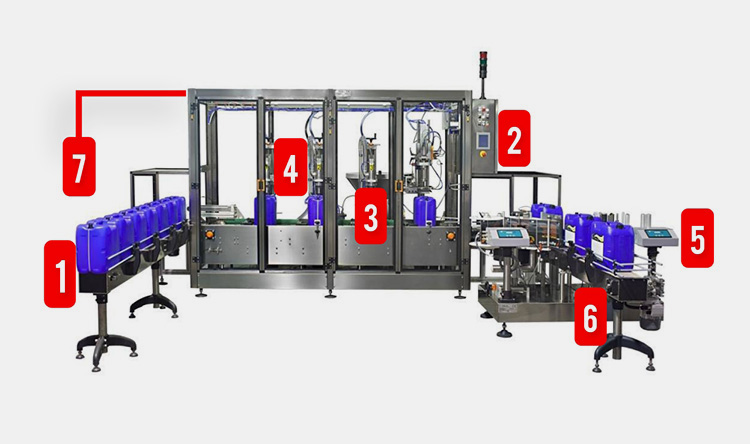

Automatic Smart PLC Control Solvent Base Paint Ink Filling Machine Automatic liquid filling line

Allpack ink filling machine automatic liquid filling line can be used for filling filling various liquids into bottles. Such as ink, shampoo, laundry detergent, shower gel, detergent, tomato sauce, sauces, lubricants,cooking oil, etc. It is suitable for filling in large quantities of factories, and can be connected to the production line before and after.It can be used together with the capping machine, capping machine, labeling machine and inkjet printer.According to your actual production requirements, single head, 2 heads, 4 heads, 6 heads, 8 heads, etc. can be selected.

Allpack Ink Filling Machine Details:

Allpack Ink Filling Machine Products:

Allpack Ink Filling Machine Features:

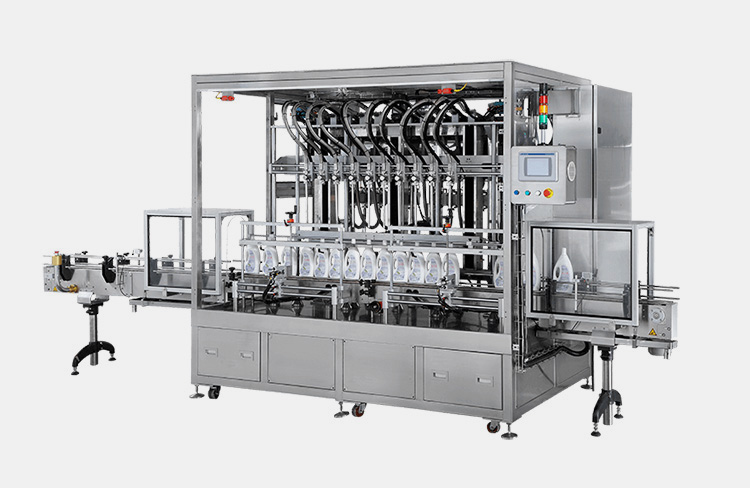

1.It adopts peristaltic pump filling, with with large filling scope, easy to replace liquid tubes for different materials, no mixed filling pollution, easy to wash & maintain, especially good for comsetic, daily checmical liquid & gel bottle filling capping.

2.With PLC & touch screen system, it's easy to operate & maintain.

3.Linear & humanized design, it's suitable for different bottles & can do quick production changeover without tools, with highly production flexibility & efficiency.

4.No bottle, no filling; auto counting, auto washing, breakdown self-detecting etc

5.With inverter to control speed, It not only can operate seperately, also can be linked to production line to meet high automation.

Allpack Ink Filling Machine Technical Specification:

| Filling range | 5-1000L |

| Fill Capacity | 400-2200barrels/hour |

| Filling precison | <1.0% |

| Hopper volume | 120L |

| Filling system | Gear pumps |

| Control system | PLC+Touch screen |

| Power supply | AC220V 50Hz/60Hz 0.35KW |

| Air consumption | 0.6-0 .8Mpa, 0.35cbm/min, |

| G.W. | 2570*635*1660mm |

The Buyer's Guide

Ink Filling Machine: The Complete Buying Guide In 2023

Ink has remained one of the essential tools of writing and sketching in the past. Its history goes back to ancient times when Chinese civilization invented ink in 256 BC. This new invention was indeed astonishing for people of the time, who took great advantage of it by utilizing it for dying, painting, decorations, cosmetics and range of other operations.

Today, huge number of large scale industries have based their businesses on ink production and supply. Keeping in view, the growing demand of quality material as well as the contemporary challenges of market competition, business owners are required to use advance technologies for processing ink. In this way, ink filling machine is an undeniable need which can boost the current production output with an immaculate performance. This guide is brought into context to enable you with the ink filling machine, its features, procedure, components and much more. So, be ready to traverse it!

1.What Is Ink Filling Machine?

Picture Courtesy: DECA

Ink is a colored fluid available in numerous shades carrying great significance in today's globalized world, where it is used for branding, identification, designing and other activities. Different small to large scale industries who are engaged in ink processing, require ink filling machine to accomplish their responsible task of filling ink in various containers.

Therefore, ink filling machine is a type of liquid filling machine utilized for filling ink in range of small to large containers including jerrycans, barrels, drums and buckets. With advanced combination of features and benefits, this machine adopts high speed filling method while taking care of precision and product volume.

2.Enumerate The Benefits Of Ink Filling Machine?

Ink filling machine greatly contribute to your existing production line through its innovative technology. Here, we have highlighted some of its essential attributes:

Enhance Production

Ink filling machine is far more efficient than hand filling machine. It ensures consistent filling with multiple nozzles which resultantly increase the production output.

Reduce Product Waste

Ink filling machine is highly beneficial in terms of minimizing waste. By using time based, weight based or level based method, precise amount of ink is dispensed into containers which eliminate over filling.

Long Term Use

This large scale ink filling machine is designed with ergonomic features and advance structure. Hence, with proper monthly maintenance, it can keep your business running smooth and longer.

Resilience

It is not that ink filling machine only fill same kind of liquids and containers, rather liquids with diverse viscosities can be easily dispensed via this machine in any fixed measurement.

Upgradable

The most interesting feature of an ink filling machine is that it is scalable which means you can upgrade it with increase in your production by fixing additional filling nozzles through customization.

3.What Are The Uses Of Ink Filling Machine?

The application of ink filling machine is not confined to filling ink only, instead, it is eligible for substances with diverse backgrounds. Following are the key applications of ink filling machine:

| No | Description | Pictures |

| 1 | Ink Processing Industry - For Precision | |

| When talking about uses of ink filling machine, ink processing industry will always be in front due to its precision. In fact, the worldwide easy mobility of top quality inks is the result of modern technology including ink filling machine. |  |

|

| 2 | Healthcare Industry - For Hygiene | |

| Health industry is among one of the areas where hygiene is the condition and for attaining this goal, ink filling machine is utilized for range of medical fluids. |  |

|

| 3 | Agrochemical Industry - For Safety | |

| Agrochemical industry deals with the manufacturing of pesticides and chemicals like ammonia to reduce crop damage. These fluids are made up of harmful ingredients which are dangerous for humans. Therefore, enclosed ink filling machine safely fill them into containers. |  |

|

| 4 | Daily Chemical Industry - For Preservation | |

| Industry where household chemicals such as detergent, bathroom cleaner, floor cleaner and dish wash liquids are prepared is known as daily chemical industry. These substances are soapy in nature and need gentle filling to avoid foam. The bottom fill attribute of ink filling machine thus comes into action here. |  |

|

| 5 | Beverage Industry - For Productivity | |

| Similar to other industries, beverage firms cannot imagine their business growth without using liquid filling machine. Therefore, ink filling machine is highly beneficial due to its high productivity.

|

|

|

4.Which Type Of Inks And Products Can Be Filled While Using Ink Filling Machine?

Do you know? That, ink filling machine is flexible enough to fill great variety of liquids and the diversities of ink itself. So, let's bring them to light!

Types Of Inks

Water Based Ink

Water based ink is the most environmental friendly due to the ingredients which it holds including water, pigments, defoamers and other agents used for adhesion. It is free flowing and has good ratio of quick absorption which is why it is used for paper, textiles, and cardboard etc.

Oil Based Ink

In contrast, oil based ink is used for low absorbent material like plastic. Due to holding hydrocarbons and oil it may create volatile organic compounds which is hazardous for environment and workers. Therefore, it must be used with necessary precautions.

Solvent Based Ink

Such ink use solvent as its core fluid and is thick in nature. Solvent based ink is water-proof and ideal for glass, metal and plastic.

UV Based Ink

UV based ink is curable ink made up of safe ingredients including monomers, oligomers and additives. It quickly gets dry under UV light and is more durable, rubbing resistant and gives glossy look due to non absorption. It is widely used for ceramics, glass and wood.

Types Of Other Liquids

Drinks

Common fluids which are used for drinking such as juice, milk, wine and smoothies also comes under the jurisdiction of ink filling machine.

Medicines

Medicine syrups and other surgical fluids such as spirit and piodine are often circulated in large containers throughout the world. Here, again an ink filling machine can be used to perform the filling of these fluids into containers.

Daily Chemicals

By daily chemicals, we mean those chemical compounds which are used for cleaning purposes and not meant for human consumption. Some examples of daily chemicals include detergent, acid and bathroom cleaner, floor cleaner etc., which can be easily filled by ink filling machine.

5.What Is The Working Procedure Of Ink Filling Machine?

The working procedure of an ink filling machine can be easily understood by the underlying steps we have enumerated:

Ink Depositing

The very initial step for proceeding ink filling mechanism is indeed loading ink in a large chamber. This loaded chamber is then attached to the ink filling machine through pump.

Containers Loading

Picture Courtesy: Asset Packaging Machine

Here, bulk of containers such as drums, jerrycans or buckets are stacked together in feeding station. When machine get started, containers are transported towards machine filling station via conveyor belt.

Ink Filling

The final step of ink filling machine occurs here, when containers are automatically positioned in accurate direction right under the filling station. The filling nozzles then reach the lowest level of containers for dispensing fixed amount of ink in each of them. The filling nozzles move slowly in upward direction towards neck of container to avoid foaming.

Discharging

At the same time, filled containers are discharged by conveyor towards further processing of capping, sealing and labeling etc.

6.Describe The Main Components Of Ink Filling Machine?

The robust structure and effective performance of ink filling machine is undoubtedly the result of sophisticated components who work together to give extraordinary performance. These parts are described below:

Container Inlet

This part of machine allow containers to enter into the machine for filling. Container inlet is also responsible for the serialization of containers via conveyor belt.

Control Panel

Control panel is sort of mini board built for operating the machine. It has several keys/ buttons over it, which helps in switching the machine.

Ink Feeding Tank

Ink filling machine has integrated feeding tank where bulk ink is stocked before starting the operation. With the help of pump, ink is transferred from feeding tank to filling nozzles and containers respectively.

Filling Nozzles

Filling nozzles are also known as filling heads, are narrow shaped metal tubes designed to control the direction of fluid. It dispenses the precise amount of ink into containers.

Human Machine Interface

Programmable logic controller is an essential component of ink filling machine which control the processing of machine. While using user-friendly Human Machine Interface HMI, operator sets the basic parameters of machine for execution.

Bottle Detector

The machine's sensors and detectors are crucial components because they identify empty bottles, check for ink in the chutes and check to see if the safety covers are in place, all of which help to eliminate errors.

Main Frame

Main frame of the ink filling machine is made up of stainless steel that works as a supporting stand for it and make the process stable by avoiding shaking during operation.

Conveyor Belt

Conveyor belt works as a transportation device for containers. It is driven by mechanical drive system integrated in machine.

7.Enlist The Various Types Of Ink Filling Machine?

Ink filling machine has several types each designed with unique specifications that can improve your facility of production. They are described below:

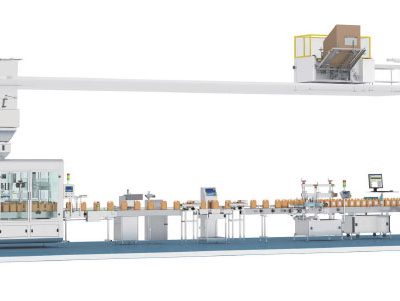

Fully Automatic Ink Filling Machine

Picture Courtesy: PROCMA

Fully automatic ink filling machine is self operated device that fill ink into range of containers by repetitive cycle once the machine is started. It has complex structure with many components and can be integrated with auxiliary machines for larger production lines. In addition, the machine is effective in terms of filling speed, accuracy and hygiene.

Semi-Automatic Ink Filling Machine

Semi-automatic ink filling machine is suitable for medium scale production as it require manual intervention for loading and unloading of containers. However, it is more precise than fully automatic machine due to small number of components. Its reasonable price and effective performance are the key factors for its preference of newly formed industries.

Gravity Ink Filling Machine

Picture Courtesy: APACKS

Gravity filling machine is an advance equipment made with unique features and heavy-duty construction of stainless steel. It carries out the filling task on the basis of time. With accommodation of 16 filling nozzles, it gives high production output. Moreover, the machine is ideal for filling inks and other fluids with high viscosities.

Volumetric Ink Filling Machine

Picture Courtesy: KWT

As the name suggests, volumetric filling machine fill containers by weight. It uses flow meter to gauge the weight of ink and fill desired level of volume into cans. This machine is particularly employed to undertake the filling of thin, greasy and finally liquids. Furthermore, it is capable to fill up to 5000ml of volume into different sizes containers.

8.Differentiate Between Gravity Ink Filling Machine And Volumetric Ink Filling Machine?

Gravity ink filling machine and volumetric ink filling machine are two effective types of ink filling machine with distinctive features. Knowing their differences may help you on great extent. For this, consider the table below:

| No | Factors | Gravity Ink Filling Machine | Volumetric Ink Filling Machine |

| 1 | Definition | Gravity ink filling machine is used to fill same amount of ink in number of containers while using time based filling. | Volumetric ink filling machine undertake the task of filling equal amount of ink with the help of measuring weight. |

| 2 | Process | It continues the spilling of ink into containers until the time for each cycle is completed. | It takes the predetermined volume of ink from hopper and dispense it into containers. |

| 3 | Characteristic | It follows time based principle. | It follows weight based principle. |

| 4 | Speed | It has higher filling ratio due to free flowing liquids. | It may require more time than that of gravity filling machine due to high viscosity liquids. |

| 5 | Ink Processed | It processes low viscosity, water based ink. | It can fill variety of high viscosity ink including UV ink, oil and solvent based inks. |

| 6 | Application | Ink industry, food industry, beverage industry, chemical industry etc. | Paint industry, coating industry, cosmetic industry etc. |

| 7 | Picture |  |

|

9.Mention The Containers Eligible For Ink Filling Machine?

Ink filling machine is capable of filling range of containers such as:

Jerrycans

Jerrycans are durable containers made from either plastic or pressed steel. It is widely used in liquid processing industries for low to medium volume. The enclosed construction and integrated cap keeps the inside content protected from pollution and waste.

Gallons

Gallons are larger than jerrycans and can hold up to 25 liters of liquid volume. Plastic is the main ingredient of their production. They are cost-effective and easy to carry via hands which make them appealing to large number of industries.

Drums

Along with other types of containers, drums can also be easily filled by ink filling machine. Most of the large scale industries prefer using drum as they can hold capacity up to 200 liters.

Buckets

Bucket is cylindrical container usually made of plastic with a lid over it and handle joined on dual sides of opening. UV ink and oil based ink are mostly filled in buckets for convenience. It has the capacity to hold up to 10 liters of ink.

Intermediate Bulk Containers

Intermediate bulk containers are extra large industrial grade containers used for storing ink and other liquids. An ink filling machine can better fill such containers through automatic processing.

10.Which Methods Can Be Used For Increasing The Accuracy And Efficiency Of Ink Filling Machine?

Mere operating the machine will not give you results as productive as you want. For this, you should be solicitous about its maintenance and some of the other tips we have provided here:

Regular Maintenance

Regular maintenance is one of the key steps, that keeps your ink filling machine on track. Therefore, you need to be vigilant in examining your machine on daily basis and resolve the minor issues to avoid significant downtimes and ensure effectiveness of machine.

Technological Upgradation

Upgrading your machine with advance features such as automation, HMI, control panel and additional filling nozzles is essential with an increase in production volume. It will ultimately reduce human errors and production cycle, eventually, leading to the accuracy and efficiency of machine.

Providing Adequate Knowledge

It must be noted, that efficiency not entirely depends upon the machine, rather skilled and competent workers is another need which requires proper knowledge and training to be able to understand the machine functionalities and timely resolve its intricacies.

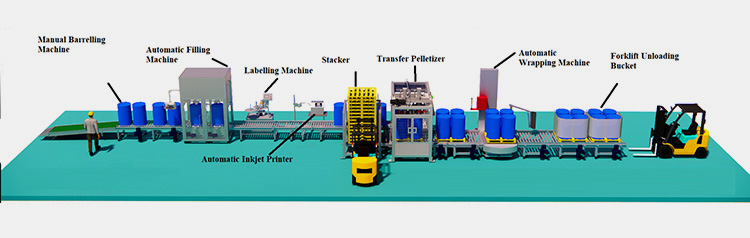

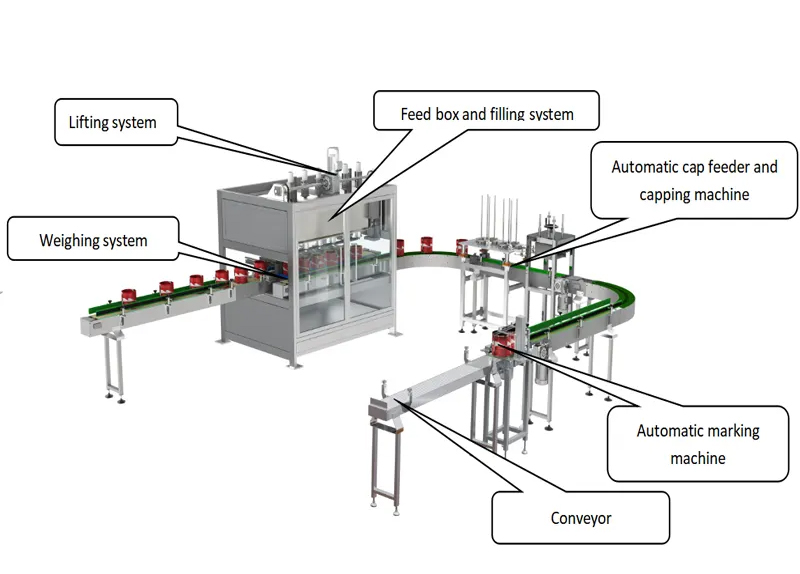

11.Explain The Production Line For Ink Filling Machine?

For 200 Liters

For 10 to 30 Liters

The production line of ink filling machine is comprehensive that completely covers overall tasks related to its packaging. It includes following machines:

Manual Barreling Machine

Manual barreling machine is also known as tumbling machine employed to clean the inside area of drums and other containers by polishing before ink filling operation.

Automatic Capping Machine

Automatic capping machine is an effective tool that can secure different sizes of caps over jerrycans, drums and other containers.

Labeling Machine

Labeling machine works as an applicator of labels made up of either sticker paper or plastic. It comes into action when containers are moved from filling and capping phase, where it applies labels to containers.

Servo Tracking Capping Machine

This machine is adopted for the capping of screw caps. With the help of multiple servo motors, it controls the movement of capping head and makes sure that bottles are well capped without any damage.

Stacker

When containers get filled, capped and labeled, stacker start picking them and stacking on a single wooden platform in order to unite them for further processing.

Automatic Inkjet Printer

Automatic inkjet printer is highly efficient in its performance. It is used for printing batch no, barcode and expiry date on filled containers.

Robotic Palletizer

Robotic palletizer is one of the excellent machines designed for reducing human labor. With an integrated arm, it automatically picks up multiple containers at the same time and place them on a pallet.

Horizontal Strapping Machine

Horizontal strapping machine is used for binding one or more items together for maintaining integrity which is obligatory for goods prepared for transportation.

Automatic Sword-Piercing Strapping Machine

In this type of strapping machine, goods are strapped in a more powerful way to avoid disintegration. It uses a sword like device that holds the band in its mouth and pass it through the bundle of goods, eventually, turning them into a single unit over stacker.

Automatic Wrapping Machine

Automatic wrapping machine releases flexible plastic film over palletized containers. This film is stretched over containers to strengthen their bond and eliminate scattering during shipping.

Forklift

Forklift is a mini truck with lifting forks in its front. It is used for transporting the packed containers into cargos for their final destination of shipping. Forklift can bear weight up to 50,000 lbs.

12.What are the safety measures for using ink filling machine?

While ink filling machine is effective enough to cope with the complexities of filling various types of inks, it brings along with it some essential safety features. These include:

304 Stainless Steel Body

Ink filling machine is made up of corrosion resistant stainless steel body which ultimately reduces the risk of getting eroded by interaction of different chemicals.

Enclosed Structure

Sometimes, inks have toxic nature due to which they cause harm to environment as well as users. Hence, the enclosed construction of ink filling machine minimize the direct exposure of ink during processing which ensures environmental safety.

Explosion Proof:

The explosion proof system of machine is best for transmission protection as well as electrical protection. It makes the machine capable of withstanding minor short circuit and electric shocks and avoid explosion caused by strong reaction of flammable chemicals.

13.What Are The Mandatory Considerations For Ink Filling Machine?

It is better to take necessary considerations on account instead of jumping to conclusions which might lead you towards making wrong decision. Here, we have provided some of the noteworthy tips for you to follow:

Nature of Material

As we discussed above, ink has several types on the basis of thickness and ingredients. Therefore, it is crucial to consider the type of ink you are processing. For instance, water based and free flowing can be easily filled by gravity filling machine. On the other hand, volumetric filling machine is good for high viscosity thick inks such as oil based and UV based ink.

Production Scale

Are you engaged in large-scale manufacturing or low to moderate-volume production? It is important to answer the query, as number of containers which are to be filled depends upon the automation of machine. The higher the automation, the large number of containers machine will fill.

Concerning Quality

Considering quality of the machine is most important aspect of your business. For this, you can check the warranty policy of vendor as well as international quality certifications to whom the machine should comply including ISO, EU and GMP.

Containers Used

Which type of containers you are using for ink filling machine? This question carries great significance, as it will impact upon your entire production line. For example, the capacity, holding and labeling of jerrycans are different from that of drums.

Conclusion

Ink filling machine holds lucrative position in modern day industries and its application encompasses other sectors including food, medical and chemical etc. By using this machine, the production efficiency can be achieved, product waste can be reduced and at the same time benefits can be multiplied. So, what are you waiting for. Let's take the final step towards boosting your business by purchasing standard ink filling machine offered by Allpack. You will also get 24/7 hours customer support. For getting further information make sure to contact us through our website!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Automatic liquid filling line Related Products