Pet Food Packaging Equipment: The Complete FAQ Guide In 2025

Do you have any idea that pet food has become a vital part of current society? Pets are becoming like family members. The need for fine quality and healthful pet food is surprisingly increasing day by day.

To preserve the nutritious value of pet food, good packaging is required. Different kinds of materials are used to package pet foods. Pet food packaging obligates for an efficient equipment to assure the safety and quality of pet food.

Pets Are Becoming Like Family Member-Picture Courtesy: KSL NewsRadio

Do you have any idea that pet food has become a vital part of current society? Pets are becoming like family members. The need for fine quality and healthful pet food is surprisingly increasing day by day.

To preserve the nutritious value of pet food, good packaging is required. Different kinds of materials are used to package pet foods. Pet food packaging obligates for an efficient equipment to assure the safety and quality of pet food.

Either you are a small-scale manufacturer or large scale producer, choosing suitable packaging equipment will have a long term impact on your production. This will assure you a high quality product that meets mandatory standards.

This guide offers answers to all commonly asked questions about pet food packaging equipment to help you make well informed decisions.

Either you are a small-scale manufacturer or large scale producer, choosing suitable packaging equipment will have a long term impact on your production. This will assure you a high quality product that meets mandatory standards.

This guide offers answers to all commonly asked questions about pet food packaging equipment to help you make well informed decisions.

1.What do you know about pet food packaging equipment?

Premium Quality Pet Food-Picture Courtesy: Printpack

Pet food packaging equipment is specialized machinery planned to package pet food items with care and effectiveness. These machines hold a diversity of packaging arrangements like pouches, bags, cans and containers while establishing the product originality, purity and durability.

There is no doubt that pet food industry is achieving vigorous growth now days. Pet owners demand premium quality of pet food for their pets. A good packaging guarantees the stability and originality of food product. High quality packaging equipment has become crucial to get desirable pet food packaging.

2.What are the benefits of pet food packaging equipment?

Unique Style Pet Food Packaging-Picture Courtesy: Lovely Package

Pet food packaging equipment ensures good quality and safety of pet food, which is demanded by both manufacturer and pet owners.

Investing in efficiently working equipment has a long term impact on pet food industry and this could increase the growth to many folds. There are several benefits of pet food packaging equipment, stated below:

Efficient production:

A Range Of High Quality Pet Food-Picture Courtesy: Cats.Com

Pet food packing equipment offers established production with high speed and profound quality. This equipment has low labor cost with high productivity rate. It also assures the reduce chances of human errors.

Increased product safety and hygiene:

Air-Tight Pet Food Packaging

Pet food packaging equipment establishes remarkable safety and hygiene of pet food product. It prevents contamination caused by human contact, physical and chemical reactions. It provides air-tight and tamper-proofed packaging. Due to this property, the furnished product possesses increased durability.

Uniform quality:

Accurately Sealed And Labeled Pet Food-Picture Courtesy: DJANGO

Pet food packaging equipment ensures uniform quality of pet food. It packages pet food with great accuracy of amount and then sealed and labelled it according to mandatory standards.

Cost effective:

Low Cost, Biodegradable Pet Food Packaging-Picture Courtesy: Wolfworthy.Co.Uk

Pet food packaging equipment carries out operation efficiently. This result in low expenditure, reduce waste production but high productivity.

Versatility:

Dehydrated Pet Food-Picture Courtesy: The Honest Kitchen

Pet food packaging equipment has profound versatility inside it. It can holds different kinds of packaging like bags, pouches, cans etc. It packages various pet food sizes and formats such as wet, dry, treats etc. with precision.

Sustainability:

Nature-Friendly Pet Food Packaging-Picture Courtesy: City Dog Expert

Pet food packaging equipment offers sustainable pet food products. This promotes nature-friendly practices. Recyclable and biodegradable pet food packaging material is used by equipment. Precise measuring and sealing also serves as an addition in sustainability of equipment.

Submission with industry regulations:

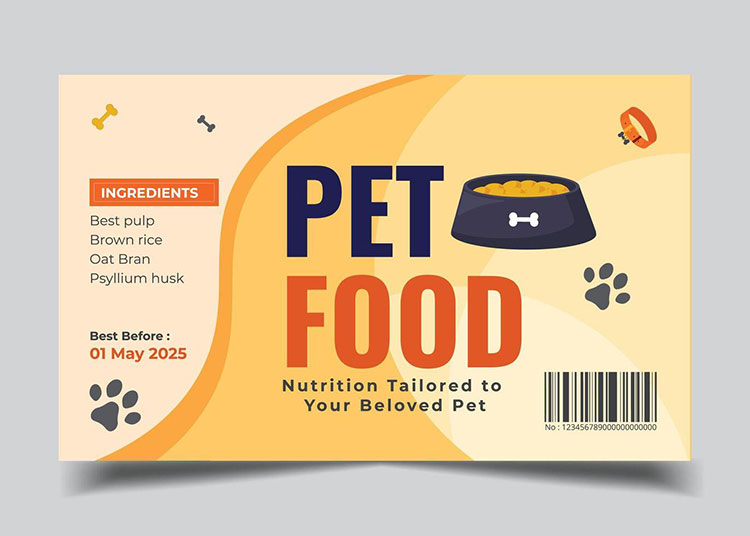

Pet Food Label-Picture Courtesy: Vecteezy

Pet food packaging equipment secures that the packaging must be similar to the industry safety standards. It delivers complete nutritional information, expiry date and barcode by well-aimed labeling.

Easy to handle and maintain:

Easy To Handle And Maintain-Picture Courtesy: Training Tale, NRTC Automation

To your surprise, despite of giving so much efficiency in every step of packaging, pet food packaging equipment is very easy to handle and maintain. It is user-friendly, has touch screen interfaces, automated controls for elementary operation. Pre-programmed system permits rapid adjustments for various packaging types. Basic training is required to operate the equipment.

This equipment is constructed with stainless steel. It causes less chemical reaction between pet food and stainless steel and maintains quality of product.

3.What kind of packaging can be used by pet food packaging equipment?

Different Kinds Of Packaging Material-Picture Courtesy: City Of Oklahoma City

Different kinds of packaging can be used pet food packaging equipment. The consumption depends upon product needs and characteristics. Types of packaging are further classified according to format and material.

Pouch:

| Type of pouch | Appearance | Information |

| Stand-up pouch: |

Picture Courtesy: Vista Print.ie |

It possesses a level base design with edged at the top. The flat bottom of pouch allows it to stand upright on stock shelves. It offers top quality custom printing for visibility of brand. It is flexible packaging, widely consumed to package dry and wet pet food due to usefulness and durability. |

| Quad-seal pouch |

Picture Courtesy: Law Print & Packaging |

It contains four vertical seals (one on each corner), which shaped it like a box. This helps to hold greater amount of dry pet food like kibble, treats and rigid structure aids to take less place on shelves. It is counted as premium flexible packaging due to its high stability and sturdiness. It offers wide front and side panels for top quality branding. |

| Flat-bottom pouch: |

Picture Courtesy: Pet Food Packaging |

It counts as best choice for keeping greater amount of pet food as it possesses great space at the bottom. It owns five sides that permit better display of brand details, which catches the attention of consumers |

| Side-gusset pouch: |

Picture Courtesy: Tripod Thai Packaging |

As the name shows, this type of pet food packaging consists of two folded sides. Upon filling, these side gussets swell and form a cylindrical shape. At the same time it does not has a level base so it cannot stand on stock shelves. This structure of pouch allows holding less amount of pet food due to restricted space. |

| Spout pouch: |

Picture Courtesy: Wiz Packaging |

This pouch has spout-like seal for convenience in drawing pet food. It is available with a cap, has the choice of resealing after use. It is consumed to package wet and semi-wet pet food such as gravies, curries etc. |

Carton boxes:

Carton Boxes Of Pet Food-Picture Courtesy: Vital Essentials

These are rectangular and square shaped and come into formation by utilizing cardboard or paperboard. Dry pet food items like biscuits, treats, small snacks are commonly packaged in carton boxes. These are used for huge packaging and also contain other pet food containers for the purpose of storage and shipment.

Cans:

Canned Pet Food-Picture Courtesy: Royal Canin Canada

These are formed from utilizing metals like aluminum and tin, which construct them sturdy and durable. Such containers are used for wet pet food like purees, curries etc.

Jars:

Pet Food Jars-Picture Courtesy: Human & Pet Human & Pets

These are cylindrical-shaped containers, commonly formed by sturdy plastic and glass. Less often glass is also used by manufacturers for premium quality packaging. Dry and wet pet foods are packed in them. These containers show greater product display because of being transparent.

Trays:

Pet Food Tray-Picture Courtesy: Encore Pet Food

These are formed by aluminum foil and are shallow in nature. These containers possess resealable closure so that it can be closed after consumption of food item. These are considered best to package single-sleeve or portion-control packaging.

4.What materials can be used by pet food packaging equipment?

A vast variety of material is used to pack pet food according to product needs and consumer’s demand. All materials carry their own pros and cons and are preferred on the basis of necessity.

Aluminum:

Aluminum Tray Used To Package Pet Food-Picture Courtesy: Constantia Flexible

This material is strong, rigid and adaptable metal, commonly used to form cans and foil pouches. This metal can keep wet or semi-wet pet food items like gravies etc. Aluminum offers a strong barrier against environmental factors.

Plastic:

Pet Food Packaging Made From Plastic-Picture Courtesy: Packaging Design Archive

Huge range of plastics such as PET, HDPE, LDPE and PP are utilized to create pet food packaging. HDPE and LDPE are mostly used to make bottles and jars. Transparent bags and flexible pouches are produced by using PET and LDPE. There are different properties of different plastics; however, they occasionally build air-tight and damp-proof packaging.

Glass:

Pet Food Jars-Picture Courtesy: Etsy

For the purpose of forming premium quality pet food packaging, glass is commonly used by manufacturers. Jars and bottles are produced by glass, which serve as a non-reactive and air-tight packaging for pet food. It also provides clear display of pet food.

Card board or paperboard:

Paper-Made Pet Food Packaging-Picture Courtesy: www.geise.com.do

Fold-able cartons or boxes are made from cardboard or paperboard. This type of material proves to be vigorous and durable and helps in printing tremendous vibrant graphics.

Laminates:

Laminated Packaging Of Pet Food-Picture Courtesy: Umaras

It is produced by multi-layered plastic or paper. This material counts as a vital part of flexible pet food packaging. It possesses many benefits including even and glossy finish, increase compactness and reluctant impenetrable barrier.

Compostable materials:

Sustainable Pet Food Packaging-Picture Courtesy: Fleetful

These materials are designed to cleave down in to natural things by the action of microorganism. Mostly paper is used to produce them. These are introduced to be consumed in place of plastic packaging material and serve as a nature-friendly material.

Biodegradable plastics:

Biodegradable Pet Food Packaging-Picture Courtesy: Scrumbles

This kind of plastic is comprised of combined layers of paper and bioplastic, which is derived from corn starch, seaweed and potato. This nature of product helps it to get decompose by the action of microorganism. This is used in place of plastic material and due to having eco-friendly characteristic; it is often utilized to make pet food pouches.

5.Whatare the types of pet food packaging equipment?

Automated pet food packaging equipment guarantees various advantages that includes high efficiency, cost effectiveness and enhanced product quality. There is various kind of pet food packaging equipment. The type of pet food and preferable packaging method defines the choice of equipment.

Vertical form-fill and seal (VFFS) machine:

Vertical Form Fill And Seal Machine-Picture Courtesy: Propac Industrial

Vertical form fill and seal machine is aimed to package pet food by forming bags or pouches from a leveled roll of film. It is a commonly used pet food packaging equipment. The machine is assembled vertically which is space-saving and also the flow of material is assisted by gravity which keeps operation continuous and efficient. It can accommodate both kind of pet food either dry (kibble, treats) or wet (gravies etc.), which makes it a preferred choice.

Working principle:

First of all, a roll of film is supplied to the machine, where unwinding of film roll takes place.

After that film roll is dragged down to the forming tube, where formation of pouch takes place. The bottom of pouch is made and sealed by using heat.

Pet food is then filled in to formed pouch by utilizing auger-filling mechanism, in which large amount of pet food is loaded in to hopper and then it is moved towards filling station and forced in to pouch.

After filling of pouch, upper part of it is sealed by using heat or pressure, making sure that the pouch is enclosed properly.

Horizontal form-fill and seal machine:

Horizontal Form-Fill And Seal Machine-Picture Courtesy: SA Packaging Machinery

Horizontal form fill seal machine is a specialized machine to fill and seal pet food products in horizontal way. This machine is used for pet food packaging on large-scale as speed of operation is very high plus vast amount of pet food can be packaged.

Horizontal form fill seal machine has great advantages. It is very versatile and flexible equipment. It can hold a variety of packaging types and sizes. It is cost effective and provides precise outcome with far rapid speed.

Working principle:

A flat roll of film is supplied, where it is unwound and subjected horizontally in to the machine.

After that film is moved forward to form pouches by the help of set of rollers.

Once the pouch is formed, it is taken to filling station by help of conveyors, where it is filled with pet food.

After filling, pouched is sealed by using heat or pressure.

Flow wrapping machine:

Flow Wrapping Machine-Picture Courtesy: Jochamp

Flow wrapping machine is a specialized machine used to wrap pet food into a flexible film either plastic or aluminum foil and forming a sealed bag with one side open.

This type of machine provides such packaging which preserves the originality of dry pet food like treats and reduces the risk of contamination. It has various benefits. We can customize packaging size in it and get high quality production.

Working principle:

Roll of packaging film (plastic or aluminum foil) is introduced in to the machine, where it is unwound and subjected to area of wrapping.

Pet food is loaded into machine by the help of conveyor belt and is moved into flow wrapping area in horizontal-form.

Pet food must be positioned properly on conveyor before wrapping and it is assured by using product positioning system.

The film is wrapped around pet food (dry) leaving one side open by the aid of rollers. The film is then sealed by using heat or pressure sealing.

Pre-made pouch fill and seal packaging machine:

Pre-Made Pouch Fill And Seal Packaging Machine-Picture Courtesy: DP-Pack Process Packaging

Pre-made pouch fill and seal packaging machines are used to fill and seal pre-formed pouches, usually used for premium pet food. You can package different types of pet food like wet or dry as per needed. These machines are getting popularity as being simple to use, space saving and yield high quality results.

Working principle:

Pre-made pouches of different materials are subjected on to a conveyor.

A set of mechanical grippers is used to open pouches and then moved it towards filling station where it is filled with pet food.

Once the pouch is filled, it is sealed by using heat or pressure sealers.

Can/Jar/Bottle filling and sealing machine

Can Filling And Sealing Machine-Picture Courtesy: LiDLi

This machine is commonly used to package wet pet food in to jars, cans or bottles. The filling mechanism involved in this machine is volumetric or weight filling. This machine assures a precise filling of pet food.

Working principle:

Large amount of pet food is subjected into hopper, from where it is moved to filling stations.

Cans are placed below filling nozzles by the help of conveyor and then it is filled with accurate amount of pet food by using specially designed filling nozzles unit.

After filling, cans are introduced to sealing units where capping is done accordingly.

6.What other equipment can be combined with pet food packaging equipment?

Pet food labelling plays a vital role in establishing strong stability of pet food. For this purpose we consider labeling machines as key part of pet food packaging equipment. A pet food label must be comprised of name of product, weight or volume, list of ingredients, nutritional value, guidelines about feeding, manufacturer information and expiry date

For the purpose of proper storage of pet food, palletizing machines are used. It makes packaging process more convenient and efficient.

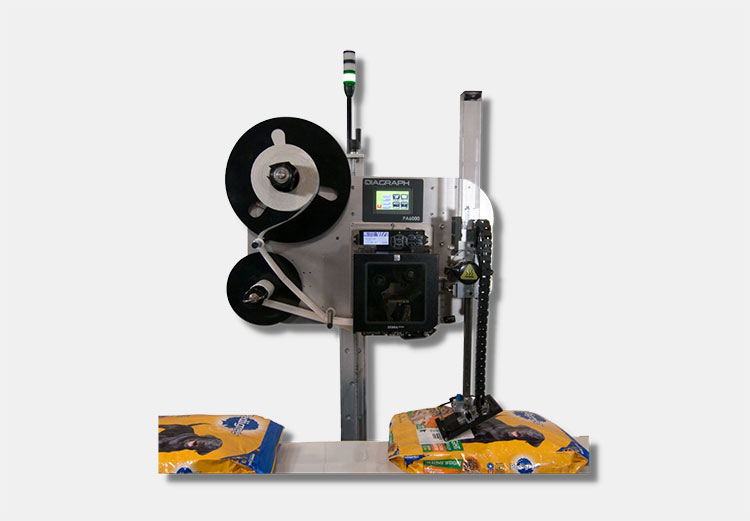

Labeling machine:

Labeling machine-picture courtesy: Diagraph

This machine is necessary for guaranteeing that the pet food is competent with regulatory standards. It makes sure that the product looks attractive and recognizable to consumer.

It is used to apply labels to different packaging types like can, pouch, bottle, bag etc. which delivers all information about the product needed by consumer.

Working principle:

The desirable packaging type either it may be pouch, can or bottle is subjected to conveyor, from where it is taken to labeling station. Sensor is installed to check alignment of containers.

Unwinding of labels takes place by the help of rollers and then these labels are moved forward for application

Label is applied to the product by different mechanisms either it is by implementing pressure or by wrapping label around the product using heat or wet glue.

Inspection system is installed to be ensured about adhesion of label to the product.

7.What is the difference between dry pet food packaging equipment and wet pet food packaging equipment?

Different varieties of pet food are available in the market. This all depends upon the choice of pet-owner to buy pet food according to their pet’s fondness. Pet food comes either in dry or wet form, requires packaging equipment according to its nature.

Dry And Wet Pet Food-Picture Courtesy- Tufts Your Dog

The pet food packaging equipment employed to package dry pet food and wet pet food varies on the basis of some factors which are listed below:

| Dry pet food packaging equipment | Wet pet food packaging equipment | |

| Application | Ø This equipment is used to package dry pet food like kibbles, treat etc. | Ø This equipment is used to package wet pet food like curries, gravies etc. |

| Procedure | Ø Main steps involved in packaging of dry pet food are filling, bagging and sealing of food product | Ø Main steps involved in packaging of wet pet food are filling, sealing and sterilization |

| Main equipment | Ø Commonly used equipment are pre-made pouch fill and seal packaging machine, flow wrapping machine, VFFS and HFFS | Ø Commonly used equipment are pre-made pouch fill and seal packaging machine, can filling and sealing machine, VFFS and HFFS |

| Packaging type | Ø Packaging type preferable for it, includes bags and pouches, bulk sacks | Ø Packaging type preferable for it, includes cans, plastic trays, pouches |

| Sealing option | Ø Sealing is performed by heat sealing or zip-lock application | Ø Sealing is performed by can seaming, tray sealing etc. |

| Sterilization | Ø Sterilization is not required due to zero presence of moisture content | Ø Sterilization is necessary to prevent contamination caused by presence of moisture content |

| Speed | Ø This equipment works mostly on high speed and are cost-effective | Ø This equipment works slower due to steps of sterilization involved in it. Hence these are complex and expensive. |

8.What measures can be taken to maintain pet food packaging equipment?

Maintenance of pet food packaging equipment is essential for securing competency, quality and stability of product according to regulatory standards. The approach behind maintaining equipment is discussed below:

Deep cleaning:

Cleaning Of Conveyor System-Picture Courtesy: Stock-Adobe.com

Removal of product particles, dust and waste matter from conveyors, sealing bars and filling nozzles must be carried out on daily basis.

Areas that are susceptible to get contaminated must be cleaned deeply as per required.

Utilize such cleaners that are approved for use in food processing environment to disinfect the packaging equipment and prevent growth of bacteria.

Lubrication:

Lubrication Of Moving Parts-Picture Courtesy: Micro-Lube

Apply such lubricants that are approved for use in food processing environment on moving parts like conveyor belts, bearings, and motors to avoid wear. This application must be carried out on daily basis.

Calibration of equipment:

Calibration Of Pet Food Equipment To Maintain Quality Of Operation-Picture Courtesy: Upkeep

Look over belts, gears, and seals for cracks and degradation, restoring them before failure.

Assure the calibration of weighing scales and filling nozzles to maintain the uniform packaging weight.

Regulate the temperatures of sealer and alignments of blade to avoid packaging defects.

Sensors and controls: Inspect sensors, programmable logic controllers (PLCs) and control panels to achieve responsiveness and accuracy.

Check hoses, valves and connections for any kind of leakage and genuine pressure levels.

Check competency to standard regulations:

Educating Staff About Packaging Equipment-Picture Courtesy: Elimpo

Act in accordance with recommended maintenance schedule of manufacturer for belts, motors, and bearings. Retain a log of maintenance activities to trace patterns and predict part replacements.

Educate staff on right maintenance procedures and lockout/tag out (LOTO) protocols.

Assure compliance with food safety regulations like FDA, GMP, HACCP for production of pet food.

9.How to elaborate about technical problems and solutions of pet food packaging equipment?

Pet food packaging equipment marks a key role in securing product originality, durability and competency with industry regulations. Sometimes technical problems can be faced by manufacturer which affects the overall quality of product. Some technical issues and their expected solutions are listed below:

Machine downtime:

Downtime Is Time When Equipment Is Not Available For Use-Picture Courtesy: Global Electronic Services

Causes:

Downtime of machine is happened because of:

Packaging material gets stuck due to disarrangement of film foil, poor quality packaging material and fault in control system.

Electrical issues could be due to improper wiring, damaged sensors, changes in power and inappropriate software updates.

Solution:

Make proper alignment of film foil, use good quality packaging material and calibrate control system.

Inspect electrical system, make replacements where needed, keep software updated.

Incorrect weighing and filling:

Inaccurate Weighing Of Product-Picture Courtesy: Awm Limited

Causes:

Inaccurate weighing and filling is prompted by:

Defective weigh sensors or load cells.

Product choking in filling cells.

Solution:

Calibration of weighing system.

Deep cleaning and right alignment of filling system.

Poor sealing quality:

Mouldy Pet Food Due To Poor Sealing Quality-Picture Courtesy: The Mail

Causes:

Poor sealing quality is inspired by:

Presence of contaminants on sealing surface.

Unsuitable temperature settings.

Wear and tear of sealing jaws.

Solution:

Cleaning of sealing surface.

Adjustment of sealing temperature.

Altering worn-out parts.

Labeling errors:

Pet Food Label

Causes:

Labeling errors are arisen because of:

Sensors deranged in labeling system.

Inaccurate pulling of label roll.

Presence of dirt resulting in defected adhesion of label.

Solution:

Calibrate labelling machine.

Overheating of equipment:

Make a schedule for operating equipment-picture courtesy: K-flex packaging

Causes:

Overheating of equipment is generated due to:

Working of equipment for extended hours without break.

Poor ventilation system.

Overheating of mechanical or electrical components.

Solution:

Make a schedule for operating equipment.

Calibrate ventilation systems, mechanical and electrical components.

Conclusion:

Pet food equipment is a key component in securing the quality, efficiency and safety of pet food industry. In order to get increase in production and to fulfill consumer’s demand for original & safe food and to apply nature-friendly implications. It’s necessary to install automated pet food packaging equipment.Spending on high efficient equipment results in robust growth of pet food industry and it also builds strong trust of pet owners on manufacturers. If you want to learn about pet food packaging equipment, you can contact AIPAK at any time.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours