Powder Filling Equipment: The Complete Buying Guide In 2025

Powder Filling Equipment: The Complete Buying Guide In 2025

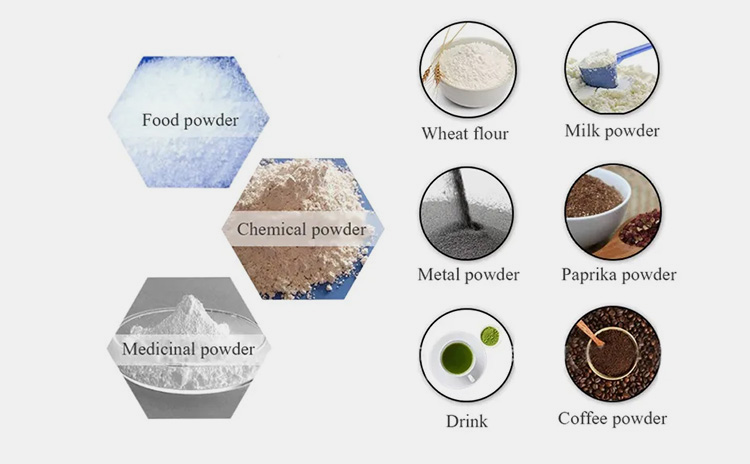

In the world of modern filling machinery, it may seem odd to talk about general filling items like spices, coffee, sugars, or you can simply refer them as ‘Powders.

Regardless, the numerous brands, innovations, and new machines comes into existence rapidly, but there’s still confusion about finding exact solutions for your product. When it comes to choosing machine for either free-flowing or non-free flowing product.

You directly google hundreds of available brands and models. In this article, we will specifically help you in describing ‘powder filling equipment’ and important aspects relevant to the machine that can greatly impact on your long-term business success.

Let’s start!

1.What Is Powder Filling Equipment?

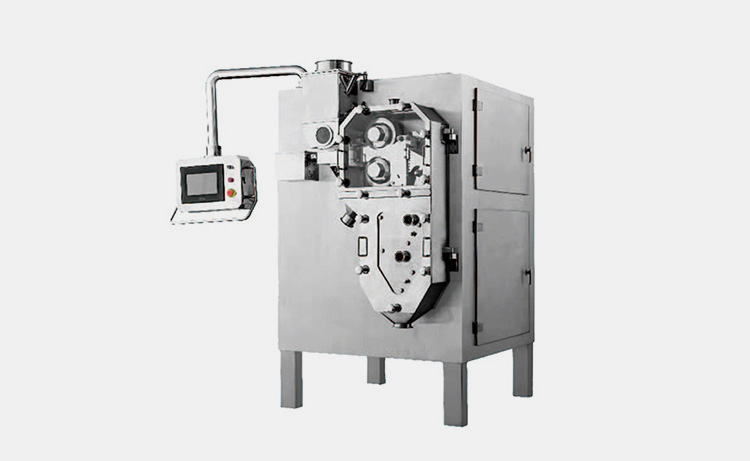

Powder Filling Equipment

This is equipment that is specifically referred to as a dispensing tool for filling and packing of substances that are powdery in nature.

This categories meets with free flowing and non-free flowing powder which encompasses a broad range of materials that are frequently utilized in the various production companies in the packaging of products that you use in your general routines such as medicines, food items, household, and much more.

To ensure precise filling with a uniform output, powder filling equipment is used which is presented in the market with various amazing brands, models, features, and types. Last but not least, this machine is very affordable and also presents with broad price ranges so anyone from you can enjoy its operability properties in order to achieve easiness in filling and packaging processes.

2.Where powder filling equipment is used?

The industrial uses of powder filling equipment are numerous, some of which are discussed below:

Pharmaceutical Industry

Capsules powder

In the pharmaceutical industry, from syrup to tablets, from ointment to IV antibiotics, and from instant sachets to capsules, the entire formulation needs powder filling equipment for safe and precise filling of the dosage form. This machine is high in demand before and after productions of medication in manufacturing companies to maintain the efficiency of medicines.

Food and Beverage Industry

Food spices powder- picture courtesy: avnifoods.in

The food and beverage industry is the most demanding area where powder filling equipment is required in utilization filling of products like spices, instant formula milk, flour, coffee, instant sodas, baking powders, grains, pulses, etc.,

Chemical Industry

Bleach powder- picture courtesy: socraftyme.com

In the filling of sensitive as well as general chemicals, a powder filling equipment is used for dealing dyes, pigments, bleaches, and acidic or basic compounds, in their respective containers or pouches. Hence, this machine is promising to use to obtain exact and precise measurements of potential chemical under a safe manner.

Cosmetics Industry

Crushed Face Powder Blush

This is another important industry where applications cannot be completed without the presence of a powder filling equipment. For example, filling and production of face powder, dusting powder, eye shades, foundations, blushes, and much more.

Agricultural Industry

Organic fertilizer powder- picture courtesy: jkfertilizers

An agricultural industry is nothing without utilizing a powder filing machine which is essentially required in the making and filling of products like pesticides, fertilizers, insecticides, and growth promoters, as well as once cropped are harvested, it is used in the packaging in their respective packaging materials. So you cannot ignore this machine to attain proper work process.

Vet Industry

Vet powder- picture courtesy:hbvs

In the preparation of antibiotics, corticosteroids, and general painkillers for animal based wellness or the veterinary industry are prepared, filled, and packed using powder filling equipment.

R&D

R & D Labs Powder- Picture Courtesy: Easypeasysciencefail

such Desktop powder filling equipment is commonly used in R&D labs to prepare and test initial drugs or assess trials. These mostly include very careful preparation of substances hence the equipment is giving promising results in sections.

Detergent and Cleaning Products

Detergent powder- picture courtesy:getsclean

You must have noticed that there are multiple household-relevant products that are filled by the help of powder filling equipment during the production process. Yes, whether detergents, mold killers, shiners, or carpet cleaners, all powder associated items are packed by utilizing a powder filling equipment ensuring promising workflow.

Coating Industry

Coating powder- picture courtesy: doublermfg

This industry involved in making of paints, varnishes, whitewash, wall primers, etc where a powder filling equipment is used to get specialized amount of product into the filling containers.

3.What Are the Benefits of Powder Filling Equipment?

Imagine a large production industry where day to day production and filling of powder takes place. Powder filling equipment is like a robotic helper that helps in measurement and distributing or putting the products in the assigned packaging materials such as pouches, bags, or containers. So, this is the reason behind its high demand. Some of the important significances of powder filling equipment are discussed below

Superb Filling in Precise Time

Filling in Precise Time machine- picture courtesy: tianhongmachine

Powder filling equipment is an excellent helper that ensures fast processing in a limited amount of time. You don’t to worry about its inaccuracies when using this technically perfect machine. You can fill a large batch in a certain couple of minutes means a powder filling equipment makes things faster.

No Expense- No Wastage

Powder organization waste makeup

Due to its high accuracy ratio, it doesn’t spill or waste your product, so it is like a wizard to save money, and your products. Means you can only fill product what you need to deliver or market- There’s no room for more or less.

Caters Broad Range Materials

Spice powder pouch- picture courtesy:tedpc

Whether using rigid material or flexible, small particles or sticky one, whether packing in pouches or containers, a powder filling machine can cater them easily. Means this tool is helpful for almost every production line belonging to any field.

A Tidy Workplace- No Dust Formation

Machine Design with No Dust Formation- Picture Courtesy: Muller

Powder filling equipment is specially designed to fill and pack powders without spreading and forming dust all over your workplace. This means whether you’re allergic or dealing with potentially unsafe materials. This promising machine is reliable to use without creating a workplace and health related mess.

Simple & Easy to Use

Using powder filling equipment is Easy- picture courtesy: CVC Tech

Operating a powder filling equipment doesn’t need specialized training or any science rocket theories to learn and use for its operation. This is a user-friendly machine that doesn’t create any fuss.

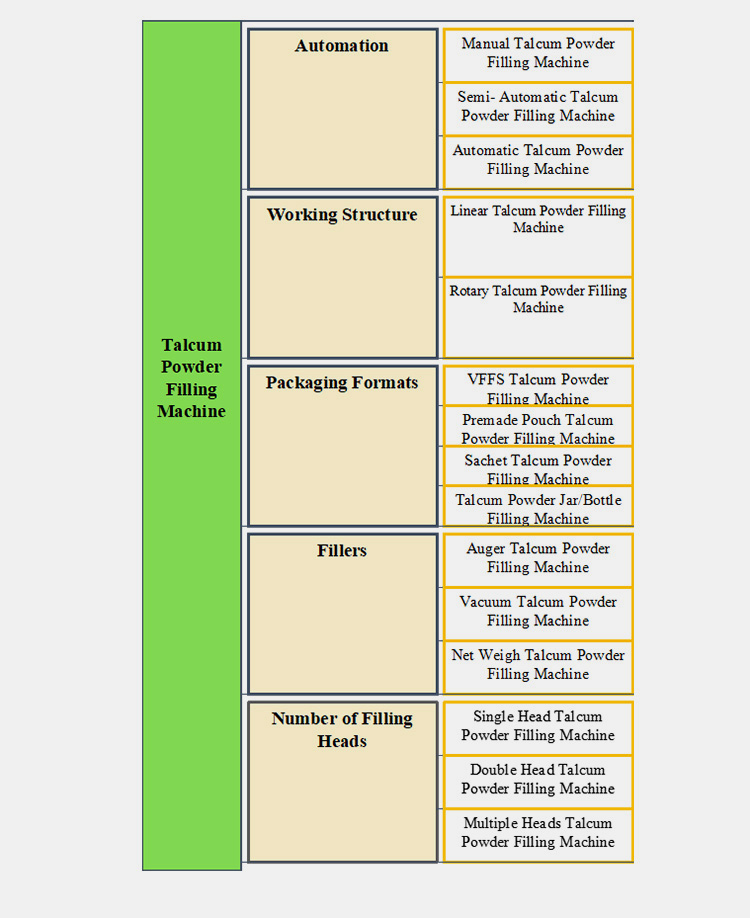

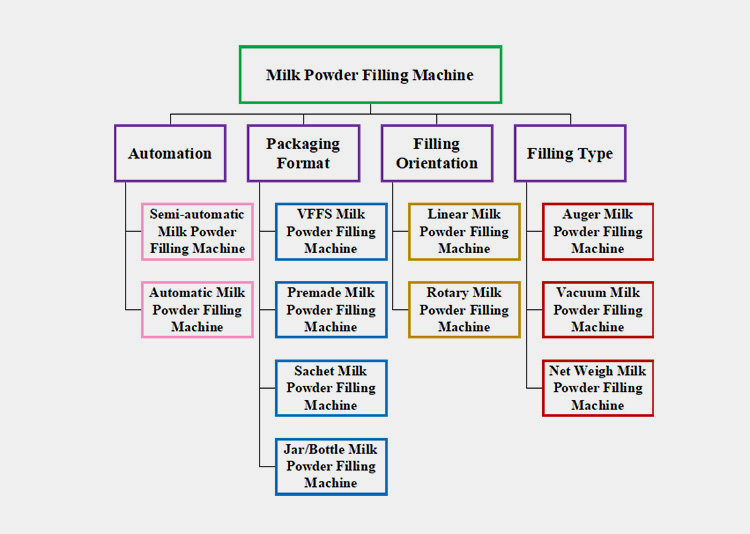

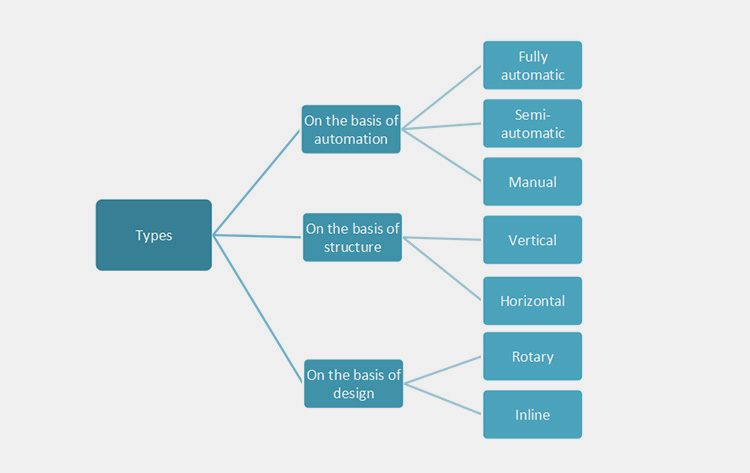

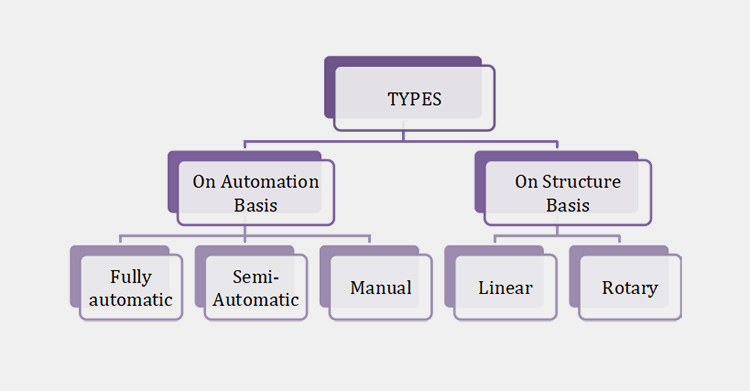

4.How to Classify Powder Filling Equipment?

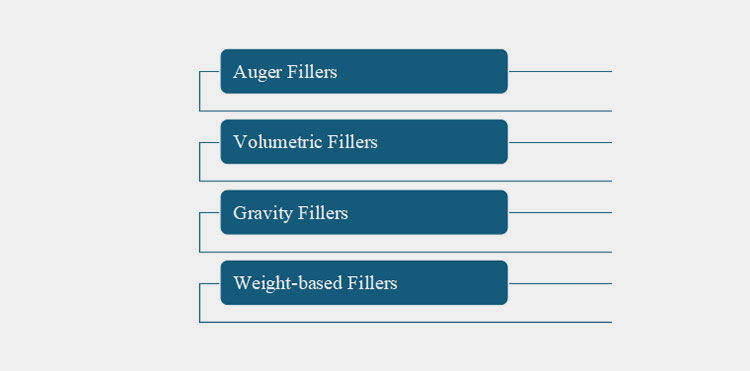

Powder filling equipment is broadly classified into the following categories.

Classification Of Powder Filling Equipment

Filling Mechanism

The powder filling machine works by following the specific working or filling mechanism that we have mentioned below in simple terminologies for your clear understanding.

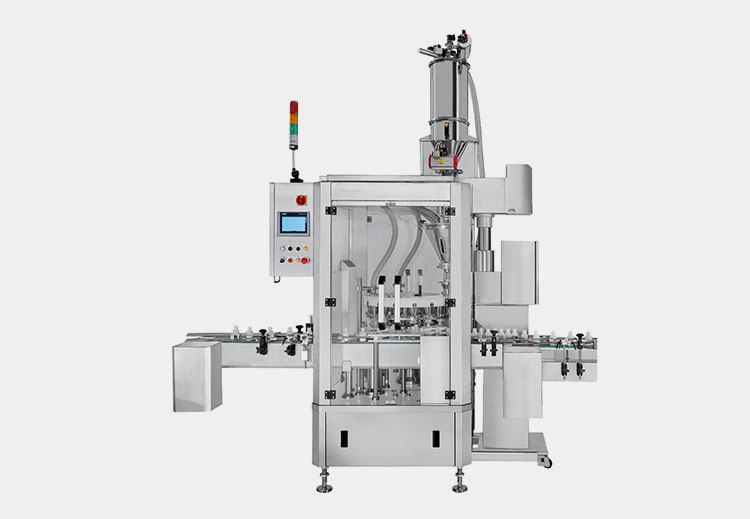

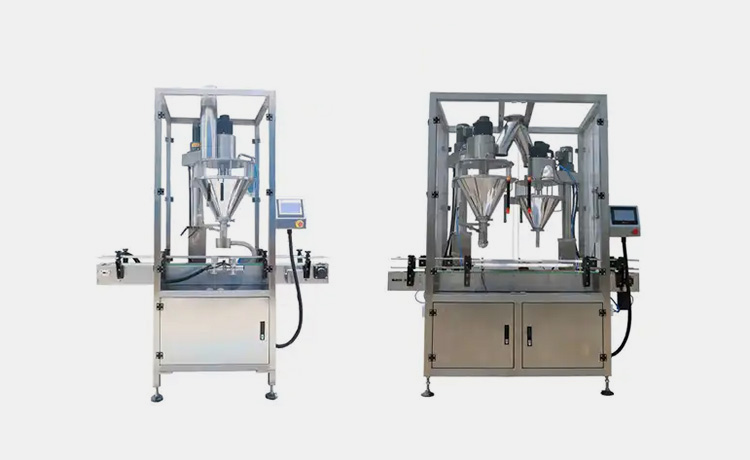

Auger Filler

Auger Powder Filling Equipment

This filling type is very common that uses an agitator or rotating auger which is also known as a screw. This auger is supporting the precise measurement and dispensing of the exact concentration of powder needed for the filling. This machine is a broadly and frequently used type of powder filling equipment. The purpose of the agitator inside is to facilitate fast and smooth flow of powder from the hopper to the nozzle.

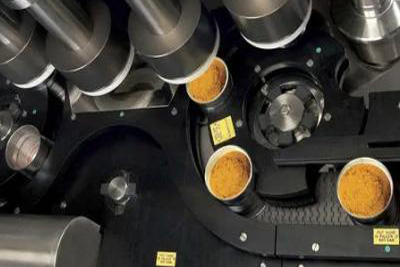

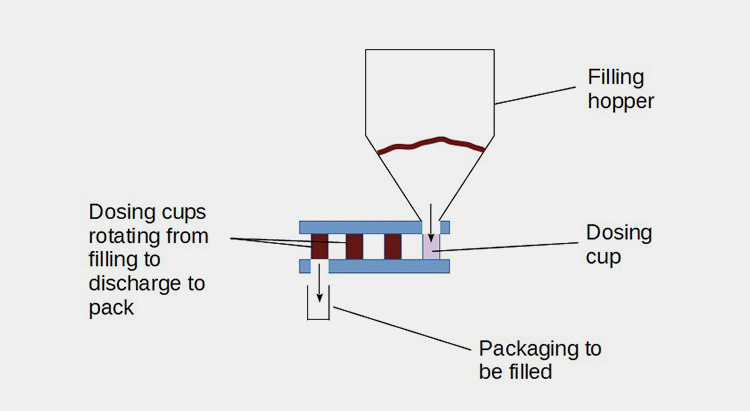

Volumetric Filler

Volumetric Powder Filling Equipment

A powder filling equipment that is featured with cup or volumetric piston or rotary valves for the filling process in order to deliver an accurate quantity of powder.

Gravity Filler

Gravity Powder Filling Equipment

Many free-flowing powders or substances are dispensed by using a gravity filler where the flow of powders into filling material takes place by utilizing force of gravity without the need for any helping feature.

Weight-based Filler

Weigh based powder filling equipment- Picture Courtesy: WeighPack

In those industries where large production batches are required, weight based filler is used; here, a powder filling process is subjected to measuring weight or based on weight related product’s filling.

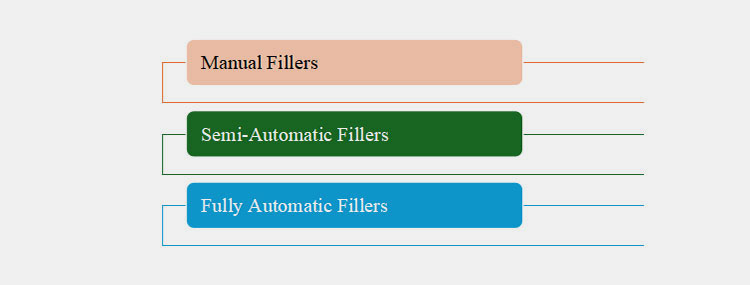

Automation Level

Powder filling equipment is available in various working automation; the basic machines are described below:

Manual Powder Filling Equipment

Manual Powder Filling Equipment

This machine is simple and very affordable and is operated by user involvement. Manual powder filling equipment basically requires strict supervision and time handling to bring precise outcomes without worry about error. Experts suggest using this machine when you’re subjecting production to limited or small batches.

Semi-Automatic Powder Filling Equipment

Semi- Automatic Powder Filling Equipment

Running a medium to large production batch? A semi-automatic powder filling equipment is a good option to invest in. Various stages of semi-automatic are involved in automatic operating while a few steps need human intervention such as placing and removing of container or pouch. This is an affordable and modern way to use for production lines.

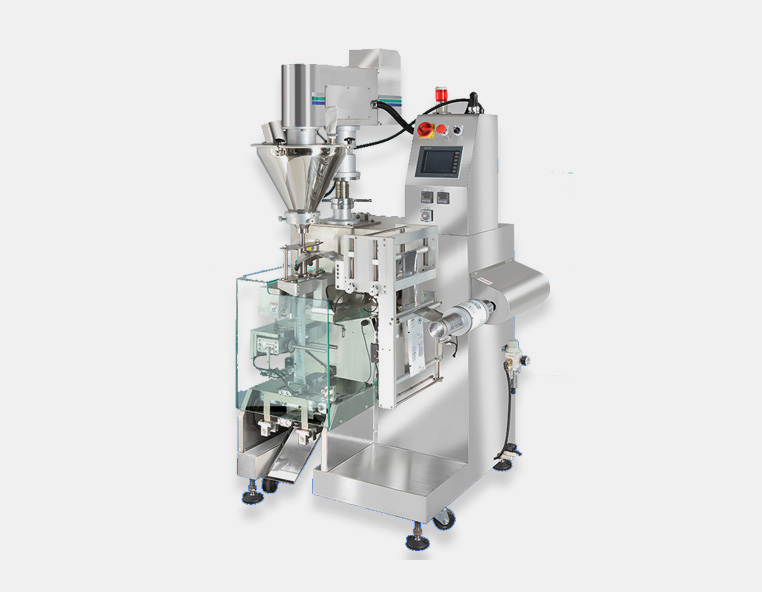

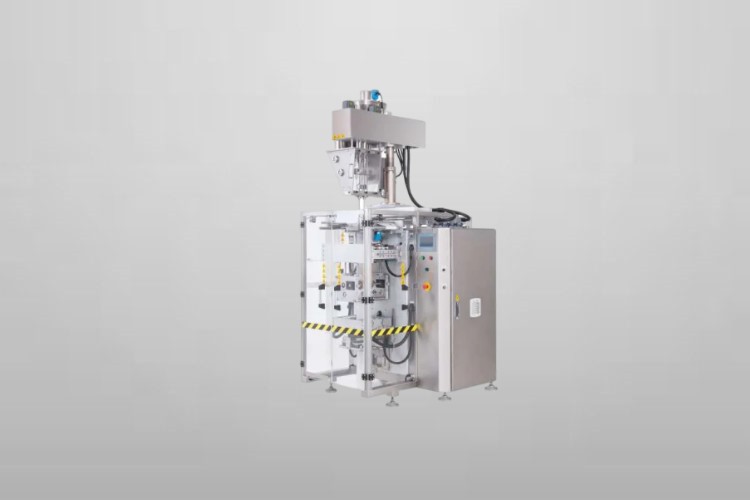

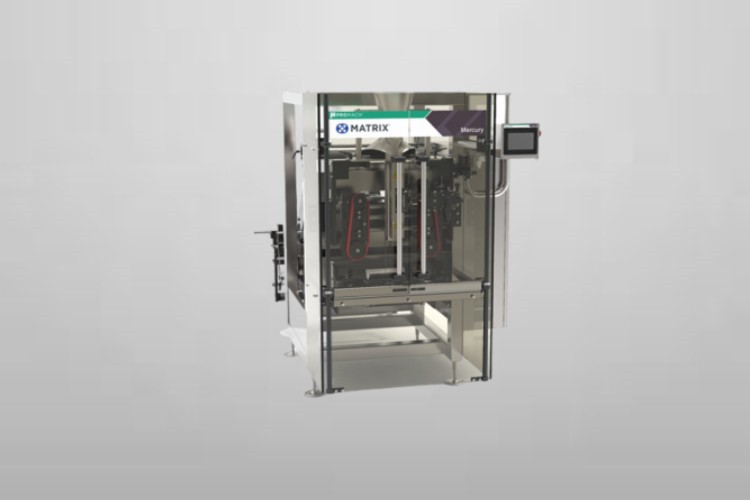

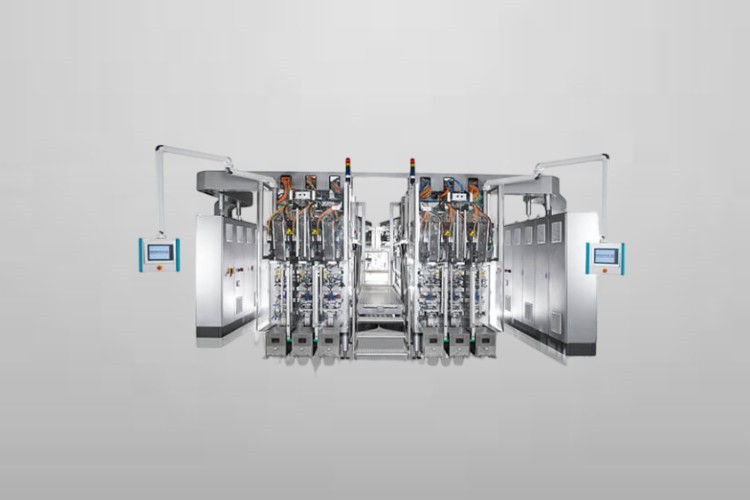

Automatic Powder Filling Equipment

Automatic Powder Filling Equipment

This is a masterpiece addition for the powder-filling process which doesn’t require any human handling or intervention to bring the outcome. You just need to feed in the protocol in the machine using the touchscreen interface. This machine is ideal for running production belonging to high capacity as this is much faster and more accurate than other remaining types.

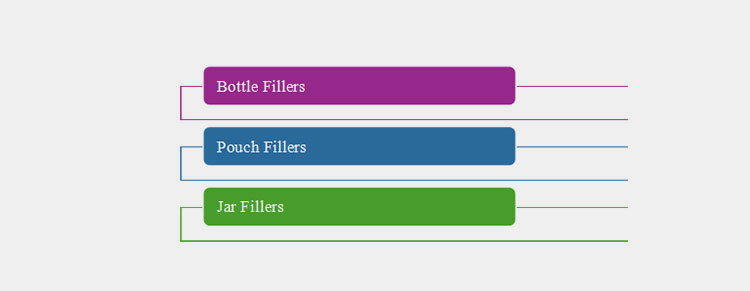

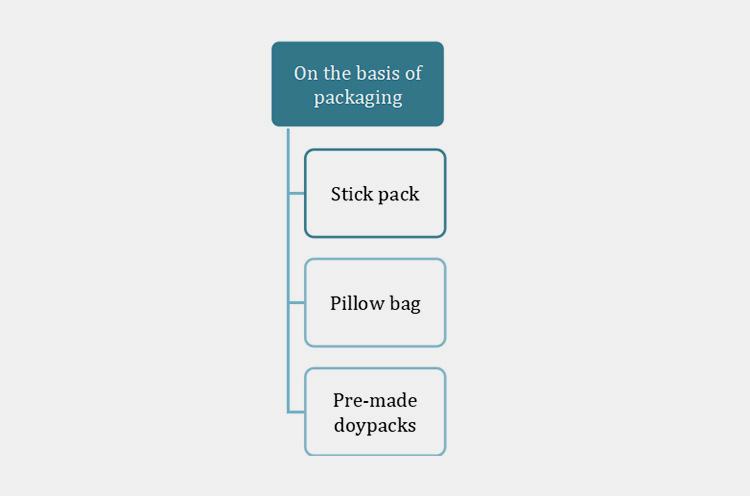

Container Type

A powder filling equipment is an adjustable machine to fill material in various types such as:

Bottle Powder Filling Equipment

Bottle Powder Filling Equipment- Picture Courtesy: Nexus Australia

The machine is specially designed for filling and packing powder into bottles. This is mainly required for medicine and chemical products.

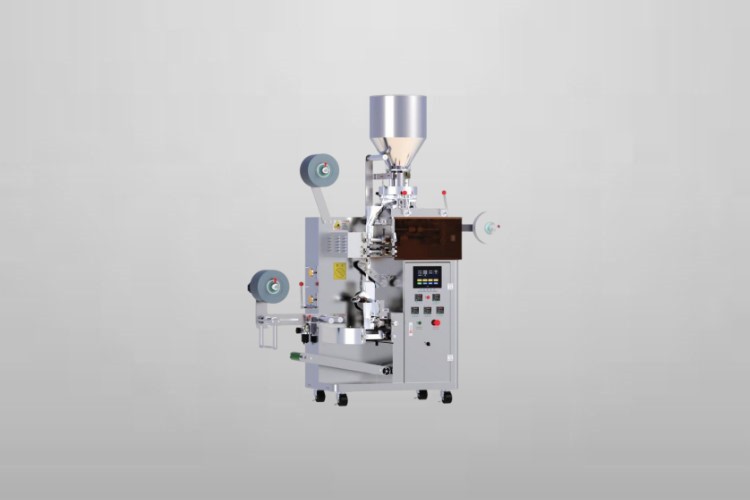

Pouch Powder Filling Equipment

Allpack Pouch Powder Filling Equipment

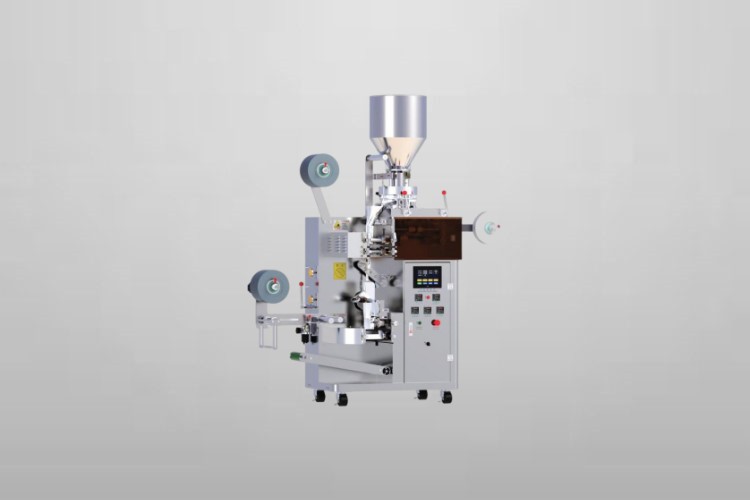

A tailored option for those packaging materials that are filled and packed in pouches, sachets, or premade pouches. These are mostly known as FFS powder filling equipment including ‘vertical film forming machines and horizontal film forming machines’.

Pre-made pouch Powder Filling Equipment

Allpack Pre-made pouch Powder Filling Equipment

This machine is advanced equipment where already formed pouches are fed in the magazine that is grabbed by mechanical-based grippers.

Inflators inside the machine helps in the opening of each pouch and allows powder inside followed by sealing and discharging. This machine preferable solution in various companies where high production capacity is require as it gives a high production throughput.

Jar or Bucket Filling Machine

Jar or Bucket Powder Filling Equipment

When filling powders into jars containers or buckets, this machine is suitable can pouring the ideal and optimum quantity of weight into each individual jar perfectly.

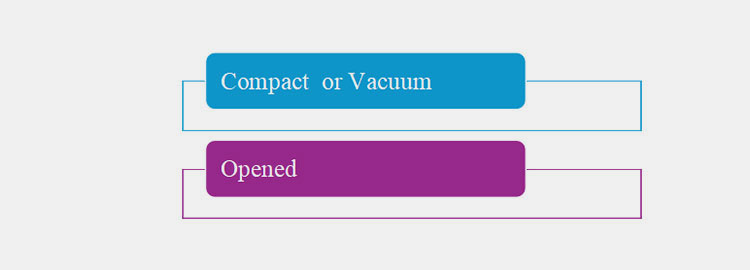

Structure Type

A powder filling equipment is presented with the following structure type such as:

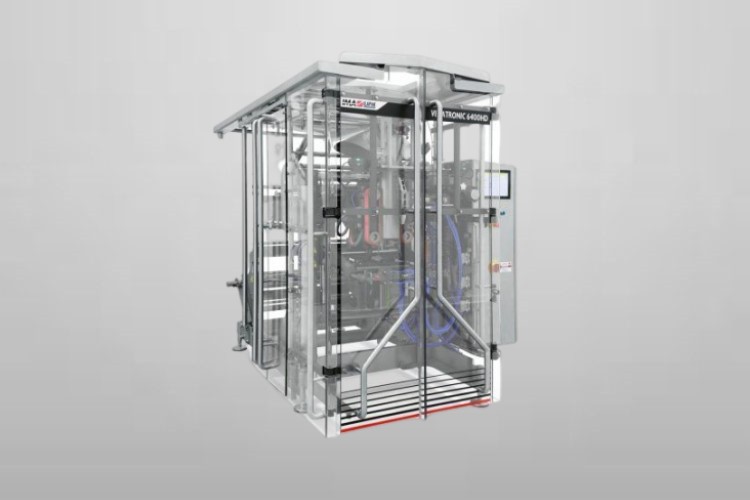

Compact or Vacuum Powder Filling Equipment

Vacuum Powder filling Equipment- picture Courtesy: JBT

This machine is designed to fill materials that are sensitive or hygroscopic in nature. Therefore, machine has enclosed housing to keep material intact inside the system with vacuum mechanism where vacuum suction helps in the flow of particle ultimately keep environment dust free. This is commonly required for medicinal, chemicals, or other departments associated with dealing with susceptible products.

Opened Powder Filling Equipment

An opened Powder Filling Equipment

This is the common or general structure of a powder filling machine where normal applications take place with materials that are not very specialized or do not require special filling conditions.

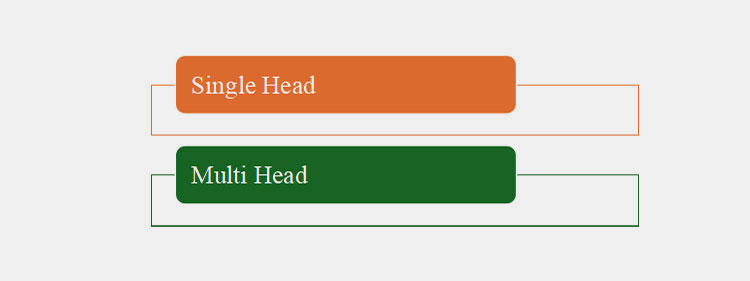

Filling Heads

Considering number of filling heads, powder filling equipment is categorized into the following:

Single-Head Powder Filling Equipment

Allpack Powder Filling Equipment

This is designed with a single head hopper to make a specific type flow of powder into filling materials or packaging type.

Multi- Head Powder Filling Equipment

Allpack Multi head Powder Filling Equipment

This machine includes multi head configuration which is used to deal with larger production in a short time with more accuracy and flexibility.

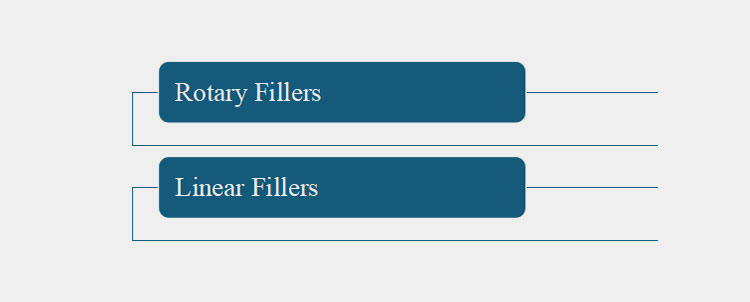

Motion Pattern

A powder filling equipment is designed to follow different motion patterns such as:

Rotary Powder Filling Equipment

Allpack Rotary Powder Filling Equipment

This machine follows the mechanism of rotation to fill powder into containers or pouches. A rotary powder filling equipment is suitable for large production batches as it gives a high speed filling process via passing several filling stages following circular motion.

Linear Powder Filling Equipment

Allpack Linear Powder Filling Equipment

A linear powder filling equipment follows a straight or direct motion pattern from entry to discharging of packaging material. This machine is suitable for running moderate to large batches.

Operate in a linear or straight-line fashion, with containers moving in a linear path through the filling stations. Linear fillers may be suitable for applications where precision and flexibility are important.

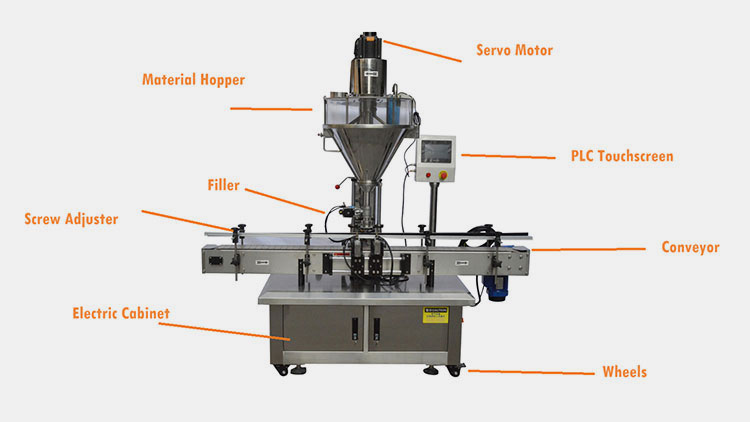

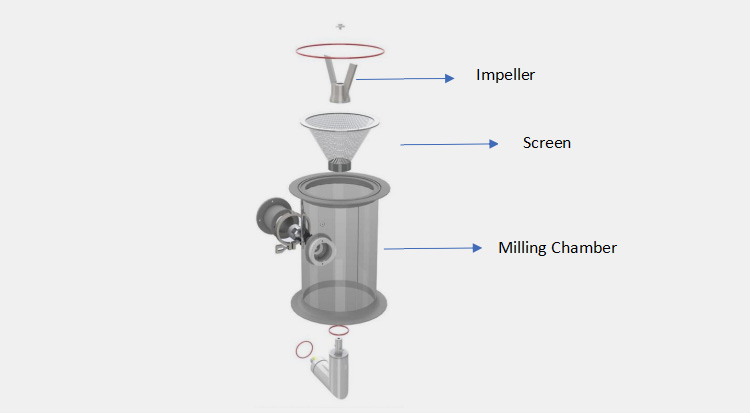

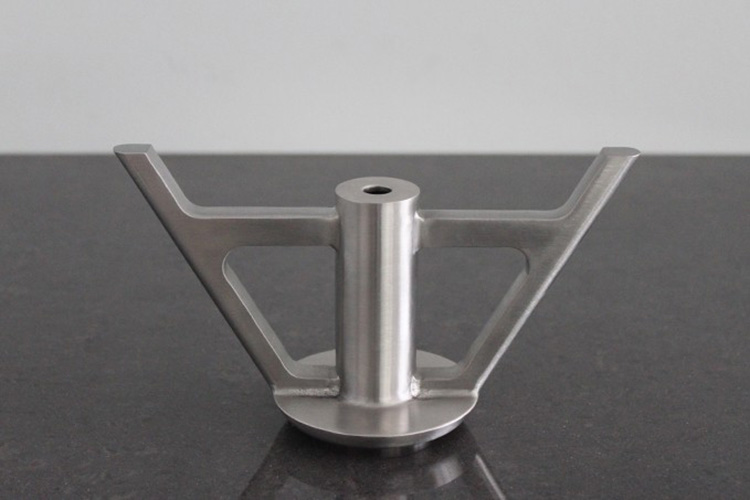

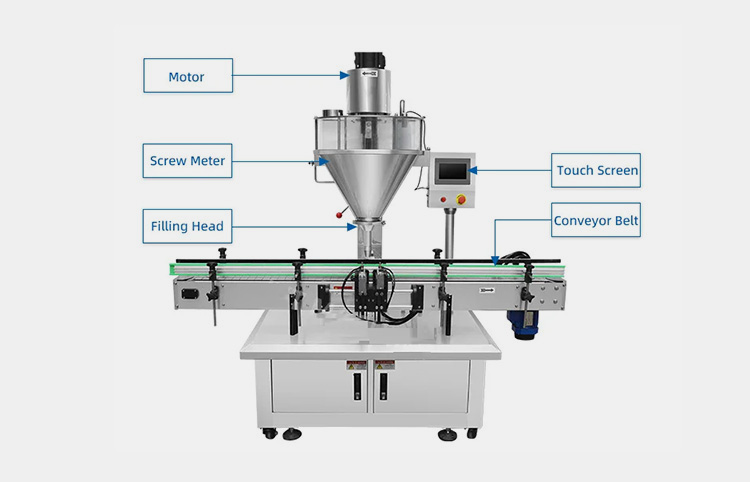

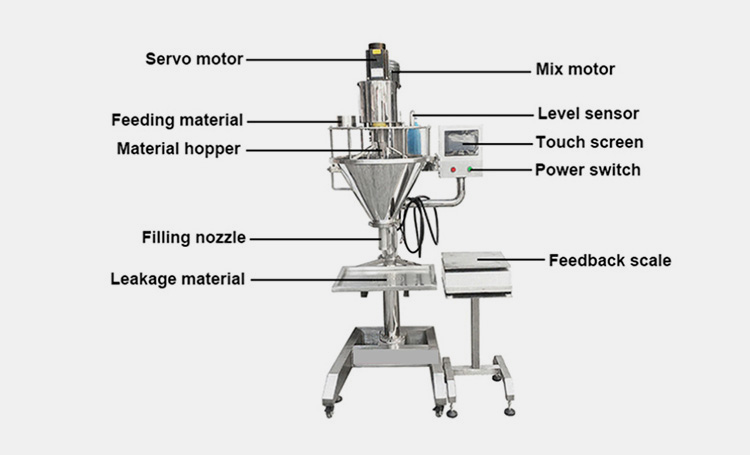

5.What is the structure of powder filling equipment?

Allpack Powder Filling Equipment Parts

Servo Motor

This is the prime unit that supports mechanical movement inside the machine such as filling, movement of container, filling velocity etc.,

PLC (Programmable Logic Controller) Touchscreen

This unit serves as a brain that transmit order to various parts of machine for balance coordination during filling procedure. All instruction inside the machine is made possible by using a touchscreen interface which is composed of various programable keys to bring flexible processing.

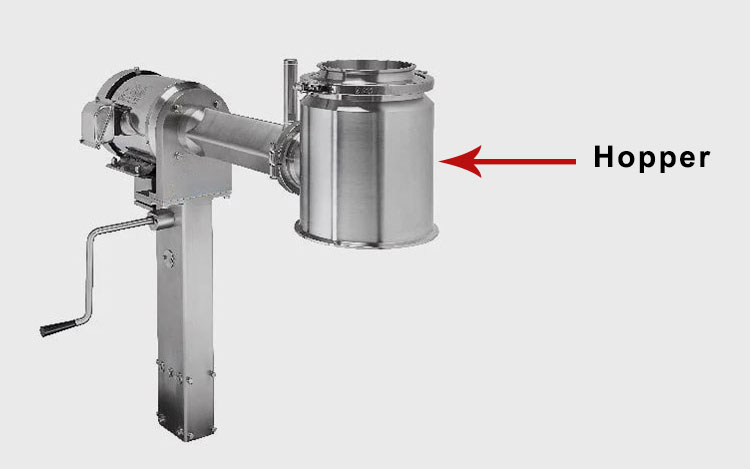

Material Hopper

Material to be dispensed is stored inside hollow cylindrical tank known as a hopper which upon vibration or agitation facilitates the process ensuring smooth flow of powder from hopper toward other parts of the equipment.

Filler

This is commonly known as a filling nozzle, which is a narrow passage ensuring dust free dispensing of powder with precise dosing.

Screw Adjuster

This unit allow fine adjustment to stabilised filling material and avoids falling down of bottles or containers from the equipment during entry or discharge. The unit is flexible to cater bottles or containers of various sizes and shapes.

Conveyor

This is a passage where bottles or containers can directly subjected to the filling nozzle and leaves once treated.

Wheels

You can move machine from one place to another by simply using universal wheel that helps in the flexible transportation.

Electric Cabinet

Machine wiring and electrical components are enclosed inside a specialized cabinet which is user safe and reliable.

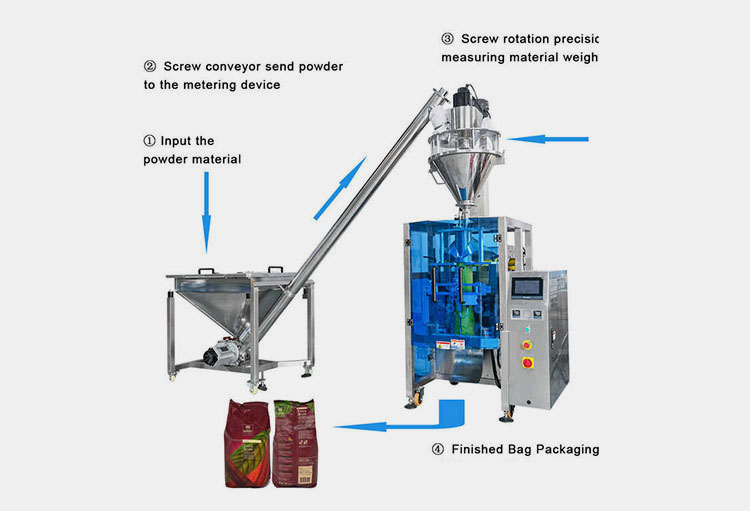

6.How does powder filling equipment work?

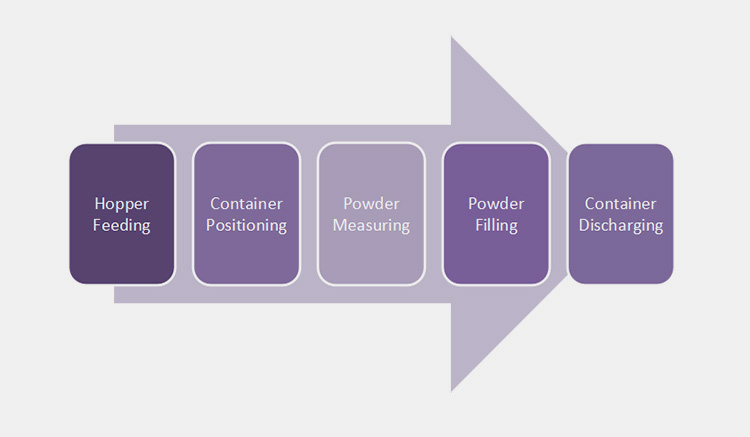

The working of powder filling equipment is based on the following crucial steps, such as:

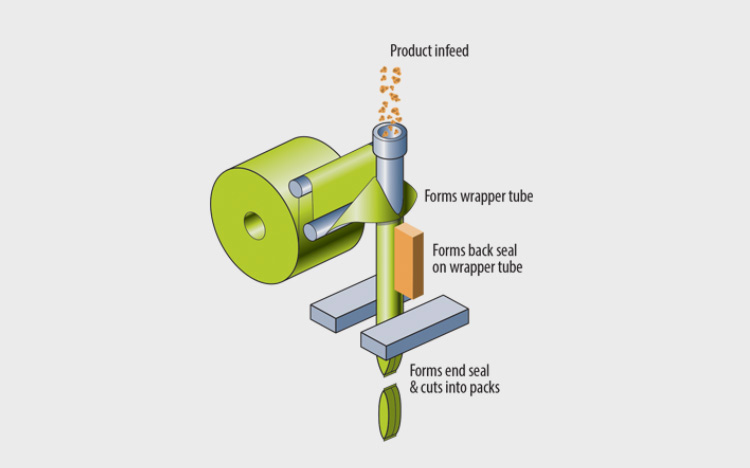

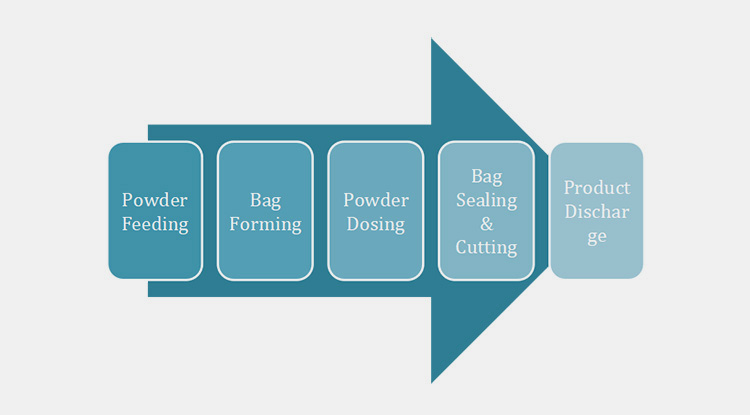

Process steps of powder filling equipment

Step 1: Input The Powder Material

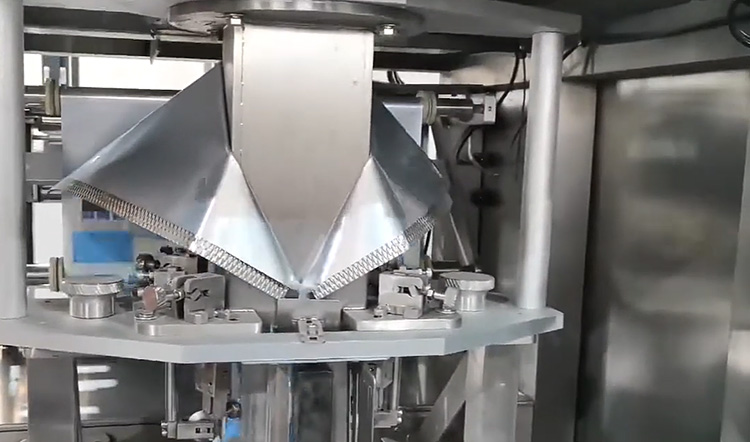

The first step of powder filling equipment is based on the putting powder material in the unit followed by placement or introduction of empty bottles or containers via conveyor passage. A gentle movement of these packaging materials are controlled by machine own system. For FFS series, the film formation is taken place by using former to acquire shape and sealers to combine the edges and form a pouch, sachet, or stick packs.

Step 2: Screw Conveyor Send Powder to Metering Device

Powder from storage unit is send to machine hopper by the help of conveyor that transfer powder uniformly into the equipment.

Step 3: Screw Rotation Ensure Precise Dispensing of Powder

Once the bottles are subjected to filling section such as filling nozzles. The sensors detect presence and let the system to allow powder pouring from the hopper inside the packaging material. In this step, you can select specific filler type such as auger, volumetric, or gravimetry, etc.,

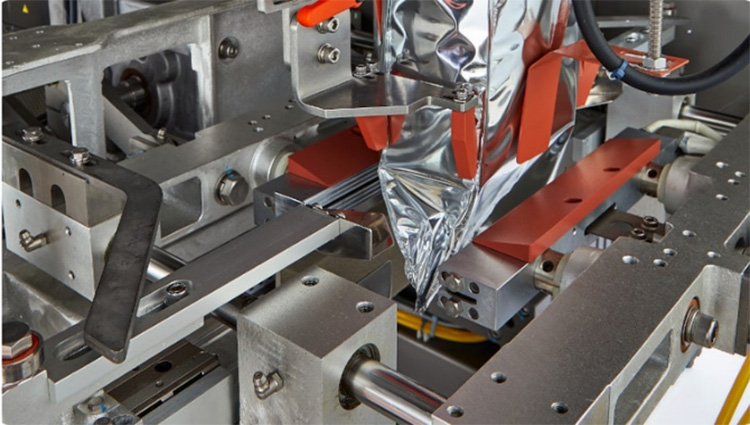

Step 3: Closing & Discharging of Finished Product

Once the material s filled, depending upon material type, further closing steps are taken place such as sealing for films, and capping of bottles followed by discharging from the machine for further process steps. In the case of film formation machines, the sharp cutters or cutting jaws helps in the separation of each pack and continuous the further process.

7.Is powder filling equipment an auger filling equipment?

Powder Filling Equipment

Yes, when think about auger filler or powder filling equipment, you must not be confused about distinct features. The auger filler is helpful in the measuring and filling of materials known as free flowing, non-free flowing or granular products.

The powder filling equipment are features with auger filler that can be suitable for FFS series i.e. VFFS, or HFFS, pre-made pouch, stand up pouches, and other. As discussed above the designed of auger is featured with a rotating auger that helps in the pushing of powder into the packaging materials with an optimized speed rate in order to offer a precise dose.

8.What is difference between manual and automatic Powder filling equipment?

| Feature | Manual Powder Filling Equipment | Automatic Powder Filling Equipment |

| Rate of Powder Filling | Due to manual features and working process, its speed is very low.

|

Due to fast processing and greater automation, it has a high filling rate. |

| Labor Requirement | It requires fixed human intervention thus showing high labor needs. | No human involvement, no labor requirements. |

| Throughput | Low to medium output capacity with average accuracy and consistency. | High throughput with highest accuracy and consistency rate. |

| Budget | This is very simple machine and so much affordable. | This machine requires high investment in the beginning, but for a longer time, it saves your money in the term of no human requirement or labor cost. |

| Integration | This machine is mostly used alone or showing no integration capabilities. | This machine is flexible to integrate with other equipment of the production line. |

9.How Powder filling equipment Overcome Dust Formation?

The powder filling equipment can deal with overcoming dust formation by the following reasons.

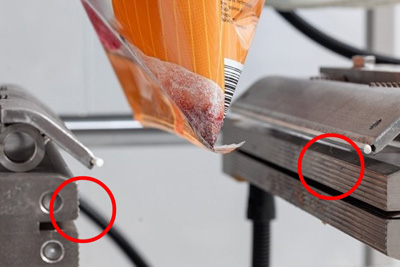

Compact Jaw Drives

Compact Jaw Drives

This is a specially designed feature for reducing the formation of dust blowing by entirely enclosed jaw drives which protects causing dusty environment.

Dust Proof Enclosures

Dust Proof Enclosures powder machine- picture courtesy: CVC Tech

The machine is wrapped in an enclosed structure that demonstrates dustproof as well as waterproof working. This is mostly denoted by giving an IP rate from the manufacturer to every machine.

Dust Suction Equipment

Dust Suction Equipment- picture courtesy:Hanningfield

The powder filling machine is mainly designed with dust suction that will help in the strong suction of dust present in the environment ultimately reduces the possibility of dust floating.

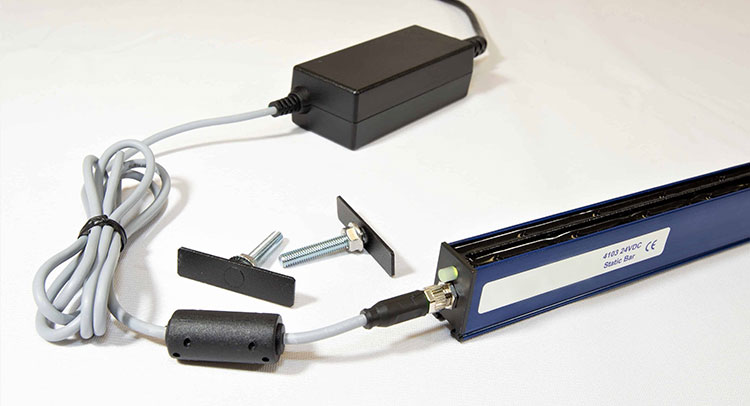

Static Elimination Bars

High speed Static Elimination Bars- picture courtesy: static-clean

The static elimination bar also known as an anti-static bar is another important practice to follow when designing powder filling equipment to avoid piling or building up of powder by neutralizing the charges adsorbed by electricity ultimately cleaner environment.

Dust Hoods

Usage of Dust hood

The installation of dust hoods is effective method to overcome dust from air or the workplace. This is mostly installed within the device as well as your vicinity.

Vacuum Pull Belts

Vacuum Pull belt Can overcome friction and dustiness

The standard powder filling machine are designed with friction pull belts that mostly forming friction and making conditions dusty, but alternatively, new machines are designed with vacuum pull belts which pull belt in order to minimize the effects of dust formation and make smooth and neat working.

10.What are Malfunctioning and Troubleshooting of Powder Filling Equipment?

The powder filling equipment is robust and reliable equipment; but there might be a possibility that it may encounter unpredictable problems. To solve them, we have designed some solutions below:

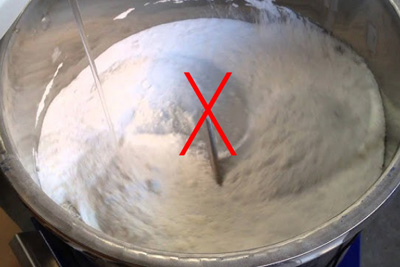

Why Powder Jams in Auger?

Auger powder jam machine- picture courtesy: IVS Engineering

Sometimes powder flow becomes stuck and obstructs the dispensing of material to move properly. This is due to the clogging of powdery molecules which is due to the creation of static forces between them, or due to the state of particles.

To solve them, you need to monitor the parts of a machine if damaged, moreover use anti-static bars, remember to check the movement of the auger, remove any obstruction or sticky particles there, and lubricate its internal parts to check proper shaking causing appropriate dispensing of the powder.

Why do you find Inaccuracies?

Powder filling machine of Inaccuracies

Powder filling equipment gives an accurate filling i.e. over or under filling. This condition can compromise the final product and quality.

To overcome the problem, calibrate your equipment regularly. Configure the entire setting correctly and check if the auger and agitator settings are corrected. Maintain or regulate the filling speed using PLC and regulate the speed of the conveyor to get the desired filling.

Why do you Meet Cross-contamination?

Preventing cross contamination- picture courtesy: foodsafe

As powder filling equipment has complied with international quality standards, then why it happen that you find cross-contaminated products, it is due to improper hygiene maintenance in your workplace. Remember to clean the machine before and after use. Moreover, using dust control parameters (discussed above) can also help to minimize the potential hazards.

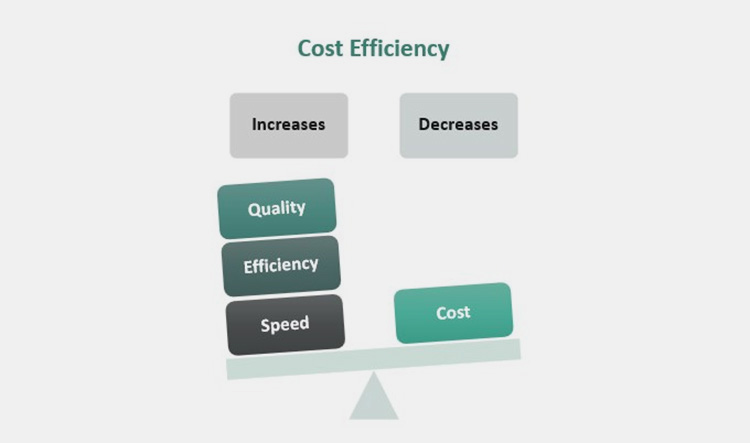

11.What are things to consider when Purchasing Powder Filling Equipment?

When purchasing powder filling equipment, consider the following factors to get the right one.

Type of Product

Clogging of powder products

Different materials are confined with different flow properties. Therefore, select equipment that must be capable of dealing with properties of your product to overcome clogging, jamming, or bridging.

Production Capacity

Production capacity of powder- picture courtesy: thedieline

The most important factor you should never ignore is knowing your production capacity to pick the machine that can address factors such as matching with your rates of flow, rate of filling, and production batch per hour.

Material Size and Type

Material Size and Type- picture courtesy: www.iqsdirectory.com

If your packing material is a pouch then refer FFS series, if bottles or containers then it is crucial to select the machine that can deal with containers or such packaging material with already already-designed conveyor.

Quality Standards

Quality control and safety standards- picture courtesy: CVC Tech

Your equipment must comply with international quality standards that are essential to minimize the risk of product contamination and user safety and facilitate easy cleaning options.

Supplier Reputation

Supplier Reputation With Promising Services

Buying a machine from 5 5-star recognized vendors would be an excellent choice to get the right one. Because this would not only offer a promising machine but you can avail many other options like excellent customer services and post-sale offers.

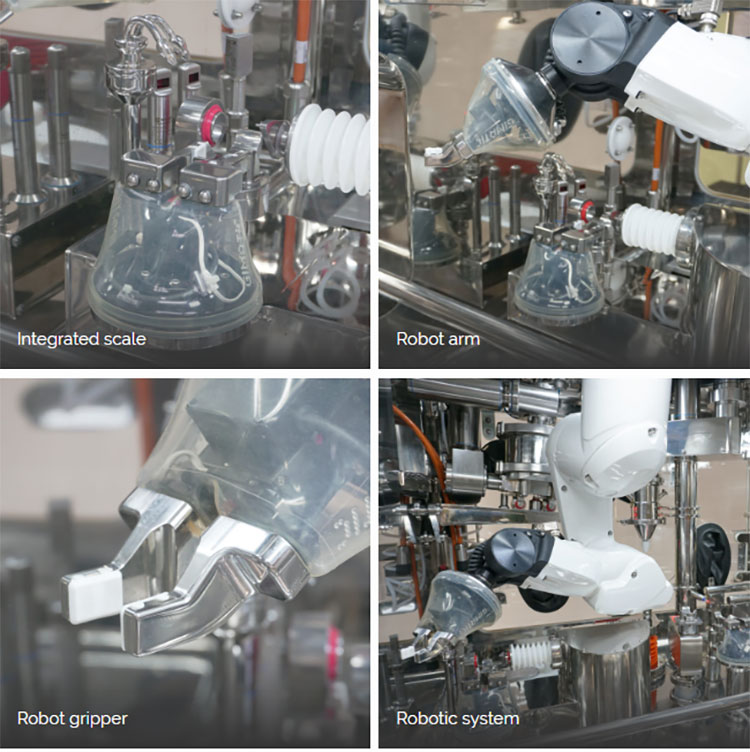

12.Are there New Technologies in Powder Filling Equipment?

Yes, a powder filling equipment is an exceptional machine that’s involved in more tremendous innovation and advancement presently. For example, using of robotic skills has made this processing more productive, safe, and economically sound.

A micro-robot powder filling equipment- Picture Courtesy: Romaco

Evolution of micro-robotics has taken attention of manufacturing companies as it offers small batches production with intricate filling using turbulence flow isolation methodologies can fill thousands vials hourly.

The equipment is featured with advance tools and techniques with high sensory system that giving a promising sanitized filling procedure without chances of inaccuracies or cross-contamination, thus can allow swift programming in a limited time.

Conclusion

After reading the blog post on ‘powder filling equipment’, you must be able to know many significant points that will help you to select the right machine. So, don’t be confused or messed up with the exact choice you want to get! If still have questions or want to buy a machine under your affordability. Allpack is the right solution for you! We promise that our welcoming team of experts and professional engineers will contact you to answer your questions. Contact us now

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Powder Filling Equipment: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

4-side Seal Powder Packaging Machine

4-side Seal Powder Packaging Machine

Entry – Mid Production Powder Packaging Machine

Entry – Mid Production Powder Packaging Machine

Powder Packaging Machine SN-60AK

Powder Packaging Machine SN-60AK

MF58 Powder Packaging Machine

MF58 Powder Packaging Machine

4 Side Powder Packaging Machine

4 Side Powder Packaging Machine

Screw Vertical Powder Packaging Machine

Screw Vertical Powder Packaging Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

VFFS S250/300

VFFS S250/300

Hayssen ISB Vertical Packaging Machine

Hayssen ISB Vertical Packaging Machine

SN 169 Vertical Packaging Machine

SN 169 Vertical Packaging Machine

R/RM-series Vertical Packaging Machine

R/RM-series Vertical Packaging Machine

SLIM-280 Vertical Packaging Machine

SLIM-280 Vertical Packaging Machine

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours