Packaging Machine for Spices: The Complete Buying Guide in 2025

Spices are originally considered as one of the significant ‘Powerhouses’ of aroma, flavors, and tantalizing taste in your dishes. If you’re thinking the magical secret of spice lies in its origin, then it is actually not the exact reason.

Though, the spice packaging is yet an important science that has brought them fresh with intact flavors. To perform this job, there are various packaging machine for spices that embark with pivotal responsibilities in savoring and preserving a true flavor to you around every corner of the world.

1.What is a packaging machine for spices?

A Packaging Machine for Spices

The packaging machine for spices is designed to cater to the process of filling and packaging spices and related products into various respective products.

This is a state-of-the-art machine that primarily has streamlined the production process to enhance productivity and preserve quality, and flavors, with ultimately controlled and reduced cost. It plays a significant role in preventing the rancidity of spices against moisture, light, oxygen, and cross-contamination. So, the machine assures you that the inside product is safe.

2.What are the benefits of packaging machine for spices?

The benefits of packaging machine for spices are described below:

Sustainable Packaging Machine for Spices

Sustainable Packaging Machine for Spices

Today, everyone is conscious about attaining energy efficient machinery and acquiring sustainable packaging. The packaging machine for spices are featured in a way that reduces in wastage of raw and finished product by offering an optimized utilization of natural resources. As it offers an eco-friendly operation thus it is helpful in delivering outstanding packaging.

Streamlined Various Packaging Solution

Streamlined Various Packaging Solution

A packaging machine for spices has an impressive way of implementing and offering spice packaging with cutting edge streamlined packaging solutions which improves working efficiency and along with productivity.

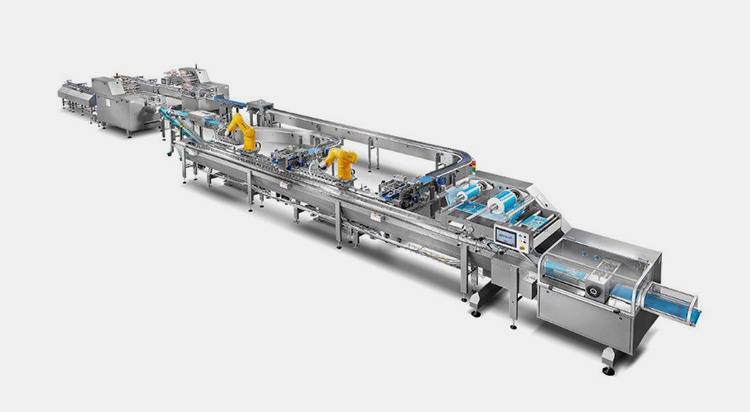

Integrated Packaging Solutions for the Spice Industry

Integrated Packaging Solutions for the Spice Industry- Picture Courtesy: Palamatic

This is well-known that every manufacturing industry is not only restricted to using packaging machine for spice, but there are a series of machines that are integrated with them to carry smooth functionality. So, technological advancement has optimized a harmonious way to integrate the packaging machine for spices with other integrated units required to fulfill the packaging task. This includes bottle unscrambler, labeler, induction sealer, etc.,

Improved Packaging Speed

Improved Packaging Speed- Picture Courtesy: Made in China

The significant benefit of the packaging machine for spice is obtaining an accurate packaging with high speed without worrying about dusting, material wastage, or affecting production targets. The packaging for spices is the utmost engineered solution that maintains the aroma and flavor in a filled pack for a longer period of time.

To preserve Freshness

Packaging machine for spices is better way to preserve Freshness- Picture Courtesy: Bluecart

The packaging machine for spices is designed with a narrow filler for the purpose of confined packaging without the generation of dust. The product is intricately packed and secured in an intact form as harvested and prepared.

To Boost Marketing and Customer Satisfaction

To Boost Marketing and Customer Satisfaction- Picture Courtesy: Chris Koch

Receiving neat, cleaned, and aesthetically well-presented spices from market shelves directly improved marketing and client’s opinion about the product. The packaging machine for spices plays a pivotal role in enhancing the branding factor of your business.

3.What is the classification of packaging machine for spices?

You might be surprised to know that classification of packaging machines for spices is somewhat broader than your imagination. But the story is not ended yet, as their increase demand brings more innovation and new development in the term of machineries. Our experts have briefly specified the list with their working principles for readers understanding. Let’s go through it!

Based on Automation

The packaging machine for spices are available in different automations which are described below:

Manual Packaging Machine for Spices

Manual Packaging Machine for Spices- Picture Courtesy: New Direction Australia

This is very simple and cost-effective device that entirely needs to be handle by an operator to bring neat and aesthetically well-packaging. This machine is recommended if you’re running a small project of packaging spices as this is very economical to run.

Working Principle

An operator needs to pour bulk spices in the hopper. You need to hold the packaging container just exact position to the filler and pull the handle to pour required quantity of the spices. Once product is filler, you can secure the pack by manual sealing and capping if required.

Semi-Automatic Packaging Machine

Semi-Automatic Packaging Machine for spices

This is a modern and advanced machine which is recommended for small to moderate production facilities. Here operator has to load and unload the packaging product by himself, apart from them, the entire procedure is operated by the machine itself.

Working Principle

The machine works by placing container manually at filling unit. The machine itself fills the spices as indicated and fed the protocol in PLC. Once they’re filled operator removes the set of packed products manually.

Automatic Packaging Machine for Spices

Automatic Packaging Machine for Spices

This type of packaging machine for spices are highly advanced technology that needs almost very little human intervention that’s only switch on and off and feeding the operating protocol. They are mostly recommended to run large production packaging industries to attain high volume working capacities.

Working Principle

When operator feed in the working data, machine senses the presence of container and introduce the optimum or required concentration of spice as managed by PLC controlled unit. Once they’re filled, the machine automatically discharges the filled packets/containers/product to the next machine.

Based on Packaging Type

Bottles/ Jars/ Cans Packaging Machine for Spices

Bottles/ Jars/ Cans Packaging Machine for Spices

Spices are commonly packed in bottles/ jars/ cans that needs bottle filling machine for medium and high production ranges. The body of the machine is made up with stainless steel and featured with an enclosed structure that is flexible and recommended for spices packaging against making dust during packaging.

Working Principle

The working of bottle/jars/cans packaging machine for spices takes places when material comes in contact with auger filler via conveyor unit. The precise amount of the spices is dispensed in each bottle/jar/can and secure with induction sealing and capping.

Pre-made Pouch Packaging Machine for Spices

Pre-made Pouch Packaging Machine for Spices

This machine is an efficient system that allow filling and packaging of premade pouches with different product pouch designs. The machine offers an optional unit for inspection, number of fillers, and sealers. The machine is available in small and large sizes that can deals product with multiple concentrations.

Working Principle

Machines works by picking manually stacked premade pouches one by one by help of grippers. Strong air inflators help in the opening of the bag, once the bags are opened, filling nozzles place the spices and allow next bag for the repeating the same procedure.

Based on Type of Fillers

The packaging machine for spices are also classified according to different fillers. Such as:

Auger Filler

Auger Filler for Spices- Picture Courtesy: IVF

This is commonly filler which is accompanied by an auger that is screwed in order to offer precise measured quantity of spices into each packaging material.

Volumetric Filler

Pre-determined Volume Filler

A volumetric filler is extremely accurate filling of spices with already pre-determined specifications. The design of the volumetric filler is presented with graduated volume such as scoop or cup.

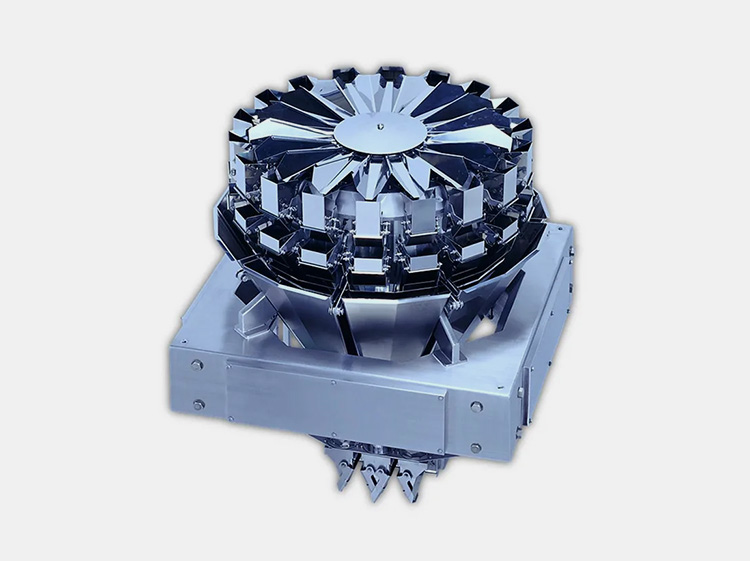

Multi-head Filler

Multi-head filler for spices

To fill large volume of packaging material for spices, a multi-head filler is used that can positioned an accurate number of spices into various packaging materials at the same time. This machine ensures that you can achieve large production capacity in a short time.

Based on Filling Method

On the basis of the filling method packaging machine for spices is classified into two.

Rotary Filler

Rotary Filler for spices- Picture Courtesy: CVC Technology

The rotary filler packaging machine for spices works by continuously rotation of filling material which stays below the filling nozzle and leave the unit once filled. The entire procedure follows circulatory motion for entering and leaving the unit.

Linear Filler

Linear Filler- Picture Courtesy: Shree Bagwati

This is another method where filling and packaging process is taken place by following the linear fashion. The filling material comes straight into the unit while leaves the machine once filled with spices from the filling station.

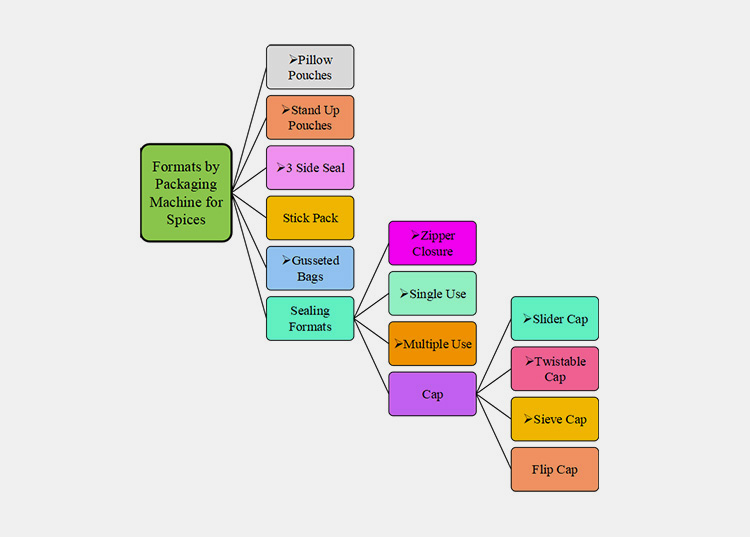

4.What formats a packaging machine for spices offer?

A packaging machine for spices offers different formats for dispensing the spices to you. We’ll read about them below.

Pillow Pouches

Pillow Pouches

Pillow pouches are used for packaging of various products and it comes with bottom, top and back seal. These pouches are made of materials like PP and BOPP , are multilaminate to enable maximum level of shelf life freshness. They can hold quantities from 50 grams to 5 kilograms.

Stand Up Pouches

Stand Up Pouches- Picture courtesy: TedPack

Standup pouches are mostly made of LDPE as it provides food grade safe packaging to the spices inside. Its bottom part or side part is usually gusseted which allows easy display on shelves. Some of these pouches has clear window laminates letting the consumer to view the spice inside.

3 Side Seal

3 Side Seal- Picture courtesy: TedPack

These pouches contain seals from 3 sides of the packet, as the name suggests, and one of the open sides is thermally sealed after the spice has been filled inside.3 side seal packaging can be used as a single serving, easy to go option and has the potential to lock the freshness inside.

Stick Pack

Stick Pack- Picture courtesy: The insiders- Mc Cormick

Stick pack is an adjustable format of packaging which can accommodate powders like spices and can be used for single purpose or as serving sample. If designed with appropriate quality of material, it can prolong the shelf life of the product inside. Stick packs are convenient and portable for usage.

Gusseted Bags

Gusseted Bags- Picture courtesy: Chegos.pl

Gusseted bags are flexible form of spice packaging which offers flat bottom support which enables easy shelf display and also occupies less space for storage. They are available inside or bottom gusseted design, in which one side of the bag is folded inwards to allow extra space inside the bag. These bags contain the spices by protecting them from dust or moisture.

Sealing Formats

These bags and pouches are closed or sealed using various methods that can be such as zipper closure or slider seal, single time use, multiple use etc. Let’s see them one by one.

Zipper Closure

Zipper Closure- Picture courtesy: Pouch Makers

Zipper seal or slider seal is a reclosable and convenient option for packaging, as it brings moisture proof freshness to the spices inside.

Single Use

Single Use- Picture courtesy: Food Network

Pouches sealed with single time use option are made to be tamper evident. They are sealed using heat and is applied on packets that are to be used for one time only such as blister packs, sachet packs and stick packs.

Multiple Use

Multiple Use- Picture courtesy: Toopus- Medium

Flexible pouches such as stand-up pouch or gusseted bags have the easy tear feature at the top of the packaging, which can be resealed after opening using heat or by using ziplock, thereby making them for multiple use.

Capping Formats

The spices are packaged not only in pouches and bags but also in bottles, jars and containers. Different capping styles are adopted according to the type of material enclosing the spices in any packaging format, such as slider cap, twistable cap, sieve cap, flip cap etc.

Slider Cap

Slider Cap

These caps are usually made of plastic and have one side of the cap allowing to be shifted for easy opening and delivering of spice out of the bottle. These are also called butterfly caps.

Twistable Cap

Twistable Cap-Picture courtesy: Browin

Twistable or metal lug caps allow the consumer to get controlled amount of spice , which can be opened or closed by a slight twisting action.

Sieve Cap

Sieve Cap

Sieve cap or sifter cap are made up of plastic or metal and have small holes in it which allows for controlled volumetric dispensing of spices. This is the most commonly used type of closure cap for spice bottles.

Flip Cap

Flip Cap- Picture courtesy: Food Ingredients First

Flip caps are like hinge opening, they can be easily opened without the need to open the cap completely. They are usually used in seasoning spice bottles.

5.What packaging materials a packaging machine for spices run?

It is crucial to select a certain type of packaging according to the type of spice you have to enclose in it in order to maintain its integrity. What different types of specific formats are offered for spices packaging; we’ll find out below.

Jars And Containers

Jars And Containers- Picture courtesy: Kath and Kin

Jars and containers made of glass material are one of the typical forms used for spice packaging. They include wide mouth jars, square or rectangle shaped jars , opaque and transparent containers which may be made up of both glass and plastic, involving the use of a metal lid or wooden stopper as a closure.

Cans

Cans- Picture courtesy: 99Designs

Cans made up of steel ,tin and Kraft paper material is similarly popular for packaging among spice manufacturing companies. Cans packaging provide safety to the spices inside by giving them airtight freshness and being inert to the product inside. However, it also has the potential of spoiling the ingredient inside if reacted with moisture or if exposed to heat and light.

Bottles

Spices Bottles- Picture courtesy: SKS Bottle

Spices can be packed up inside bottles that are made up of plastic or glass, with a closable lid of metal or plastic. These are also popularly seen on the shelves of supermarkets as they come in various shapes and sizes. Spice bottles offer easy storage and reusability options, as they are sleek in design. Most of the bottles are made transparent allowing consumers to see the type of spice and they also offer airtight freshness. As the glass bottles are easily breakable, they offer this disadvantage and comparatively to other forms of packaging their capacity for filling spices is less too.

Pouches, Sachet, and bags

Pouches, Sachet, and bags

Spice manufacturers prefer packaging of whole or ground spices usually in pouches or bags for offering bulk and consumer packages to the market. These pouches or bags are made up of different materials such as paper, plastic and variously composed laminate films. Consumer packs arrive in different shapes and sizes of pouches that are flexible and reusable for their users.

6.What techniques must be used to avoid Problems with Packaging machine for spices?

Packaging machine for spices are integral in beautifully packaging spices in tough and sturdy containers, but unfortunately, it is also prone to problems. Still, different techniques are applied to easily resolve these problems. A list of problems and techniques to avoid them is penned below:

| Reason | Prevention | Image |

| Failure in Heating of Sealing Bars | ||

| Defect in the wires that connect the sealing element.

Old or damaged heating tube |

Repair or replace the wires if needed.

Check for faults in a heating tube and replace it. |

Failure in Sealing Bar- Picture Courtesy: Viking Masek |

| Loose Sealing of Spice Packaging | ||

| The temperature required for sealing is below the threshold.

Packaging material is not smooth. Non-uniform sealing pressure. |

Adjust the sealing temperature so that it is in optimal range.

Adjust the tension in the packaging material and use a cutting knife to trim irregular material. Fix the compressed air or vacuum so that the sealing pressure is even |

Picture Courtesy :ZB |

| Premade Pouches Do not Open | ||

| Defective or faulty vacuum pad.

Improper loading of premade pouches results in sagging. Defective or unclean filter Fault in air valve |

Properly fix and repair faulty vacuum pad.

Properly place pouches in the bag magazine. Replace filter. Repair or replace air valves. |

Pouch Not Opening- Picture Courtesy: Pouch Makers |

| Jamming and Blockage in Packaging Machine for Spice | ||

| Packaging film gets trapped inside the machine part.

Machine components are not properly aligned |

Remove the packaging film caught between parts.

Fix the alignment of machine components such as belts, guides, etc. |

Jamming of Packaging Machine for Spice |

| Failure in Detection of Registration Mark | ||

| Wear and tear in sensor.

Misalignment of sensor component. Unclean sensor Faulty sensor readings. |

Repair faulty sensor

Check and realign sensor component. Wipe the sensor with a clean cloth. Calibrate the sensor readings. |

Failure in Detection of Registration Mark- Picture Courtesy: Viking Masek |

| Poor Film Cutting | ||

| Cutting knife hangs in a lower sealing bar due to rusty chain linkage.

Poor timing of cutting knife when it hits a lower sealing jaw. |

Thoroughly clean the lower jaw pockets and oil linkage chain.

Adjust the positioning of knife cam by untightening cam mount. Move machine till jaw roller and cam are properly aligned and cutting knife is about ¼’’ in lower sealing jaw pocket. |

Poor cutting- Picture Courtesy: Landpack Packaging Machine |

| Poor Film Tracking | ||

| Non-uniform unwinding of roll stock.

Forming tube is not correctly installed. Misalignment of film rollers |

Adjust tension for even unwinding of film.

Reinstall the forming tube with proper caution. Realign film roller including shaft roller for smooth tracking. |

Poor Film Tracking -Picture Courtesy: Viking Masek |

7.What is Role of Nitrogen flush in packaging machine for spices?

Nitrogen Flush in Packaging Machine for Spice Picture Courtesy MTPak Coffee

Do you know how spices retain their tangy aroma after being packed for a long time? The answer is due to nitrogen flush. It has a significant contribution in keeping spices fresh and aromatic for spicing up food. The packaging machine for spices is comprised of a nitrogen flush component that has a role in blowing food-grade nitrogen inside the spice pouches.

99% Nitrogen Flushed Spice Packaging- Picture Courtesy: Solo

Before sealing, oxygen (the main culprit in degrading spice quality) is expelled out of the spice container by the introduction of nitrogen gas. Immediately after filling of nitrogen, the spice package is sealed to prevent nitrogen leakage.

It is an inert gas that does not react with spice components, consequently keeping them flavorful for a longer time. 99% nitrogen is utilized for preserving nutrition in spices. This process is known as Modified Atmosphere Packaging.

Oxygen can cause rancidity and browning of spices by reacting with oils in spices. Moreover, it is responsible for the growth of bacteria, fungi, molds, and yeast. But with nitrogen flush in the packaging machine for spice, you can pause oxidation of spices, limit replication of microbes, and also provide cushioning to spices by filling up a container.

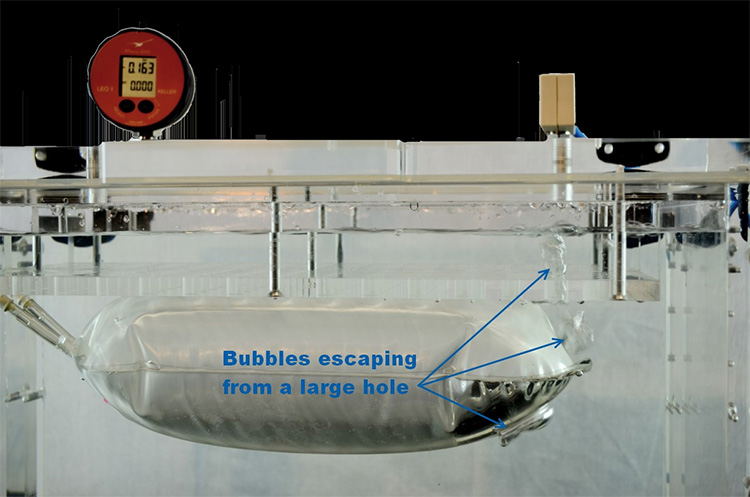

8.What are the leakage tests for packaging machines for spices?

Different types of leakage tests for spice packaging machines are done to ensure there is no leakage. If there is any kind of microscopic tear or scratch in the packaging, it results in contamination of spices either by environmental agents like air, moisture, temperature, and also by molds, fungi, bacteria, pests, insects, etc.

These leakage test methods are a failsafe way to establish seal integrity and toughness of spice packaging. These tests are detailed below for your understanding.

Trace Gas Leakage Test

Trace Gas Leakage Test- Picture Courtesy: Interpack 2023

This test is specifically designed to identify the smallest of leaks inside airtight sealed spice packaging. It detects minute quantities of gases such as helium, hydrogen, and carbon dioxide leaking outside of packages. For testing, first trace gas is injected inside the spice package and then it is placed in a vacuum measuring chamber. With the help of a sensor, trace gas evasion is identified. Pressure change created due to an escape of trace gas is detected by the sensor.

It is a cost-effective method as it typically uses carbon dioxide that is already present in the spice packages.

Water Bath Leakage Test

Water Bath Leakage Test -Picture Courtesy: GBPI Testing Instruments

This leakage test is conducted without using trace gases. For testing leakage, the container is put inside a water bath while the air is eliminated above the water position using a venturi nozzle present in a pneumatic system. Due to the removal of air, the spice package contracts under the water's surface, and the escaped air from the package is seen in the form of bubbles. The bubbles indicate the leaking in the package,

Picture Courtesy: Sealtick

It is easy to determine the position of leakage and to establish the cause of leakage such as poor seal or faulty packaging material with this test.

9.What are the Best Practices should Follow prior purchasing packaging machine for spices?

Purchasing a packaging machine for spices can put a serious dent in your wallet therefore, this machine must be well aligned with your business goal otherwise, you would not get more benefits out of this deal. Here are some best practices you should follow to obtain a proper match.

Select Your Packaging Container

Spice Packaging

Various packaging machine for spices package spices in different containers such as tin can, bottles, and pouches. Thus, it is important to choose in what container will you package your spices. Furthermore, if you choose pouches as your packaging container, then decide whether you will use premade pouches or roll stock. This is because form, fill and seal packaging machines for spices and premade pouch packaging machines for spices are significantly distinct from each other.

Determine Your Packaging Speed

High Packaging Speed in Packaging Machine for Spice- Picture Courtesy: Packaging Digest

It is essential to estimate the number of spice containers you will package per shift and how much larger will be your batch. The larger the batch more speed of the machine will be required. Speed is dependent upon the automation of the packaging machine for spice. A fully automatic packaging spice for spice will cost a lot but if you require higher productivity then investing in this equipment will be beneficial for you in the longer run.

Give More Numbers to Sustainability

Sustainability in Packaging Machine for Spice

Companies that have lower carbon footprints are popular among customers. Lowering packaging waste is advantageous in terms of expenses and also for the environment. Therefore, it is vital to purchase eco-friendly equipment. This machine will use green materials for packaging, will make accurate cuts to lower wastage, and will use a small amount of energy.

Consider Future Demands

Modular-built packaging machine for spices-Picture Courtesy: Zeus Petruzalek

Invest in a packaging machine for spice that is modular-built. In this way, it will not only fulfill your present demands but also will support your future growth. Moreover, opt for a versatile packaging machine for spice as it processes multiple containers varying in shapes and size, hence it will satisfy your evolving packaging requirements.

Ponder on Safety Features

Safety Doors in Packaging Machine for Spices- Picture Courtesy: Purpak

Safety is one of the most important aspects in the design of a packaging machine for spice. Safety barriers and glass doors keep the workforce safe while offering a clear view of packaging operation. Hence, go for a packaging machine for spice that is equipped with safety features because these installations minimize the risk of injuries and strain to operators.

Conclusion

An indispensable part of the world of cooking constitutes of spices and condiments, for which it is mandatory to preserve its freshness, aroma and quality of taste. Packaging machine for spices takes care of spices by providing good assurance of it’s dispensed format till it reaches the hands of consumer. If you’re planning to procure packaging line into your production facility. Then Allpack is the one-stop-solution for you. The company is offering tremendous services to their clients with 100% satisfactory reviews. Just message us now to open the horizon for excellence and innovative machines.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide