Multi-lane Special Shapes Bag Sauce Packing Machine: The Complete Buying Guide In 2025

Are you looking for a powerhouse machine which can package your products into sachets and bags as smoothly as possible? Are you worried whether the machine you will buy will be worth the investment? Is it going to benefit you in the long run and yield the results you desire? Is it going to pose problems for you in the future due to which you would have to discard the equipment? Would you be able to use it for multiple applications?

Don’t worry, you have stumbled upon the right blog! Because we have got answers to all your questions. Let us introduce you to this magnificent piece of equipment known as multi-lane special shapes bag sauce packing machine. We will discuss about this machine in detail. So fasten your seat belts! Because we are about to begin our journey of getting to know about multi-lane special shapes bag sauce packing machine!

1.What is multi-lane special shapes bag sauce packing machine?

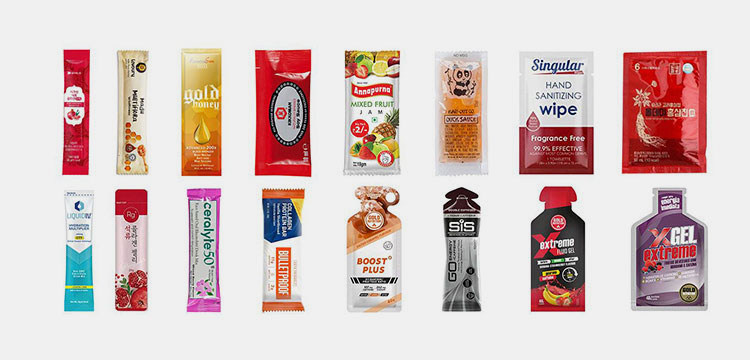

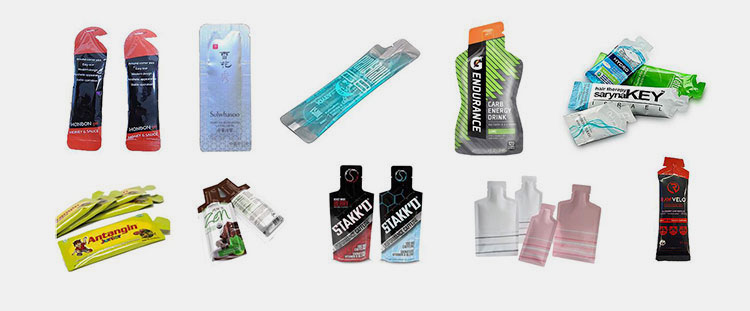

Multi-lane special shapes bag sauce packing machine, as the name suggests is used to package various products like sauces, cream, lotion, medicinal solutions into special shape bags or pouches effectively. It can provide you with multi-functional features which give optimum results and reliable products which you can easily ship to their appropriate destination.

This equipment was made with latest technology which features minimum wastage and would provide you with perfectly sealed and packaged bags or pouches filled with your desired product. it packages accurately every single time a new batch arrives, thus would help you in maximizing your profits.

2.What are the benefits of multi-lane special shapes bag sauce packing machine?

You must be wondering by now what kind of benefits this machine would provide you. This equipment has many advantages which would be beneficial for your company due to the number of advanced features this machine has been provided with when it was being manufactured. Let’s see what these benefits are.

High production capacity

One of the best advantages of multi-lane special shapes bag sauce packing machine you would see is that it has the ability to package many products at the same time since it has the multiple fillers which would fill and package your products into special shapes bag simultaneously. So if you want a machine which can cater to your high production demand, then this one is perfect for you.

Accurate dispensing

You might have heard about some machines which spill the products and do not package them correctly. Well not this one. Because multi-lane special shapes bag sauce packing machine is provided with an intelligent PLC and human machine interface which fills your product with high precision. So you don’t have to spill your anger out on the machine or your worker!

Versatility

If you have factories which are involved in various sectors, then you have stumbled upon the right machine because it can be used in multiple industries. From packaging sauces, creams, lotions to chemicals and medical ointments. You name it, and this machine can do the packaging for you.

Compact design

If you have a small workspace and you’re worried whether you can install it in your production line. Then don’t worry because multi-lane special shapes bag sauce packing machine is designed in a way that it takes minimal space. So it can easily integrate into your working space with ease.

3.What are the applications of multi-lane special shapes bag sauce packing machine?

This perfect piece of equipment can be used in several sectors which makes it one its most attractive feature. It can fill and package any product into special shapes bags, pouches and sachets. Whether it is in a medical setting or a food sector. Let us discuss where this machine can be used.

Pharmaceutical industry

Ointment cream- Picture Courtesy: Trade india

This large-scale industry can reap huge benefits from a machine like multi-lane special shapes bag sauce packing machine. its multiple fillers can package medical ointments, bandages solutions, creams, drugs into special shapes bag with high precision. So your medicinal products will be available to the customer in perfect packaging without any wastage.

Chemical industry

If you deal with chemicals, then packaging them smoothly to prevent their chemical degradation would be your utmost priority. We’ve got you covered! multi-lane special shapes bag sauce packing machine can package chemicals like ethanol, acetone, pyridine, hydrogen peroxide and various other solutions into airtight special shapes bags and pouches, providing you with perfectly sealed products free from any harm.

Food industry

Instant coffee powders- picture courtesy: Aranow

Who wants spoiled or stale food on their plate? No one! So for freshly sealed and packaged food items, you can use multi-lane special shapes bag sauce packing machine. it can package various sauces, mayonnaise, ketchup, honey, maple syrup, chocolate syrup and much more into air-tight special shapes bags. Thus, they are shipped to the customer in the same state they were made, fresh and ready to use!

Cosmetic industry

Multi-lane special shape bag sauce packing machine- Picture Courtesy: Packing machine

This multi-billion dollar industry which manufactures thousands of beauty products every single day needs a machine which can cater to its demand. Multi-lane special shapes bag sauce packing machine can package sunscreens, shampoos, serums, lotions effectively and perfectly sealing them in their containers.

Household products industry

Various special shape bag-picture courtesy: thespruce.com

As the name suggests, it packages various household cleaning items like detergents, soap solutions, fabric softeners, glass cleaners. These items are transported from the hopper into special shapes bags and other packaging materials which are then sealed and shipped to their final destination.

Veterinary industry

Attention to all the pet lovers out there! If you see a company which uses multi-lane special shapes bag sauce packing machine, then rush to buy their items. Because this machine uses advanced technology to package animal care products, their ointments, drugs, shampoos, gels and cream into various colorful special shapes bags, jars and pouches.

4.What is the working principle of multi-lane special shapes bag sauce packing machine?

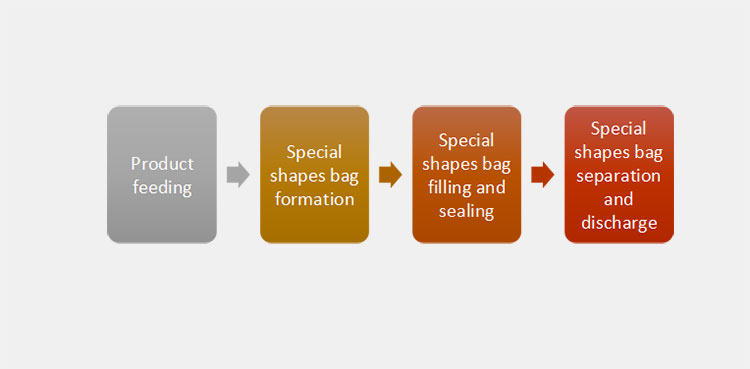

In order to operate multi-lane special shapes bag sauce packing machine efficiently, you must know exactly the mechanism it follows. It is quite straightforward so you don’t have to think deeply and get into its depth since its working principle is quite easy to understand. So let’s discuss the way this machine works.

Product feeding

First of all, you will feed your desired product, whether it is a sauce, ointment or any other liquid into a hopper. In this way, the hopper will be filled with your product ready to be pumped into their package.

Special shapes bag formation

Now the film holder starts its action by unwinding the film with the help of film rollers. The unwound film is then transformed into special shapes bag when the horizontal and vertical sealers seal the film from the top and the bottom. The special shapes bags are now ready to be filled with the product.

Special shapes bag filling and sealing

The piston fillers whose nozzles now contain the product fill the special shapes bags with high precision. The filled bags are then sealed using horizontal sealer bars which use high pressure for this process. The value for which is 0.8 MPa.

Special shapes bag separation and discharge

The special shapes bags are separated from each other into single unit with the help of cutters. The individual bags are finally discharged from the machine through the conveying outlet and are then transported to the other side of the production line where they will be further packaged for their shipment to their final destination.

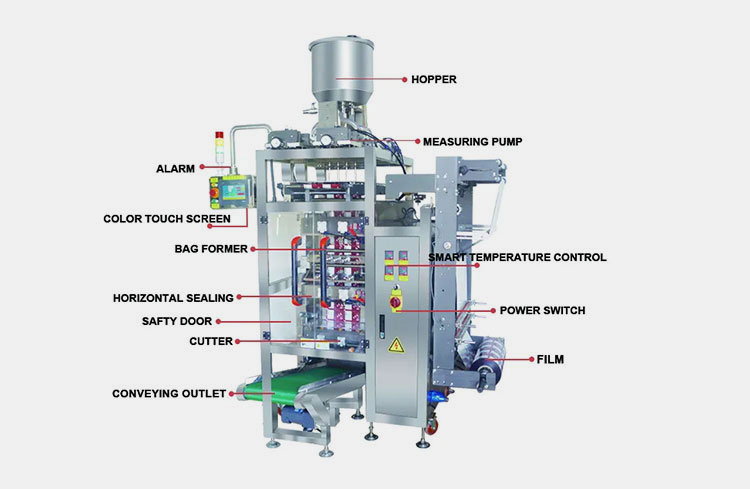

5.Describe the structure of multi-lane special shapes bag sauce packing machine.

Multi-lane special shapes bag sauce packing machine has several parts, each serving its own purpose. It is therefore important the individual function of each of its component. Let us discuss them below.

Multi-lane special shapes bag sauce packing machine

Hopper

The hopper is used as a storage compartment where your desired product is fed into with the help of a pump. After this, the product will be packaged into the special shapes bags or pouches.

Measuring pump

The measuring pump is supported by PLC control which directs it to ensure that it is pumping accurate amount of liquid product into the packaging material, thus ensuring precise and error free filling process.

Smart temperature control

This smart temperature control ensures that when the packaged product is being sealed, it is done at the right temperature. If fluctuating values are detected, then the smart system will detect it and change it back to the desired value. Thus, ensuring proper sealing everytime.

Power switch

This power switch is used for simply turning on or switching off the machine. If you want to start the process, you can use this switch to begin the process. However, if for some reason you have to suddenly stop the process, you can immediately do so by simply turning off the machine through the switch.

Film

The film contains film sheet which is wrapped around the product for sealing process. The film holder rotates to unwind the film which is then used to seal the special shapes bags.

Alarm

The alarm is an important component which will trigger instantly the moment some abnormality happens during the process. The triggered alarm will in termination of the process which will prevent any further damage to the machine or the people around it.

Touch screen

Touch screen is used as a screen through which you can monitor the whole process and change the parameters if needed for optimum working of the machine.

Bag former

This is the area where your packaging material like special shapes bags and pouches are made, cut into specific dimensions and are then filled with the product.

Horizontal sealing

When the special shapes bags or pouches are filled with the product, they are sealed by the horizontal sealers which use high pressure to seal the top of the pouch.

Safety door

Safety door is essential for the protection of the worker who is handling the whole process of the machine to prevent any accidents on site.

Cutters

When the special shapes bags, sachets or pouches have been filled and sealed, they are cut into individual pieces with the help of cutters.

Conveying outlet

This part is where the special shapes bags, achets or pouches fall after getting filled and sealed. They are then taken out from this outlet and sent for final packaging and shipping.

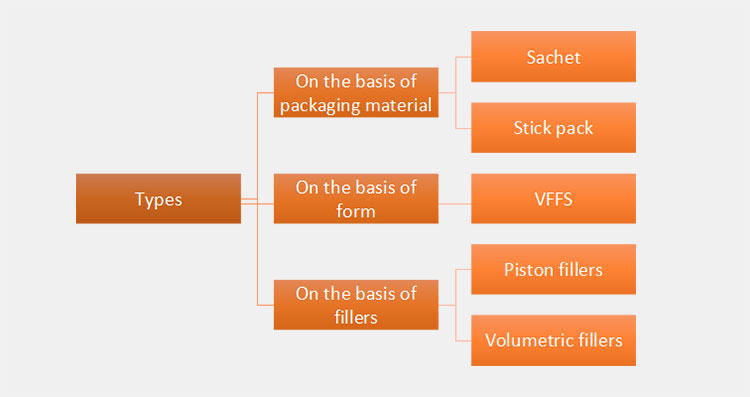

6.Explain the types of multi-lane special shapes bag sauce packing machine.

Multi-lane special shapes bag sauce packing machine has many variants. Each have their own unique specifications to cater to different sectors and products. So you have lots of options to choose from according to your specific requirements.

The types are categorized according to their characteristic features. Let us discuss each of these type below.

On the basis of packaging material

Sachet multi- lane special shapes bag sauce packing machine

Sachet Multi-lane special shapes bag sauce packing machine Picture courtesy: onepacking.com

This easy to use equipment is manufactured using advanced technology where all the components work together to ensure easy flow of process. It has the ability to fill package and seal your product into sachets which are then sealed.

Working principle

Firstly, the film is unwound by a film holder where it is then transported to the forming station. The film is then shaped into various sachets. The product is poured into the sachets with the help of pump fillers after which the sachets are sealed and discharged to the next station.

Stick pack multi-lane special shapes bag sauce packing machine

Stick pack Multi-lane special shapes bag sauce packing machine Picture courtesy: onepacking.com

This machine features multiple where the product is packaged into stick packs simultaneously at the same time. The stick packs can sealed on all four sides if you need it and it has great production capacity of packaging hundreds of sachets every hour.

Working principle

First of all, the stick packs are made when the film holder unwinds the film and produces stick packs by sealing it from its base and at the top. The product is then poured into these newly formed stick packs and sealed with the help of sealing jaws. The filled stick packs are cut and discharged, ready to be shipped.

On the basis of form

VFFS multi-lane special shapes bag sauce packing machine

VFFS Multi-lane special shapes bag sauce packing machine Picture courtesy: gzmiziho.com

This type, as the name suggest fills and seals product vertically in a smooth and efficient way. It is perfect for packaging products which flow or are liquid in nature and so is perfect for packaging juices and liquid beverages.

Working principle

The process starts when the film of package material is unraveled by the film holder and produced into special shapes bags, pouches, sachets, stick packs or any other packaging material. It is then sealed by horizontal sealers after which the desired product is poured into these by pump fillers. The pouches are sealed and discharged.

On the basis of fillers

Multi-lane special shapes bag sauce packing machine with piston fillers

Multi-lane special shapes bag sauce packing machine with piston fillersPicture courtesy:plantitpackaging.com

This type is equipped with piston fillers whose characteristic feature is that it can pour accurate amount of liquids into special shapes bags. It is therefore ideal for packaging thick liquids or sauces, thus ensuring that each packet is filled with the exact amount of liquid every time.

Working principle

The packaging material like special shapes bags, pouches or zipper bags, after they have been made and sealed are aligned with the piston fillers. These fillers which contain the product then dispense it into these packets accurately. The filled packs are then sealed and discharged. They are ready to move to the next stage of production line.

Multi-lane special shapes bag sauce packing machine with volumetric fillers

Multi-lane special shapes bag sauce packing machine with volumetric fillers Picture courtesy:samfull.net

This type is featured with volumetric fillers. As the name implies, the machine is preset to dispense accurate volume of liquid into packs in each batch. As a result, the all the filled products are exactly the same. It can also be integrated easily into other production line.

Working principle

The machine is firstly preset to dispense an exact value of product into special shapes bags, sachets, pouches and containers according to your requirements. The product which is in the hopper flows in to the volumetric fillers where they dispense them into packaging materials. The filled bags are sealed, cut into individual pieces and discharged for final shipping.

7.How to maintain multi-lane special shapes bag sauce packing machine?

Operator maintaining machine

Just like every other machine which requires a regular maintenance for its optimum working, Multi-lane special shapes bag sauce packing machine too needs regular check up to ensure that it is providing you the best results. Some of the factors which you need to keep in mind are.

Cleaning: After working for the whole day, filling, packaging and sealing, the machine would be covered with dust or product debris. So use a clean fabric cloth and remove any dust particles on the horizontal sealers, cutters, conveying outlet and the hopper.

Inspection: Make sure you regularly inspect the machine parts to see whether they are looking fine or not. In this way if you detect problem with any of the component, you can quickly fix them or replace them with a new one. This way, you will be saved from a bigger financial loss.

Lubrication: Just like the other machines, if you do not lubricate multi-lane special shapes bag sauce packing machine moving parts regularly, they will easily wear and tear due to friction. So lubricate the moving parts monthly to prevent such damage.

8.What quality standards should multi-lane special shapes bag sauce packing machine meet with?

It is very important for you to know that there are certain international rules and regulations which you must comply with so that your product can be used by the consumer. If the rules are not followed, then your product will be banned from using. These rules are.

FDA: Food and Drug Administration is an important regulatory body which gives out important guidelines to ensure that the products being made are of highest quality.

ISO: International Organization of Standardization gives out laws which are universally accepted to ensure that safe and effective products are being made all around the world.

CE: This certification is used in European Economic Area which gives out proper guideline to ensure that the products are safe to use.

GMP: Good manufacturing practice is a regulatory system which directs the manufacturers to make products which can pass the quality standards given by the organization.

9.What are the factors for choosing the best multi-lane special shapes bag sauce packing machine?

Choosing which kind of multi-lane special shapes bag sauce packing machine can be a little difficult for you. Because everyone wants to make the best possible decision since there is lots of capital which is being invested into these costly expensive. Don’t worry, we’ve got you covered because we are going to give you some tips to choose the best Multi-lane special shapes bag sauce packing machine for you!

Financial capital

How much money does Multi-lane special shapes bag sauce packing machine cost? This question might be worrying you. So it is important to know how much financial capital you can invest and if you have the means, then go for it. Whereas if you are having difficulty, then you should look for second hand equipment for your business.

Type of packaging material

Different types of packaging material picture courtesy epac.com

What kind of packaging material do you deal with? Is it special shapes bag, flat pouch, zipper pouches or sachets and stick packs? Thus, according to your packaging material, buy that type of Multi-lane special shapes bag sauce packing machine which would be able to cater to your specific packs, otherwise your machine will become unusable for your business.

Working space

Working space is quite critical when it comes to which type you would buy. You have to check how much space is in your workplace and whether the machine you are intending to buy can integrate easily into your production line.

Production Speed

Multiple stick packs

The production speed of your machine would be quite important and you would have to see whether it would be able to cater to your demands. So you would have to see whether your production requirements is in line with the speed of your machine.

Conclusion

After discussing in detail about multi-lane special shapes bag sauce packing machine, we hope that by now you would be well aware of the specifications of this machine, its features, benefits, use and whether it is worth buying or not. You must have been convinced by now that investing in this machine will be quite beneficial for you, the benefits of which you can reap for many years to come. So if you are thinking of buying it, then do consider Allpack because we have got some of the best machines with advanced features that we can offer! For more information and details, please contact us now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours