Multi-Row Granule Packaging Machine: The Complete Buying Guide In 2025

Isn’t multi row granule packaging machine surprising you? In the arena of granular packaging, the multi-row granule packaging machine comes at the top. Granule packaging is filled with lots of problems like inaccuracies, seal leakage, material sticking, lower speeds, and lower packaging quality.

However, with the multi-row granule packaging machine, these problems are a thing of the past. This machine smoothly, accurately, and efficiently packs the granules in drastically less time.

Are you pondering about procuring a multi-row granule packaging machine? Then first, carefully take time to read this guide because we are complying list of important things to know about the multi-row granule packaging machine.

1.What is a Multi-Row Granule Packaging Machine?

Allpack Multi-Row Granule Packaging Machine

Multi-row granule packing machine has intelligent and sophisticated technology with which it form, fill, and seal packaging containers. It has multiple rows or lanes and fabricates and packs numerous sachets or stick packs in one go. This feature increases its throughput rate and production capacity.

This machine is equipped with smart control, touch screen interface, and PLC unit so that it efficiently and smartly performs packaging operations. Multi-row granule packaging machine is designed to process free-flowing granular products.

2.Why Multi-Row Granule Packaging Machine is Important?

Multi-row granule packaging machine is important because of its high productivity, versatility, and speed packaging. There are various reasons due to which this machine has a significant place in industries such as:

Flexibility For Changing Needs

Flexibility For Changing Needs with Multi-Row Granule Packaging Machine

The multi-row granule packaging machine is a highly resilient and adaptable unit, processing multiple types of granules as well as flakes. Easily changeable parts allow to accommodate both current and future products. Due to its flexibility, a multi-row granule packaging machine is well-suited for production that packs multiple products.

No Under and Over-Filling

Lower Operational Cost with Multi-Row Granule Packaging Machine- Picture Courtesy: Vitali-T

Multi-row granule packaging machine features highly sensitive metering devices that monitor minute changes in the granules. These metering and filling devices allow this machine to achieve precision in the fill. With its precise filling, there is no chance of over or underloading.

Lower Operational Cost

Lower Operational Cost with Multi-Row Granule Packaging Machine

Due to its smart and up-to-date computerized and mechanical parts, this machine carries out forming, filling, and sealing independently, reducing the requirement for a labour force which decreases labour wages. Furthermore, this machine has lower maintenance costs and lower energy requirements that contribute to its cost-effectivity.

Lower Wastage and Merchandise Rejection

Lower Wastage with Multi-Row Granule Packaging Machine

Human error is unavoidable in hand filling that leads to wastage of product due to overdosing of granules in the containers. These human mistakes also cause damaged products and product rejection. However, the multi-row granule packaging machine uses lower packaging material and with its accuracy, it reduces both product and material wastage.

Better Quality

Better Quality with Multi-Row Granule Packaging Machine

Humans poorly fill and wrap sachets and other packaging containers. It decreases impulse buying and upsets customers, But with automation, the multi-row granule packaging machine beautifully and consistently forms, fills, and seals products, increasing product quality that improves profitability.

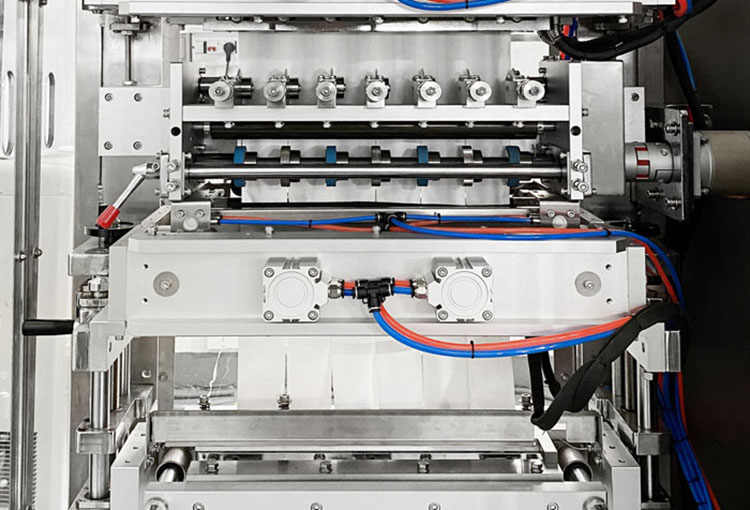

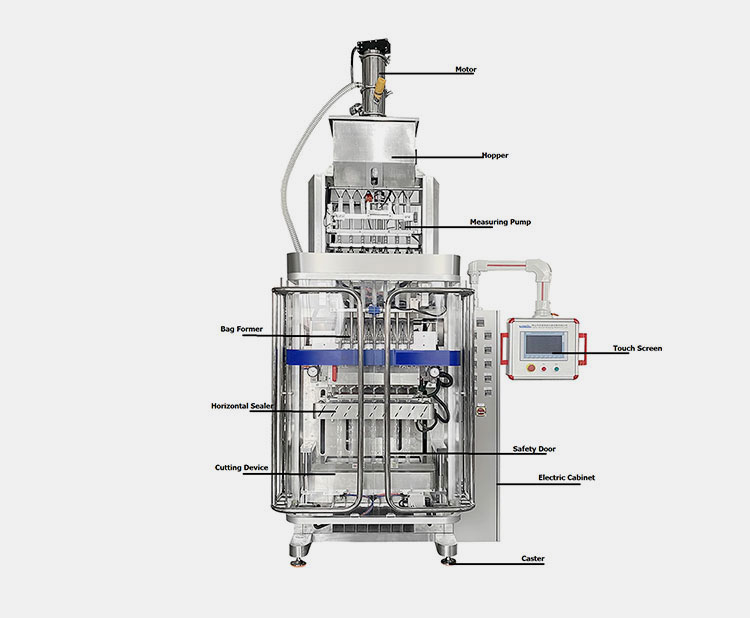

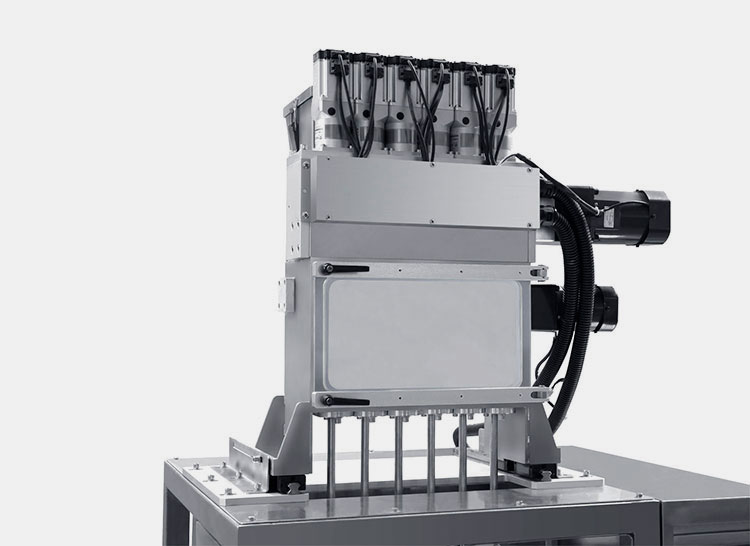

3.What are the Basic Components of a Multi-Row Granule Packaging Machine?

Different electric and mechanical components are present in a multi-row granule packaging machine that have an important and specific role in forming, filling, and sealing sachet and stick packs. These parts are discussed in detail below:

Parts of Multi-row Granule Packaging Machine

| Motor | This is a powering part of the multi-row granule packaging machine. it provides mechanical energy to different parts like filling devices, horizontal jaws, and film rollers. |

| Hopper | For uninterpreted packaging flow, a hopper device located at the top, stores huge quantities of granules. |

| Measuring Pump | These pump systems present below the hopper calculate the amount of granules passing through them. These systems maintain the accuracy of the multi-row granule packaging machine. |

| Bag Former | This is cone shaped part that creates bags using packaging film. This film is wrapped around the core of the forming tube to fabricate different packing containers |

| Horizontal Sealer | As the name indicates, the direction of action of these sealers is horizontal. They join the top and bottom edges to hermetically seal the packaging containers. |

| Cutting Device | Two consecutive sachets and sticks are linked with each other. A sharp cutter disjoins two successive packaging containers. |

| Touch Screen | It is a coloured display screen that aids in programming different operational components. Different input options are displayed on this screen, and operators easily select them by touching their fingers. |

| Safety Door | It is a clear or coloured glass door that separates the machine's inner components. This is a safety feature that prevents unintentional machine contact while it is running. |

| Electric Cabinet | It is a sturdy and robust cabinet that has different machine cables, wires, switches, and, circuit breakers. |

| Caster | These are the stands that bear the weight of the machine and stabilize the machine. |

4.Where is the Multi-Row Granule Packaging Machine Found?

The multi-row granule packaging machine is quite popular and found in different industries because it packs single-serving granular products. Some of its important industrial applications are:

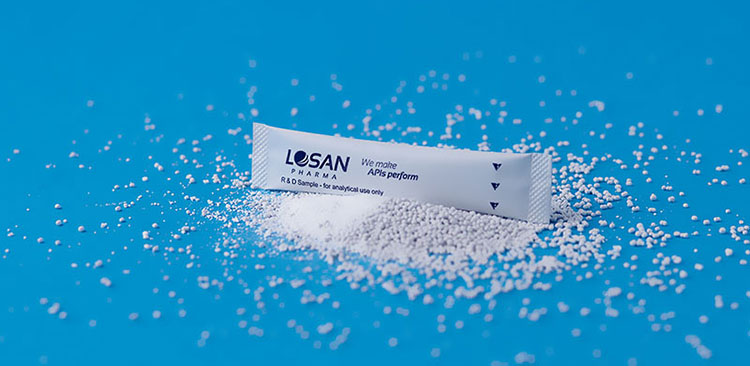

Pharmaceutical Industry

Use of Multi-row Granule Packaging Machine in Pharmaceutical Industry-Picture Courtesy: Losan Pharma

The pharmaceutical sector is an area where hygienic processivity is required. Therefore, a multi-row granule packaging machine is used because it is a closed device with no chance of contamination. It packs nutraceutical, pharmaceutical, and herbal granules in the stick packs and sachet.

Household Chemical Industry

Use of Multi-Row Granule Packaging Machine in Household Chemical Industry- Rox Hospitality

Household chemicals are abrasive and damaging, hence; these chemicals should be safely processed. A multi-row granule packaging machine carefully and precisely loads chemical granules like detergents, disinfectants, bleach, cleaning agents, and, mothballs in packaging containers.

Agriculture Industry

Use of Multi-Row Granule Packaging Machine in Agriculture Industry- Picture Courtesy: Native Seed Box

In the agriculture industry, product precision is essential and this precision is achieved by the multi-row granule packaging machine. Different seeds, organic fertilizers, humus, pesticides, and herbicides, are granular and thus are packed by the multi-row granule packaging machine.

Food Industry

Use of Multi-Row Granule Packaging Machine in Food Industry- Picture Courtesy: L28.nl

Accuracy and exactness are the core principles of food packaging. These fundamental principles are attained by the multi-row granule packaging machine. It packs a wide range of food granules like cereals, seeds, nuts, sugar, coffee, salts, flakes, chilli mixes, etc in the food industry.

Grain and Pulses Industry

Use of Multi-Row Granule Packaging Machine in Grain and Pulses Industry

Multi-row granule packaging machine instantly and accurately fills different kinds of grains like rice, flour, and pulses like lentils, quinoa, and roasted chickpeas in unique types of sachets and stick packs. This machine is known for its versatility in the grain and pulse industry.

Snack Industry

Use of Multi-Row Granule Packaging Machine in Snack Industry- Picture Courtesy: Joe & Seph’s

Yes, the multi-row granule packaging machine is also utilized in the snack industry for packaging chips, tortillas, popcorn, biscuits, and pretzels in the sachet or stick pack. This machine assures fill accuracy and high packaging speed.

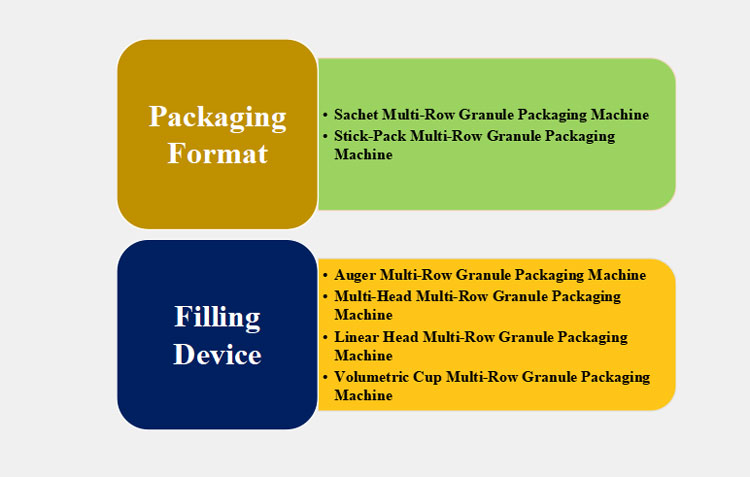

5.How to Classify a Multi-Row Granule Packaging Machine?

In the market, different classes of multi-row granule packaging machines are seen, differing in their packaging type and filling devices. The classification of this machine is penned below:

According to the Packaging Format

Sachet Multi-Row Granule Packaging Machine

Sachet Multi-Row Granule Packaging Machine

It forms and fills rectangular-shaped sachets that have more width. Sachet multi-row granule packaging machine has a multiple number of lanes that pack numerous sachet in a single setting. This machine is equipped with a variety of filling devices that increase its flexibility. It is a perfect single-serve packaging solution.

Stick-Pack Multi-Row Granule Packaging Machine

Stick-Pack Multi-Row Granule Packaging Machine

It forms and fills tubular-shaped stick packs that have a greater proportion of length to width. This machine has up to twenty lanes, hence; can pack twenty stick packs at a time. Stick pack multi-row granule packaging machine has greater floor print. This machine also packs single-serve of granules.

According to Filling Device

Auger Multi-Row Granule Packaging Machine

Auger Multi-Row Granule Packaging Machine

It is a closed device that safely and hygienically processes and packs granules. It is important when contamination-free and sterile processing is required. It has auger screws that rotates auger plates for filling. It is a frequently used machine for powders and granule filling.

Multi-Head Multi-Row Granule Packaging Machine

Multi-Head Multi-Row Granule Packaging Machine

This machine consists of several channels, each with its hopper for precise and accurate filling. These multi-head hoppers measure exact quantities of granules and dispense them in packing containers. It is fast, versatile, and has extreme accuracy.

Linear Head Multi-Row Granule Packaging Machine

Linear Head Multi-Row Granule Packaging Machine

Unlike the circular arrangement of heads in a multi-head multi-row granule filling device, this machine has a linear arrangement of heads. These weighing hoppers dispense precise amounts of granules inside the packing container. It is used for filling different-sized granules.

Volumetric Cup Multi-Row Granule Packaging Machine

Volumetric Cup Multi-Row Granule Packaging Machine

This machine contains a tray with multiple cups. A required amount of granules is loaded inside the cup in a volumetric cup multi-row granule packaging machine that is then loaded inside the packing container. It is a straightforward instrument, best for free-flowing granules.

6.Explain the Working of a Multi-Row Granule Packaging Machine.

The multi-row granule packaging machine has straightforward working steps. Every component harmoniously performs its role in packing different versatile packaging containers. Here is a detail of the working steps:

Working of Multi-row Granule Packaging Machine

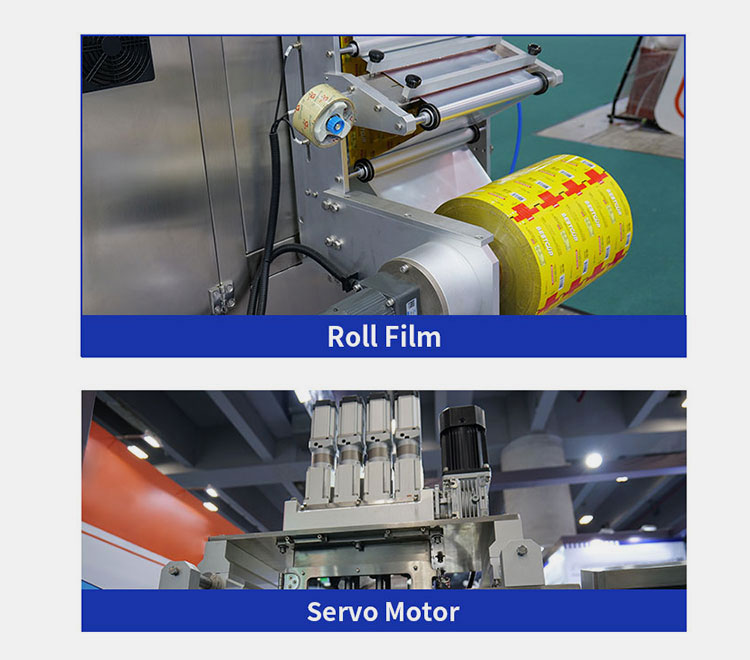

Film Roll Loading

First, for continuous packaging operation, the large film roll is put over the film holder. This film is unravelled and directed over cylindrical rollers and the dancer’s arms. These two components have significance because they keep the film on track and minimize its chances of slippage.

Servo-Motor and Product Loading

A huge hopper is present on the top for product loading. Before the operator, large quantities of granules are housed inside the hopper using infeed tanks. The Servo motor located with a hopper offers power to move mechanisms in filling devices.

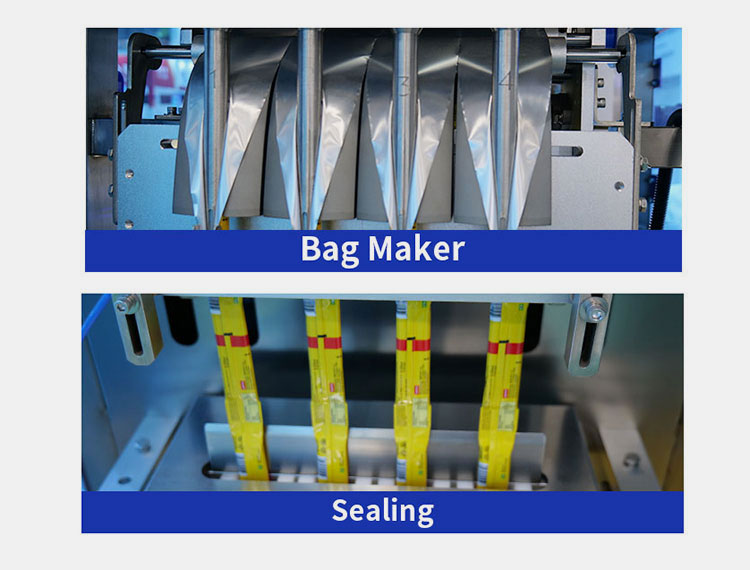

Bag Maker

The film is cut into smaller strips by the cutter. Each strips are moved to its respective lanes where different bag makers are present. These bag makers are conical-shaped forming tubes and vertical sealers. When the film arrives at the bag maker, it is doubled over and covers the entire forming area to form bags. The granules are filled inside the formed bags by filling nozzles.

Sealing

Upon granule loading, the next step is sealing which is executed by the horizontal sealers. They are the sealing elements that seal the top edges together using heat, pressure, or impulse waves. Separation of two joined bags is carried out by the sharp cutters. Cutters trim away sealed edges. Now the bags are ready for secondary packaging.

7.What Granular Products are Packed by Multi-Row Granule Packaging Machine?

As already discussed, multi-row granule packaging machine has diverse applications in different types of industries. So, this machine can process a wide range of granules like:

| Pharmaceutical Granules

This machine can pack a variety of pharmaceutical granules that contain drug ingredients in their core. These pharmaceutical granules are easy to swallow and ingest. |

Pharmaceutical Granules |

| Seeds

Different types of seeds, for instance, sunflower seeds, chia seeds, moringa seeds, carom seeds, etc are packed by this machine. These seeds are a perfect mix of trace nutrients. |

Seeds |

| Desiccants

Silica gels and other desiccant materials are loaded inside the sachet by a multi-row granule packaging machine. These desiccant sachets are often found in pill bottles for absorbing water vapours. |

Desiccant Sachet |

| Cleaning Agents

Different household cleaning agents like detergents and dishwashers are often granular. These cleaning agents are packed by a multi-row granule packing machine. |

Cleaning Agents |

| Pet Food

Dry pet treats like biscuits, kibbles, and other pet snacks are loaded inside a small one-time-serve sachet and stick pack by this machine. |

Pet Food |

| Herbs and Spices

Different dried herbs like oregano, thyme, basil, parsley, lemongrass, and cilantro, and spices like chilli, mint, coriander, clove, mint, pepper, etc are filled by this machine. |

Herbs and Spices |

| Sweet Candies

Multi-row granule packaging machine loads different sweet and sour candies, chocolates, taffy, jellies, marshmallows, bunties, coco balls gummy bears, gummy worms, toffee, etc. |

Sweet Candies |

| Cereals and Flakes

This machine also loads breakfast sweet and crunchy cereals, granolas, and trail mixes in stick packs or sachets. |

Cereals and Flakes |

| Nuts and Dried Fruits

Almonds, cashews, hazelnuts, peanuts, pecans, pistachios, raisins, dates, and many more are also processed by this machine. |

Nuts and Dried Fruits |

8.What Packaging Container Types are Processed by a Multi-Row Granule Packaging Machine?

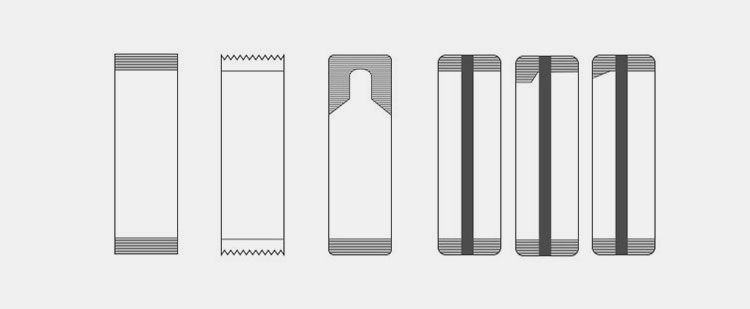

There are two main types of packaging containers- sachets and stick packs- are processed by the multi-row granule packaging machine. These are further divided into different types based on shapes, seal type, and cutting pattern.

Sachets

These are usually rectangular or square packs having four distinct corners. They pack single-serve of the granules. They are classified into different types such as:

According to Seal

| Three- Side Seal Sachets

These sachets have seals on three different sides. These are various combinations of seals like one side, top, and bottom or two sides and one top. |

Three-Side Seal Sachet |

| Four-Side Seal Sachet

They have four distinct seals on every side that is one top, one bottom, and one side. |

Four-Side Seal Sachet |

| Back Seal Sachet

It is also called the central seal. These sachets are called T-seal sachets as a distinct seal runs along their entire back length. |

Back Side Sachet |

According to Shape

| Regular Sachets

These are normally rectangular or square sachets with four different sides and corners. |

Regular Sachets |

| Irregular Shape Sachets

These have atypical shapes like bottles, hearts, stars, jars, hands, etc to captivate passersby and increase chances of selling. |

Irregular Shape Sachet |

Stick Packs

These have tubular long packs resembling a stick. These packs have a greater ratio of length to width. There are different types of stick packs such as:

| Flat Cut Stick Pack

It is one of the commonly found types of stick pack. This stick pack has a simple, horizontal cut that offers the stick pack a clean and elegant appearance. |

Flat Cut Stick Pack |

| Pattern Cut Stick Pack

This type of stick pack has patterned cuts like zig-zags or perforations. This cut increases the product appeal of the stick packs. |

Pattern Cut Stick Pack |

| Shaped Cut Stick Pack

Different kinds of cutters are utilized to create unique shape cuts on the stick pack like V or irregular shapes. This unique design plays a role in the marketability. |

Shaped Cut Stick Pack |

| Round Cut Stick Pack

A sharp cutter creates a round cut on the stick pack. These stick packs are also known as round-corner stick packs because of their round corners. The round cut provides a premium look to stick packs. |

Round Shape Stick Pack- Picture Courtesy: ePac Flexible Packaging |

| Tear-Easy Stick Pack

This type of stick pack has perforations that increase its tearability and reduce the risks of cutting. |

Tear-Easy Stick Pack |

9.What is the Difference between a Multi-Row Granule Packaging Machine and a Single-Row Granule Packaging Machine?

Single-Row Granule Packaging Machine

Both of these machines pack granules but there are numerous differences between a multi-row granule packaging machine and a single-row granule packaging machine. Some of these differences are discussed below:

| Features | Multi-Row Granule Packaging Machine | Single-Row Granule Packaging Machine |

| Configuration | This machine consists of multiple lanes. | This machine has one lane for creating, loading, and sealing granules. |

| Output | This machine packs numerous sachets in one cycle. This results in an increased output rate and more production speed. | It packs only one sachet at a time; hence, it has a lesser output rate and speed than a multi-row granule packaging machine. |

| Cost | This machine has numerous lanes and a complex design, consequently, it has a higher purchase cost. | The single-row granule packaging machine is a more affordable option for smaller industries because of its simple design. |

| Packaging Format | It packs several similar types of packaging sachets and stick packs. It is mostly useful for massive volume productions. | It is more versatile and can create different unique sachets or stick packs one after another by simple changes in parts. |

| Maintenance | It is difficult to operate and maintain a multi-row granule packaging machine because of its complicated design. | It is relatively easy to clean and maintain this type of granule packaging machine. |

| Footprint | It has a higher footprint because of its numerous lanes. | It is more suited to smaller industries with space constraints because of its smaller footprint. |

10.What are Troubleshooting Suggestions for a Multi-Row Granule Packaging Machine?

Unanticipated problems are part of the routine working of a multi-row granule packaging machine. These problems lower the production efficiency of the machine and result in huge repair costs. These problems can be troubleshooted by following remedies.

Presence of Foreign Objects in Granules

Presence of Foreign Objects in Granules

Granules are contaminated with dust, debris, or other products.

Causes

- Sealing mechanisms are uncleaned and dirty.

- Defective or unclean packaging materials.

- Inconsistent sealing of packing container.

Solution

- Thoroughly clean the sealing jaws.

- Ensure packaging materials are clean and free of defects.

- Ensure seal quantity.

Differences in Lengths of Finished Packaging Sachets or Stick Packs

Differences in Lengths of Finished Packaging Sachets or Stick Packs

There are variations in the lengths of the packaging container.

Cause

- Incorrect input of bag length parameters

- The forming and cutting parts are not properly positioned.

- Damaged forming and cutting parts.

Solution

- Reset the bag length parameters on the machine’s touch screen.

- Position and level forming and cutting parts correctly.

- Replace worn-out forming and cutting components.

Uneven Flow of Granules

Uneven Flow of Granules

There is inconsistency in the movement of granules from the hopper.

Cause

- Clumping or agglomeration of granules in the hopper.

- Hindrances or blockage in granule filling systems.

Solution

- Ensure granules are free of clumps at the time of loading.

- Dispel any hindrance in the granule-filling device.

Slippage or High Tension in the Film

Slippage or High Tension in the Film

Sometimes, there are problems with the film tracking.

Cause

- Misalignment of dancer’s arm and rollers.

- Incorrect positioning of film on the holder.

- Poor film weaving.

Solution

- Re-align properly the dancer’s arm and rollers.

- Ensure correct film positioning on the film holder.

- Re-thread film accurately over rollers.

Improperly Formed Seals

Improperly Formed Seals

The seals are uneven and weak.

Cause

- The sealing temperature is too low.

- Poor sealing pressure.

- Dirty sealing bars.

- Worn-out sealing jaws.

Solution

- Maintain proper sealing temperature as per the recommended range.

- Ensure accurate pressure while sealing.

- Clean dirty sealing elements.

- Replace old sealing jaws.

Conclusion

Dear Reader! Hopefully, you have found this blog post “Multi-Row Granule Packaging Machine” interesting and worth reading. Now, you know the important points of a multi-row granule packaging machine like its parts, benefits, types, working, and uses. Considering these points, you will make a confident choice regarding this machine. However, if you are still confused about selection then do not shy away from seeking help. We, Allpack are here to guide you in making a perfect decision and will provide excellent quality machines in your budget range.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide