Pill Filling Machine: The Complete Buying Guide in 2025

Do you know Pill is the world most used solid dosage form needs specialized filling machine? A pill filling machine is an affordable and convenient machine carrying promising responsibilities of filling sensitive and general medications till you.

Stay on this page to know more about ‘pill filling machine’, we are here to help and described expert suggestions related to this machine. by the end of this blog, you will be able to know to select machine of your choice that can boost your filling production line. So Ready Steady Go!

1.What Is Pill?

Various Pill Formulation

A pill also called a tablet or capsule is a medicine that is administered as an oral dose. A pill is a small, solid dose of medication that you take by swallowing. It’s a simple interface to get medicine in the body. It consists of a mixture of the active substances and the excipients it contains. The active substances are usually in the form of a powder. The powder is then pressed or compressed into a solid dosage.

2.What Is Pill Filling Machine?

Allpack Pill Filling Machine

A pill filling machine is a type of equipment, to automate the process of filling pill or capsules for medication. The materials they fill with active pharmaceuticals ingredients include powder, pellets, tablets, granules, liquids, or various combinations. These machines can process a lot of pills; less manual labor is required which boosts productivity.

3.What Are Benefits Of Pill Filling Machine?

There are several benefits provided by pill filling machine to the pharmaceutical industry. Let’s discuss each benefit in more detail.

Increased production efficiency

Efficient Production

The process of pill filling or capsule is automated by the pill filling machine, which contributes to increased production speed. Compared to manual filling, these machines can fill a large number of pills in a shorter amount of time.

Accurate dosages

Dosage

Medication is dispensed precisely into each pill or capsule by filling machines. This lowers the possibility of under- or overdosing by ensuring that the dosage is accurate and consistent. Exact dosages are essential to the efficiency and security of pharmaceuticals.

Reduced risk of human error

Risk of Human Errors- Picture Courtesy: tablet & capsule

Human error in manual pill filling can lead to inconsistent filling and incorrect dosage. By automating the procedure, pill filling machine assist removing these mistakes. These lower the possibility of errors and guarantee the consistency and quality of the filled pill.

Time and labor savings

Time and Labor- Picture Courtesy: USA Today

Pharmaceutical companies can reduce labor expenses and save time by automating the pill filling process. The amount of pill that pill filling machines can handle decrease the need for manual labor. This increase worker productivity by enabling them to concentrate on other crucial responsibility.

Flexibility in Filling

Allpack Pill Filling Machine for Manufacturing

It is possible to program pill filling machine to fill various kinds and sizes of pills and capsules. This offers flexibility, enabling pharmaceutical companies to use a single machine to produce multiple medications. It streamlines the manufacturing procedure and eliminates the requirement for several machines to handle various pill sizes.

4.What Are Industrial Applications Of Pill Filling Machine?

Pill filling machines have many industrial uses, they aid in the precise and effective automation of the tablet, capsule, and pill filling process. Some of these applications are:

Pharmaceutical Industry

Pills or Capsules in Pharmaceutical Industry- Picture Courtesy: Science Friday

Pill filling machines are widely used in the pharmaceutical industry to fill tablets, capsules, and pellets on daily basis. A pill filling machine accelerates the large-scale filling process, guaranteeing a high degree of accuracy, correctness, and precision in the product volume dispensed.

The superior automation, high consistency, robustness, and dependability of pill filling machines ultimately help to achieve specific production goals and meet the demands of pharmaceuticals industry.

Nutraceutical Industry

Pills or Tablets in Neutraceutical Industry

Pill filling machines are used in nutraceutical industry to fill capsules or tablets with different kind of dietary supplements, vitamins, and herbal products. The pill filling machine guarantees accurate dosage and constant quality which improves production efficiency.

Agriculture Industry

Agriculture Industry

The producers of growth promoting bio-stimulants for the agriculture sector are continuously making progress, whether it is through the production of tablets, capsules, or small pellets. These products are preferred by many agricultural businesses because they facilitate cell division, growth promotion, and the rapid development of crops.

Chemical Industry

Pills in Chemical Industry- Picture Courtesy: Valley news live

Pill filling machine have the widest range of uses in chemical industry. There are many hazardous conditions as you manufacture, fill, and package chemical goods. When it comes to observing and filling chemical products, pill filling machines are vital and protective.

Veterinary Industry

Pill or Tablets in Veterinary Industry- Picture Courtesy: Crossroadsanimalhospital

The veterinary industry frequently uses pill filling machine to dispense oral medication at high-level which are used to treat the conditions in animals.

Cosmetic Industry

Pharmaceuticals & Cosmetics- Picture Courtesy: Antonpaar

Pill containing powder, oil, and other cosmetic formulation can be filled with the help of pill filling machine. This insures concise of the cosmetic products and helps to expedite the manufacturing process.

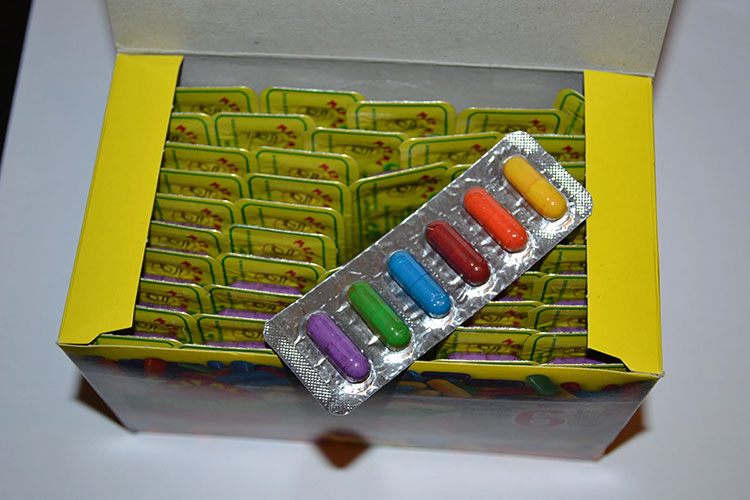

Food Industry

Egg Colors in Capsules- Picture Courtesy: Eatingrules

The pill filling machine promises an intelligent and timely reaction wether it has to do with filling capsules or big or small tablets. A pill filling machine is the ideal tool for filling pulses, almonds, coffee beans, chocolate beans, and other food items.

5.What Are Types Of Pill Filling Machine?

The industries require different kinds of pill fillers, so different kind of pill filler machines are available in the market. Three major categories can be used classify pill filler.

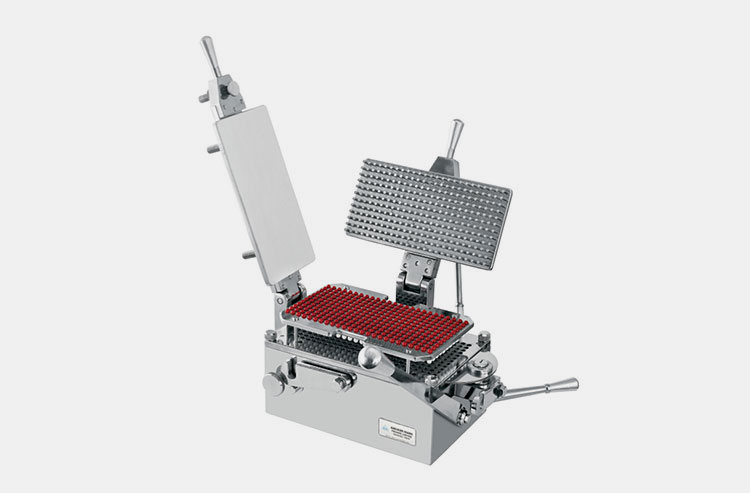

Manual Pill Filling Machine

Manual Pill Filling Machine- Picture Courtesy: Anchormark

A manual pill filling machine is a kind that needs to be operated by hand in order to fill tablets or capsules. It is made up of a tray or platform on which the tablets and capsules are left empty. The user then uses handheld tool or machine to manually fill the capsules or tablets with the required amount of ingredients.

A pill filling machine can be useful for small-scale production or for people who prefer a hand-on approach; even though it might take longer time then automated machines.

Semi-Automated Pill Filling Machine

Allpack Semi-Automated Pill Filling Machine

A Semi-automated or hybrid pill filling machine combines both manual and automatic components. The semi-automated pill filling machine requires fewer efforts from the operator. Its design allows it to automatically fill and rearrange the capsule cap in accordance with preprogramed computer code, so long as the apparatus complies with the industry’s stringent hygienic standards.

It can be configured for manual operations to generate a restricted number of capsules. The semi-automated pill filling machine is sturdy build and practical design make it extremely long lasting and low-maintenance piece of machinery for pharmaceutical industry.

Automated Pill Filling Machine

Allpack Automatic Pill Filling Machine

Automatic pill filling machine is made and designed to fill the required pharmaceutical ingredients into the capsules either automatically or directly without the need of operator or external command. These machines follow commands entered into them and are programmed by the computer.

The pharmaceutical industry uses this automatic pill filling machines primarily for large-scale capsule production. Pill filler are capable of efficiently packing fine or powder into the capsule body.

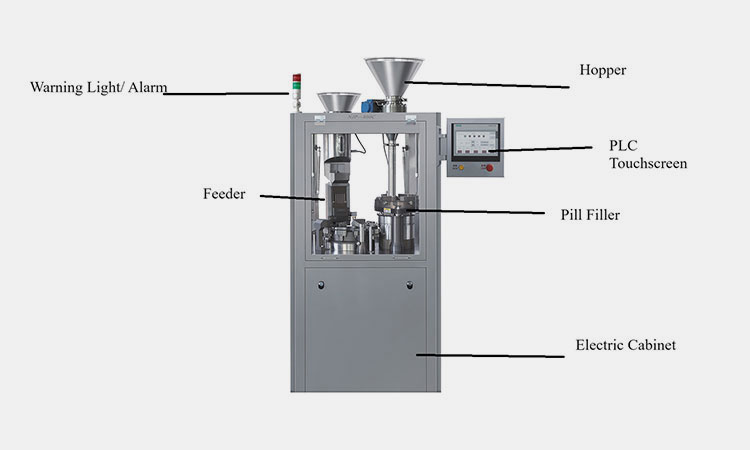

6.What are the parts of pill filling machine?

Allpack Parts of Pill Filling Machine

In a pill filling machine, there are several key parts that work together to facilitate the filling process. Some of the main parts include:

Hopper

This is the container that holds the content of the pill and filling content. It contains the majority of the ingredients that are going to be put into the pill.

PLC Touschreen

PLC is a computer program that allows the operator to control the machine by touching the touch screen interface. Operators enter commands, change settings, and track the machine’s performance by touching the screen.

Warning Light/ Alarm

This sensor or part in the pill filling machine uses light to detect the presence of pills. This ensures that the pills are accurately counted and placed in the proper container. The photoelectric eye is an important part of the pill filling machine. It assists in the detection and regulation of the filling procedure.

Feeder

Pills are offered to the machine by the help of feeder. This unit helps in the opening of the pills in rotary die.

Pill Filler

An optimized amount of drugs is filled in pill filler. Once it is filled it is now set to closing again.

Electric Cabinet

Electrical components are constructed in an enclosed box for user’s safety. It includes wires, plugs, etc to run process.

7.Is pill filling machine can cause cross-contamination?

Cross-Contamination in Pills- Picture Courtesy: Crotraining

No, the machine body is made up of stainless steel and carefully constructed to control chances of cross-contamination but if appropriate maintenance and cleaning procedure are not followed it may leads to cross- contamination. To avoid contamination or ingredient mixing, it’s crucial to make sure the machine is completely cleaned in between the batches or types of pills. The risk of cross contamination in pill filling machine must be reduced by routine cleaning and adherence to good manufacturing practice.

8.What Product can be filled by Pill Filling Machine?

Product Filling in Capsules- Picture Courtesy: Pharmaapproach

The main purpose of pill filling machine is to fill different kind of pills or capsules. A large variety of pharmaceutical products can be processed by these machines, which includes:

Solid Oral Medications:This includes tablets, caplets, capsules, and soft gelatin capsules.

Granules:Certain medications are formulated as granules, and pill filling machines can fill them into capsules or sachets.

Pellets:These are small, spherical medication forms. Pill filling machines can accurately fill pellets into capsules or other appropriate containers.

9.What are Problems and Solution of Pill Filling Machine?

When it comes to pill filling machines, there can be various problems that may arise during operation.

Some common issues include:

Filling error- picture Courtesy: Berxi

Inconsistent Filling: This occurs when the machine does not dispense the correct amount of medication into each pill or capsule. It can be caused by factors like improper calibration or worn-out parts.

Solution: Provide operators with thorough training on how to use and maintain the pill filling machine correctly. This helps prevent errors and ensures smooth operation and avoid inconsisties.

Capsule Jamming

Jamming: Jamming happens when pills or capsules get stuck in the machine, leading to a halt in the filling process. This can occur due to issues with the feeding mechanism or incorrect alignment.

Solution: Slow the filling speed. Calibrate the machine. check type and shapes of pills being subjected to the machine.

Contamination problem- Picture Courtesy: Safecor

Contamination: Contamination can occur if the machine and its components are not properly cleaned and sanitized. It can lead to compromised product quality and safety.

Solution: Follow proper cleaning and sanitization protocols to prevent contamination. Use approved cleaning agents and regularly clean all contact surfaces.

10.What are the Top Manufacturers Companies of Pill Filling Machine?

Manufacturers- Picture Courtesy: Sgs

There are several top manufacturers of pill filling machines known for their quality and reliability. Some prominent companies in this industry include:

- Bosch Packaging Technology

- IMA Group

- MG America

- Romaco Group

- Allpack

- Marchesini Group

- Uhlmann Group

- Körber Medipak Systems

- CAM Packaging Machines

- ACG Worldwide

These companies offer a range of pill filling machines with various features and capabilities to meet different production needs. It's always recommended to research and compare different manufacturers to find the one that best suits your requirements.

11.What Factor Should be Considered when Purchasing Pill Filling Machine?

When purchasing a pill filling machine, there are several factors to consider:

Pill Fill Production Requirements

Production Capacity:Determine the desired production output and choose a machine that can meet your volume requirements.

Look for a machine that can consistently fill pills with the correct dosage to ensure product quality and safety.

High Flexible Output- Picture Courtesy: Depositphoto

Flexibility:Consider the machine's ability to handle different types and sizes of pills, as well as the ease of adjusting settings for different production needs.

Opt for a machine that is user-friendly and has intuitive controls, reducing the learning curve for operators.

Pill filling machine compliance with international standards- Picture Courtesy:Fierce Biotech

Compliance with Regulations:Ensure that the machine complies with relevant regulatory standards and guidelines for pharmaceutical manufacturing.

Allpack cost effective pill filling machine

Cost:Consider the initial investment cost, as well as any additional costs for installation, training, maintenance, and ongoing operational expenses.

Research the manufacturer's reputation and read reviews from other customers to gauge their experience with the machine.

Conclusion

When it comes to purchasing a pill filling machine, it's important to carefully consider factors such as production capacity, accuracy, flexibility, ease of use, maintenance and support, compliance with regulations, cost, and the manufacturer's reputation. By taking these steps in mind, you can make a well-informed decision and find a pill filling machine that meets your specific needs. For any queries or purchase please feel free to contact Allpack team right now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide