How Do You Choose A Stick Packaging Machine?

Don’t you think manual powder packaging is a daunting task that is filled with many challenges?

To overcome issues, a special machine known as a powder back sealing machine is introduced in the market.

Powder Back Sealing Machine

The powder back sealing machine is an innovative technology used to resolve challenges and problems with traditional filling. It is a pathbreaker in various industries of the world. Modern industries use this machine for its seamless packaging, efficiency, and no fill errors.

If are you in search of an informative buying guide about the powder back sealing machine then you are at the right place. This blog post will explain different facts about powder back sealing machines.

1.What is a Powder Back Sealing Machine?

Allpack Powder Back Sealing Machine

A powder back sealing machine is an efficient machine, designed for sealing powders in packs. This machine produces different packaging containers with the back seal. This seal is a neat vertical seal present along the entire middle at the back side of the sachets or stick packs.

The powder back sealing machine is an automated and speedy unit, packaging numerous packs per minute. It is an innovation popular in various industries like food, pharmaceutical, chemical, etc due to its accuracy and minimal wastage of valuable powders.

It offers increased packaging efficiency by forming, filling, sealing, and cutting packaging sachets and stick packs in one cycle. It is designed to fulfil the demands of powder packaging like speedy powder flow with minimal dust generation.

2.Why is the Powder Back Sealing Machine Important?

The powder back sealing machine is important in industries because it comes with compelling lists of benefits that in turn produce great profit margins for the industries. Yes, this machine is extremely fruitful. Here are some handy advantages of the powder back sealing machine.

Production Efficiency

Production Efficiency- Picture Courtesy: Forshan Land Packing Machinery Co., Ltd

It is the ultimate goal of manufacturers to have efficient production and hence, they install the powder back sealing machine. This machine offers numerous times higher production efficiency than manual filling. It is a time-saving device because it packs multiple packs in one go.

Fill Accuracy

Fill Accuracy- Picture Courtesy: Hydration By Keppi

When it comes to money-making, fill accuracy is very essential. Because with fill accuracy, manufacturers can deliver a great number of products in the market without the fear of product recall. So, that is why the powder back sealing machine is important in industries. It fills powders with no chance of error.

Cost-effectivity

Cost-effectivity

Manufacturers prefer to have the powder back sealing machine in their production because it decreases overall running costs. Even though, it requires heavy capital for its purchase. It saves expenses in the long run. There is minimal need for human operators to supervise this machine which cuts down labour expenses.

Augmented Packing Quality

Augmented Packing Quality

Packaging quality is not only important for keeping the products fresh but also for attracting customers. Thus, powder back sealing machine is employed in the industries for its highest packaging quality. It forms smooth and beautiful seals that maintain product integrity but also create a captivating look to compel customers to buy powder products.

No Cross Contamination

No Cross Contamination

The powder back sealing machine safely and securely packs the powder products with no risk of cross-contamination. Cross-contamination increases the risk of microbial growth and degrades the quality of the powder products, sometimes seriously affecting the health of the consumers. So, the powder back sealing machine has a significant place in the industries for its safe and operative packaging and sealing.

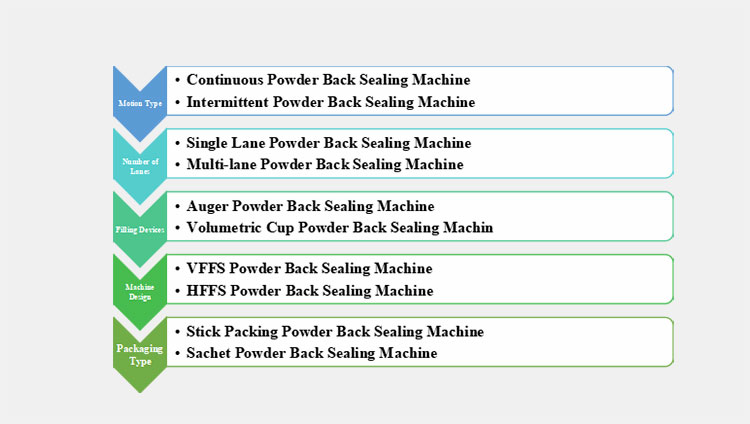

3.What are the Classes of the Powder Back Sealing Machine?

There are various classes of powder back sealing machines available in the market, each has specific production requirements. These machines have different characteristics and designs. The powder back sealing machine is classified into different types based on motion type, number of lanes, and filling devices.

According to the Motion Type

Continuous Powder Back Sealing Machine

Continuous Powder Back Sealing Machine

In a continuous powder back sealing machine, the packaging process occurs without any pause. It operates continuously as long as there is powder in the hopper and film available. This machine is known for its high-speed efficiency as it packs many powder products in a short cycle. It is typically seen in large-scale products because it maximizes uptime.

Intermittent Powder Back Sealing Machine

Intermittent Powder Back Sealing Machine- Picture Courtesy: Schmucker (S.R.L.)

It is a start-pause machine where after every step the machine pauses. After every step like forming, filling, and sealing, the machine takes breaks and then starts again. It is usually found in production where a low output rate is required, as it has a slower speed. However, expensive and valuable powders are filled via this machine because of its precise filling.

According to the Number of Lanes

Single Lane Powder Back Sealing Machine

Single Lane Powder Back Sealing Machine

It has a simple design due to its single lane for forming, filling, and sealing, It is ideal for small-scale businesses because of its low output rate. However, there is no difference in the fill consistency and versatility between single and multi-lane powder back sealing machines. Moreover, it is less expensive than a multi-lane powder back sealing machine.

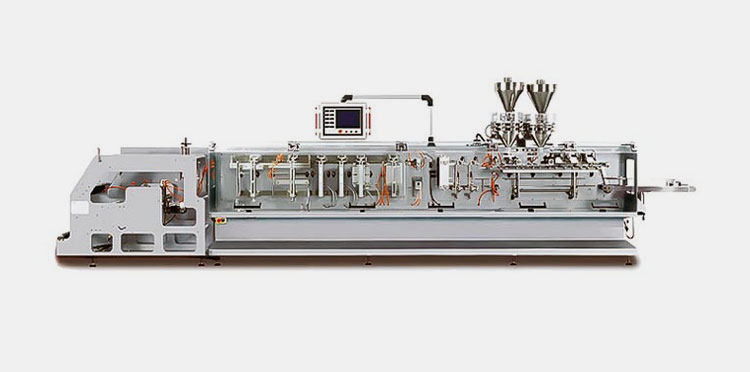

Multi-lane Powder Back Sealing Machine

Allpack Multi-lane Powder Back Sealing Machine

It has a complicated design due to the presence of multi-lanes for forming, filling, and sealing different powders in back seal packs. It has more production capacity and rate of production because it uses multiple lanes for packaging multiple packs at a time. Multi-lane powder back sealing machine is more suited to large-scale industries.

According to Filling Devices

Auger Powder Back Sealing Machine

Auger Powder Back Sealing Machine

It is the most popular machine for filling powders. It has a closed device known as the auger with which this machine performs contamination-free filling. It has a compact design consisting of an auger device, auger screws, a hopper, auger plates, and fill nozzles. Rotation of auger screws aids in achieving consistent filling.

Volumetric Cup Powder Back Sealing Machine

Volumetric Cup Powder Back Sealing Machine

This type of powder back sealing machine consists volumetric plate in which different cups are fixed. For precise powder loading, the weight-checking systems load pre-measured amounts of powders in the cups from where these powders are dispensed into the packaging container via filling nozzles.

According to the Machine Design

VFFS Powder Back Sealing Machine

VFFS Powder Back Sealing Machine

In the vertical, form, fill, and seal (VFFS) powder back sealing machine, the packaging operation occurs in the downward direction and finished packing is discharged from the machine in the product chute located at the bottom. This device is on a smaller size of the spectrum usually producing pillow pouches with back sealing.

HFFS Powder Back Sealing Machine

HFFS Powder Back Sealing Machine- Picture Courtesy: lenis Machines Inc.

Unlike the VFFS powder back sealing machine, the packaging operation in the horizontal form, fill, and seal (HFFS) machine occurs in the sidewise direction. The film is input from one side while the packaging output is from the other side of the machine. This machine requires much higher foot space. However, it is speedy and versatile.

According to the Packaging Type

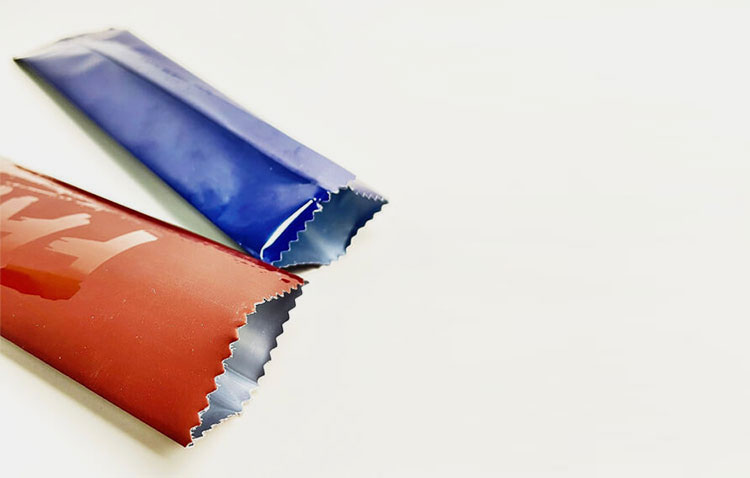

Stick Packing Powder Back Sealing Machine

Stick Packing Powder Back Sealing Machine

This machine has compact and simple construction consisting of one or numerous lanes. The stick packing powder back sealing machine outputs many stick packs with back sealing per minute. It dispenses accurate portions of powder in the stick packs and offers air-tight sealing.

Sachet Powder Back Sealing Machine

Sachet Powder Back Sealing Machine

A small and single-serving powder back-sealed sachet can be produced by a sachet machine which is a compact device significantly capable of supplying precise and optimized quantities of powders. This machine is used in small and large production sectors for creating and filling sachet packs with presentable shapes.

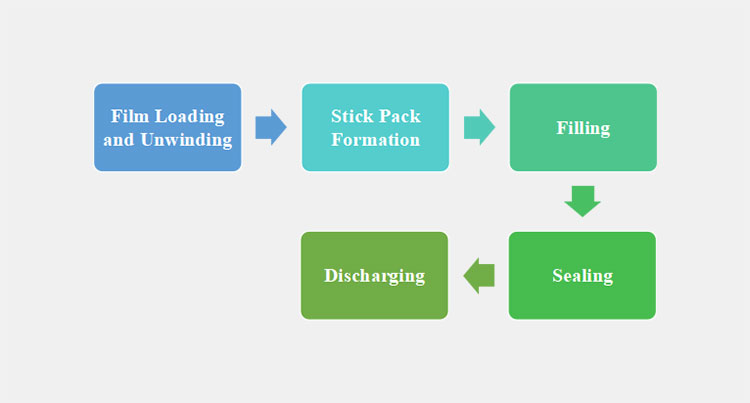

4.Do You Know the Working Principle of a Powder Back Sealing Machine?

The powder back sealing machine is a remarkable invention that smoothly performs its work. However, the working principle of a powder back sealing machine is based on efficiency and precision. The stages present in the working of the powder back sealing machine are as follows:

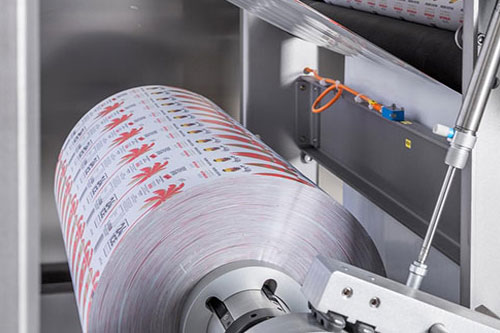

| Film Loading and Unwinding | |

Film Loading and Unwinding |

This machine employs a single layer of film wrapped around the rollstock. The film is unravelled from the rollstock. This unwinding step occurs due to the rotation of the roller and cross-seal jaws. |

| Film Tension and Cutting | |

Film Tension and Cutting |

After printing, the film is passed through a set of rollers called nip rollers. These rollers exert constant pressure on the film and are essential in maintaining the film's tension. The film also passes through the dancer’s arm which moves up and down to aid in constant tension application. Then the film is moved to different cutters that cut the film into smaller strips. |

| Stick Pack Formation | |

Stick Pack Formation- Picture Courtesy: Greatvffs.com |

From the cutting station, the strips of the film go towards their respective forming tube. The film fragment wrapped around the forming collar and resulted in a stick pack. The vertical sealer present at the side of the forming station aids in the formation of the back seal. They press against the film and fold, resulting in the back seal. |

| Filling | |

Filling- Picture Courtesy: greatvffs.com |

After the formation of the stick pack, the powder from the top hopper is moved to the filling devices from where the powder is carried out the filling nozzles. The filling nozzles are a vital part of the powder back sealing machine as it fills precise quantities of powder in the back seal stick pack. |

| Sealing | |

Sealing- Picture Courtesy: Greatvffs.com |

After filling, the horizontal sealer comes into play. They not only seal the top side of one stick pack but also the bottom side of the next stick pack simultaneously. With that, the back seal stick packs are ready to discharge. |

| Discharging | |

Discharging- Picture Courtesy: Diagraph |

Before discharge, the motorized cutting knives come forward and separate two successive stick packs from each other. |

5.What is the Structural Design of Powder Back Sealing Machine?

There are various parts in the powder back sealing machine. These parts act together in synchronization to form back-sealing stick packs. Some of these types of powder back sealing machines have additional parts but common parts are detailed below:

Structure of Powder Back Sealing Machine

Material Hopper

It is a storage containers that accommodate huge quantities of the powders. It stores a significant quantity of powders before directing them to the filling devices. The hoppers have numerous designs like rectangular, cylindrical, conical, and triangular. The quantity of the powders, it can accommodate is usually dependent on its size.

Packaging Film

It is the type of wrapping materials doubling and shaping in which back sealing packs are formed. The layers of packaging film are fused for the creation of a back-sealing pack.

Mounting Rack

It is also called a film frame or film holder and, on this rack, a large film roll is mounted. It assists in the smooth unwinding of film.

Date Printer

This device is a separate unit installed in the powder back sealing machine. It stamps or imprints the batch number, bar code, or expiry date on the back sealing pack.

Bag Former

A bag former is the section that is equipped with a forming tube sometimes called a shaping tube and carries out the shaping and formation of the stick packs. It forms stick packs of various lengths. The packaging film gets doubled around the forming tube and shaped into a back sealing pack.

Vertical Sealer

It is a significant component in the powder back sealing machine and it carries out effective back sealing with heat or ultrasonic sealing. It presses again the middle backside of the tubular stick pack to create a backside seal.

Pulling Roller

It is also called a film transport roller and this pulling roller as the name indicates is responsible for pulling the film and its unwinding. It has a significant role in the smooth and precise transportation of the film material across various stations of the powder back sealing machine.

Horizontal Sealer

It is yet another important component in the powder back sealing machine and its main job is to fuse or seal the top and bottom part of the back sealing pack.

Moving Wheel

The moving wheel is responsible for the portability and mobility of the powder back sealing machine by its rotation.

Stainless Steel Body

A stainless steel body is the favoured component in the powder back sealing machine because of its durability and resistance to corrosion. With a stainless steel body, it is easier to clean and maintain the machine.

6.Enumerate Industrial Uses of the Powder Back Sealing Machine.

The powder back sealing machine is seen in different industries, as numerous industrial sectors have integrated this machine into their production line. Some common industrial uses of this machine are:

Food Industry

Use of Powder Back Sealing Machine in the Food Industry

The powder back sealing machine has gained quite traction in the food industry because of its job of making aesthetically pleasing food stick packs in a short period. It packs different kinds of spices and chilli powders in the stick packs. It also loads cocoa powder, baking soda, sugar, salt, and yeast in the back sealing packs.

Beverage Industry

Use of Powder Back Sealing Machine in the Beverage Industry- Picture Courtesy: kenparkmdpllc.com

In the beverage industry, powder back sealing machine is utilized for its consistency and accuracy. It ensures homogeneity in the product loading and increases the packaging quality in turn leading to customer satisfaction. It packs different kinds of teas, instant coffee, and juice mixes in the back sealing packs.

Dairy Industry

Use of Powder Back Sealing Machine in the Dairy Industry- Picture Courtesy: Dribbble

The importance of the powder back sealing machine in the dairy industry is increasing day by day. This machine holds a special place in the dairy industry because of its streamlined packaging. By integrating this machine, dairy industries experience a significant increase in profit margins. This machine is utilized for packaging dairy and non-dairy products like powdered milk, and baby milk powder in the dairy industry.

Pharmaceutical Industry

Pharmaceutical Stick Packs- Picture Courtesy: Aranow

Different kinds of pharmaceutical powders like antibiotics, gastric powders, and UTI powders are loaded in the back sealing packs by the powder back sealing machine. It offers stricter hygienic processing by reducing the necessity of human intervention.

Nutraceutical Industry

Use of Powder Back Sealing Machine in the Nutraceutical Industry- Picture Courtesy: cen-mp.org

In the nutraceutical industry, this equipment is employed for the packaging of single-dose health supplement powders like protein powders, probiotics, vitamin powders as well as dietary fibres in the powdered form. Precision is the key aspect of the powder back sealing machine in the nutraceutical industry.

Chemical Industry

Use of Powder Back Sealing Machine in the Chemical Industry

Powder back sealing machine has many utilities in the chemical industry. This machine dispenses different kinds of chemicals like industrial chemicals, dyes, pigments, and laundry powders into the back sealing packs.

Cosmetic Industry

Use of Powder Back Sealing Machine in the Cosmetic Industry: Picture Courtesy: AIPAK

In the cosmetic industry, this machine is utilized for its versatility and flexibility. Packaging outlook is very important in the cosmetic industry so the powder back sealing machine creates beautiful packs for talcum powders, face powders, bathing salt, and dry shampoos.

7.What Types of Powder Does Powder Back Sealing Machine Process?

The powder back sealing machine processes two main types of powders which are:

Non-free Flowing Powders

Non-free Flowing Powder

These powders have hindrances in their flow and they clump together. Thus, they cannot move freely. These powders have irregular shapes which is the main reason for clumping. Also, these ingredients absorb moisture or have ingredients like molasses and oil which clump and stick their particles together. The non-free flowing powders filled by the powder back sealing machine are brown sugar, milk powder, cocoa powder, and many more.

Free-flowing Powders

Free-flowing Powders

These powders do not stick or clump together, consequently moving freely in the powder back sealing machine, leading to accurate dispensing. Examples of free-flowing powders loaded by the powder back sealing machine are table salt, white sugar, detergent, etc.

8.Does the Powder Back Sealing Machine Have a Dust Collection Device?

Dust Collection Device in Powder Back Sealing Machine

Yes, some variants of the powder back sealing machine may have an integrated dust collection device that comes in handy while filling dusty or fine powders. These dust collection devices have a suction fan that sucks the dusty particles of the powders as they are being loaded.

These dust collection devices are composed of enclosed hoods that catch the airborne dust particles and remove them from the system. Dust collection devices are important for the cleanliness of the environment and the health and safety of all operators.

9.What Types of Sealing Does a Powder Back Sealing Machine Offer?

The powder back sealing machine seals different packaging containers to preserve product integrity and prevent product leakage. There are different types of sealing offered by the powder back sealing machine such as:

Heat Sealing

Heat Sealing- Picture Courtesy: Behance

It is the main type of sealing present in the powder back sealing machine. In this sealing, high temperatures melt and join two layers of the packaging film. It creates tough and reliable seals and is suitable for various packaging materials.

Ultrasonic Sealing

Ultrasonic Seal- Picture Courtesy: Behance

In this sealing, high-energy ultrasonic vibration creates a frictional force that melts the packaging film. It has minimal thermal impact and is widely popular for heat-sensitive powders and materials.

Impulse Sealing

Impulse Sealing- Picture Courtesy: Behance

Heat in the impulse sealing is generated by a short impulse of electrical energy. This heat melts the film material. Impulse sealing offers precise temperature control and creates strong seals.

10.What are the Seal Integrity Tests for the Powder Back Sealing Machine?

Seal Integrity Tests

The seal integrity tests are important for the powder back sealing machine to ensure a tough and reliable seal. These seal integrity tests detect incomplete seals or other defects in the seal. These tests also identify leakage points in the seal. Some common seal integrity tests are:

| Visual Inspection Test | In this test, the seals are examined visually to see any wrinkles, marks, consistent seal lines, and gaps in the seals. |

| Burst Test | The burst test is the application of pressure or compression force to the seal till it pops open. The pressure at which the seal bursts is measured. Strong seals are tolerant to high internal pressures. |

| Peel Test | The force required to break or pull apart the seal is measured in the peel test. A strong seal can withstand high peeling force. |

| Vacuum Decay Test | The back sealing packaging container is placed in the water tank under the vacuum condition. If no air bubbles are rising from the package, it means that there is no leak in the packaging. |

| Dye Penetration Test | A dye is applied to one end of the seal if it moves towards the other end, it means that there is leakage in the seal. |

11.What are the Technical Faults in the Powder Back Sealing Machine? How to Overcome Them?

A powder back sealing machine can encounter some serious technical faults, consequently affecting the productivity and efficiency of the system. If these problems are identified timely then it could decrease productivity loss and prevent serious accidents. Some typical technical faults and their rectification are:

| Image | Cause | Rectification |

| Failure in Film Tracking | ||

Failure in Film Tracking |

Faulty film alignment.

Film guide rollers are not used. Defective sensors and control systems cause incorrect film alignment. |

Check and fix the film alignment systems to ascertain the film is going in a straight line through the equipment.

Employ film guide rollers for proper tracking. Change the defective sensors and the control systems. |

| Product Spillage | ||

Product Spillage |

Overfilling of the back sealing packs.

Incorrect handling of the powders. |

Fix the dosing systems to ascertain the right quantity of the product is loaded in the packaging containers.

Train the workforce on correctly handling the powders to decrease the spillage rate during packaging, |

| Variation in Bag Length | ||

Variation in Bag Length |

Variation in the film tracking components.

Blunt cutting knives Out of synchronization cutting blades and film feed. |

Calibrate the film tracking mechanism to ascertain uniformity in the film feed.

Sharpen the cutting knives. Ensure there is synchronicity between cutting blades and film feed. |

| Gaps in the Seals | ||

Gaps in the Seal- Picture Courtesy: Allied Pharma Technologies Ltd |

Defective or dirty sealing jaws.

Misalignment of sealing jaws. Inconsistent seal time, pressure, or temperature |

Repair and clean the sealing jaws

Align the sealing jaws so that they are in line with the film. Increase sealing time, pressure, and temperature. |

| Film Adhere to Sealing Jaws | ||

Film Adhere to Sealing Jaws |

Dirty sealing jaws

Improper coating of the sealing jaws High temperature of sealing jaws |

Clean the sealing jaws.

Use appropriate coating for the sealing jaws Decrease the sealing temperature |

12.How To Purchase the Best Powder Back Sealing Machine for Production Plants?

When going out to purchase a powder back sealing machine, you encounter unfamiliar territory. This is because there are several machines available in the market, each having its special characteristics and features. These different options may overwhelm you. But do not worry, as we are giving some tips to resolve this challenging task.

Production Rate

Production Rate- Picture Courtesy: flexible packaging

The manufacturers first calculate the number of packs they are going to produce before buying the powder back sealing machine. Different variants have different output capacity that depends on the packaging speed and number of lanes present in the machine. So, it is essential to understand your production goal and then buy the machine that fulfils these needs.

Hopper Capacity

Hopper Capacity

Select the machine with a large hopper space because it will decrease the frequency of refilling. Hopper holding a sufficient amount of powders decreases the packing time and increases the packing efficiency.

Quality Requirement

Quality Requirement- Picture Courtesy: Wise IT

Quality is the main factor when it comes to purchasing the powder back sealing machine. So, you must buy a machine that fulfils all the regulatory standards. Compliance with regulatory guidelines is a mark of the quality of the equipment.

Technology and Automation

Technology and Automation- Picture Courtesy: Wevolver

New and latest powder back sealing machines are coming into the market due to improvements in technology and automation. Select that machine with improved and user-friendly controls as it will increase the efficiency and uptime.

Budget

Budget

Your available budget impacts the type of machine you can buy. So compare and calculate your purchasing expense, maintenance fee, operational cost as well as the return on investment to know how much budget will you set aside for the purchase of a powder back sealing machine.

Conclusion

In conclusion, a powder back sealing machine is an efficient unit processing both free and non-free-flowing powders. It is typically seen in industries where powders are packed in back-sealing packs. This modern machine is undoubtedly the requirement of every powder packaging line. If you did not invest in the powder back sealing machine then you cannot gain the edge over your competitors. Do consider investing in this machine of the year as it will accelerate your business growth. If you are convinced to buy this equipment then reach out to Allpack, where the best professionals will aid you in your decision making.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours