Olive Oil Packaging: The Complete FAQ Guide In 2025

Olive oil contains immense health benefits, it packs a powerful punch of antioxidants and omega-3 fatty acids that are good for the heart, brain, and joints. In recent years, sudden expansion in the market of olive oil packaging has been observed because of its high use for medicinal and culinary purposes. With olive oil packaging, freshness, nutritional valve, and, flavour of olive oil is sealed. This packaging is also adopted by brands because of its aesthetic appeal that serves as a branding tool and its surface area for labelling.

Interesting in starting your new olive oil venture and keen on learning about various olive oil packaging styles? Then start reading this blog now because we have included all informative facts about olive oil packaging just for you in this guide.

1.How Can You Define Olive Oil Packaging?

Olive Oil Packaging- Picture Courtesy: Package Inspiration

Olive oil packaging is an important step after pressing in olive oil processing. An enclosed container airtightly covered from all sides used for storing the olive oil is called olive oil packaging. It is known for its higher aesthetics, exceptional stability, and quality.

The shelf life of olive oils depends upon the right type of packaging. For delivery of top-quality olive oil with maximum nutrition and flavorful taste, olive oil packaging is very important. Moreover, for convenience in handling, storing, marketing, and, transporting, olive oil is packed into sturdy and robust containers, for instance, pouches, bottles, and jerrycans, to name a few.

2.What Advantages Olive Oil Packaging Brings to Buyer and Seller?

Due to the health awareness of customers, the demand for olive oil and in turn exigency of olive oil packaging has been rising over the last few decades or so. The olive oil packaging is stout and brings huge advantages to both buyers and sellers that are listed below:

Source of Convenience

Convenience with Olive Oil Packaging- Picture Courtesy: La Panza Olive Oil

Olive oil packaging is designed with spouts and nozzles that help in controlling the pour quantity with which product wastage can be reduced. Moreover, it also results in mess-free and spill-free pouring. Thus, packaging is advantageous for buyers as it saves them from the hustle of measuring the perfect amount of olive oil for cooking.

Resealability

Resealibity of Olive Oil Packaging- Picture Courtesy: Trend Hunter

Twist-off caps in bottles and spout pouches aid in re-sealing the olive oil packaging after its use which improves its consumable time. Some pouches are manufactured with resealable zippers and strips that are tied once olive oil dispensing is finished. This resealing also saves the products from contamination and deterioration.

Customization For Enhanced Branding

Customization of Olive Oil Packaging- Picture Courtesy: Dieline

Tailoring olive oil packaging with a stylish design element, trendy designs, earthy colours, and striking topography always gives an edge to brands and customization of packaging according to the aesthetic sense of the target market often creates a unique selling opportunity. With creative packaging, there is no need for a hefty marketing budget, as this packaging is an advertisement on its own.

No Counterfeiting and Altering

Olive Oil Packaging- Picture Courtesy: The Branding Journal

Today, olive oil has made a significant headway from traditional bulky containers. There are smart packaging such as QR codes, RFID, barcodes, tamper-evident seals, holograms, and many more are included on the olive oil packaging to make it tamper-proof and anti-counterfeiting. These features play a vital role in security, safety, tracking, and tracing the olive oil packaging. Furthermore, brands ingeniously leverage these improvements to add worth to their packaging and attract their customers.

Ease in Shipping

Olive Oil Packaging- Picture Courtesy: Cobram Estate

Last but not least, with olive oil packaging, the olive oil remains intact and undamaged throughout the supply chain. This stackable packaging aids in the logistics and transportation of products across long hauls. It needs a small space and is easier to handle, ensuring a spill-free means for the import and export of olive oil.

3.What are Popular Olive Oil Packaging Styles?

As there is huge saturation in the market of olive oil, therefore, brands utilize unique-styled packaging to differentiate their product in the market, consequently olive oil packaging of all shapes and sizes is seen in stores. Some of these popular packaging styles are discussed below:

Standup Pouch with Spout

Spouted Standup Pouch

This spouted pouch is known for its distinct shape and tall structure that is easily observed from afar. This design with bottom folding makes a huge contribution to the marketability of the product. It is a high-demand packaging format because of its cost-cutting feature.

This pouch is fabricated with a narrow spout or nozzle usually found at the corner or in the middle of the pouch and offers ease in dispensing olive oil. Moreover, it is re-sealable with twist-off or flip-off caps.

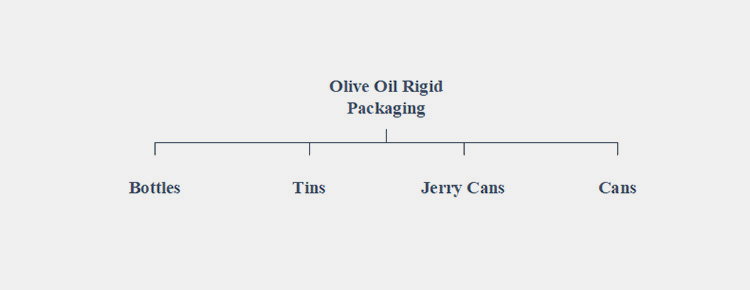

Rigid Olive Oil Packaging

Similar to pouch packaging, there is also a wide range of rigid olive oil packaging styles such as:

Bottles

As bottles are a popular packaging format for olive oil, therefore, it is found in all and sundry designs such as:

| Boston Round Bottle

It is a classical bottle style for filling olive oils and resembles old apothecary bottles. As the name indicates, this bottle has a round design, consequently giving a strong look. Amber-tinted, green, or clear Boston round bottles are ideal for packaging olive oil. |

Boston Round Bottle- Picture Courtesy: La Carolina Roja Farm |

| Marasca Bottle

It is a typical olive oil bottle with a tall or slender look. Marasca bottles have square edges. It has a cubic design at the lower part and has a rounded neck. |

Marasca Bottles- Picture Courtesy: By Ofifacil |

| Dorica bottle

It is another commonly utilized olive oil bottle and has a slender shape but with rounded edges. Its round shape is perfect for wraparound labelling, thus presenting a sophisticated look. |

Dorica Bottles- Picture Courtesy: SVA Design |

| Bellissima Bottles

This bottle has a striking physique marked with a narrow neck and wide round base just like a bell. Its expectational design gives its unique look. |

Bellissima Bottles- Picture Courtesy: Blogs de EL PAÍS |

| Bulbous Bottles

This bottle features an everted rim and a rounder base that tapers off at the top giving the neck of the bottle a slender look. These bottles have a distinctive look due to their bulbous base. |

Bulbous Bottles- Picture Courtesy: Designer Daily |

Tins

They are yet another renowned packaging style for olive oil. These are manufactured using steel, aluminum, and tinplate. The common tin style for olive packaging is:

| Round Tins

These have a cylindrical structure and are widely employed tin packaging style for olive oil. They may have a spout for pouring olive oil. |

Round Tins- Picture Courtesy: Waldemar Art |

| Rectangular Tins

They have four distinct edges and feature rectangular or square shapes. They are often preferred over round cans because of their stackability. |

Rectangular Tins- Picture Courtesy: Oliviers & Co |

Jerry Cans

Olive Oil Jerrycan- Picture Courtesy: Real Foods

They are heavy-duty olive oil containers holding bulk volumes of olive oil. They typically encompass a rectangular or square design and are closed with twist-off caps.

Cans

Olive Oil Cans- Picture Courtesy: Willow Creek Olive Estate

These containers are robust with their metallic or plastic construction and are often employed for shipping large volumes of olive oil. They either come in rectangular or round construction.

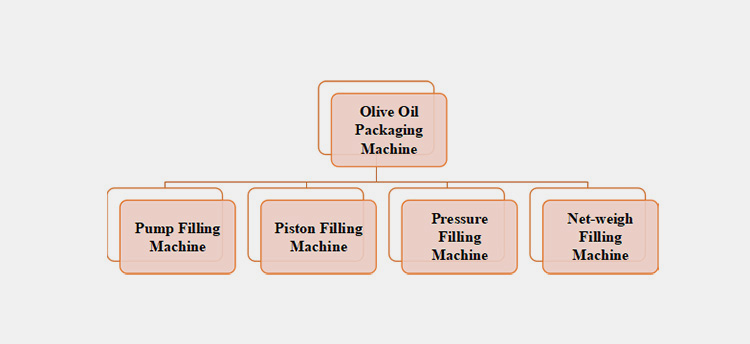

4.What are Common Packaging Machines for Olive Oil Packaging in Production Lines?

Olive oil packaging machines are classified in two different ways. The detail of these systems is discussed below:

According to the Filling Type

Here is a list of olive oil packaging machines differing in their filling method.

Pump Filling Machine

Pump Filling Machine

This machine consists of diverse kinds of pumps, such as lobe, gear, and cavity pump that controls the amount of olive oil flowing through machine piping, therefore, providing accuracy in the fill. With the positive displacement method and servo-driven controls, it can fill virtually any kind of olive oil, virgin or extra-virgin.

Working Principle

This machine runs on the working principle of time-based and pulse-based feeding. In tine-based filling, the pumps are rotated for a specific time interval, predetermined by the operator. This rotation of pumps moves the olive oil through the hose pipe and filling nozzle. However, in pulse-based filling, olive oil is dispensed inside the container for a fixed number of pulses.

Piston Filling Machine

Piston Filling Machine

For accurate and high-viscosity dispensing of olive oils, piston cylinders with their individual filling nozzle and tubes are used in this machine. Precision in fill is achieved with piston stroke. The piston movements allow for the smooth and consistent flow of olive oil from the hopper to the container.

Working Principle

On signaling from the PLC system, the piston moves forward in the cylinder that exerts the pressure on olive oil and it flows from hopper to cylinder. With the backward movement of the piston, the olive oil is hauled into the filling nozzle from where it slowly trickles down into the packaging container. Upon filling of required volume of olive oil, the PLC system signals for the pause in filling.

Pressure Filling Machine

Pressure Filling Machine

This machine has a simple and compact design, operating similarly to gravity gravity-filling machine. The olive oil is filled inside the container using low pressure developed either by a vacuum system or compressed air. Heavy-duty conveyors are fitted in this equipment that ensure smooth and steady transfer of packaging containers between different stations.

Working Principle

The hopper located at the top has high pressure while packaging containers are at low pressure in this machine. Due to the pressure difference, the olive oil flows from the hopper down in the packaging containers through the filling nozzle. Time-based filling is also employed in this equipment for dispensing olive oil.

Net-weigh Filling Machine

Net-weigh Filling Machine

This machine operates at a fast speed and fills the olive oil by measuring its accurate weight. The load cells are the important component in this machine that correctly determines the weight of olive oil. It is usually employed in large industries that package bulk quantities of olive oils for shipment and storage.

Working Principle

The load cells present at the bottom of packaging containers measure the fill amount in the bottle. This load cell is controlled by electric cards that monitor the fill weight, estimated by the load cell. Upon loading preprogrammed weight, the load cells signal the PLC system which in turn transmits the signal to the filling valve to close and stop dispensing olive oils.

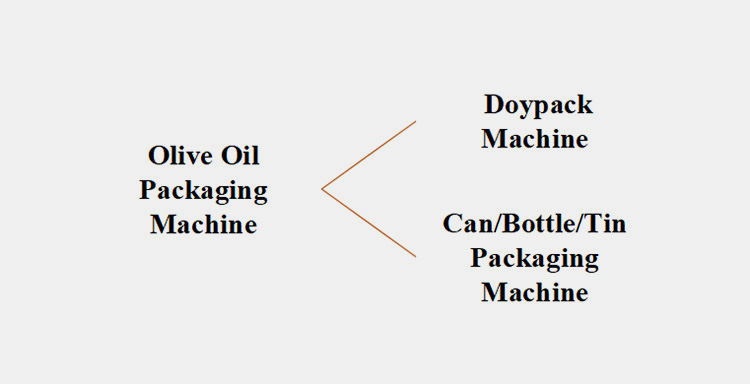

According to the Packaging Format

There are different models of olive oil packaging machines depending on the type of packaging format.

Doypack Machine

Doypack Machine- Picture Courtesy: Allpack

It is the most flexible machine that can process any shape and sized olive oil pouch without the need to change parts. This machine can fabricate a variety of pouches. This machine has hygienic and safe processing of olive oils because it is fabricated and assembled with stainless steel and food-grade materials that offer no chance of product contamination. With a high-efficiency volumetric filler, it can load viscous olive oils within no time.

Working Principle

The working of the machine starts with a flat sheet of film which horizontally moves inside the assembly of the machine to form a bag by series of hot sealers which joins the bag from three sides followed by inserting a spout. Now olive oil can be dispensed into the inflated bag followed by final sealing of the upper part of bag with final discharge.

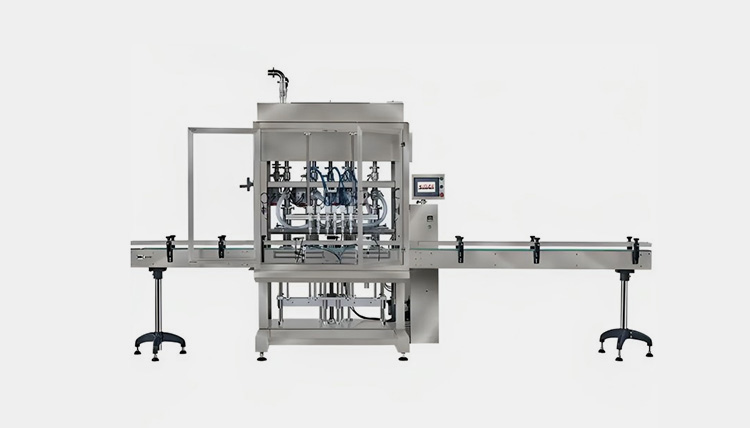

Can/Bottle/Tin Packaging Machine

Can/Bottle/Tin Packaging Machine

It is the most frequently used machine for packaging olive oil as most customers prefer their olive oil inside bottles or tins. A durable and robust filling system, servo-driven conveyors, and sophisticated PLC make this machine, world world-class and capable unit that accommodates and processes any type of rigid container.

Working Principle

With a guided conveyor system, the containers move to an accurate filling system, where state-of-the-art filling nozzles quickly fill the pre-determined quantity of olive oil in the packaging container upon signaling by the PLC system. After loading, the containers are guided towards other stations for capping and sealing.

5.What are Widespread Volume Sizes of Olive Oil Packaging?

Volume Sizes of Olive Oil Packaging- Picture Courtesy: The Telegraph

Olive oil is seen in all kinds of packaging, each having their packaging volume. To avoid, confusion, below mention are some common packaging styles:

Olive oil in 0.75-litre bottles is widely packaged and popular among retailers, followed by olive oil in 0.5-litre bottles. Its 0.1-litre bottles are also well-liked by the consumers. Samples of olive oil bottles for tasting purposes have 6 ml of olive oil.

Single-dose serving sachets contain 10 ml of olive oil. The biggest canister of tinplate holds around 3-5 liters of olive oil while frequently produced tins have a volume of 1 liter. The most commonly used flexible standup and spout pouches contain 1 liter and 1.5 liter of olive oil.

6.Why Is Olive Oil Packed In Dark Bottles Packaging?

Dark Olive Oil Bottle- Picture Courtesy: moresh.com

Olive oil packaging in dark bottles is high in demand and brands prefer to store it in these containers because of photo-oxidation. It is a phenomenon in which light accelerates the reactivity of oxygen with fats and oils, causing the production of aldehydes and ketones. These compounds give characteristic bad smell and smell to olive oil.

Nevertheless, with colored bottles, such as amber-tinted or green color, this reactivity is prevented due to blockage of light. Hence, the shelf life of olive oil is longer in dark bottles.

7.What are the Labeling Requirements for Olive Oil Packaging?

Olive Oil Labeling- Picture Courtesy: World Brand Design Society

The labelling on olive oil packaging is essential for two reasons - to communicate facts about olive oil for the safety of consumers and to create a beautiful look for appealing customers. It is mandated by food regulatory authorities to include certain obligatory facts about olive oil and thus, brands do so in a visually pleasing manner.

Certain obligatory information on olive oil packaging is discussed below:

| Characteristics of Olive Oil | It is obligatory to include information about olive oil, like extra virgin or virgin olive oil. These two types of olive oils are vastly different from each other. Extra virgin is pure olive oil and is the highest-grade olive oil and extra care such as, the prohibition of excessive temperature and chemicals is taken during extracting and pressing. Virgin olive oil is also a pure olive oil but there are some impurities in it, thus it is a grade below extra virgin olive oil. |

| Country of Origin | Another essential information to include on the packaging label is the country in which olives are harvested, extracted, and pressed. It is compulsory to mention that olives are obtained from one country and olive oil is produced in another country. This section has phrases like obtained in, produced in,100% produced in, harvested by, etc. |

| Net Volume or Weight | The total quantity of olive oil should be described on the front label followed by a unit, for instance, 1 litre, 100 cl, 1000 ml |

| Best Before Date | For the health safety of consumers, the best before date or expiry date must be denoted on the packaging label in readable fonts for the convenience of users. |

| Storage or Use Conditions | As olive oil is a sensitive product, its proper storage instructions must be indicated on the container. Terms like place in dark, cool, and dry areas must be mentioned to remind end-users. |

| Name and Address of Manufacturing Business | It is mandated by law to include the name and address of the brand under whose name the merchandise is advertised. It must include the name of the producing company |

| Nutrition Facts | The necessary nutrition is provided per serving like the percentage of carbohydrates, proteins, fats, vitamins, and minerals. It must be denoted on the back label of the container. It must also mention the total calorie count per serving. |

| Batch Number | This is another obligatory information that is included on the label. The batch number denotes the lot to which olive oil belongs. |

8.What are the Most Popular Capping Styles for Olive Oil Packaging?

There are quite a variety of popular capping styles for olive oil packaging:

Cork

Corks- Picture Courtesy: Grecian Purveyor

They are made with natural cork bark or they can be synthetic, manufactured using plastic and rubber. They are one of the oldest closures for olive oil bottles. The corks should be non-porous and should not have fungus spores but these caps are not recommended because they have high air penetrability.

Metals Caps

Metal Caps- Picture Courtesy: Real Italiano

These caps have screws for tightly fitting caps on the mouth of bottles. Moreover, there is a plastic liner inside the caps that provides more airtightness and impermeability to environmental agents. These caps are manufactured using aluminium. Metal caps are found on 15% of olive oil bottles.

Thermal Retractable Capsule Caps

Thermal Retractable Capsule Caps- Picture Courtesy: Dieline

These are also called heat shrink caps and are generally utilized for closing olive oil bottles. They are made with PVC that shrinks on exposure to heat and adheres to caps. It has a retractable stopper located on the top of the cap that tightly seals the bottle. It also improves the aesthetic effect of the olive oil bottle packaging. About 72% of olive oil bottles feature these kinds of caps.

9.Why Inert Gases are Used for Olive Oil Packaging?

Olive Oil Packaging- Picture Courtesy: Mani Bläue

Before filling olive oil in the bottles, pouches, or other packaging containers, inert gases like argon and nitrogen are blown inside the containers. The bottles are transferred to a special machine that inverts them and introduces liquid nitrogen or other inert gas inside them. This liquid nitrogen changes into a gaseous state upon contact with the container. By this, it removes oxygen from the packaging container.

Afterwards, bottles or other olive oil packaging are straightened and relocated to proceed with packaging operations during which nitrogen remains in the container because of its heavier density. The containers are loaded with olive oil while preventing oxygen entry.

The olive oil package under inert gases has optimal quality throughout its shelf life because these gases eliminate oxygen and other volatile contaminants from packaging. Oxygen is one the major culprit that promotes lipid oxidation rate in oils and causes their rancidity, subsequently reducing their quality and creating a bitter taste and smell in olive oil.

10.What is the Shelf Life of Olive Oil Packaging?

Shelf Life of Olive Oil Packaging- Picture Courtesy: OliveOilsLand

Olive oil is well-liked by end-users all across the globe because of its appetizing taste and pro-health benefits. Phenolic compounds serve as antioxidants promoting health and virility and also offer olive oil resistance against spoilage. But their quantity decreases over time. Thus, the shelf-life of olive oil also degrades with passing months.

It has been estimated that olive oil should be consumed within 12-24 months, as after this time it will develop an unpleasant taste and lose its nutritional benefits. Olive oils should be stored at 16 – 18°C (61 – 64°F).

Its serviceable life also depends upon the type of packaging. Olive oil packaged in glass bottles has a maximum shelf life of around 1-2 years. The olive oil stored in PP and PE materials whether pouches or bottles should be bought within 4 weeks of packaging, as these materials are permeable to air which could cause oxidation of fats in olive oil. In contrast, olive oil in PVC bottles is good for 3 months without experiencing quality loss.

Conclusion

Olive oil packaging is favoured by brands and end-users due to its dependability, protection, waste reduction, and aesthetics. With olive oil packaging, brands extend the shelf-life of their products by safeguarding them against degrading agents- oxygen and moisture consequently, hitting higher profits. The most important thing beautiful olive oil packaging can bring is a high number of interested customers. Curious to know more, Allpack is prepared to show you, all that there is about olive oil packaging and how you can achieve your business goals with perfect packaging.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide