Plastic Gauge Thickness

The crinkling sound that resonates in your hearing coming from any plastic packaging you handle might oftentimes please you.

Perhaps the word ‘plastic’ itself sounds so fascinating as it engulfs wide aspects of processes owing to it’s flexibility and versatility. There is a certain unit which measures thickness criteria for regulation and compliance of any plastic based product.

Plastic gauge thickness will be the term that would be elaborated and explained in accordance of it’s significance and conversion parameters. Continue further to read this blog that would give you thorough knowledge of what you should know about plastic gauge thickness.

1.What Is Plastic Gauge Thickness?

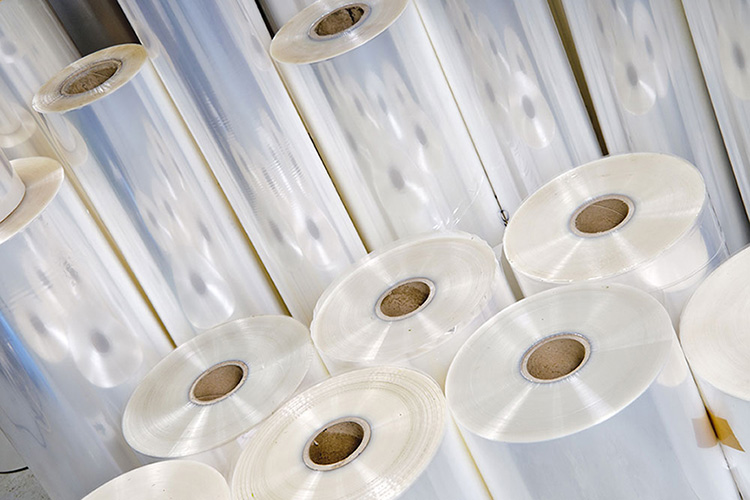

Plastic Gauge Thickness

Fundamental to the wide plastic industries is the measurement of plastic film or sheet’s thickness, which is the basis for deciding in which form of material and for what purpose the plastic would be required and shaped.

This plastic thickness is usually calculated in units called ‘gauge’ or ‘mil’ which is equivalent to thousandth part of an inch. An immense importance is held by the chart that contains different values in many units such as millimeters, microns, gauge and inches that helps you to convert and decide on the standard you choose.

The width of the gauge that you decide plays a role in resilience, reliability and appropriateness of the plastic material. Typically, the higher the number of gauge/millimeters/ microns, the thicker and sturdier your plastic type will be.

2.What Is the Significance of Plastic Gauge Thickness?

Plastic Gauge Thickness Significance – Picture courtesy: Interplas Insights

Plastic Gauge thickness is a crucial and paramount factor that must be looked upon before deciding plastic thickness.

Firstly, because many industries need assurance confirming standard of their desired thickness for their plastic gauge products as slightest deviation might be of severe consequences concerning safety guidelines and functionality. Listed for you below are some industries to help you understand it’s significance:

In packaging industry plastic gauge thickness can deduce for you whether you want a robust or lightweight packaging for your content.

In construction industry, is the best plastic gauge thickness is crucial as it makes barriers, roofing and insulation. This will decide how will be the material’s ability to withstand environmental conditions.

Automotive industries have to maintain accurate structural conformity of their parts such as exterior body panels in accordance with right gauge thickness.

Electronics sector requiring appropriate thickness of plastic for their insulation , circuits and various components to function properly

Medical industry utilizes plastic gauge thickness in selection for their disposable medical devices, sterilization and packaging materials. It is therefore necessary to ensure safety and efficiency.

Measuring thickness of any product is a criterion for assessing quality control. Since plastic gauge products need inspection of their quality to verify that it meets predetermined specifications .

Maintenance and proper understanding of units of plastic gauge thickness according to what needed leads companies to reduce cost and decrease waste therefore improving environmental impact.

To avail greater implications of plastic gauge thickness, it is vital for you to ensure that the material meets standards and the choice of selecting it's measurement techniques relates with specific requirement of applications.

3.How Can Plastic Gauge Thickness Be Measured By Various Techniques?

Plastic Gauge thickness is a physical property that needs a specific tool to measure it. There are various techniques that would help assure material quality and conformity to specifications.

MEASURING PLASTIC THICKNESS USING TOOLS & TECHNIQUES

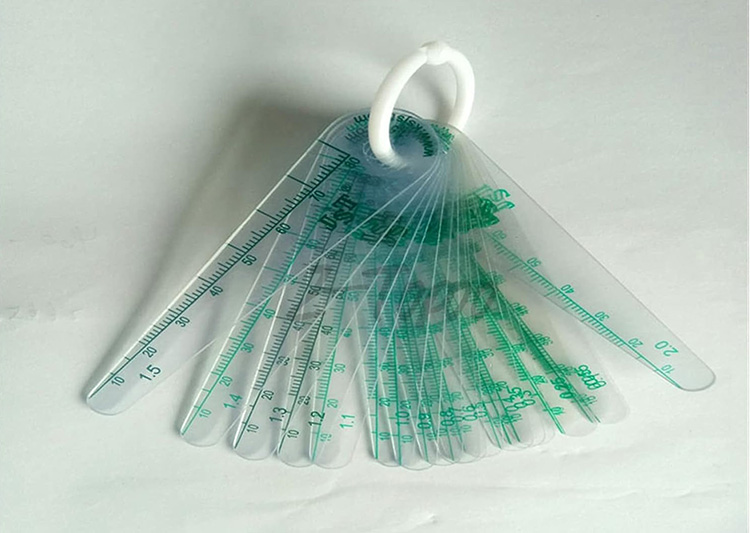

| Calipers

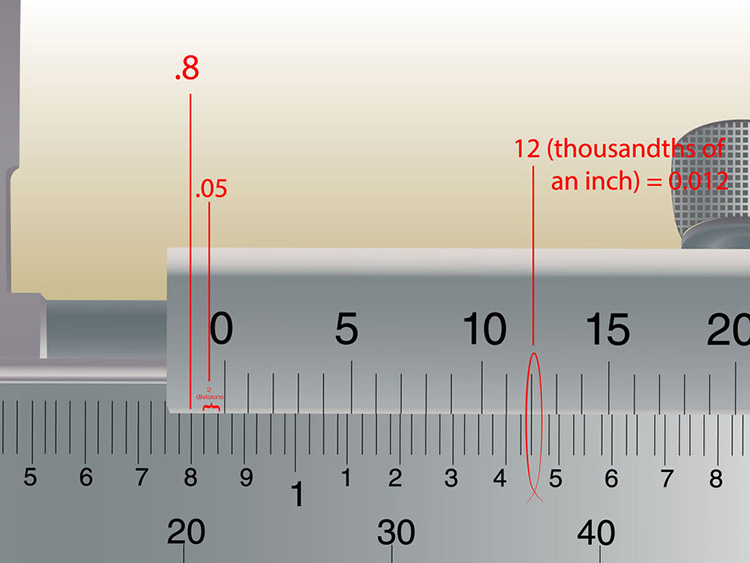

This hand held tool comes in two types of calipers that can measure plastic sheet’s thickness by either contact or non-contact plastic film calipers. Contact gauging is same like using a micrometer which easily measures thickness of plastic film , while non-contact gauging precisely gives quick reading of thin plastic. |

|

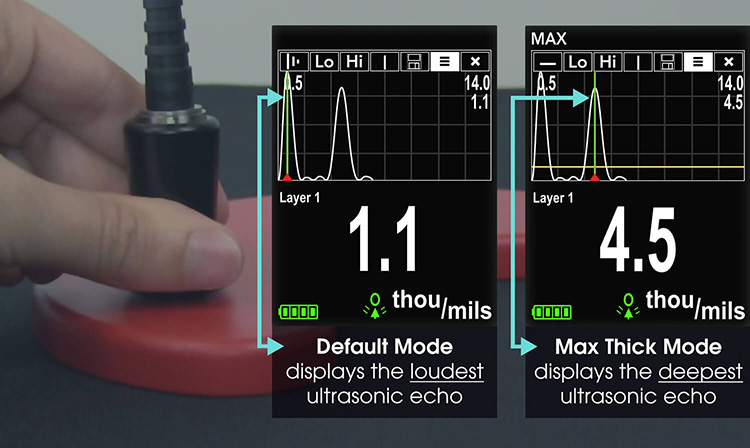

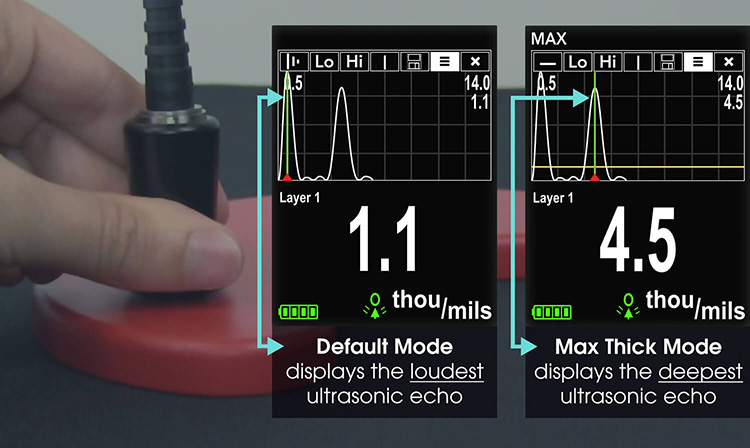

| Ultrasonic Thickness Gauge

Ultrasonic gauge measures thickness of any shape of plastic including that of complex shapes using sound waves. |

|

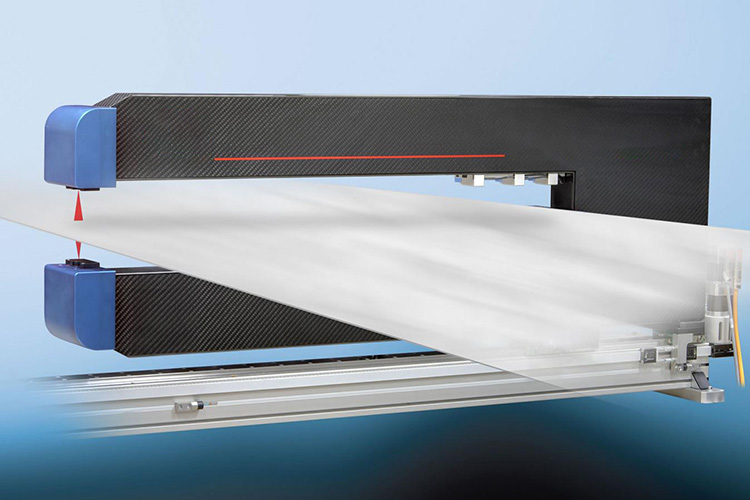

| Laser Sensors They measure thickness and distance with high precision using laser beam. Laser sensors are of due importance in industries such as electronics and optics. |

|

MEASURING PLASTIC THICKNESS USING DESTRUCTIVE OR NON-DESTRUCTIVE METHODS

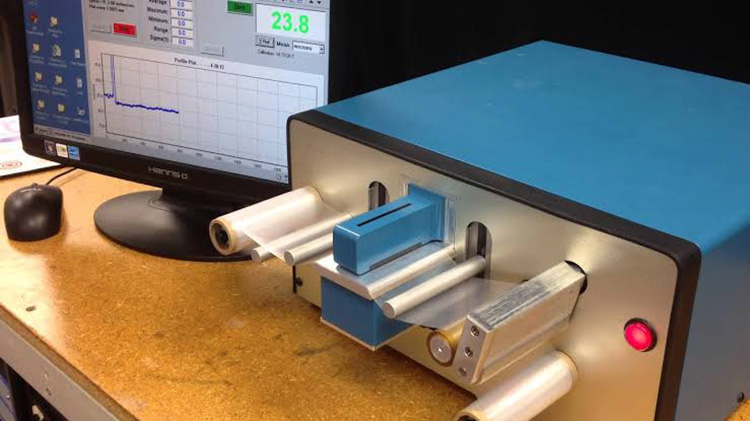

Techniques To Measure Plastic Gauge Thickness – Picture courtesy: SolveTech Thickness Gauge

| Destructive methods

Destructive methods involves physically changing thickness of plastic or removal of certain material during the measurement. This can be explained by microtoming, which chops of the material into thin slices. This technique can be utilized where extremely precise measurements are wanted or when sample testing is done to check the material’s properties. |

|

| Non Destructive methods

This method is of generally no harm to the plastic product, and it is used where preserving material’s integrity is necessary too while measuring it’s thickness. Although this method has a limitation relative to measurement of very thin materials. Ultrasonic thickness gauge and laser sensors are such examples of non destructive methods of measuring plastic gauge thickness. |

|

4.What Are The Different Units Used For Measuring Plastic Gauge Thickness?

Various units used for measurement of plastic gauge thickness depends on its applications and the industries where the material is being used. However, the regional standard unit of measurement selected for manufacturing of plastics are also considered. Let’s see those units below:

| Micrometers

A micrometer (μm) unit is one millionth part of a meter, a metric unit that is applied for measuring thin plastic material. This unit is suitable for measurement of thin materials. Measurement in this unit is preferably rounded off to nearby whole number. |

|

| Millimeters

A millimeter (mm) is one thousandth part of a meter, a metric unit that is used to measure thicker material such as plastic thickness. |

|

| Mils

This is a regional standard unit that is widely used in America and also some other countries. One thousandth of an inch equals to one mil. Mil is frequently used to measure plastic gauge thickness. |

|

| Inches

Inches (In) are utilized by industries that need to make thicker plastic materials. |

|

| Gauges

In order to measure plastic gauge thickness, this is one of the most commonly used unit which can be denoted as mils or micrometers depending on the situation. Gauge is employed for thicknesses that are below 1 Mil. |

|

PLASTIC GAUGE THICKNESS CHART

Ranging from tough plastic sheets that is used by construction or a polycarbonate sheet employed for glazing, this chart aids professionals those who work with multitudinous plastic materials and need to deal with it’s thickness in different industries.

As you read above there are many units that are interchangeable and according to your preferences and selection of appropriate standard , plastic gauge thickness chart can be utilized to convert units from one to another easily. The chart below can be comprehensively adapted to be offering many guidelines for thin to thick and robust plastic gauge thickness.

| Gauge(Mils) | Thickness (microns) | Thickness (millimeters) | Thickness (inches) | Material |

| 1 | 25.4 | 0.0254 | 0.001 | Polyethylene plastic, lightweight plastic |

| 5 | 127 | 0.127 | 0.005 | Thin plastic film wraps |

| 10 | 254 | 0.254 | 0.01 | Plastic folders , cover |

| 20 | 508 | 0.508 | 0.02 | Thick plastic sheets |

| 30 | 762 | 0.762 | 0.03 | Heavy duty plastic sheets, tarps |

| 40 | 1016 | 1.016 | 0.04 | Hard plastic signs, industries |

| 45 | 1143 | 1.143 | 0.045 | Medium to thick plastic sheets |

| 50 | 1270 | 1.270 | 0.05 | Thick plastic sheets and films |

| 100 | 2540 | 2.540 | 0.10 | Tough plastic sheets for construction |

| 150 | 3810 | 3.810 | 0.15 | Thicker plastic film for industries |

| 200 | 5080 | 5.080 | 0.20 | Very thick plastic sheets and barriers |

In order to easily switch between units you must know this basic conversion scale that is listed below:

Mil= 1000 × inch

Micron= Mil × 25.4

Micron= Gauge × 0.254

Gauge= 100 × Mil

Gauge= Micron × 3.937

These formulas can be incorporated to use for selecting a certain plastic thickness specification.

5.What Are Some Factors That Can Lead To Inconsistent Measuring Plastic Gauge Thickness?

Measuring Plastic Gauge Thickness - Picture courtesy: MS Motorservice International

Inconsistent measurement of plastic gauge thickness may be due to several factors including:

User Efficiency: Operators that have experience and expertise in using measurement techniques and therefore precisely measuring is responsible for measurement consistency. Personnel unaware of training may lead to inadequate or error in measuring plastic gauge thickness.

Calibration Of Measuring Tools: It is mandatory to calibrate and check regularly the accuracy and precision of plastic gauge thickness measuring instruments so that it might not result in inaccurate readings.

Material Variations: Variability in type of material such as density and surface irregularities gives incorrect measurement . You must consider that if your plastic is going to endure stress it must be of such suitable thickness that can withstand the load.

Environmental Impact: Environmental conditions like moisture , temperature and ultraviolet radiation can affect plastic material’s conformation and thus lead to inaccurate measurement and variation in thickness. You would need a thicker plastic gauge for resisting such all situations.

Precise Sampling: Samples that are presented for measurement should be developed with focus and consistency to ensure correct results.

Conclusion

Mastering the art of choosing and selecting relatable technique and a standard unit for any of your materials will give you durable and high performance plastic gauge thickness. Whether gauge or mil, millimeters or micrometers, plastic gauge thickness chart will assist you to convert between units easily. Allpack has an experience of several years having welcoming and friendly expert staff at your service. Moreover, we have highly calibrated and reliable equipment that is available in many varieties that you can select as per your needs. Contact our given number or email us for any inquiries. Our team will be pleased to help you!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours