Piston Filling Machine: The Complete Buying Guide In 2025

Piston Filling Machine: The Complete Buying Guide In 2025

Number of industries that are engage in filling and packaging of liquid materials are busy in identifying simpler solutions that can ease their process work. Piston filling machine is one of the best solutions that accurately dispense liquids into containers. Piston filling machines are used for filling of both medium and high viscous materials.

But there is always confusion while selecting the best type of piston filling machine. Allpack is providing you a complete buying guide for choosing the right and best type of piston filling machine according to your necessity. So, read it and enjoy!

1. What Is A Piston Filling Machine?

Piston filling machines are the types of liquid filling machine that are used to fill cans, containers and bottles with liquid and paste type products. The machine works by using a piston or plunger that dispenses a specific volume of liquid into a container.

The piston moves forward and backwards, upward and downward inside the cylinder and draws liquid out from the supply tank. The dispensed liquid is then filled into the packaging material. Completely precise and controlled process takes place in a piston filling machine.

With advancement in technology now piston filling machines are mostly used in food, pharmaceutical, cosmetic and chemical industries where containers are filled with liquids and paste substances like creams, sauces, liquids and etc. Piston filling machine can efficiently fill containers of various sizes and shapes.

2. What Materials Can And Can Not Be Filled By A Piston Filling Machine?

Variety of materials and products can be filled using a piston filling machine. They can be divided according to the industry they are manufactured in.

Materials that can be filled using a piston filling machine

- Different Liquids

Honey, oil, juices, wine, syrups, vinegar, and other food products can be easily filled using a piston filling machine. Similarly, Eye and ear drops, liquid syrups and IV drips are few pharmaceutical and medical products that can be filled easily.

For cosmetic and chemical type of products like cream, gels, lotions, shampoos, lubricants, motor oil, solvents and adhesive products can be filled using a piston filling machine.

- Different Paste

Pastes with low, medium and high viscosity can be easily used to fill by a piston filling machine. These pastes include gel, sauces, lotions, creams, liquid soaps, peanut butter, toothpaste and etc.

Materials that cannot be filled using a piston filling machine

Some of the materials that cannot be filled using a piston filling machine are

- Flammable Liquids

The liquids that are highly flammable and combustible like alcohol, gasoline cannot be filled due to the safety measures of the machine.

- High Viscous Liquids

Other than that, high viscous liquids with large element particles cannot be filled by a piston filling machine. Products like liquid cement, concrete, gravel and construction materials cannot be filled due to their clogs. The filling can also damage the machine.

- High Corrosive Liquids

Lastly, highly corrosive or reactive liquids materials stand third in this list that cannot be filled using a piston filling machine.

3. What Are The Applications Of A Piston Filling Machine?

Piston filling machines are mostly applied for filling of variety of liquid and semi-liquid and paste products depending upon their viscosity. These machines are used for accurate filling of materials into different types of packaging shapes. Some of the specific applications of a piston filling machine are

- Food Industry

Piston filling machines are widely used to fill different types of food and beverages products like condiments, dressing, including sauces, honey, jams, syrups. Beverages like milk, juices, water and drinks are also filled using a piston filling machine.

Other than liquid products, food industry also uses a piston filling machine to fill specific paste products like peanut butter, toothpaste, tomato sauce, mayonnaise and etc.

- Pharmaceutical Industry

Various types of pharmaceutical and medical products that include liquid medications, syrups, ointments, creams, and lotions are easily filled using a piston filling machines.

Piston filling machines can also be used to fill and package personal care products that are mostly paste type in nature. These include liquid soaps, sanitizers and paste syrups that are commonly used by every person in the world.

- Cosmetics and Chemical Industry

Cosmetic industry also uses a piston filling machine for packaging of lotions, creams, shampoos, serums and gels whereas as chemical product like lubricants, paints, enamels, coatings, cleaners and solvents that are usually found in both liquid and paste form.

4. What Are The Features And Advantages Of A Piston Filling Machine?

Piston filling machines are highly useful and an advanced technology for filling of products and ease the work of any manufacturer. Some of the most common features and advantages that can be received using a piston filling machine are

Features Of A Piston Filling Machine

- Piston Pumps

One of the unique features of a piston filling machine is that it has piston pumps that are used to dispense precise amounts of liquid into containers. This allows the machine to resists any type of spillage of material.

- Filling Heads

Some piston filling machines also have multiple filling heads that are used to fill multiple containers at same time. This directly increases the productivity of any filling process and reduces machine filling time.

- Diving Nozzles

Driving nozzles are present in some of the piston filling machines that is used to fill containers starting from the bottom to the top. No content of air can be trapped in between of this filling of container that ensures complete weight and quantity. This also increases the life of material.

Advantages Of A Piston Filling Machine

- Versatility

Piston filling machines are used to fill wide range of liquid products that can be different with respect to their viscosities, particulate contents, densities and thickness. The machine remains versatile and suitable for filling process in numerous types of industries.

- Accuracy And Efficiency

Piston filling machines are highly accurate and precise when it comes to filling of containers. It releases consistent volume of product and ensuring that each container is consisting of same amount and unique identity.

Also, piston filling machines can fill containers at a high speed without leaving its efficiency.

- Adjustable Filling Volume

An important advantage of piston filling machines also exists that it can easily be adjusted at different volumes to fill containers of different sizes.

- Flexibility

Piston filling machines are easily adjusted to accommodate different container sizes and product types within its packaging process. This makes them suitable for use with a variety of products.

- Reduced Product Waste

The last advantage that can be gained using a piston filling machine is that its mechanism minimizes the amount of product that is wasted during the filling process. Greater cost of both material and machine loss can be reduced and saved using a piston filling machine.

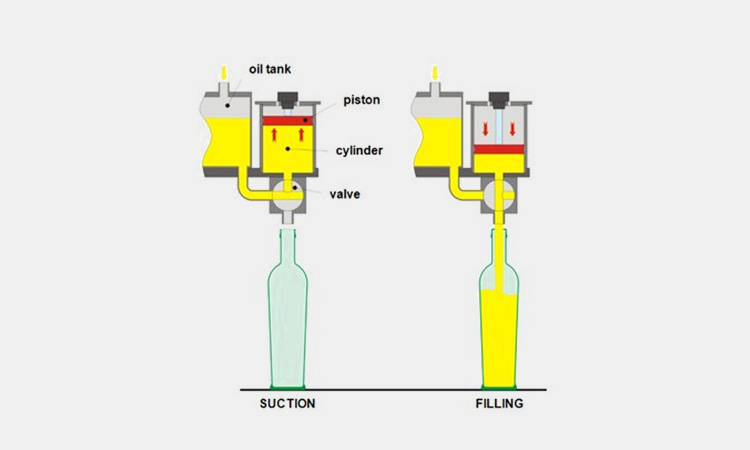

5. What Is The Working Principle Of Piston Filling Machine?

A piston filling machine follows simple operating principle that any individual can easily start filling containers using it. The steps for working of a piston filling machine are

- Initially the movement of a piston present in cylinder is checked properly that it flexibly moves up and down and dispenses accurate amount of liquid content.

- Once all the parameters of a piston filling machines are confirmed according to the standard, the filling products are filled in the hopper of filling containers.

- After that the operation of machine gets started. The operator feeds the container manually or automatically onto the conveyorand it moves to the feeding unit.

- As the product reaches the filling nozzle, the piston moves backward and creates vacuum. Simultaneously, the material is released from the container and reaches the inlet valve through proper filling system.

- This vacuum created due to the backward movement of piston draws product into the cylinder and discharges the material once it moves forward. The forward movement forces the product out of the cylinder.

- The specific amount of product is dispensed into the container by the movement of piston and through a proper filling nozzle.

- The process gets repeated for each container during the complete filling process.

6. What Are The Main Components Of A Piston Filling Machine?

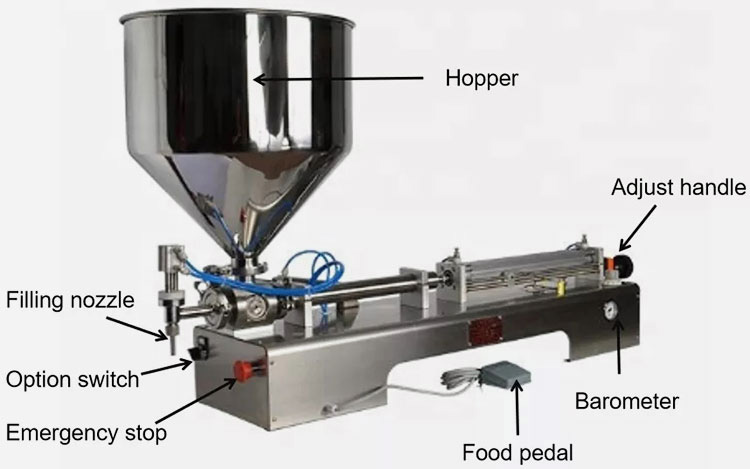

Components In A Semi-automatic Piston Filling Machine

- Barrel or Hopper

Hoppers or containers are present at the top of a manual piston filling machine from where the material is dispensed. These are mostly made up of stainless steel and due to this these machines have an ability to maintain the temperature of material that is present in it.

- Cylinder

Cylinder is the most important part of a piston filling machine as it contains the pistons that are housed inside it. They are of enough space that the piston can move up and down easily.

- Discharge or Filling Nozzle

Filling nozzle are the specialized components that dispenses the material out of the system and into the packaging material. Different types and shapes of filling nozzles are there according to the opening of containers, cans or bottles.

- Piston

Pistons made up of stainless steel or other durable materials are present in the cylinder of a piston filling machine that are used to create vacuum with the dispensing process. This then releases the material with its forward movement. Pistons ensure material safety and prohibit entrance of any type of air particle.

- Controlling Switches

Controls like foot switch, command switch, cylinder speed control and all other are also present in the structure of a manual piston machine.

Components In A Fully Automatic Piston Filling Machine

- Hopper or Material Tank

The hopper contains the product that needs to be filled into the containers. It has a capacity that can vary depending on the size of the machine and the production requirements.

- Filling nozzle

The filling nozzle is a tube-like structure that is used to dispense the product into the containers. It is designed to ensure that the product is dispensed in a precise and controlled manner. The nozzle can be customized to suit the product being filled and the container’s size and shape.

- Piston cylinder

The piston cylinder is a critical component of the filling machine that helps to control the product’s flow. It consists of a piston that moves back and forth inside the cylinder. The piston is driven by a pneumatic or hydraulic system that ensures a constant, controlled flow of product.

- Sensors

A piston filling machine is equipped with sensors that help to detect the presence of the container and signal the machine to begin the filling process. The sensors can also detect if there are any obstructions or faults in the system.

- Controlling Panel

A control panel is the main interface between the operator and the filling machine. It allows the operator to set the desired fill volume, speed, and other parameters. The panel also displays information about the machine’s performance, such as the number of containers filled and any errors or malfunctions.

- Conveyors

The movement of filling packaging product in a fully automatic piston filling machine is maintained by this conveying system. They transport it from the inlet to the system and then also taking out of the process.

7. What Types Of Piston Filling Machines Are There?

Different types of piston filling machines are there according to their usage and filling material type. Some of the types of piston filling machine commonly available are

Single Head Piston Filling Machine

As the name of machine, a single head piston filling machine only has one piston in the cylinder that is responsible for filling the material into the product. A single piston moves up and down in the cylinder and draws the material out into the cylinder. The material is then dispensed it into the container. These types of piston filling machines are suitable for filling products that are of low to medium flow rate and uniform viscosity.

Working Principle Of A Single Head Piston Filling Machine

- Initially the product is fed into a hopper that is connected to the cylinder.

- As the operation starts, the piston moves backward creating a vacuum that draws the product into the cylinder and returns back to the front with the filling material.

- The movement of piston remains continuous once the desired volume of product is reached and filling into the packaging material.

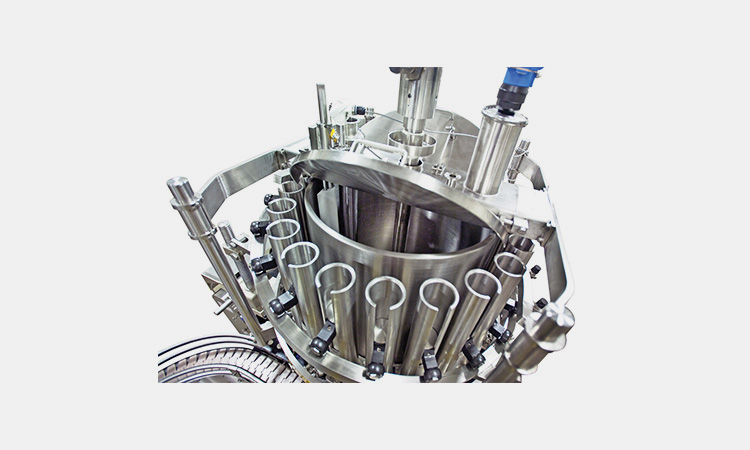

Double Head Piston Filling Machine

A double head piston filling machine is a type of piston filling machine that has two pistons in their respective cylinders. Both of the pistons work in tandem condition to fill the product in an efficient manner. Double piston filling machines are suitable for filling products that has both uniform and irregular viscosity and also materials that can manage high flow rate.

Working Principle Of A Double Head Piston Filling Machine

- Initially the material is fed into a hopper that is connected to two cylinders.

- After that the operation is turned on and the two pistons move in opposite directions drawing the product into the cylinder and then dispensing it into the container.

- Both of the pistons work in tandem, so while one piston is dispensing the product, the other piston is being filled with the product.

- This movement of pistons remains till the end of production.

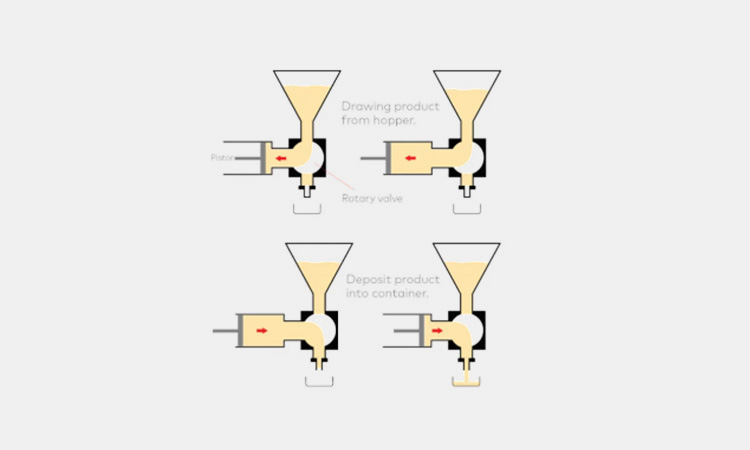

Rotary Piston Filling Machine

A rotary piston filling machine holds multiple pistons that are arranged in a circular pattern around the rotary valve. This type of filling machine are mostly found in food and chemical industries where materials are filled with high flow rate

Working Principle Of A Rotary Piston Filling Machine

- At first the filling material is fed into the hopper that is present at the top of the machine and connected is with the rotary valve.

- The piston moves in a circular motion when the operation gets started. This motion draws the product into the cylinder and then dispensing it into the container.

- The rotary valve controls the flow of the product to each piston, ensuring accurate filling.

8. What Are The Differences Between A Piston Filling Machine And Different Types Of Filling Machines?

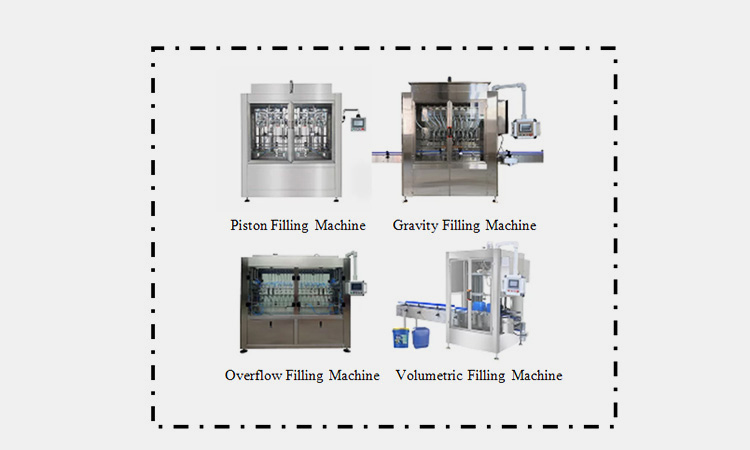

Like piston filling machine, there are also other solutions for filling of liquids and other materials. In this list volumetric filling machine, gravity filling machine and overflow filling machine are some of the most commonly used filling machines in the world. Some of the difference between piston filling machine and these other filling machine are

- Filling Method

A piston filling machine dispenses a precise volume of liquid by using a piston that moves back and forth inside a cylinder to draw in and dispense the liquid.

An overflow filling machine on the other hand, fills containers by submerging a nozzle into the liquid until it overflows, which creates a consistent fill level.

A gravity filling machine fills containers by allowing liquid to flow from a supply tank into the container through a filling nozzle, relying on gravity to create the flow.

Lastly, volumetric filling machine dispenses a precise volume of liquid by using a positive displacement pump, gear pump or rotary valve to dispense a fixed amount of liquid per revolution or stroke.

- Machine Accuracy

Piston filling machines are generally more accurate than overflow filling machines, since they can dispense a precise amount of liquid with each stroke of the piston.

Overflow filling machines rely on the level of liquid in the container and may not be as accurate.

Whereas, gravity filling machines relies on the level of liquid in the supply tank and may not be as accurate.

Like piston filling machine, volumetric filling machines are also of highly accuracy and can dispense a precise amount of liquid with each cycle or stroke.

- Filling Material

Piston filling machines can handle a wide range of liquids, from low to high viscosity, including liquids with particulates.

Overflow filling machines are better suited for low-viscosity liquids without particulates, such as water or thin oils.

On the other hand, both gravity and volumetric filling machines are better suited for low to medium viscosity liquids without particulates.

- Container Size

Piston filling machines can handle a wide range of container sizes, from small bottles to large containers.

Overflow filling machines are typically used for smaller containers and may not be suitable for larger containers.

Gravity and volumetric filling machines are not suitable for larger containers and fill only small to medium containers.

- Process Speed

Piston filling machines are generally faster than overflow filling machines since they can dispense a precise volume of liquid with each stroke of the piston.

Overflow filling machines may be slower since they rely on the level of liquid in the container to create a consistent fill level.

Gravity filling machines may be slower as they rely on the level of supplied liquid from tank to create a consistent flow.

Volumetric filling machines on the other hand depends on fixed amount of liquid per revolution or stroke and can be much slower than other filling machines.

9. What Are The Support Equipments That Are Associated With A Piston Filling Machine?

There are always support equipments that are attached with the piston filling machine and support its process. Some of the support equipments that are associated with a piston filling machine are

- Drip Trays

Drip trays are basically associated to collect all types of spillage or overflows that take place during the process of a piston filling machine.

- Agitator

Some of the piston filling machine includes agitator part in their hopper container to ensure proper mixing of liquid material and also to remove free air bubbles from the system. This component allows the filling material to remain pure for a longer period.

- Laser Inkjet

Some piston filling machines also use laser inkjets that efficiently prints the expiration and manufacturing dates on the bottles, containers or jars.

Conclusion

Varieties of filling systems are available these days but it is always difficult to select the best one for the required packaging and filling process. Allpack provides diverse collection of piston filling machines to its customer and is always there for better understanding. If still any query exists, you can directly contact our 24/7 customer service center or visit our website http://www.allpackchina.com/.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Piston Filling Machine: The Complete Buying Guide In 2025 Read More »