Protein Powder Making Machine: The Complete FAQ Guide In 2025

Protein Powder Making Machine: The Complete FAQ Guide In 2025

Are you interested in knowing about protein powder making machine? If yes, you are at the right place and at the right time. We have something new and comprehensive for you related to your interest. This guide is best for you whether you are a beginner or owning a big firm.

Protein powder making is one of the growing industries worldwide and its utilization is immense in the current age. So, please be here to know more!

The questions we are going to discuss in this article are the following:

1.What is a protein powder making machine?

Protein powder

Protein powder making machine is a specialized apparatus used for the production of protein powder from a number of sources. Passing the ingredients through various machines, finally, fine powder is formed by utilizing this equipment. It does various tasks like grinding, vaporization of moisture from protein powder, mixing it with other ingredients, and also sometimes used in casing or wrapping for such products.

Additionally, on the basis of these different purposes, these instruments are of different types and sizes. A magnificent machine that has a lot of use in your daily life. It fulfils the basic protein needs of everyone.

2.What advantages do you get from a protein powder making machine?

The machine under discussion has got advantages from its innovative technology and is beneficial for both manufacturers and buyers. Some of its major advantages are mentioned below;

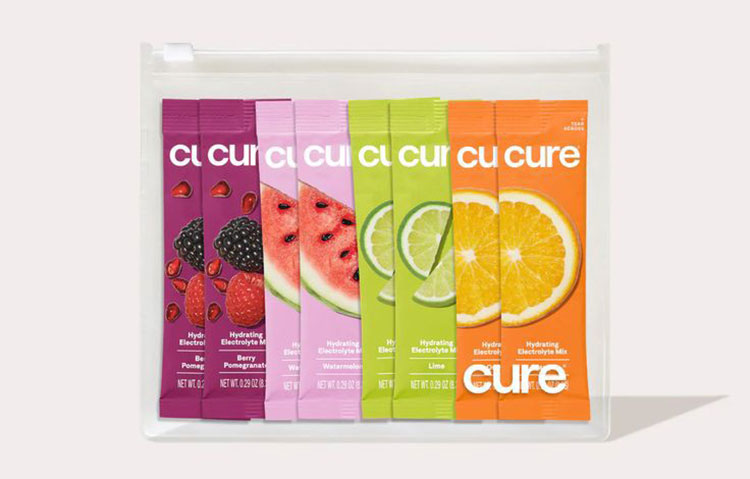

Digestive Support Drink Mix

Greater Production

High Production

It makes the process faster as compared to traditional methods of making protein powder. The process has been modernized escalating the production capabilities by utilizing this machine that completely complies with the increasing industrial demands.

Product Quality

Better quality

Its precise monitoring and command system reduces waste production resulting in a high quality product consistently. This is good for the brands to enhance their reputation among their competitors.

Lowering the Costs

Economical Choice

Protein powder making machine is fully automatic therefore it lowers labor costs. As it is not dependent on human intervention that is liable to commit errors, this machine is highly advantageous for you.

Variety

Variety of Your Choice

Protein powder making machine can deal with a variety of products such as casein, whey, collagen, and egg protein in powder form.

3.Where do you use a protein powder making machine? What industries require protein powder making machine?

Protein is an essential nutrient and a major energy source makes the use of protein powder making machine necessary at various platforms which include the following.

Drug Industry

Picture Courtesy: Nestle Medical Hub

Drug companies use protein powder making machines to make beneficial drugs for those who lack protein-type enzymes and hormones, and also for the infected one who requires antibodies and vaccines which are made of protein.

Human Food Industry

Organic Protein Formula

The deficiency of protein in human bodies is usually treated by having protein-rich food. This protein rich food is prepared by food manufacturers with the help of protein powder making machine by injecting protein powder into the food items.

Animal food industry

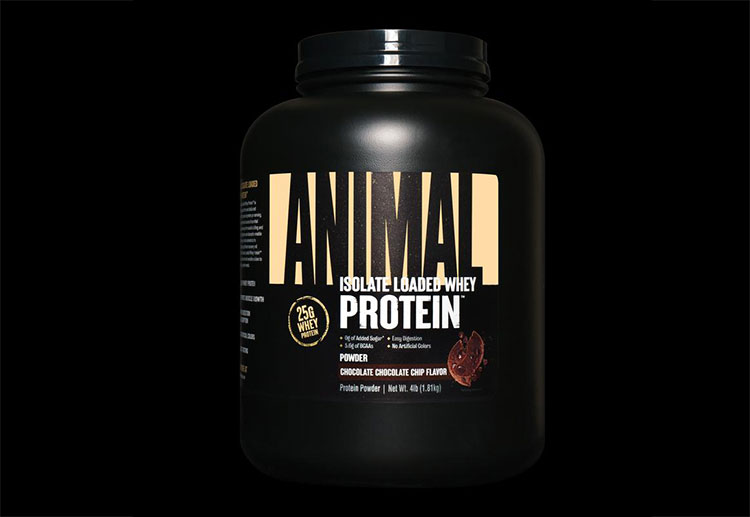

Animal Whey Protein: Picture Courtesy: Animal Pak

Animals as same as humans also require protein rich food for being healthy. So animal food industry manufactures a high protein diet for animals with the help of protein powder making machine.

Research labs

Different Protein Powder Sample

In this progressive world, research labs use protein powder making machine for testing and for a lot of new experiments to discover more about proteins.

Grooming items industry

Protein Powder for Self- Care

Protein-abundant humans have a fresh, healthy and clear skin, and long and healthy hair. So protein powder making machine is used in making cosmetics mill and in different hair products making factories.

4.Enumerate the different types of protein powders prepared by the protein powder making machine?

It helps a lot to prepare different types of protein powders. All these are produced with the help of this highly advanced machine such as pea protein, milk protein, egg protein whey protein, etc. Here are the details for each type:

Pea Protein Powder

Plant-Based Protein

This pea protein with so many benefits is prepared with protein powder making machine. As it is a valuable protein mostly consumed by those people who don’t use animal proteins. It is a plant protein, that’s why used by most of the vegans.

The machine uses pisum sativum to produce this type which contains abundant amino acids like all other proteins. It makes protein powder in such a fine manner that it can easily be digested.

This machine helps in extracting 79 to 80 percent of protein content and up To 5 percent fat content from the raw materials. Well, it gives it a smooth texture.

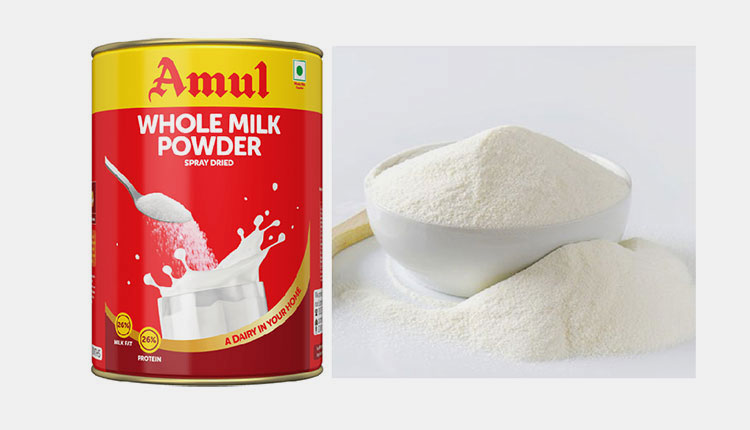

Milk Protein Powder

Meal Replacement Protein Powder

Most of the people drink milk daily at night or in the morning to bring health to them. As we have discussed the use of protein powder making machine in the food industry, milk protein that contains all essential amino acids that help to regulate body weight is also prepared with the help of this equipment.

Egg Protein Powder

Egg Whey Protein

Egg protein which has so many advantages including muscles growth, manufactured by protein powder making machine.

Whey Protein Powder

Milk-Based Protein Powder

Protein powder making machine is also used for production of whey protein. Whey even is usually prepared from liquid milk during cheese manufacturing. It contains both types of essential and branched-chain amino acids. This machine helps in the production of whey protein that is most often used by bodybuilders and athletes.

Hemp Protein Powder

Additive Free Hemp Protein: Organic Superfood

Hemp protein powder is another protein powder that can also be made by the protein powder making machine. It is prepared with the powerful granulating apparatus that is usually used to make the immune system strong and it helps in digestion and also supports the heart keeping it healthy.

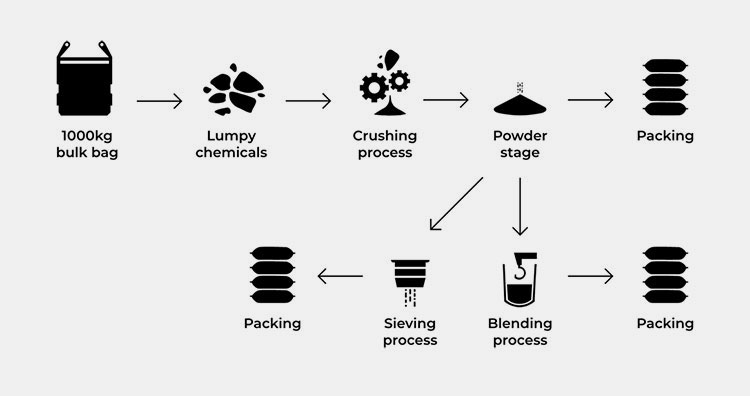

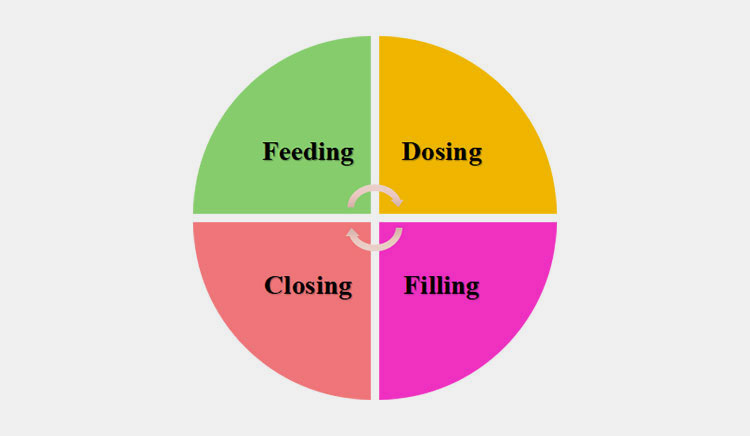

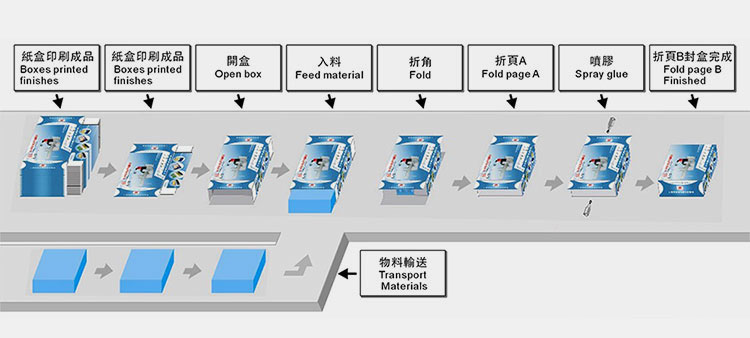

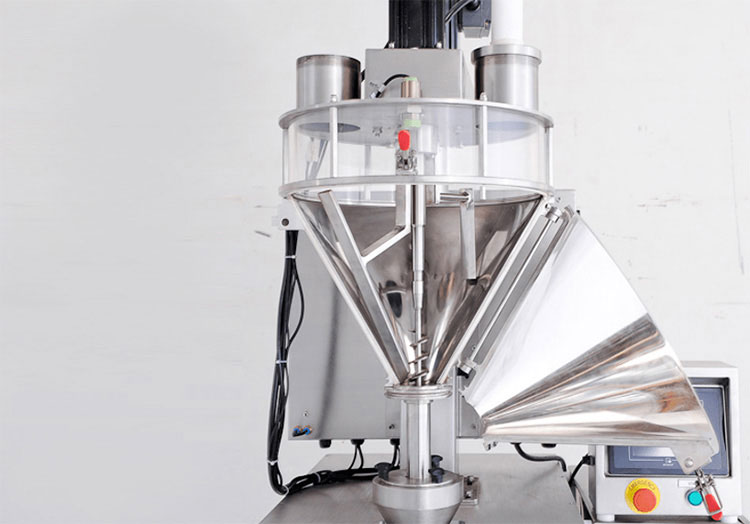

5.How does a protein powder making machine work?

Protein powder making machine works very smoothly due to its automated system and convenient process within short period of time. Let's learn the process of protein powder from milk sources step by step.

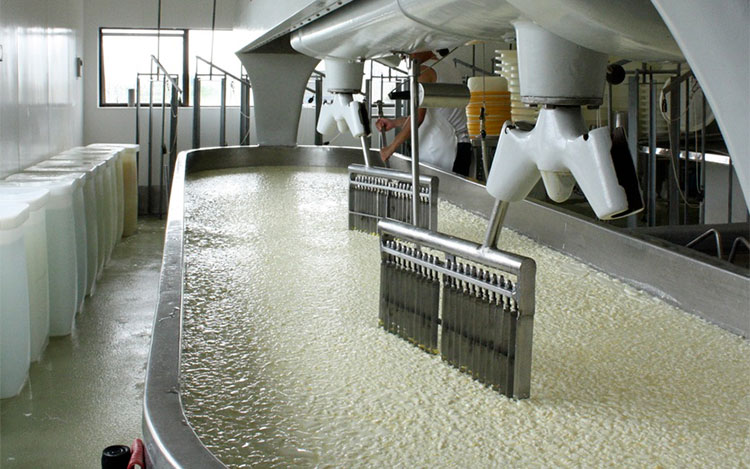

Separation

Curd and Whey: Picture Courtesy: Science Learning Hub

The actual process begins after milk is pasteurized, it goes through curdling when an enzyme named rennet is added into the milk. This process is carried out within high-qualified machines that is composed of mechanical stirs and agitators. These agitators aids in making an even mixture of milk and rennet.

Basically in this phase, the mixture is separated into solid curd and liquid whey. Pasteurization of the mixture is carried out again to ensure a contaminant free product.

Filtering

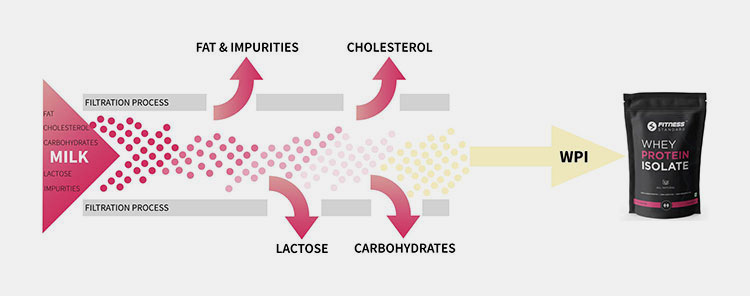

Picture Courtesy: Fitness Standard

Now, it’s time to filter the protein mixture. Here, the protein is isolated from the mixture either through membrane filtration or ion exchange method. Now we have the protein ready to be entered into next stage.

Drying

Spray Drying: Picture Courtesy: Dedert Corporation

Step it up, and the filtered protein liquid is transformed into fine powder using spray dryers for this purpose. During this process specialized machines are employed that make sure high standard and quality product. And in this way you get the milk-based protein powder in most finest form.

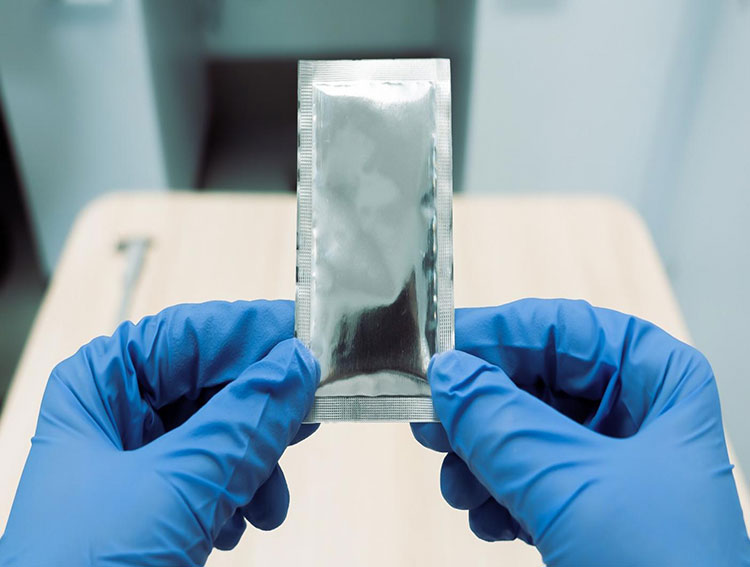

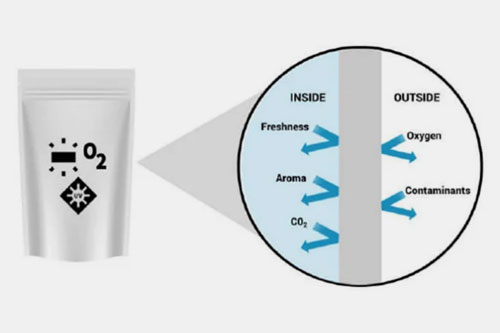

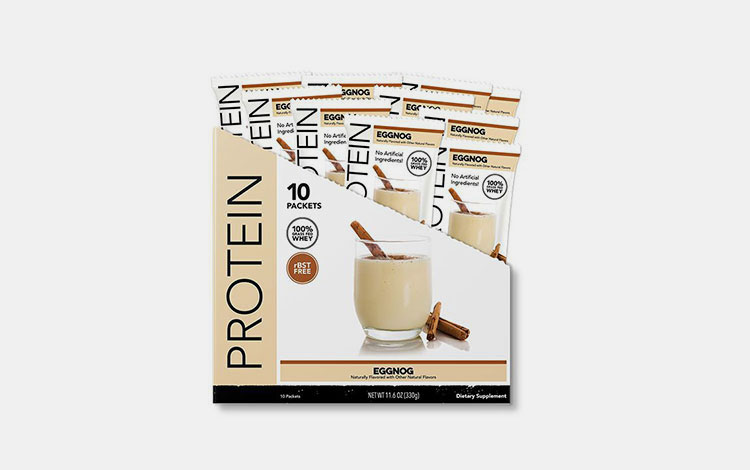

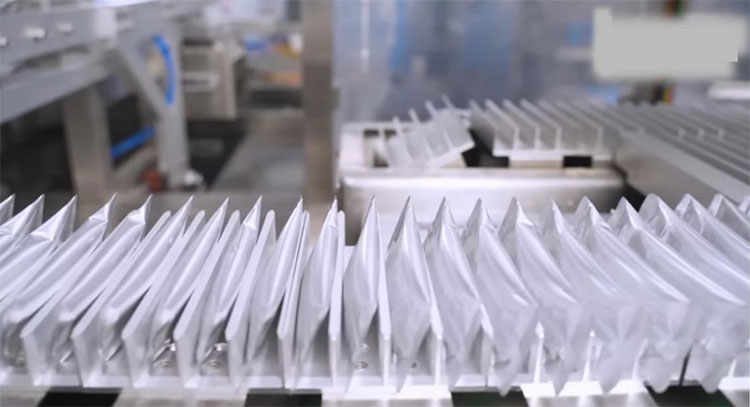

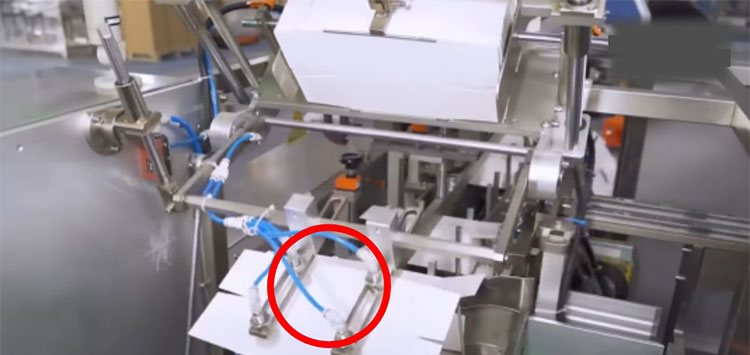

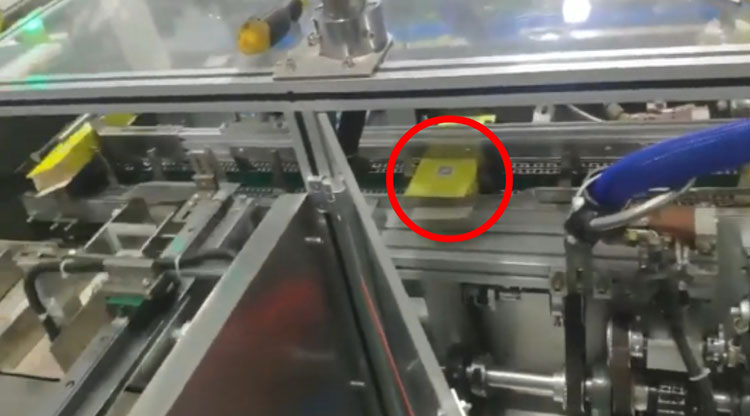

Protein Powder Filling

Protein Powder - Picture Courtesy: Healthline

When the protein powder is prepared either it is milk-based or plant-based, it goes through the process to be filled in the containers. Bags, pouches, cups, jars and cans are good choices for packaging of protein powder. So for this purpose, there are specially designed protein powder filling machines that will work automatically and provide you with high percentage of accuracy.

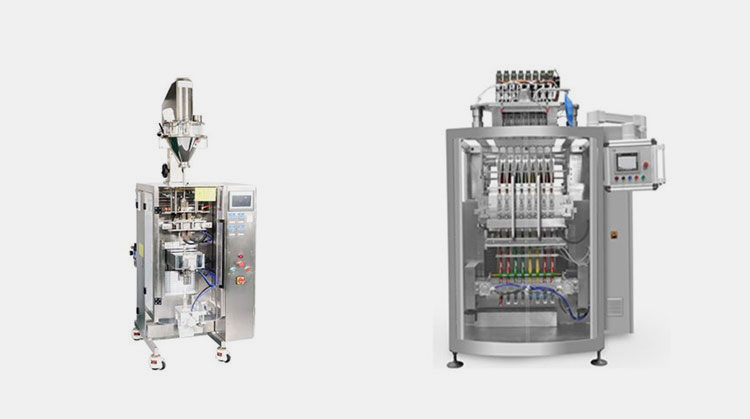

6.Do you know the various types of a protein powder making machine?

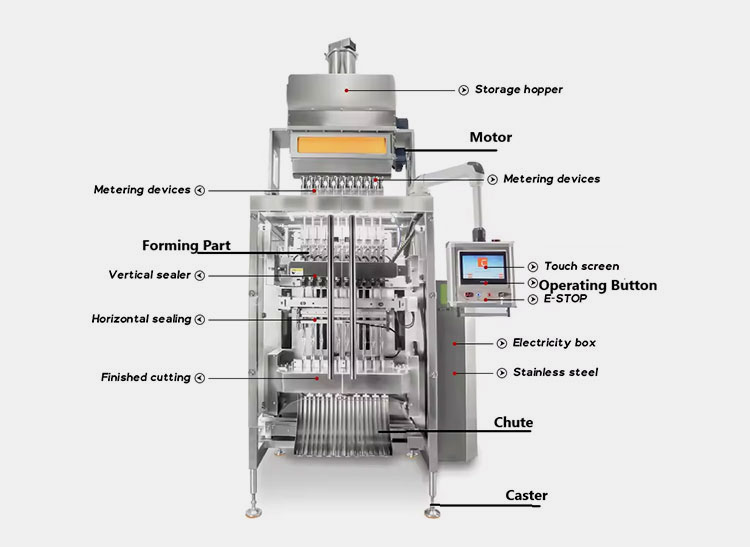

Protein powder making process is a bit complicated as it has many steps involved in it. Hence the process has to deal with many machines at a time. These machines are of many types depending on the quality of the products given out by the machine and the different working and purposes of the machine. So, following are some of the advanced machinery that is involved in this process and each machine has its own purpose in this process.

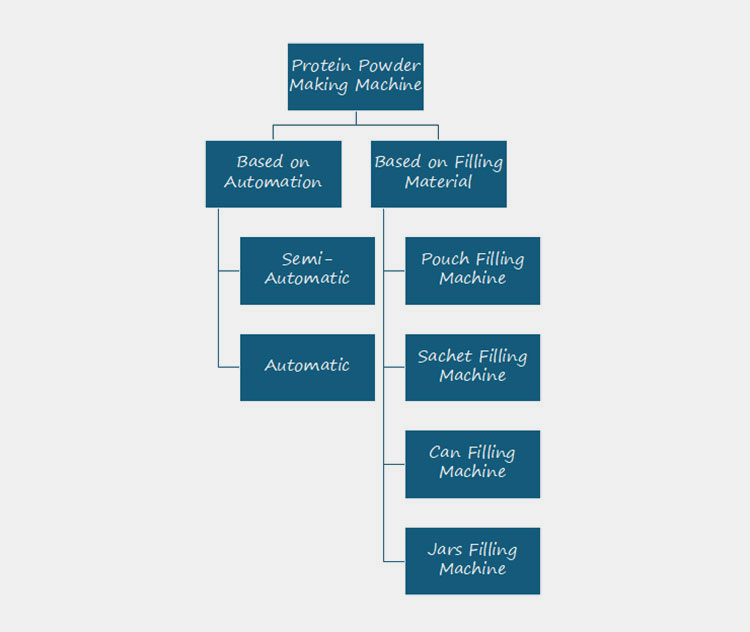

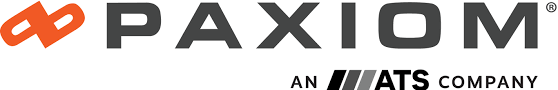

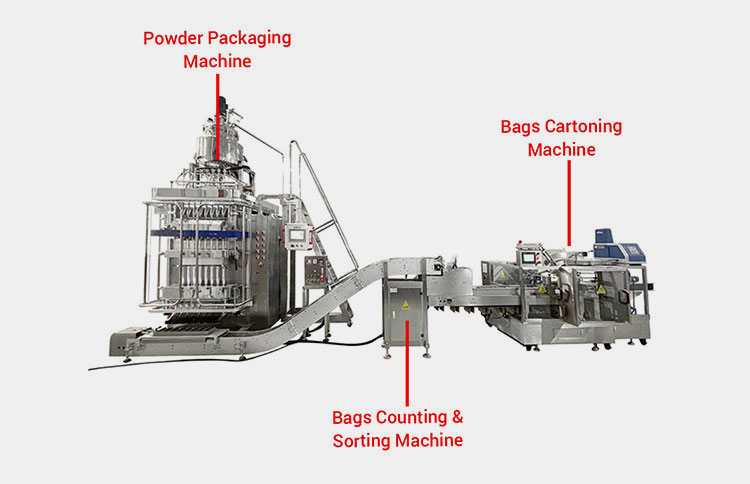

Classification of protein powder making machine

Based on Automation

There are many types of protein powder making machines based on level of automation in its operating method. Below are its types with brief description.

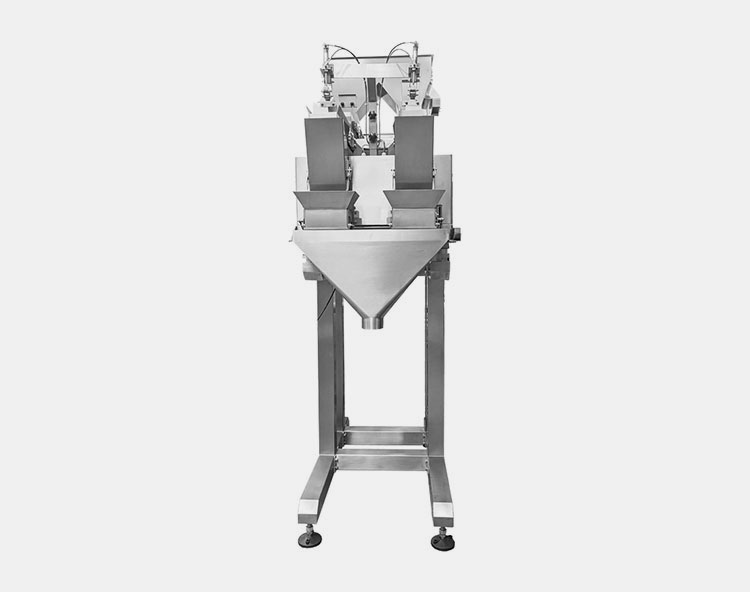

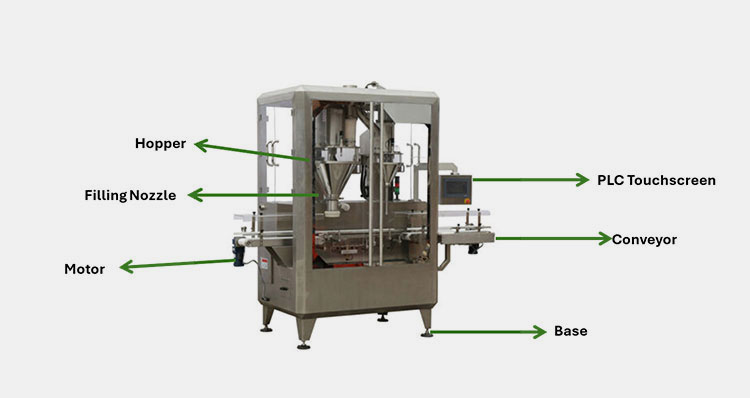

Semi Automatic Protein Powder Making Machine

Semi-Automatic Protein Powder Making Machine: Picture Courtesy: AIPAK

Sometimes proteins are present in liquid form and are required in powder form. At that time semi automatic protein powder making machine is used. It makes it easy to fill the container with required concentration of protein powder while preserving its quality. Its handling capacity makes it useful for many powdered substances such as spices, chilli, cocoa, coffee, whey, epoxy, or talcum and many more.

Its major components including a split hopper, servo motor drive screw, LCD touch system, and highly advanced dust removal system make it a promising choice among many. And it has easy maintenance and can be washed easily.

It operates in the following way;

- Feeding the hopper with ingredients.

- Place the container manually for filling.

- As the machine sense the container, it fills it through the filling nozzles with required amount of product.

- Filled container moves forward for further processing.

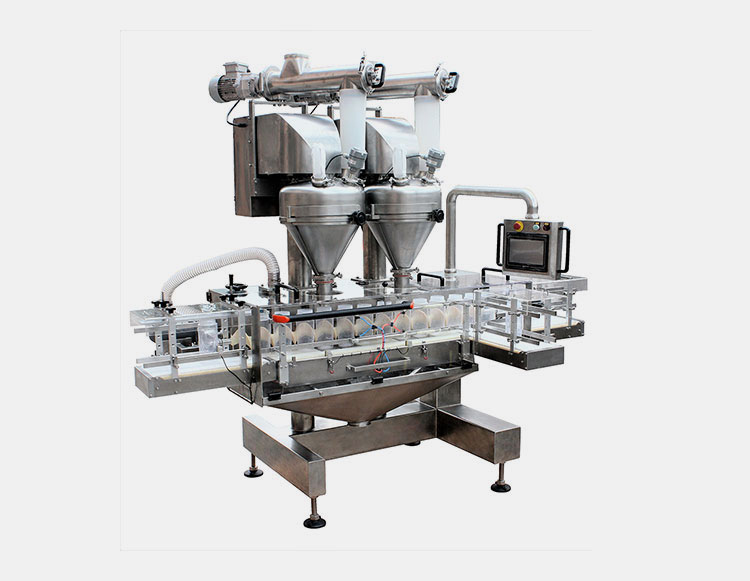

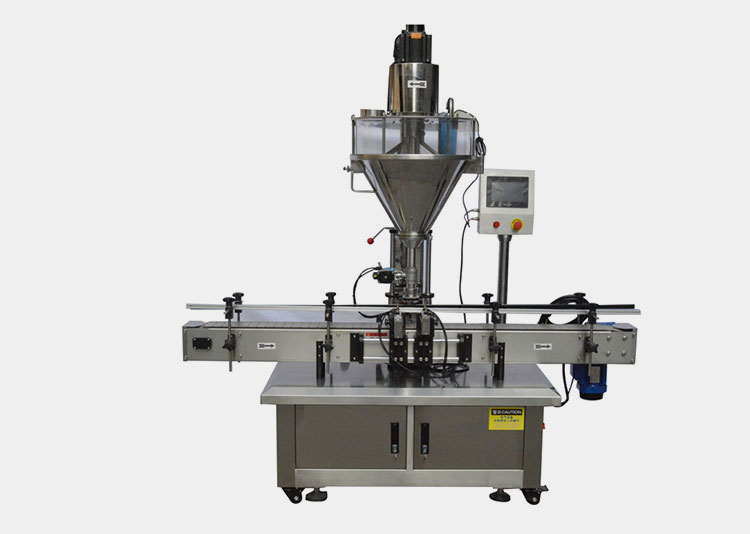

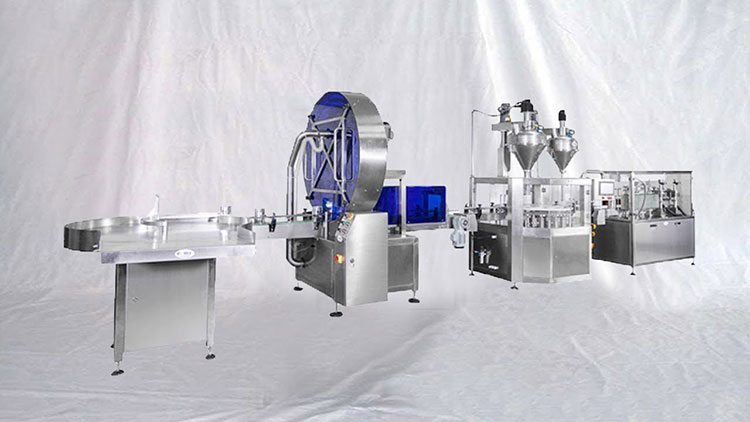

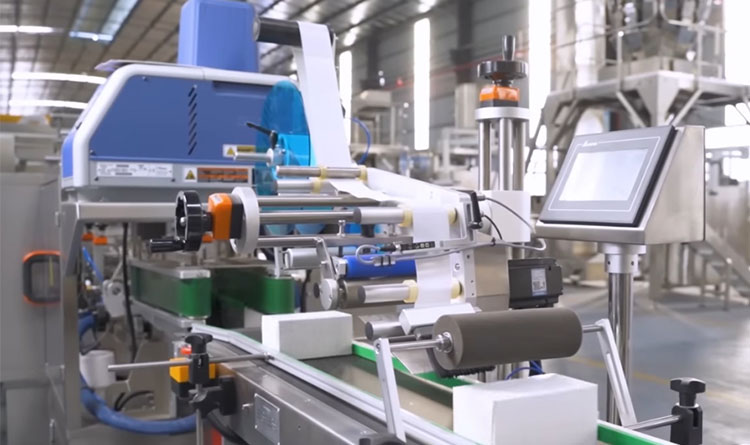

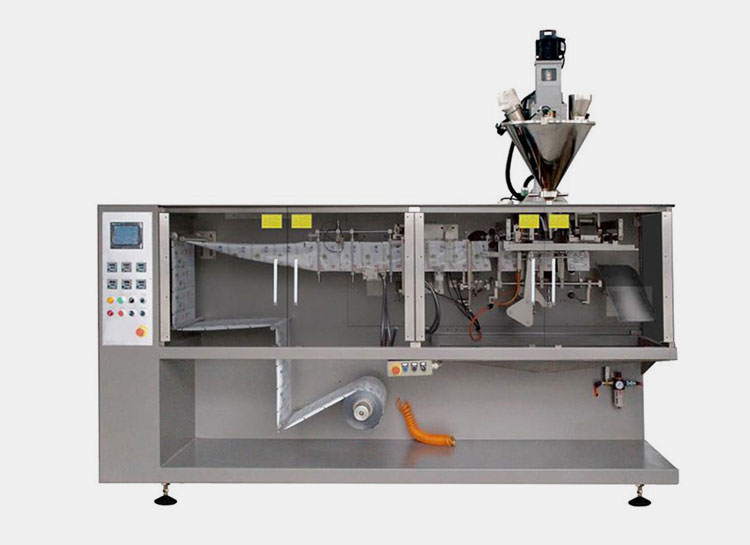

Automatic Protein Powder Making Machine

Automatic Protein Powder Making Machine: Picture Courtesy: AIPAK

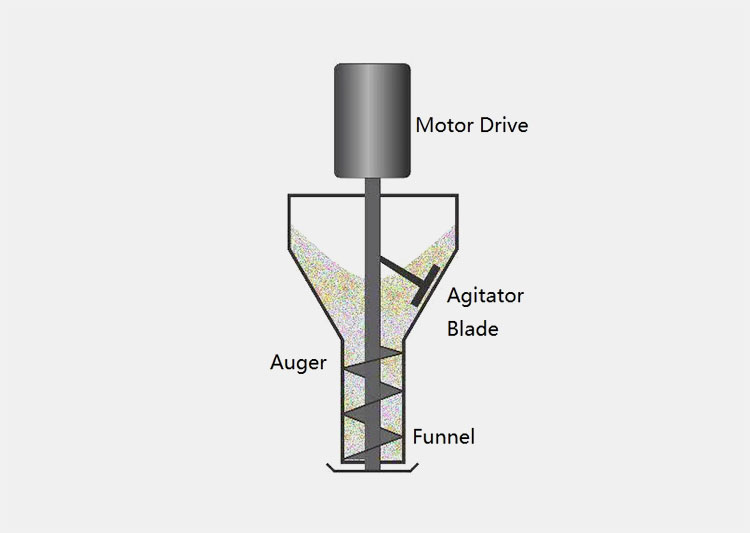

This is an automatic auger filling machine designed specifically for the filling of products into hard containers like bottles, cans, jars etc. It has made the filling process of protein powder so much easier because most of the processes such as metering, filling, and releasing of protein powder are done by its automated system and advanced technology.

Its unique design make it more appropriate for filling or packaging of dry powder or granular substances. It is widely used in a number of businesses or fields such as; food, chemical, drugs, granular additives and food items. It is featured with high power transmission system, controlling system and detection and rejection sensors that ensure high degree of accuracy and precision.

It operates in the following manner;

- All its components are connected and coordinates when they are loaded with the protein powder.

- Once the container is detected by its sensors, the machine starts filling; it uses auger devices or filling nozzles for this function.

- The container moves onward after filling with protein powder.

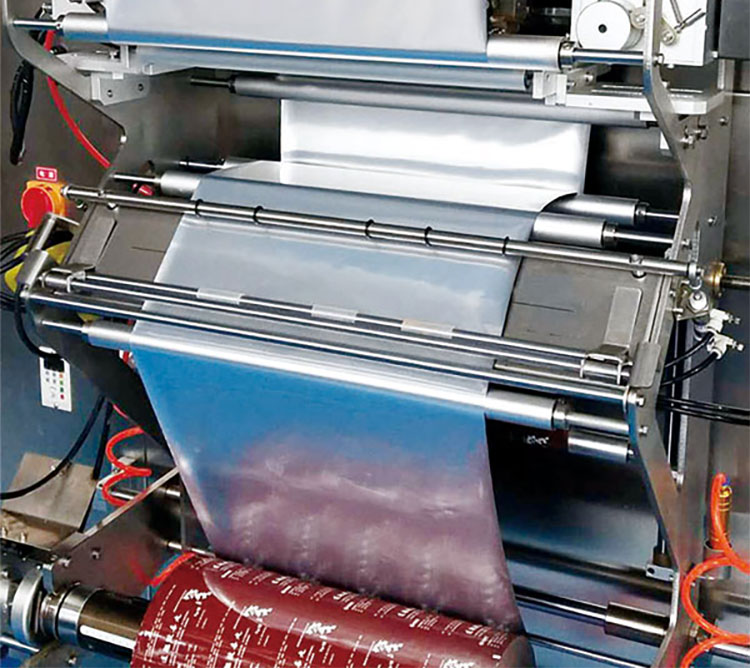

Based on Filling Material

Another category is the classification of protein powder making machines based on the filling container or material. There are varieties of protein powder making machine available in the market. Some of them with their distinctive features are discussed below;

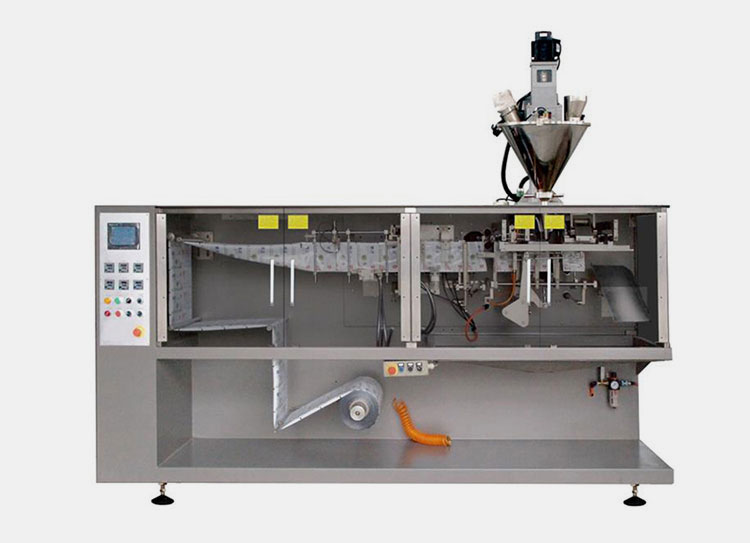

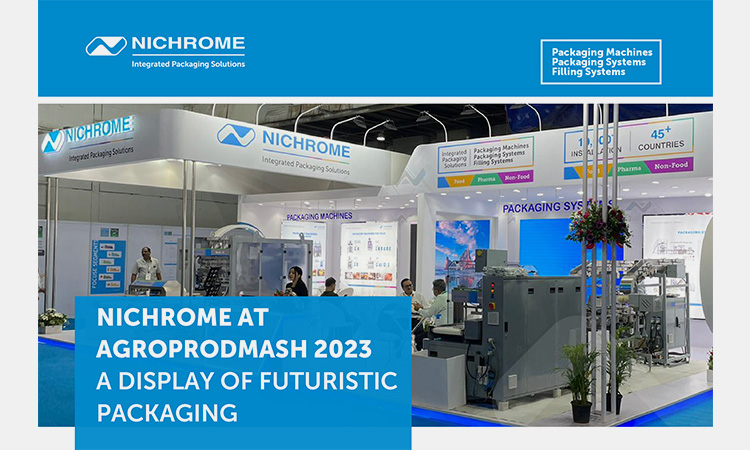

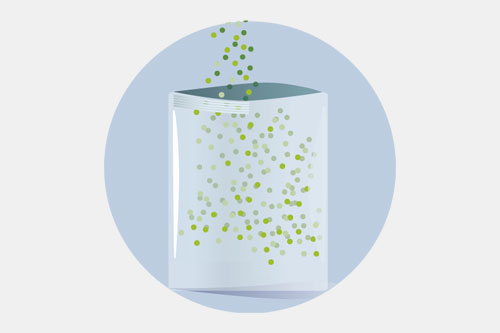

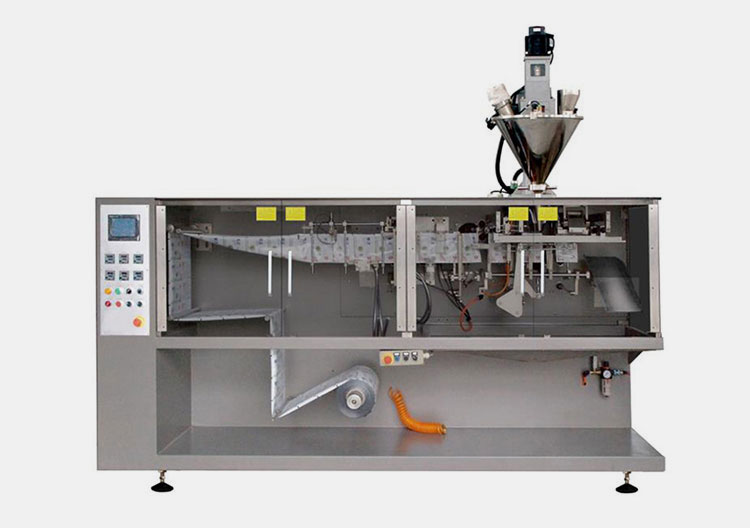

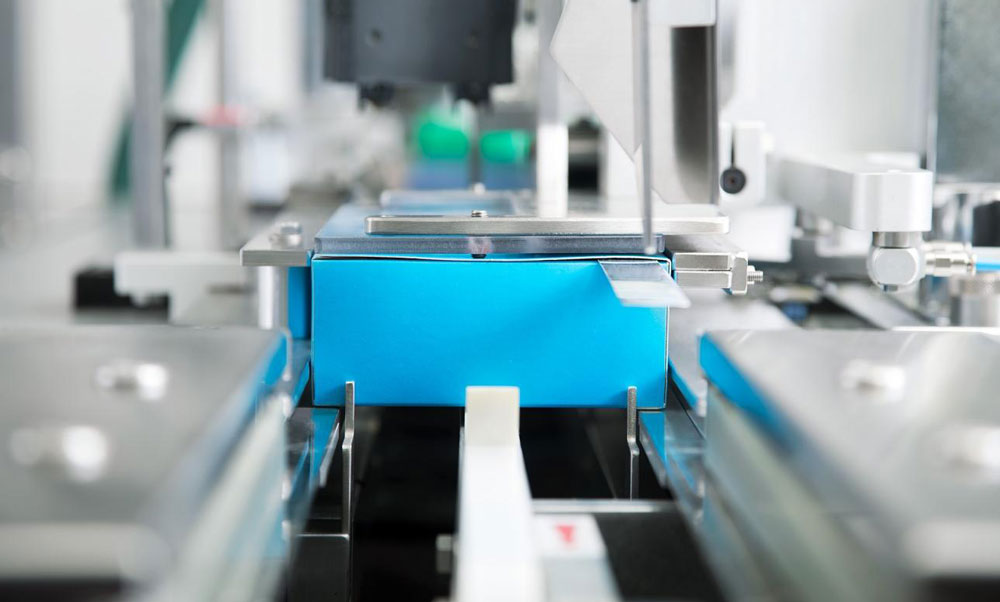

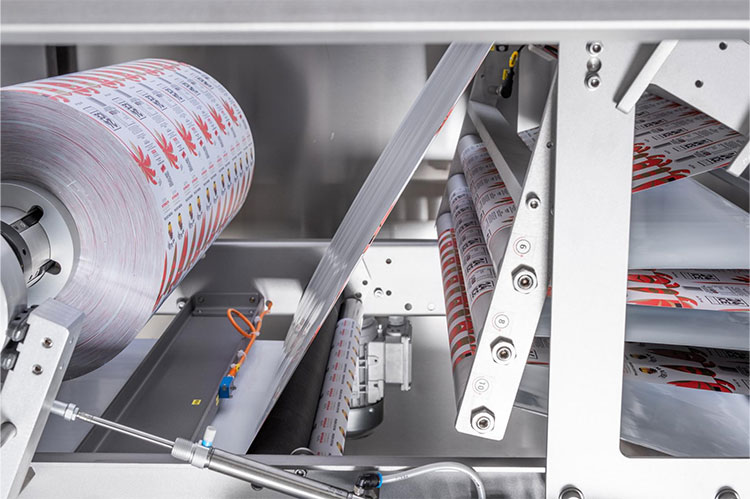

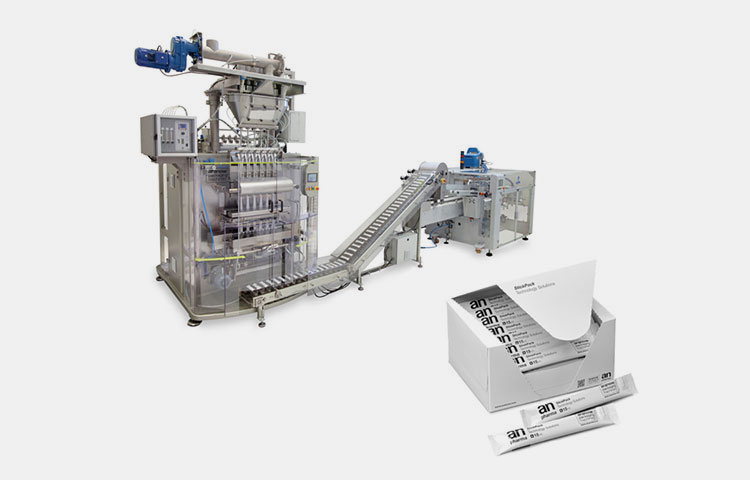

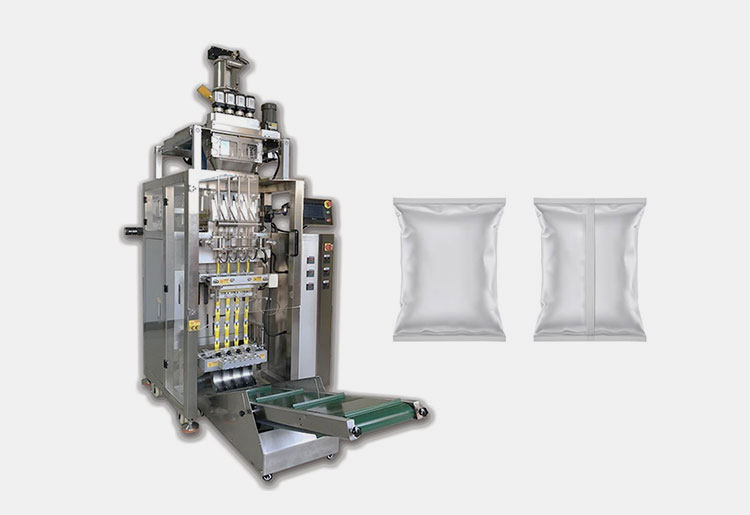

Pouch Filling Machine

Pouch Package Machine: Picture Courtesy: Lenis Machine

If you desire to get the product in ultra-fine powder form, then this machine is best for you. Its PLC control and easy interface help you in the adjustment of parameters according to your requirements. It is capable of providing high-standard packaging to the protein powder which is essential to retain the quality of protein powder increasing its shelf-life.

Moreover, it has multiple purposes and can be used in many other industries, for instance, packaging of carbon, other powder form substances or additives, chemical industry, pharmaceutical sector etc.

Its working steps are following;

- Stack of unloaded pouches are put inside a bag magazine.

- These vacant pouches are picked separately by the grippers.

- Then it is transferred to the inflating area to be blown up by the air.

- Now, these empty blown up pouches are filled the protein powder.

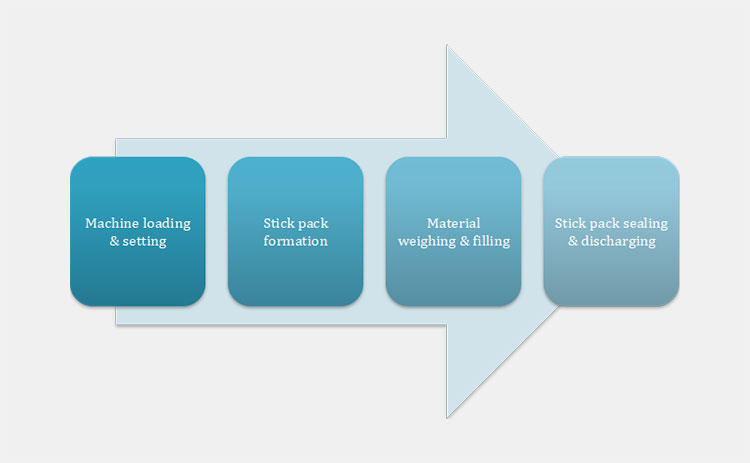

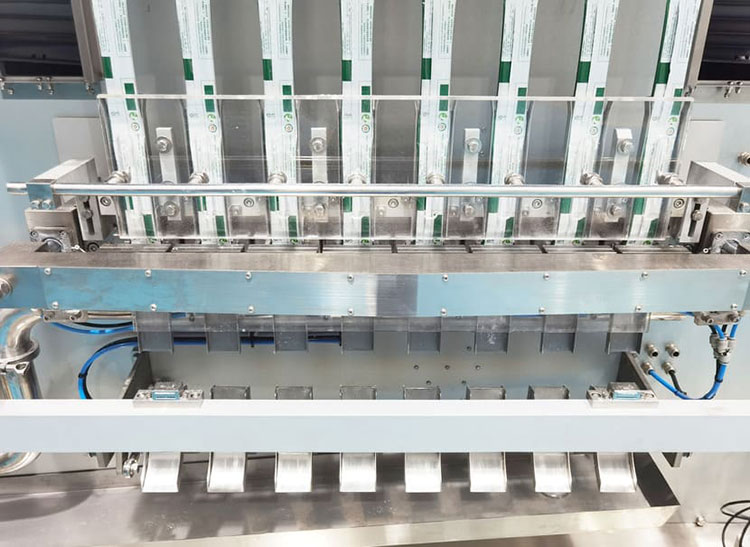

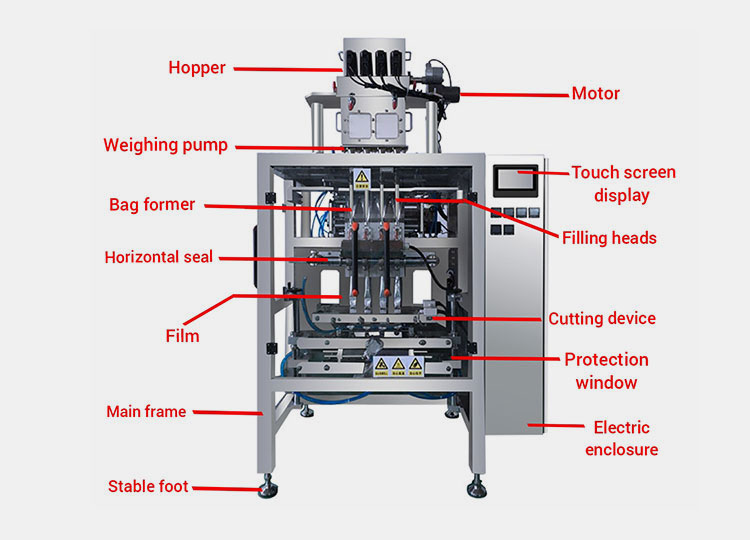

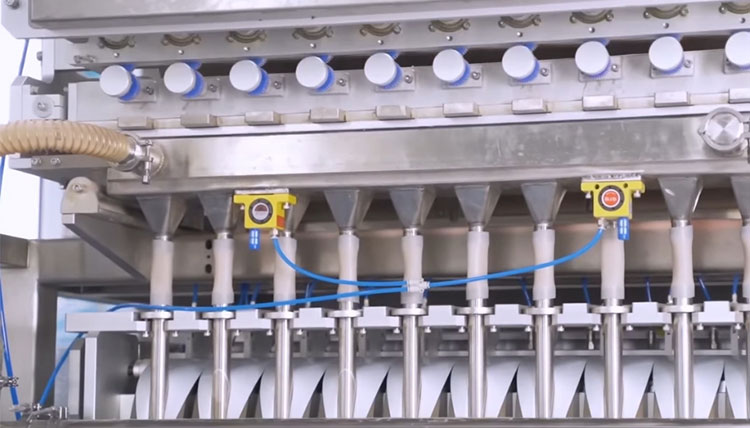

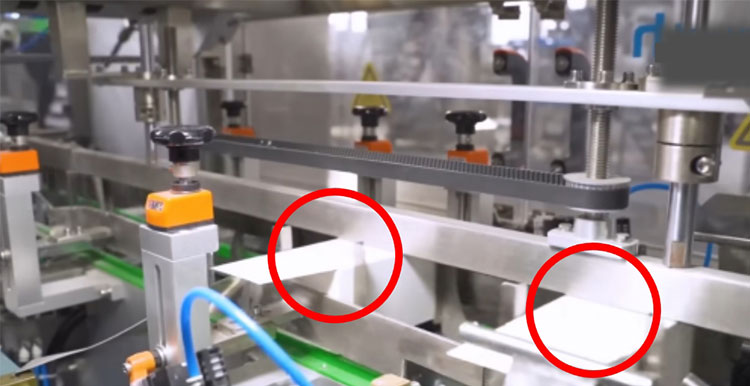

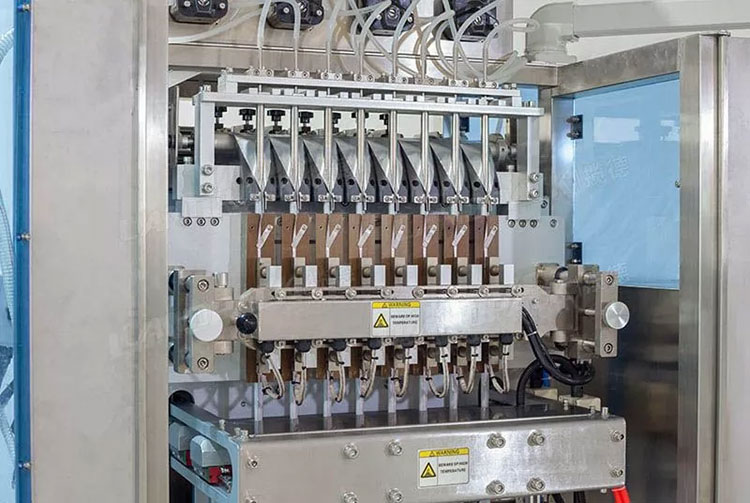

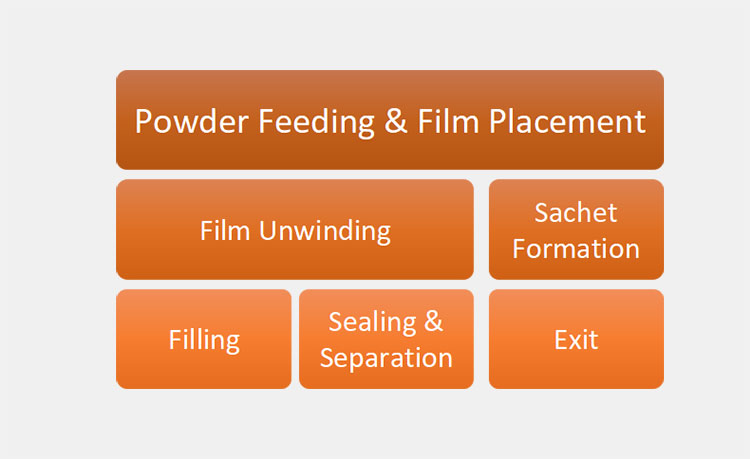

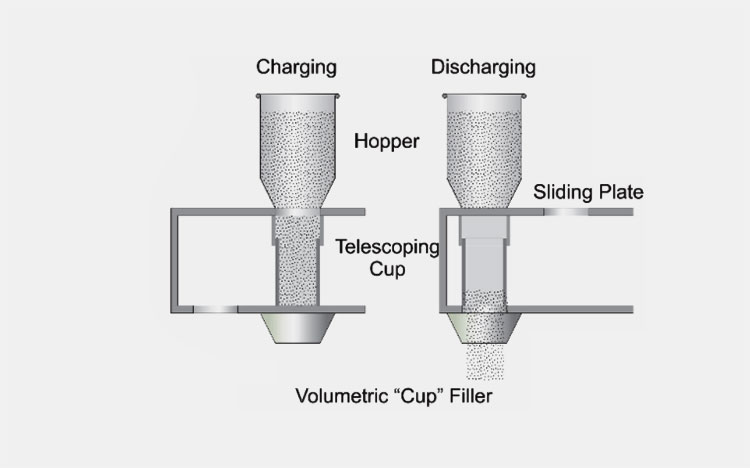

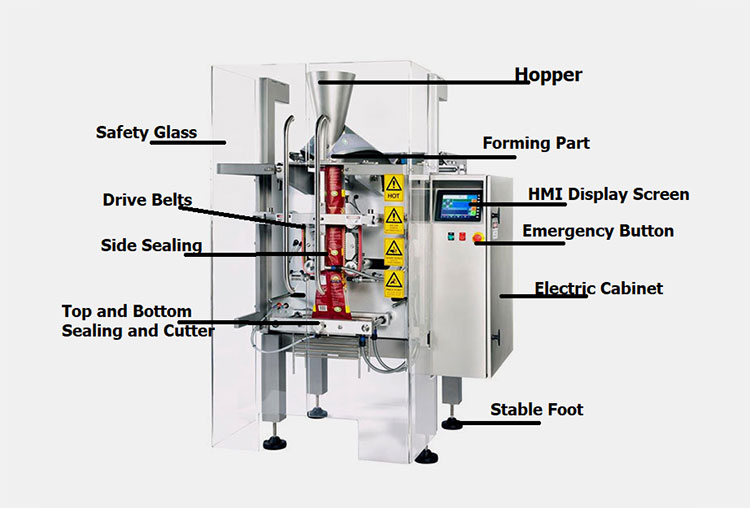

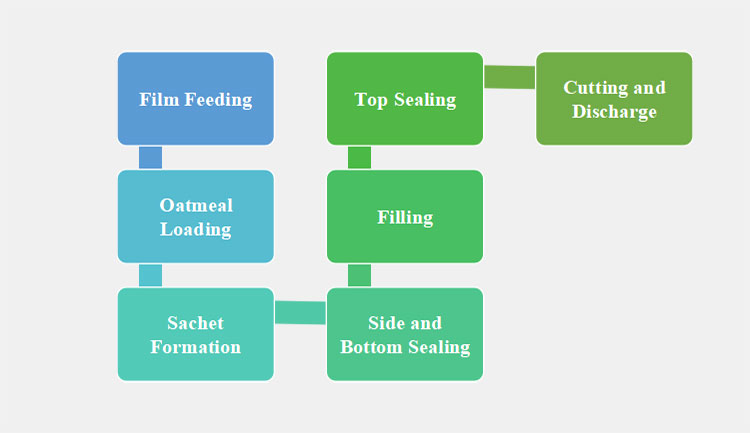

Sachet Filling Machine

Powder Sachet Filling Machine: Picture Courtesy: Samful Packing

This is one of the specialized protein powder making machines manufactured globally. It has a completely compact design with automatic features making it suitable for filling the products into sachets, bottles, jars or cans etc.

It can measure or weigh the amount of the product which helps it in rejecting the underweight or overweight amount. Moreover, for uniform process it has been devised with the photo eye detectors which detect the sachet or container. This photo eye sensor stops the filling process when detect that there is no sachet to be filled with powder.

Here in this case, it is highly recommended for protein powder making industry to fill the powder in sachet in the appropriate amount. However, you can not use this machinery for filling liquid or fluid materials into sachets.

Its working manner is discussed below;

- As for sachet, it is provided with the film on the film case.

- The rotation of the disc helps it in unwinding.

- Forming tube convert this film into a small packet like container called sachet.

- Auger filler of the machine filled the sachet with protein powder in required amount.

- Finally, the filled sachet is sealed with the glue.

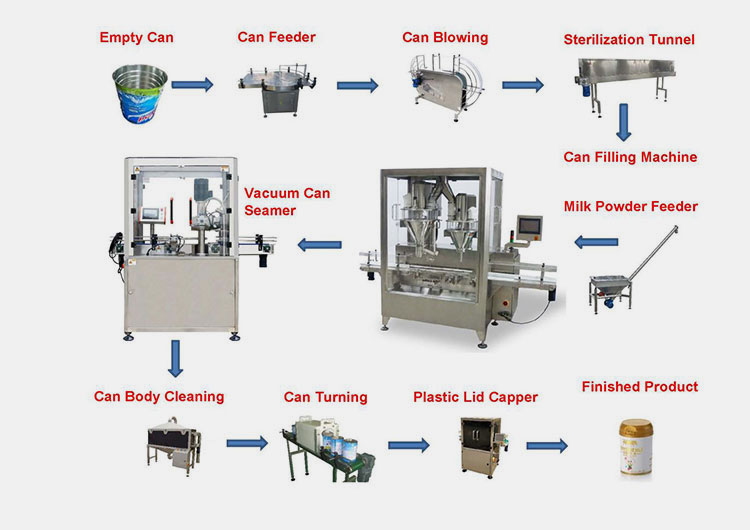

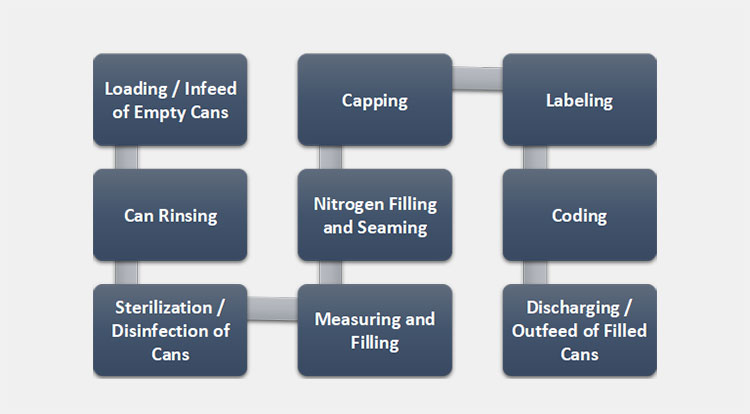

Can Filling Machine

Can Protein Package Powder Machine: Picture Courtesy: Threepac

This is an automatic can filling machine designed specifically for the filling of products into hard containers like cans, bottles, jars etc. It has made the filling process of protein powder so much easier because most of the processes such as metering, filling, and releasing of protein powder are done by its automated system and advanced technology.

Its unique design make it more appropriate for filling or packaging of dry powder or granular substances. It is widely used in a number of businesses or fields such as; food, chemical, drugs, granular additives and food items. It is featured with high power transmission system, controlling system and detection and rejection sensors that ensure high degree of accuracy and precision.

Its working principle is given below;

- First of all load the machine with empty cans.

- After detecting the empty cans, the machine starts filling it with protein powder.

- After filling with set amount of the product, can is conveyed to further packaging.

Jars Filling Machine

Automatic Jar Filling Machine: Picture Courtesy: Vtops

This is electrically powered machine that has automatic mouth locking device which prevents the powder from leakage. The protein powder jar filling machine is made of stainless steel which make its structure strong and highly resistant towards corrosion or acid.

Moreover, its servo filling system, weighing scale, and stainless steel storage bucket ensure greater accuracy. Its application varies from pharmaceutical industry to chemical and foodstuff sector.

It works on the following steps;

- At first, set the jars on the conveyors at predetermined intervals.

- Filling area bring them into the place of filling one after the other.

- By setting the parameters with PLC system, you can adjust the required quantity of the product.

- After filling successfully with powder via nozzles, the jar is transported towards capping or sealing system.

7.What are the preventive measures needed for protein powder making machine?

Quality Needs Maintenance

Here are some of the preventive measures needed to adopt while using the protein powder making machine.

Constant tidying

Regular purification of machine and it’s components lessens the chance of being defected and being deteriorated. It increases the machine’s life span.

Use lubricants

Constantly lubricating the parts of machine helps to work smoothly without any disturbance. Also it prevents the wear and tear of the parts of the protein powder making machine.

Energy assurance

You should regularly have a check on the electricity supply. It will increases your safety chances. Also helps to prevent electrical shocks and fire.

Tutoring or coaching

Machine users should be well-trained. Properly trained people know very well how to use machine in a convenient way. In this way, correct machine handling will be ensured.

Loading and unloading

If you want the machine to work properly then a specific amount of ingredients should be poured into the protein powder making machine at a specific time and the final product should be extracted out after a certain period of time.

Temperature handling

Scorching can cause inappropriate and slow working of protein powder making machine. So machine’s temperature should be kept normal by using cooling reagents.

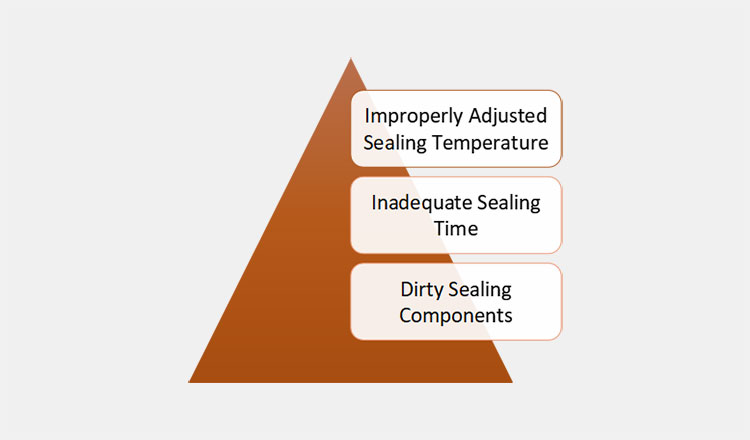

8.What are some common problems and their solutions related to protein powder making machine?

Some of the common problems you may encounter while using protein powder making machine, are given below:

Clogging

Protein powder blending: Picture Courtesy: AIPAK

Irregular cleaning and overflow of protein powder through the machine can lead to clogging and congestion of the machine. When clogged by protein powder, then there will be no product produced because the process had been stopped midway.

Solution

This problem has an easy and simple solution to clean the machine regularly after use and oil the machine 2 times a week. Also, the filling in the machine should be checked.

Failed to Start

Control Panel

You may encounter a situation when a machine fails to start. It may occur due to sudden damage of fuses or another wiring system.

Solution

It can be solved by replacing the fuse with a new one and repairing power lines or wiring.

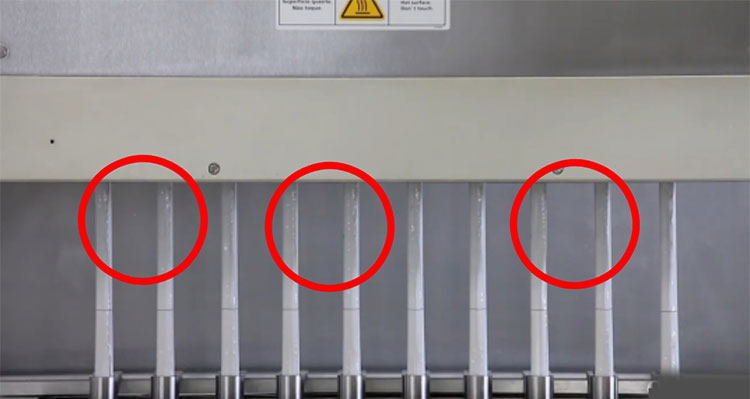

Irregular Powder Flow

Protein Powder Filling into Containers

The amount of humidity affects the powder flow during the process. The moisture present in the powder causes it to flow in irregular patterns that eventually slow down the machine’s speed.

Solution

It is good to reduce the amount of humidity and increasing the agitator speed will help reduce the irregular flow.

Producing unwanted sounds

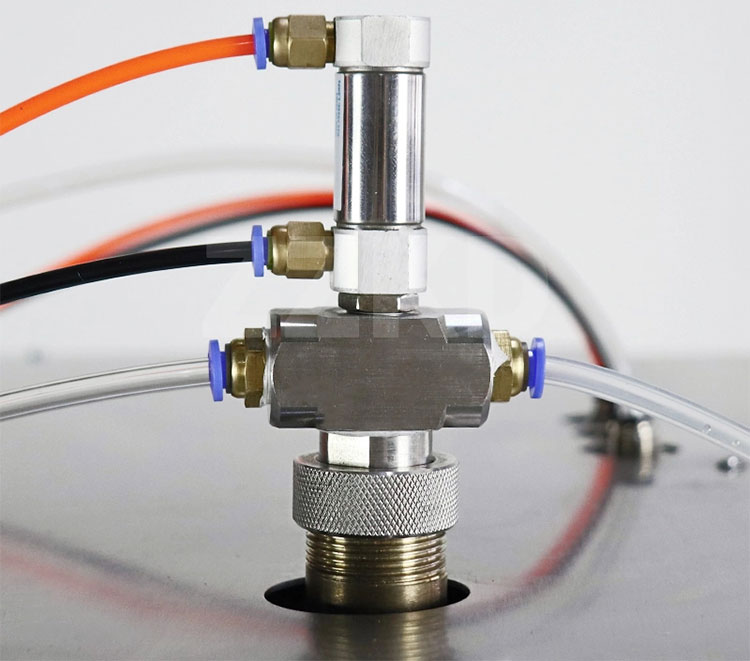

Atomizer Nozzle

Machines usually produce unwanted sounds when it is not well maintained. Then machine become clanged. Producing unwanted sounds leads to noise pollution which also affects the workers working abilities.

Solution

Examine the machine and its maintenance at regular basis. The working solution for this issue is the tightening of loose parts and repairing or replacing the impaired parts.

Over heating of the machine

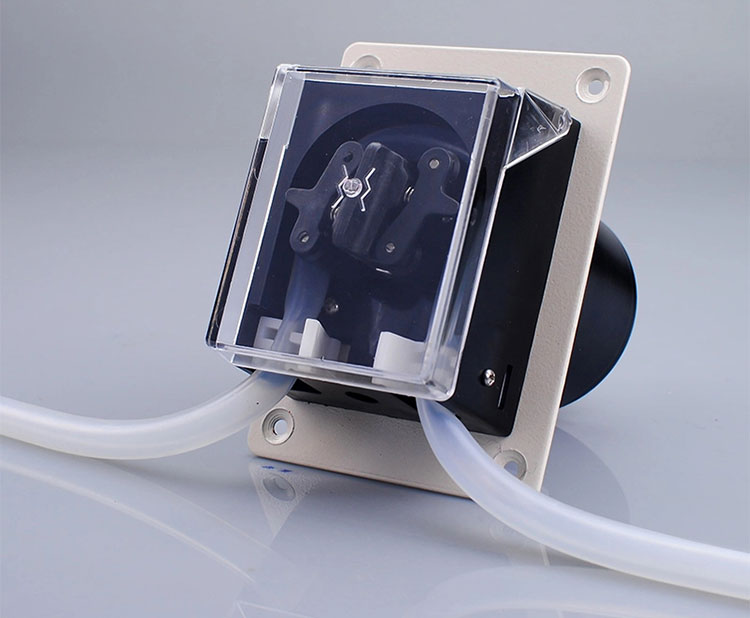

Peristaltic Pump

Machine get over heated by the usage for a long time and do not having a proper cooling and freezing system. This can cause the damage of machine. Over heated machines do not work well and it’s working ability will be affected.

Solution

It’s solution is also quite easy. Use the machine timely and giving breaks during work for a little time. And install proper cooling systems to treat the scorching of machine.

Wear and tear of the machine

Dryer Spray Equipment for Protein Detergent Powder

Every machine has a limited life span. After that they get expired. But sometimes, it is before their expiry date that their parts torn up because of overuse or being defaulted and left neglected.

Solution

The one and only solution to keep machine from being torn up before expiration is to keep a check on machine and take good care of it.

Incorrect level detection

There is a major problem regarding the level of recognition by the protein powder making machine. Sometimes machine are not purified by the workers so they remain polluted due to which protein powder making machine cannot identify the original size.

Solution

Keep check and balance while feeding the machine with raw materials and set the parameters according to requirements so that the machine can detect the material size and its dimensions for further process.

9.What are the important factors to consider before buying a protein powder making machine?

Best Quality Protein Powder

There are always some essential factors which need to be considered before buying a machine for any purpose. Same is the case with protein powder making machine .Some important factors are given below:

Output work rate

The most important factor is to check the work rate of the protein powder making machine to know that how much of protein powder can be produced in a specific amount of time.

Abrasive cutting capacity

Before buying a protein powder making machine you should check the abrasive cutting capacity of it whether it is suitable for the product you are going to make or not.

Spotlessness and purity

Cleanliness is the major factor that decides the machine’s life span. So you must opt for the machine which can easily be purified.

Scorching

The best machines are those that do not get scorched easily by working for a little. So a machine with good cooling reagents which don’t allow it to become so hot in less time should be considered.

Size

The size before buying a protein powder making machine is also a very important factor you have to look at. You should select the one with a size according to your work requirements.

Efficiency

No machine can be one hundred percent efficient but the protein powder making machine with a high efficiency is preferred.

Warranty

A Warranty of so many years provides you surety of the best working of the protein powder making machine. So it’s another factor that you should think about.

Conclusion

So this was all important information about protein powder making machine. All information regarding its construction, uses benefits, and all the factors that should be considered before its purchase is present here. Now you have got the idea and it will be easy for you to decide where to go for the best protein powder making machine. If you have further queries feel free to contact us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Protein Powder Making Machine: The Complete FAQ Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours