Powder Filling And Sealing Machine: The Complete Buying Guide In 2025

Does your business involved packaging of powder products? Are you interested in buying a powder filling and sealing machine to improve your productivity? Does your industry involve powder filling and sealing process? Do you require greater range of information regarding the operation of a powder filling and sealing machine and its types available globally? This is the place where you can get all the related information that will support you in selecting the right type of machine. Read the complete guide to resolve your queries.

1.What Is A Powder Filling And Sealing Machine?

Powder Filling And Sealing Machine

A powder filling and sealing machine is an advanced type of equipment that fills powder substances in various types of packaging containers and then seals them in an efficient manner. Materials that are produced in chemical, pharmaceutical, food, cosmetics and other industries can precisely be packaged using a powder filling and sealing machine. The amount of filling is dispensed in an automatic manner and through various mechanisms containers are sealed to prevent spillage of material.

2.What Are The Applications Of A Powder Filling And Sealing Machine?

Powder filling and sealing machine are globally used due to its highly efficient and precise filling and sealing property. Some of the industries where application of powder filling and sealing machine is found are:

Food Industry

Dry Powder Filling - Picture Courtesy: Assemblies Unlimited

Many of the food products are found in powder form like tea, coffee, sugar, dry milk and etc. These materials require an efficient and secure packaging to attract more customers and to avoid material loss respectively. Powder filling and sealing machine is used to ensure accurate quantity of filling material into packaging containers and then applies a strong seal on it that makes their travelling easier.

Pharmaceutical Industry

Calcium With Vitamin C

Medical and pharmaceutical industry is also one of the largest consumers of powder filling and sealing machine to maintain efficacy and security within material and system. Powdered medicines like drugs, chemical supplements, vitamins and others are filled with accurate dosage in different types of packaging using a powder filling and sealing machine.

Chemical Industry

Industrial Iron Oxide Chemical Powder- Picture Courtesy: Hinan Baijia

Both chemical and agricultural industries have the same use of powder filling and sealing machine. Many pesticide killers, detergents, chemical powders require proper filling and sealing so that the entrance of microbes can be prevented. These microbial organisms can affect the nature of these chemicals if not sealed properly.

Cosmetics Industry

Mineral Fusion Dry Face Powder - Picture Courtesy: Cosmetics Packaging

Products for personal care like face powders, talcum powders, baby powders and other that are produced in cosmetic industry also required efficient filling and sealing properties. These properties are maintained using highly robust powder filling and sealing machines. Products that are packaged using powder filling and sealing machine are prevented from contamination and have maintained quality for years.

3.What Benefits You Can From A Powder Filling And Sealing Machine?

Powder filling and sealing machine is a dual featured machine with numbers of advantages. Some of the benefits that can be taken from a powder filling and sealing machine are

Efficient Filling And Sealing

Efficient Powder Packaging - Picture Courtesy: Xfilpak

Most of the powder filling and sealing machine are found with automatic process that makes the system highly efficient and reduces chances of inefficient process that can cause by manual intervention. The machine is directly with certain filling quantity and it efficiently fills the same without any spoilage. Further sealing duration is also set according to the packaging material used. This reduces downtime and gives thousands of products in a single day.

Accuracy

Accurately Packed Milk Powder - Picture Courtesy: Wxtytech

Precision and accuracy are one of the most important benefit that can be taken from of powder filling and sealing machine. The consistent flow of powder into packaging material makes each of the products identical and good quality sealing helps the product remain preserved for a longer duration. It also helps in attracting a large number of customers towards it.

Versatility

Versatile Working Of Powder Filling And Sealing Machine - Picture Courtesy: Viking Masek

Powder filling and sealing machines are versatile in nature as they support wide range of powder filling and sealing in a single machine. A single machine can also be used in any of the industry depending upon its properties and productivity. A powder filling and sealing machine has a diverse application and this makes it a best choice for any powder filling system.

Adaptability

Adaptable Machine For Packaging Process

One of the features of a powder filling and sealing machine is that it can filling any of the packaging material including jars, bags, pouches, bottles and etc. The machines can be set on any of the shape and has flexibility to accommodate various types of sizes in it. Depending upon in its structure number of different can be filled and sealed using a powder filling and sealing machine.

4.What Powder Materials Can Be Filled And Sealed Using A Powder Filling And Sealing Machine?

Some of the powdered materials produced in different industries that are filled and sealed using a powder filling and sealing machine are

Medicines

Packed Powder For Oral Suspension - Picture Courtesy: Getz Pharma

Medicines those are present in powder form like vitamins, supplements, drugs, lab reagents and etc. use powder filling and sealing machines for their accurate filling and sealing purpose.

Food Powders

Wheat Powder - Picture Courtesy: Ammae

Food powders are the most that are packages using a powder filling and sealing machine. Different types of flavored milk, coffee, tea and powdered juices are the examples that are precisely filled and sealed using a powder filling and sealing machine.

Body Powders

Talc Free Body Powder - Picture Courtesy: Ejis

Some of the body care products that are produced in cosmetics and chemical industry are also packaged using a powder filling and sealing machine. These products include talcum powders, personal care powders and etc.

Baking Powders

Baking Powder - Picture Courtesy: McKenzie

Baking industry also consumes few powder materials like corn flour, cocoa powder, sugar and dairy powders. These materials are also packaged using a powder filling and sealing machine.

Spices

Spices Powder

Various types of spices that are in powder form like cumin, paprika, curry powder and others are efficiently filled and sealed using a powder filling and sealing machine.

5.What Is The Working Procedure Of A Powder Filling And Sealing Machine?

Powder Filling and Sealing Machine

A powder filling and sealing machine has following working steps

Powder Feeding

Initially the powdered material is filled into the hopper of machine present at the top of it in specific quantity so that it may not overflow from the hopper.

Loading Of Packaging Material

On the same time the packaging material like pouches, bags, jars or etc. are also loaded into the system via film rollers or conveyor belt.

Filling Process

One the packaging material reaches the filling nozzle the powder is released in an accurate amount determined by the operator. The dispensed powder stops once it reaches its maximum limit.

In some of the powder filling and sealing machines, compaction is the next step once the powder filling is gets complete. It maintains the level of powder and keeps uniformity within the system.

Sealing Process

Sealing of packaging material is done right after the leveling and compaction step. Sealing ensures that the product remains fresh for a longer period. Sealing can be through heat, induction or ultrasonic depending upon the properties and type of packaging material.

Labeling And Packaging

Finally, the quality of sealing is checked and then it is labeled with the required information to make the consumer familiar with it.

6.What Are The Different Types Of Powder Filling And Sealing Machines Available Globally?

Some of the types of powder filling and sealing machines available globally are

Semi-Automatic Powder Filling and Sealing Machine

Semi-Automatic Powder Filling And Sealing Machine

A semi-automatic powder filling and sealing machine involves both human and machine interface. The machines are not much efficient as compare to automatic one due to human involvement. Mostly medium scale industries use these machines where it is easy to maintain their productivity.

Automatic Powder Filling and Sealing Machine

Single Automatic Powder Filling And Sealing Machine

A fully automatic powder filling and sealing machine performs complete process itself with high accuracy and efficiency. This type of machine has accurate filling and precise sealing feature that prevents materials from spillage. Complete process including feeding, filling, sealing and ejection is performed by the machine that reduces chances of over and under filling.

Rotary Powder Filling And Sealing Machine

Rotary Powder Filling And Sealing Machine

A rotary powder filling and sealing machine is one of the most productive machines in terms of precision and speed. Numbers of pouches are filled in a circular path at a single time with uniform quantity of powder material. The process of a rotary powder filling and sealing machine has different filling stations that fills powder at a same time and then allows their sealing in a precise manner.

Inline Powder Filling and Sealing Machine

Continuous Motion Inline Filling Sealing Machine

Inline auger fill seal machines are highly advanced machines with screw metric systems in it. This system allows accurate dispensing of powder material into different types of packaging. An auger fill seal machine allows filling of different types of powders in a free flow manner and is applicable in many pharmaceutical, chemical and cosmetic industries.

7.What Are The Main Components Of A Powder Filling And Sealing Machine?

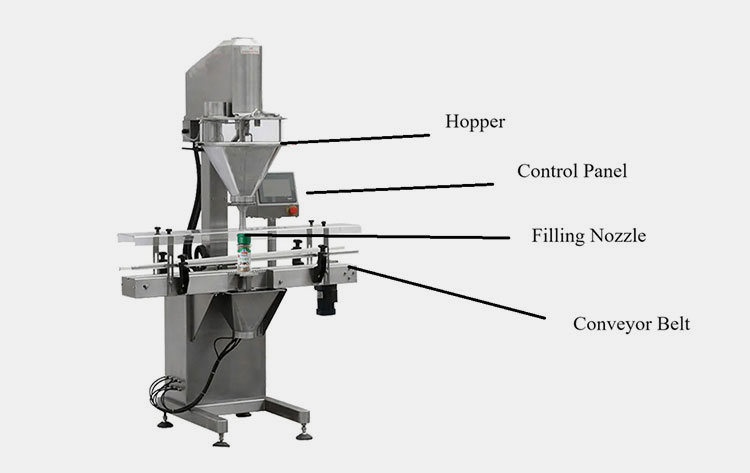

Components Of A Powder Filling And Sealing Machine

A powder filling and sealing machine has a very simple structure to perform its operation. The main components in it are:

Hopper

A hopper is present at the top of a powder filling and sealing machine that is used to store the powder material in it. It dispenses the material into the filling system where the powder is released further into packaging materials.

Control Panel

A control panel is a human machine interface that allows the operator to get complete information regarding the running process and set different parameters. It involves emergency stop, controllers, PLC and other switching selectors that can be used to maintain accuracy and precision in a powder filling and sealing machine.

Filling Nozzle

A filling mechanism of a powder filling and sealing machine has different types of working method depending upon the orientation of machine. It is responsible to store the material coming from the hopper and then dispensing in it into packaging material through filling nozzles. Accurate amount of powder travels through the filling lines and is released in a way that the efficiency is maintained in each packaging container.

Conveyor Belt

Some of the powder filling and sealing machine also use conveying systems for traveling of packaging containers within the process. It moves the container towards the filling nozzle first and then towards the sealing process for application of seal.

8.Which Packaging Containers Can Be Filled And Sealed Using A Powder Filling And Sealing Machine?

Where a powder filling and sealing machine has a lot of benefit in modern industry, some of the packaging containers that can be filled using it are

Pouches

Powder Pouches - Picture Courtesy: Powder Pouch

Most of the pouches are filled and seal in VFFS and HFFS machines where flexible packaging of plastic pouches is carried out. The machine is compatible with plastic films and forms pouches of it in an efficient manner. Many foods, pharmaceutical and chemical powdered pouches are prepared using this type of machine.

Jars

Spices Powder Filled Jars

A powder filling and sealing machine is also used for filling and sealing of jars made up of glass, metal and plastic. Jars of different size and shapes can easily be filled with powder material and then sealing is applied on its opening in the same machine.

Bottles

Johnsons Blossoms Baby Powder Bottle- Picture Courtesy: Mama Love

Bottles made up of plastic, glass and metals are used to fill powdered material in a powder filling and sealing machine. The filling nozzle dispenses accurate powder material in these bottles and then sealed with various types of caps and openers.

Bags

Printed Powder Bag

Bags made up of either plastic, paper of aluminum are suitable for filling and sealing of powder material using a powder filling and sealing machine. Flour, sugar, salt and other products are packaged in bags of different sizes and shapes are produced using a powder filling and sealing machine.

9.What Are The Major Differences Between A Powder And Liquid Filling And Sealing Machine?

Some of the common difference between a powder and liquid filling and sealing machine are:

Filling Mechanism

In a powder filling and sealing machine the filling mechanism mostly includes auger, volumetric, gravity filling methods. These allow free flow of powder material with accurate quantity.

On the other hand, a liquid filling and sealing machine mostly involves piston, gravity and pumping mechanism that allows the movement of liquid material towards the filling nozzle. The overflow of liquid material is also controlled in this type of machine.

Packaging Product

Most of the powder material used in food, cosmetic, chemical and pharmaceutical industry with different appearances are filled and sealed using a powder filling and sealing machine.

Viscous, non-viscous, lighter, denser and other types of liquid materials are primarily filled and sealed using a liquid filling and sealing machine.

Sealing Method

Most of the powder filling and sealing machine use ultrasonic, induction and heat seal mechanism to prevent spillage of material and to provide high quality look to it.

Containers that are filled using liquid filling and sealing machine have induction sealing in it as the liquid has more chances of spillage though the packaging material.

Packaging Container Material

A powder filling and sealing machine uses pouches, bags, sachets, bottles made up of plastic, glass or metal for filling and sealing of powder materials.

Same like powder material, liquid filling and sealing machine also uses pouches, bags, sachets, jars and bottles but they contain thick outer most layers to prevent liquid coming out of it.

10.What Are The Auxiliary Machines Associated With A Powder Filling And Sealing Machine?

Some of the auxiliary machines associated with a powder filling and sealing machine are

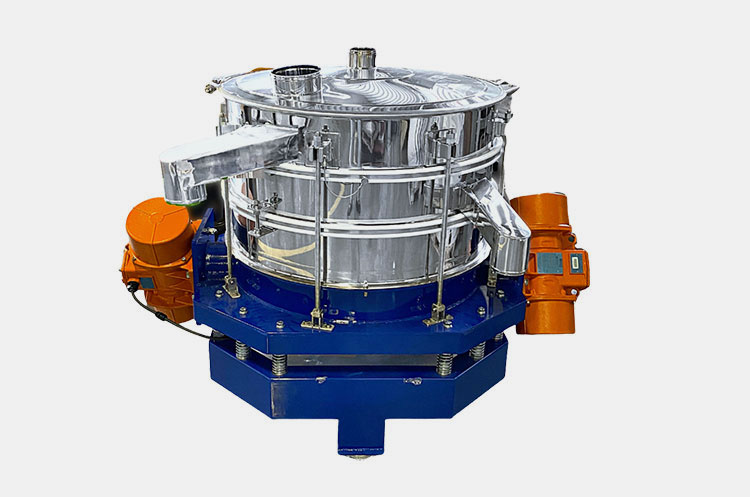

Vibro Sifter

Powder Sieving Machine - Picture Courtesy: Elcan Industries

A Vibro Sifter is used for the removal of impurities from the powdered material that is in the form of lumps or heavy particles. The machine has a centrifugal force that takes these particles to the outer layer where they can be collected easily. These collected particles are then removed from the system.

Bottle Capping Machine

Fully Automatic Press Cap Placer - Picture Courtesy: Rhino-Pak

Bottles that are completely filled with powder material are applied with caps using a bottle capping machine. These machines are highly versatile that they detect the presence of bottles and then place their respective lids. These caps prevent material from contamination and ensure its freshness.

Induction Sealing Machine

Continuous Induction Sealing Machine

An induction sealing machine is modern type of equipment that is used to create hermetic sealing on different types of packaging containers. This type of sealing creates an airtight sealing that maintains the freshness and quality of powdered materials.

Labeling Machine

Labeling Machine

A labeling machine is used to apply labels on packaging containers that contains complete product and material information in it. It also protects the packaging surface and provides an extra layer to it. This label helps the consumer to get complete product related information and makes it reliable before usage

Conclusion

For highly efficient filling and sealing of powder products, powder filling and sealing machines are the most desired machines globally. It has an integral combination of filling and sealing mechanism that makes it much reliable and economical. To understand details regarding a powder filling and sealing machines, Allpack is always available here for your guidance and assistance. If you find any query regarding a powder filling and sealing machines, contact our customer representatives that are available 24/7 for your assistance.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide