APC-12 Fully Automatic Vitamin Pectin Sweets Gummy Bear Candy Pill Counter Machine

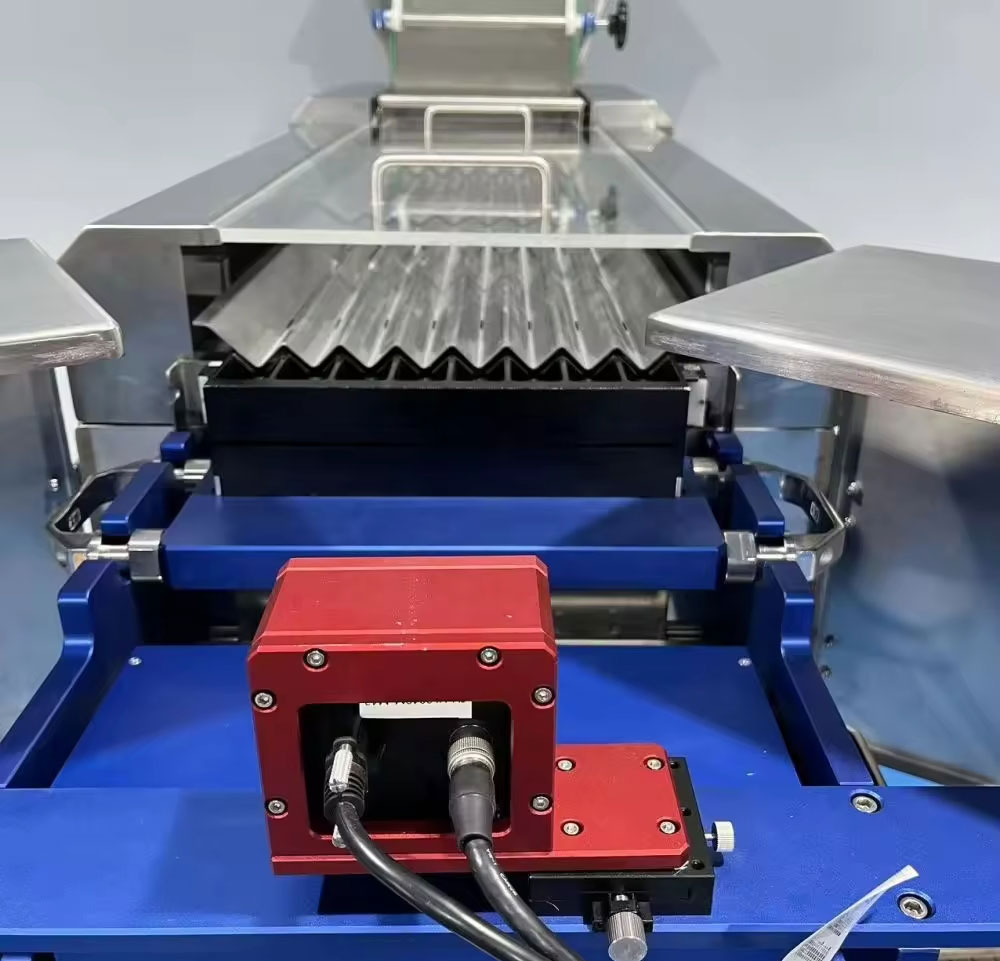

Allpack APC-12 pill counter machine is a high-speed visual counting machine adopts a high-speed line scanning CCD camera to scan, identify, capture and collect images, and use a high-speed processing chip to complete real-time image processing to quickly and accurately identify the quantity of materials. Breaking through the traditional method, the flow of goods is transported by the whole stack in a single-layer tiled state, without being divided into a single channel, and the whole stack is counted through the imaging area when it falls.

The equipment is suitable for “visual counting” packaging of various hardware, plastics, metallurgy, electronics, food candy, and other products, replacing the traditional weighing method, realizing high-speed, flexible, intelligent and efficient operation.

Adopting a three-stage vibrating disc electromagnetic oscillation, the vibration frequency, amplitude, and waveform index can be adjusted on the touch screen, and the vibration frequency can be displayed and controlled at all times. The speed is fast to ensure particle separation speed. At the same time, the equipment adopts high-speed industrial camera dynamic scanning technology, area detection, and confirms the whole, half, heavy, and broken particles based on area, with excellent dust resistance effect.

APC-12 Fully Automatic Vitamin Pectin Sweets Gummy Bear Candy Pill Counter Machine Features:

1.Visual counting method, remote imaging, not affected by dust.

2.High resolution, suitable for items of different sizes, there is no detection blind spot.

3.It can distinguish fragments, broken particles, and materials with inconsistent color and size, and at the same time, it can remove materials in small piles to avoid waste of production capacity.

4.Items do not need to be divided into single-row channels or separated. Single-layer vibration plate feeding and integration of channels greatly increase the feeding density and production capacity.

5.No high-speed gate is required, avoiding the risk of the gate breaking the product, and there is no requirement for the cleanliness of the compressed air .Compact size, optimal capacity/occupancy ratio, convenient production line layout.

6.Suitable for a wide range of applications, it can be used in the food industries to automatically and accurately count various granular substances such as solid particles into containers;

7.The bottling speed is fast. Due to the use of 8 counting channels and 1 bottle channel, our company's products can achieve a bottling speed of 20-60 bottles/min ;

8.The accuracy is as high as ± 1 out of every 10000 particles, which is significantly higher than the national standard;

9.Adopting internationally advanced door display control technology and independently developing professional image analysis hardware and software control, the human-machine interface is easy to operate and control.

10.According to GMP standards, the parts in contact with product are made of 316 stainless steel material, and the exterior parts of the body are made of 304 stainless steel material, which is easy to disassemble, clean, and maintain;

11.In the normal production process, there is no need for a dedicated person to supervise, and the machine has various protective devices such as missing bottles, bottle blockage, and bottle inversion;

12.Using an operating system with full Chinese dynamic graphics display as the human-machine interface;

Particle mechanism

Adopting a three-stage vibrating disc electromagnetic oscillation with adjustable vibration frequency and fast speed to ensure fast particle separation speed;

The sliding track of the particles adopts a three-layer stepped design, and the particles swim downward in three sections without overlapping;

Three stage vacuum design, the dust of the particles between the falling layers is completely sucked clean to avoid pollution;

Counting device

Adopting high-speed industrial camera dynamic scanning technology, area detection, and confirming whole, half, heavy, and fragmented particles based on area; Set the area range according to actual needs and accurately fill;

The high-speed industrial camera has an automatic light function, with a distance of about 300mm between the lens and the particles, and excellent dust resistance effect.

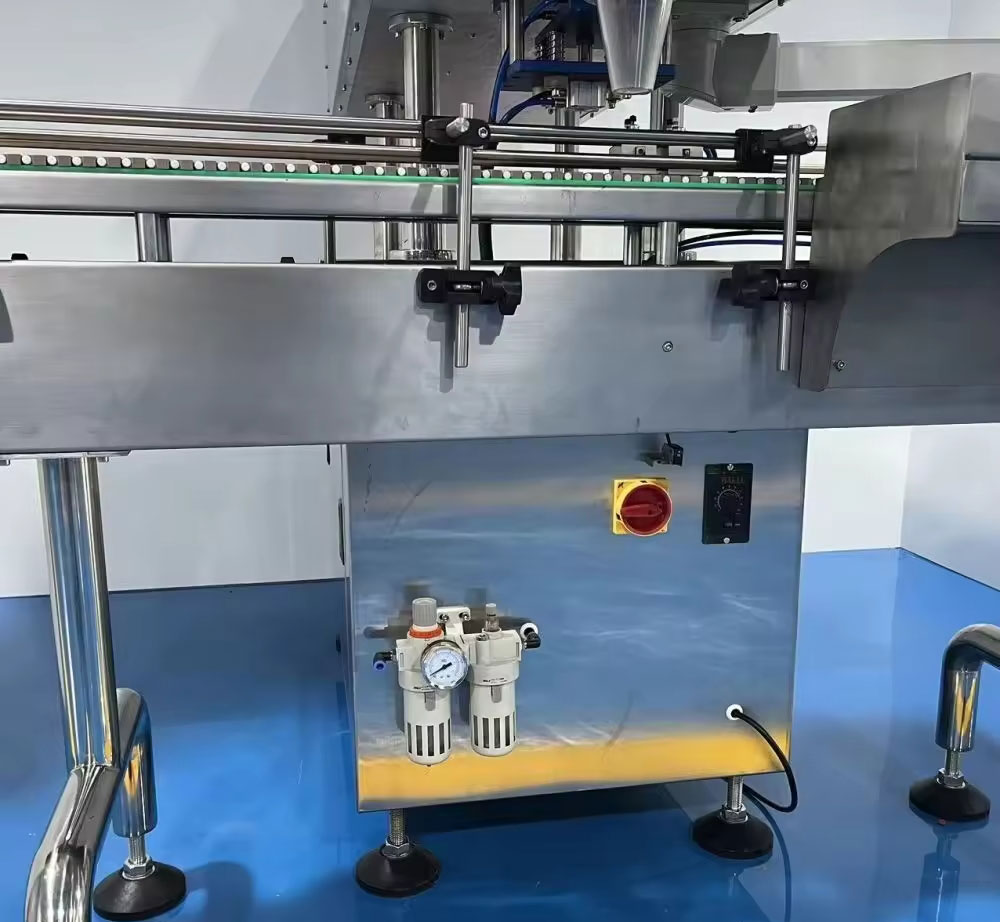

Door closing device

The key pneumatic components adopt well-known domestic brand pneumatic components, especially the integrated solenoid valve and closing cylinder for door closing, to ensure accurate bottling;

Scrap removal device

Automatically remove bottles with multiple, fewer, stacked, and 20% defective product from the count.

APC-12 Fully Automatic Vitamin Pectin Sweets Gummy Bear Candy Pill Counter Machine Technical Specification:

Applicable bottle shape :round,square plastic bottle

Filling material: Φ0~5#capsule,soft capsule,Φ5.5~12compressed tablet,special-shaped tablet,sugarcoated tablet,Φ3~12pill

Production capacity:20~40 bottles per minute(It depends on the bottle size,filling quantity and the tablet size)

Setting range of bottling volume:1—9999

Power supply:AC220V 50Hz 0.8kw

Accuracy rate:>99.5%(higher than the industrial standard )

Air pressure:0.6Mpa

Overall dimension:1450×900×1450mm

Weight:420kg

| Main technical parameters | ||||||

| Model | APC-8A | APC-12A | APC-16A | APC-24A | APC-32A | APC-48A |

| APC-8B | APC-12B | APC-16B | APC-24B | APC-32B | APC-48B | |

| Applicable | Model A:0~5#capsule,soft capsule,Ф5.5~12 normal tablets,special shape tablets,coating tablets | |||||

| Model B:00~5#capsule,soft capsule,Ф22normal tablets,special shape tablets,coating tablets,Ф3~20 pills | ||||||

| Capacity | 10-30BMP | 20-40BMP | 20-80BMP | 20-90BMP | 40-120BMP | 40-150BMP |

| Working range | Adjust from 2-9999 per bottle | |||||

| Power supply | 220V/50HZ/0.6KW | 220V/50HZ/0.8KW | 220V/50HZ/01.2KW | 220V/50HZ/1.5KW | 220V/50HZ/2.2KW | 220V/50HZ/2.5KW |

| Overall dimension | 1360*1350*1650mm | 1360*1350*1650mm | 1360*1350*1650mm | 1760*1350*1650mm | 2160*1450*1650mm | 2160*1350*1650mm |

| 1360*1650*1650mm | 1360*1650*1650mm | 1760*1650*1650mm | 1760*1650*1650mm | 2160*1650*1650mm | 2160*1650*1650mm | |

| Weight | 250kg | 320kg | 420kg | 450kg | 550kg | 620kg |

| 300kg | 380kg | 550kg | 580kg | 620kg | 680kg | |

| Remarks | 1.Capacity is subjected to the type and the size of the bottles and tablets, as well as the quantity filled per bottle; 2.BPM= Bottles per minute | |||||

Configuration

| NO | Name | Manufacturer |

| 1 | Motor | TQG(Taiwan) |

| 2 | See bottle of photoelectric sensor | OMRON |

| 3 | Count the Photoelectric Head | Adopt Everlight Electronics., Ltd |

| 4 | Pneumatic Components | SMC |

| 5 | Switch button | French schneider |

| 6 | man-machine interface | Adopt Delta-China(Siemens) |

| 7 | Main control chip | Using imported STMicroelectronics co., LTD |

| 8 | The leakage switch | Germany's Siemens |

| 9 | Switching power suppy | French schneider |

APC-12 Fully Automatic Vitamin Pectin Sweets Gummy Bear Candy Pill Counter Machine Video

Pill Counter Machine Related Products