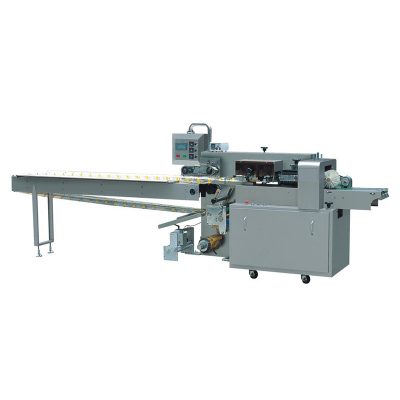

Aipak APK-300A-1 adopts full automatic loading stsyem,it is mainly used for packaging cards, stickers, plasters.With imported electrical appliances and touch man-machine interface, it is convenient and quick for you to set the parameter of this flow wrap machine.Adopts high sensitivity electro-optic eye color code tracking,the sealing and cutting position of each are accurate.

FEATURE:

- Compact structure, stable performance and simple operation.

- Double frequency conversion control, the bag length is set and cut immediately, there is no need to adjust the empty walk, one step in place, saving time and film.

- Adopts imported electrical appliances and touch man-machine interface, and the parameter setting is convenient and fast.

- Fault self diagnosis function, fault display at a glance.

- High sensitivity electro-optic eye color code tracking makes the sealing and cutting position more accurate.

- Temperature independent PID control, better suitable for all kinds of material coating.

- Positioning shutdown function, no knife sticking and no film consumption.

- The rotating system is simple, the work is more reliable and the maintenance is more convenient.

- All controls are realized by software, which is convenient for function adjustment and technical upgrading, and will never lag behind.

DATA SHEET:

| Model | APK-300A-1 |

| Bag size (mm) long*wide*high | 65~190mm*30~140mm*5~50mm |

| Vertical and horizontal sealing strength (Newton/mm ²) | > 15 n/mm squared |

| Packing speed (bags/min) | 40~200Bags/min |

| Packaging film width (mm) | 80~300mm |

| The power supply specifications | 220V 50/60Hz 2.4KVA 380V 50/60HZ 1KVA |

| Machine weight (kg) | 800kg |

| Overall dimensions (length × width × height) | 3200×680×1560mm |

Reviews

There are no reviews yet.