Packing Tape Thickness

The holiday season is ahead! Most of you would be ready to sneak up on postal addresses and packaging gifts. Side by side, stress on the supply chain, delivery and packaging departments would be busier in packaging in advance than ever before.

You might have noticed that packing tape thickness is denoted in ‘mm’ whenever you look at or purchase packing tape. Whether for shopping or retail purposes, you always require packing tape for elegant and secure packaging.

This article is all about packing tape thickness which will help you understand all the basic to advanced knowledge you need to know for effective packaging.

1.What is Packing Tape? What is the History of Packing Tape?

Multi-Color Adhesive Packing Tape Thickness

Packing tape is a simple stationary staple that is used commonly in household chores and industrial-grade tasks for sealing the packaging stuff and storing it for delivery and shipping purposes.

The above lines possibly look simple to read but the packing tape exact encyclopedia is very complex.

For example, thinking about its various sizes, thickness, types, colours, applications, and much more relevant parameters would compel you to realize its vast scope to understand.

Going back, an engineer Richard Drew developed the world’s first packing tape with 2-inch-wide tan colors with a strong pressure-sensitive backing in 1925. The creation of packing tape was intended to offer a media that could cover those parts that were not painted.

The very first packing tape was composed of min three ingredients such as oil, resin and rubber. This mixture of adhesive was applied at its backing as in a fluid state. Today, this method is transformed into a bonding agent which depends on the desired strength of the bonding agent.

2.What is the Packing Tape Thickness?

Packing tape Thickness

It is defined as a measure of the smallest dimension of the packaging type. Packing tape thickness is also the degree of its strength and durability. It varies with the weight and size of products. The product material also decides the packing tape thickness.

The main purpose of packing tape is the sealing of objects, thus strong seal is provided by thicker packaging film.

Furthermore, special applications like the sealing of delicate and fragile items demand reinforced packaging type of higher thicker whereas light items require thinner packing tapes.

The packing tape thickness range is very broad with the thinnest packing tape being about 0.196 mil or 0.005mm. This thinnest tape is ultra-thin double-sided adhesive tape.

The thickest packing tape is about 6.6 Mil or 0.168 mm. This is used for strapping bundles and pallets and is called filament packing tape.

3.What are the Units of Packing tape Thickness?

Units of Packing tape Thickness

Numerous units are used for packing tape thicknesses. The usage of units depends upon brand and applications. These units are:

Mil

Most industrial manufacturers use Mil when describing the thickness of their packing tape. It is commonly used for thinner packing tape.

1 Mil = 1/1000 inch

Micron

The standard term for micron is micrometre. It is a metric system unit.

1 µm= 1/100000 meter

1 Mil =25.4 micron

Millimetre

It is another metric system unit and is considered standard among packaging sectors for packing tape thickness. It is adapted for slightly thicker packing tape.

1 mm = 1/1000 meter

Chart for Packing tape Thickness

Here is a unit conversion chart for packing tape thickness that will help you to get the correct thickness of packing tape.

| Mil | Micron | Inch | Millimeter |

| 0.16 | 5 | 0.0001 | 0.005 |

| 0.25 | 6.35 | 0.0002 | 0.006 |

| 0.35 | 8 | 0.0003 | 0.008 |

| 0.45 | 11.43 | 0.0003 | 0.011 |

| 0.55 | 14 | 0.0005 | 0.014 |

| 0.65 | 16.51 | 0.0006 | 0.016 |

| 0.75 | 19.05 | 0.0007 | 0.019 |

| 0.85 | 21.59 | 0.0008 | 0.021 |

| 0.95 | 24.13 | 0.0009 | 0.024 |

| 1 | 25.4 | 0.001 | 0.025 |

| 2 | 50.8 | 0.002 | 0.050 |

| 3 | 76.8 | 0.003 | 0.076 |

| 5 | 127 | 0.005 | 0.127 |

| 6.6 | 168 | 0.006 | 0.168 |

4.Why Do You Need to Know Packing Tape Thickness?

Understanding and learning about packing tape thickness is essential for numerous reasons. Normally, the thicker packing tape is sturdier and bears higher strain. Knowing packing tapes is important because:

Effective Seal

Effective Seal and Packing tape Thickness

Packing tape thickness is directly related to its seal efficiency and durability. Cartons and other products are usually subjected to rough treatment during handling, so thinner packaging may accidentally open during shipment. But with thicker packing tapes secure sealing is ensured.

Higher Durability

Effective Seal and Packing tape Thickness

Sometimes there is a risk of tearing, ripping, and puncturing packing tapes, especially when they are used for securing products with cutting edges. Therefore, the use of thicker packing tape in these conditions may prevent occasional tearing or cutting.

Adhesivity

Adhesivity and Packing tape Thickness

Certain applications require higher adhesivity to withstand strong forces. This specific demand is fulfilled using thicker packing tapes. So, learning about packing tape thickness is a must for buying packing tape, otherwise, it will result in a waste of money.

Loading Tolerating Ability

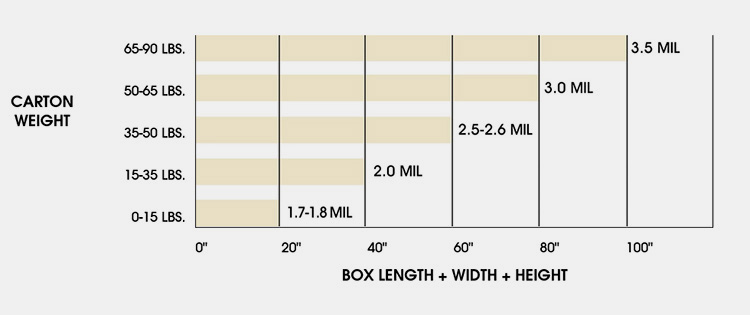

Loading Tolerating Ability of Packing tape - Picture Courtesy: ULINE

Packing tape thickness is also influenced by the weight and size of the product. Generally, lightweight smaller products are secured by the tinner packing tapes, whereas, thicker packing tapes are ideal for binding heavier large-sized products. This is because thicker packing tapes can tolerate heavier loads and the weight-tolerating capacity of thinner tapes is low.

Cost and Budget

Cost and Budget

Understanding the packing tape thickness is imperative in planning the budget for its purchase. Thicker packing tape is available at a higher cost while thinner packing tape is relatively cheap. So, comprehending packing tape thickness is beneficial for the success of your business.

Resilience Under Different Environmental Settings

Resilience Under Different Environmental Settings

Shipping and cargo usually occur in harsh environmental conditions such as high and low temperatures and wet and dry surroundings. So, it is vital to know about packaging film thickness and its resilience under different weather conditions to attain better product security.

5.What are the basic types of packing Tape?

Different types of packing tape- Picture Courtesy: Packaging Company

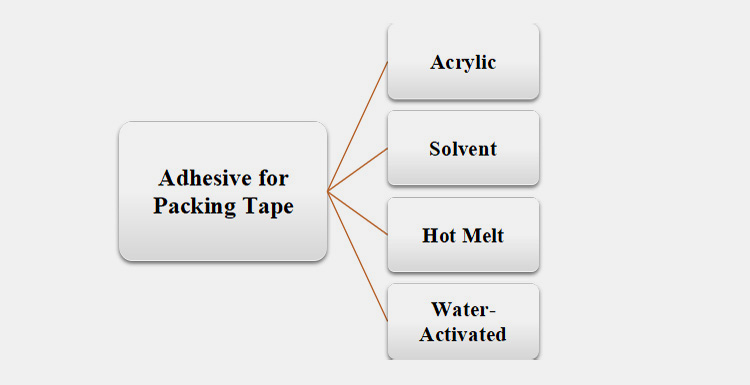

Adhesive for Packing Tape

Before knowing about the types of packing tape first, you need to know about the adhesive used for packing tape items. There are different types of adhesive used based on acrylic, hot melt, solvents, and water-activated adhesive for packing tape. These different products provide adhesiveness to the packing tape.

Let us discuss them one by one;

| Acrylic | Acrylic adhesive is commonly known as acrylate and methylmethacrylate and is a widely used adhesive for packing tape. It is available in both solvent and water states. The acrylic-based packing tapes are transparent and are commonly used for many purposes. |  |

| Solvent | It provides durability, strong adhesion, versatility, resistance to extreme environments, and the capacity to bond rapidly to the packing tape. |  |

| Hot Melt | It is a commonly used adhesive tape due to its unique characteristics and reliable stiffness abilities. |  |

| Water-Activated | It is based on starch; such a type of adhesive requires water for activation. The water-activated tape is a paper tape that is in dry form and becomes activated by water. |  |

Now let us discuss different types of packing tapes that use these above-mentioned adhesives.

| Description | Picture | |

| Transparent Packing Tape

|

Transparent tape is also referred to as scotch, carton, or clear packing tape. It is made up of polypropylene film that is coated with the acrylic adhesive. It is widely used packing tape for packing lightweight to medium-weight cartons and is mostly used in households, industries, hospitals, schools, etc. It protects any items from water or dust and is used to pack any objects. Transparent tape provides admirable clarity and makes a strong bond. |  |

| Brown Packing Tape

|

Brown packing tape, is also known as packing tape, buff tape, or parcel tape. It is made up of polypropylene film coated with solvent-based acrylic adhesive.

It is widely applicable for packing heavier items because it is stiffer than transparent packing tape. Brown packing tape is mostly used to pack large-size boxes or cartons. It seals the packed and protects the items for the long term. |

|

| Polyester Packing Tape

|

Polyester packing tape is made up of polyester film also known as PET tape.

It provides outstanding adhesion as well as tensile properties, guaranteeing a stable and durable binding on a range of surfaces. It easily sticks to cardboard, plastics, metals, and other typical packing materials due to its sticky adhesive capabilities. It offers superior resistance to chemicals, temperature, and moisture changes, guaranteeing that your shipments stay sealed and safe even in harsh conditions. |

|

| Masking Packing Tape

|

Masking tape is made up of thin crepe paper backing and coated with a nonreactive adhesive. The adhesive used for masking packing tape includes rubber, synthetic, acrylic, and silicon-based and all are adhered, tacky, and resist stress.

It is widely used in the automotive industry, electronics, painting, and building industries. It protects surfaces from leaks, overspray, and damage. Although it is not made for packing, masking tape can be applied to light-duty or temporary packaging tasks. It is less expensive and easily recyclable. It is crucial that the protective masking tape be simple to remove and leave no trace after a project is finished and the materials applied have dried. |

|

| Freezer Grade Packing Tape

|

Freezer-grade packing tape is composed of freezer-grade adhesive and polypropylene film. It is designed to keep its adhesive integrity and strength at very low temperatures, providing dependable and safe sealing under subfreezing circumstances.

It is ideal for freezer settings below -30C due to its excellent adhesion and superior age resistance. It seals easily and well to plastic, metal, and cardboard among other surfaces because of its potent adhesive qualities, creating a tight, long-lasting barrier that won't peel or shatter in subfreezing temperatures. It is widely used for packing, processing, and transportation in the food sector. |

|

| Printed Packing Tape

|

Printed tapes are unique varieties of adhesive tape that perform the dual roles of information carriers and advertising aspects in addition to their basic adhesive purpose. The firm logo, contact information, usage directions, cautions, and other related information are printed on the tape's surface. Though visually striking, this is not the only benefit of such a solution. Simultaneously, the brand and product name become identifiable. It will undoubtedly be simpler for customers to remember. Professionalism is conveyed by the tape with the brand, and the item is securely packaged without sacrificing any of its eye-catching design elements. It is made up of numerous materials such as polyvinyl chloride, polypropylene, or paper depending on the requirements of the customer. |  |

| Water Activated Packing Tape

|

Water-activated packing tape is also recognized as gummed paper or gummed tape and is usually made up of starch. It requires water to activate the adhesive properties. It is used for sealing boxes and cartons.

Before closing any fibreboard boxes, it must moisten the tape with water. It is a less expensive and widely used type of tape that due to moistened adhesive provides secure bonds. It can be easily handled due to its lighter weight and it can be easily removed from the boxes. |

|

| Duct Packing Tape

|

Duct tape is among the most widely used types of tape that you are all familiar with and adore. The robust acrylic adhesive covering on this double-woven tape is age-resistant.

Its extraordinary adhesive capability, along with its excellent shear and heat resistance, are made possible by these properties. Because it can be used for so many different things, duct tape is a common item in both homes and many other industries. |

|

| Strapping Packing Tape

|

Strapping tape, made for use in industry, works wonders for securing the upper rows of your pallets together. It has an elastic band-like characteristic that permits any load to shift as necessary without causing damage. They are all resistant to tearing, splitting, and abrasion and come with reinforcement made of fibreglass filaments. |  |

| Double Sided Packing Tape

|

Double-sided packing tape, with its powerful adhesives on both sides, makes it simple to attach two distinct surfaces. The adhesive of double-sided tape allows it to be tucked away after placement, making for a neat appearance and presentation.

It is utilized in numerous industries and is suitable for a broad range of applications. |

|

| Label Protection Packing Tape

|

Label protection packing tape is a transparent adhesive product that fulfils its name exactly. Put it over labels to retain them firmly in place on a range of materials, such as paper, plastic, metal, and wood. Both indoors and outdoors, this high-clarity, high-strength tape can withstand abrasive or harmful conditions. Even better, scratching, water, and chemical resistance are features of label protection tape. |  |

Types of Packing Tape Based on Thickness

Yes, there are distinct classifications of packing tape when it comes to thickness. These classes are discussed one by one for your understanding:

| Description | Picture | |

| Light Duty Packing tape | It is used for simple applications such as sealing gift items. This packing tape is more on the thinner side with a thickness of 0.35-1 Mils. This is ideal for packaging smaller loads as it is less strong. It is ideal for boxes with 15 pounds. |  |

| Medium-Duty Packing tape | It is about 1.5-2 Mil in thickness and works best for daily packaging jobs. It can glue medium-weight applications weighing about 15-35 pounds. This packing tape usually comes in PP, PE, or acrylic form. |  |

| Heavy-Duty Packing tape | It is robust packing tape, providing extra security and safety to the boxes. It is more weight bearing and can hold 35-50 pounds weight with a thickness of 2.5-3 Mil. It is generally used for heavy-duty applications. |  |

| Reinforced Packing tape | This type of packing tape is typically manufactured with extra mesh fibres for additional strength and resilience. It is thicker than heavy-duty packing tape with a thickness of 3.5-5 Mils. Due to its heavier thickness, it is typically employed for heavyweight packaging, for instance, products with a weight of 60-90 pounds. Moreover, it is generally employed for products with cutting edges. |  |

| Filament Packing tape | It is an excellent solution for heavy-weight bundling and pelletizing. It has embedded fibreglass and is best for strapping large pallets. It has a thickness of about 5-6.6 Mil and it has extra puncture and tear resistance. Filament packing tape can tolerate tensile strength of over 1000 pounds. It is highly tamper-evident, thus preventing unsanctioned access to pallets. |  |

Conclusion

Packing tape thickness is inseparable as packaging does not exist without proper knowledge of packing tape. From gift box wrapping to large industrial palletisation, packing tape is seen everywhere. But the difference in thickness of both these packing tape applications. For bundling large loads for shipment, thicker and more durable packing tape is used, whereas, for home-based wrapping, thinner packing tape is used. Thicker packing tape costs more money and is difficult to recycle; however, it also provides more protection and stronger adhesivity. Planning to purchase packaging film and are puzzled about thickness, we Allpack will aid you in reaching the right decision quickly. Please contact us now for more information.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide