Multi Lane Special Shapes Bag Granule Packing Machine: The Complete Buying Guide In 2025

Can the packing of your granules influence the quality and be the reason of higher consumer satisfaction? It can be fascinating to think that the freshness and quality in every portion of the granules always remain the same as if it has just been packed now. Trends in quality and freshness have led to the invention of new packing solutions that help producers in the supply chain achieve cost savings and environmental sustainability.

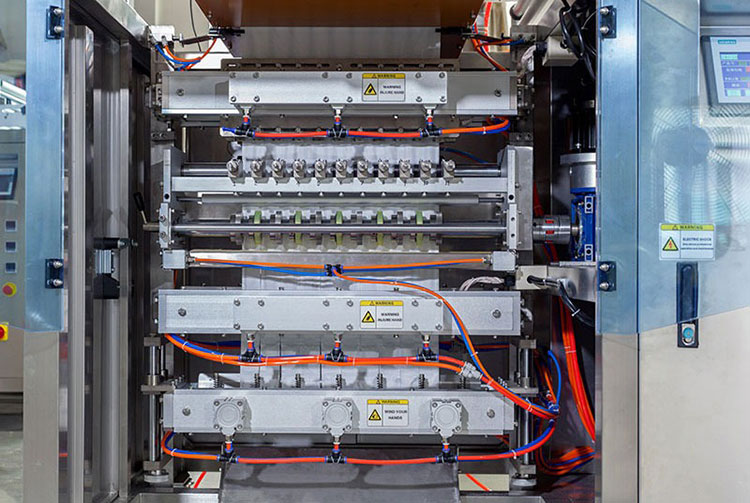

Purpose of multi lane special shapes bag granule packing machine - Picture Courtesy: WinfongPack

Time for a closer look at multi lane special shape bag granule packing machine that will maintain the natural qualities of your products.

In order to utilise its potential to the full, it is necessary to take a closer look at the working parts, functions, types, and control mechanisms of the motor. The knowledge about this machine will enable you to make a better decision when buying the right packing for the granules. In the following, we will discuss the most important points!

1.What Is The Multi Lane Special Shapes Bag Granule Packing Machine?

Multi lane special shape bag granule packing machine

A multi lane special shape bag granule packing machine is a classy packing machine that competently packs granulated materials into specific shaped bags. This machine is widely used in the food, pharmaceutical, and chemical industries to package a variety of items such as sugar, salt, seeds, cereals, coffee, snacks, and other granulated substances. It is a ribbon coding machine that does automatic blanking, weighing, bag forming, sealing, cutting, and counting.

2.What Are The Benefits Of Using Multi Lane Special Shape Bag Granule Packing Machine?

Special shape of granule pack - Picture Courtesy: Landpack.com

The multi lane special shape bag granule packing machine is recognized for its reliability, cleanliness, and efficiency. It offers enormous advantages that support industry success. Some of the perks are listed below.

Speed is Essential: The multi lane special shaped bag granule packing machine has several lanes that can make, fill, code, cut, and seal multiple sachets simultaneously. This simultaneous processing might increase the rate of production capacity. This increased speed enhances enterprises' profit margins.

High Safety: The multi lane special shaped bag granule packing machine seals the packets on all four sides, ensuring the packed particles' security and safety. The bags are packed and water-resistant, preventing air, water, dust, and other foreign things from entering the packing.

Reliability and Minimal Sample Variation: The multi lane special shaped bag granule packing machine is outfitted with automatic weighing and measuring systems. These technologies provide accurate particle loading within the packet. Furthermore, a precise forming station produces packing that is accurately sized and shaped each time. A multi lane special shape bag granule packing machine ensures consistency in each batch due to its multi lane function.

Adaptability and Multiple Uses: The multi lane special shape bag granule packing machine can create a variety of packing with a single press of a button. This capability is helpful for organizations that handle various packing types. This machine allows for the versatility of cut and seal sachets. Aside from packing, this machine can handle a variety of particle shapes, sizes, and natures.

Easy to Maintain and Clean: The multi lane special shape bag granule packing machine is made up of stainless steel. This stainless steel component of this machine makes it a solid and durable. This material is easy to clean and resistant to rust. Every part may be removed, making this machine easy to sterilize and operate.

3.What Are The Applications Of Using Multi Lane Special Shape Bag Granule Packing Machine?

An overwhelming majority of businesses all over the world make use of powder, granules and other particle product packing designs. These businesses utilize the multi lane, special shape bag granule packing machine to pack the particles and granules. The following is a list of some sectors where this machine used.

|

Food Industries

The food industry is one of the most significant consumers of multi lane special shape bag granule packing machine. Since it offers food particles in sachets that are easily accessible, this equipment is utilized by this industry. Small sachets are produced by this machine, which contains a wide variety of spices, sugars, salts, chiles, powdered flavorings, and other ingredients. |

|

Pharmaceutical Industries

Drugs used in the pharmaceutical industry, nutritional supplements, and herbal supplements are now available in powdered form in addition to tablets and capsules. This is a result of improvements in the medical and healthcare industries. This is a consequence of the significant advancements made in these companies. It is possible to utilize the powders immediately after they have been packed in special shape bags, which are pretty small and compact. As a result of the high dosage packing efficiency, it is a machine that is significantly utilized in the medical sector. |

|

Agriculture Sectors

This machine is also used to pack various agricultural particle goods, such as fertilizers, herbicides, pesticides, manure, and soils, in a special shape bags. The answer is yes; this machine is also used in the farm industry. One of the most important contributions that this machine has made to the agricultural sector is that it packs retail agricultural commodities in a compact and economical |

|

Cosmetic Industry

This machine is utilized in the cosmetic industry, specifically in those industries that deal with powders used in cosmetics. There are many different types of cosmetic powders in the little bags included in this product. These powders include face, talc, eye shades, blushes, makeup, salts for bathing, and body wash powders. |

4.What Is The Working Principle Of Multi Lane Special Shapes Bag Granule Packing Machine?

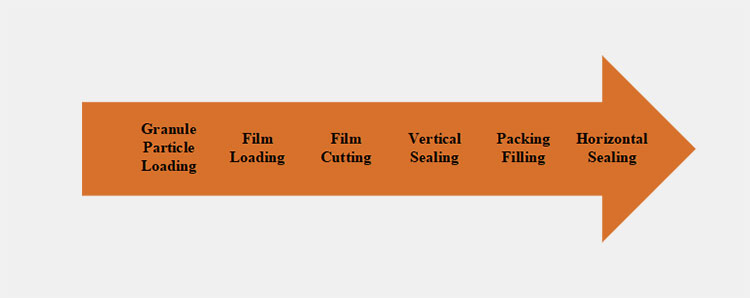

Working principle of multi lane special shape bag granule packing machine - Picture Courtesy: Landpack.com

The working principle of a multi lane special shapes bag granule packing machine is comprised of a number of sub-processes that contribute to the efficient and proper packaging of granules into bags of special shapes. This process is highly sensitive and needs to be undertaken with a lot of caution in order to retain the quality and strength of the packaging. The steps for packaging involve.

Step 1: Granule Particle Product Loading

Before starting the multi lane special shape granule packing machine, the bulk volume of the granule is proper load to the granule hopper. The machine's hopper can be filled by the operator or directly through a feed tank.

Step 2: Loading Plastic Film

After the loading step, the next step is loading the plastic film. In this step, a large film roll is placed on the film holder. Some portions of the film are separate and move over the film roller. This method keeps the film in suspense at all times.

Step 3: Vertical Packing

When the plastic film attains at the bag-forming station, the formation of packs commences. After that collecting and coiling the strips of the plastic bag film around the forming station into a tube-like pack. As of now, the bottom part seam is packed through the horizontal sealer, and the side seams are packed through the vertical sealer.

Step 4: Filling Packing

Packing the granules, Once the pack is all set up, the filling machines like the auger, multi-head weigher, and volumetric cup filler get to work figuring out just the right amount of powders and other little bits to put in. They get their instructions from the vacuum feeder and filling nozzles.

Step 5: Horizontal Sealing

This is the step where the transverse sealer intervenes and forms a tight seal that does not allow air in or out at the top. These horizontal sealers work their magic at the bottom of the sachet too. Once the packing is done, a sharp cutter comes in and gives it a clean break from the rest of the pack. When all the little bags are filled up on the multi lane special bag granule packing machine, the last step is to carefully get them into the collection bin or onto the conveyor belt. The belt then takes the finished packs along to the next packing machine.

5.What Are The Basic Components Of Multi Lane Special Shape Bag Granule Packing Machine?

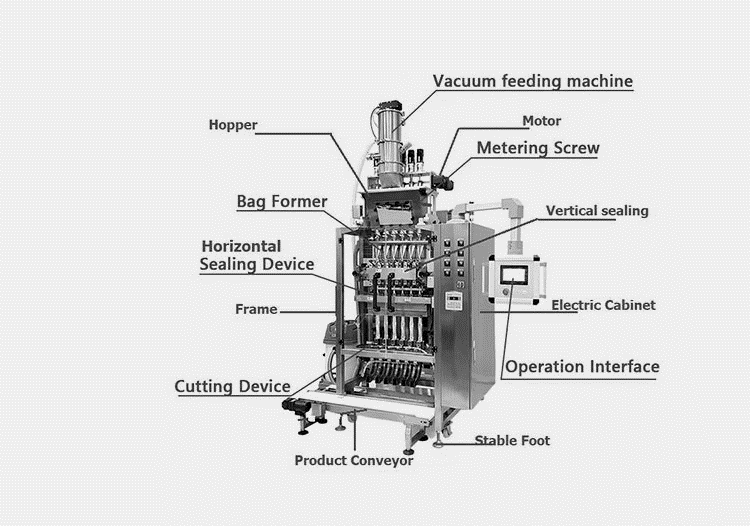

Basic components of multi lane special shape bag granule packing machine

A multi lane special shape bag granule packing machines have several components that are used for proper machine performance. These components include;

Hopper: It is the main component of the machine, which occupies the largest quantity of the remaining components in the structure. The granule particle presents in the hopper which is further used in the filling chamber.

Vacuum Feeder: This part of the machine is the useful part that is used for transferring granule powder and other particles to the filling chamber.

Motor: It is one of the essential parts of multi lane special shape bag granule packing machines, and it can realize the purpose of loading and discharging at any time. It is located on the top of the machine and it is operated through electrical energy.

Metering Screw: At the underneath of the hopper, metering screw is present which has a quick-release mechanism of the hopper lid for easy access during the cleaning process. In general terms, the machine is designed to determine the amount of granules or powders each time with high accuracy.

Bag Former:

The bag former is the large part of the multi lane special shape granule packing machine. This portion forms the pack containing the four side seals. It is a funnel-shaped part used to make the pack into square or rectangular packaging by wrapping the plastic film over it.

Vertical Sealing:

It is a machine component that encircles a vertical portion of the longitudinal of the sachets where they connect.

Horizontal Sealing Part:

The main part of the machine uses heat, pressure, or ultrasonic waves to join the top and bottom leading edges of four side seal bags.

Frame: It is considered to be the most crucial part of that machine and is said to be in charge of accommodating all the internal commodities of that system. It uses stainless steel in the construction of the frame which gives the entire appearance of the machine a high level of hygienic.

Energy Efficient Cabinet: Unlike other multi lane granule packing machines, it is considered to be the main portion of the machine. It is useful because it has different types of electrical connections that might be required in a given circuit.

Operation Interface: It is primarily a display screen interface and is often used to explain the control of machine operations.

Stable Foot: Several stable feet are found beneath the lower part of the multi lane special shape bag granule packing machine to ensure stability and equal levels.

Cutting Section of the Machine: This portion is present at the bottom of the horizontal sealing portion. It is basically used mainly for slitting packed satchels from processing satchels by sharp edges.

Product Conveyor: It is an individual tool that complies at the base of the machine. The packed product then drops on the product conveyor, complete with the finished packing process.

6.How To Classify Multi Lane Special Shape Bag Granule Packing Machine?

Multi lane special shape bag granule packing machines are classified into two main categories based on the type of filling and motion of the machine.

| Classification Based On Filling Type | ||

| Auger Multi Lane Special Shape Bag Granule Packing Machine |  |

The granule used for packing is filled with the auger in the auger multi lane special shape granule packing machine. For the transportation of the granules from the hopper to the bag, the auger screws rotated. It is favored most in filling the powders and is the most popular one among all the machines. These components necessitate the supply of precise portions of the granule products into the bags. |

| Volumetric Cup Multi Lane Special Shape Bag Granule Packing Machine |  |

It is a multi lane special shape bag granule packing machine comprising many volumetric cups, which greatly contribute to the respective dosing of the volumes of the granule particles in the bags. The materials are conveyed from the volumetric cups to the filling nozzles before being administered to the compacting station. This machine is however can be used in packing various types of granule particles. |

| Multi Head Weighing Multi Lane Special Shape Bag Granule Packing Machine |  |

Being a versatile machine, this one offers several weighing heads, several fill buckets as well as load cell. These load cells measure and control the portion of granule particles to the extent required in the specific lanes. The weighing heads are elements of this machine that perform the weighing and dosing skills. Its working principle involves the feeding of the powdery component with multiple machine heads in order to achieve the dosing at high speeds. This machine has multiple heads to facilitate the dosing process and ensure it is done at high speeds.

|

| Classification Based On Motion Type | ||

| Irregular Motion Multi Lane Special Shape Bag Granule Packing Machine |  |

This type of packing machine is called the stop-after-every-step machine due to its nature of stopping at each stage of the packing process. |

| Continuous Multi Lane Special Shape Bag Granule Packing Machine |

|

This kind of multi lane special shape granule bag packing machine does not stall in the flow cycle, instead, it does form, filling, and continuously sealing operations. This, in turn, makes it possible for the processor to offer high processing speeds since it is in this process constantly. It uses continuous motion technology, whereby several products are packed at once. |

7.How To Clean And Maintain Multi Lane Special Shape Bag Granule Packing Machine?

Cleaning and maintenance of multi lane special shape bag granule packing machine

Cleaning and maintaining the multi lane special shape bag granule packing machine in good working condition is necessary to guarantee the highest possible output.

Cleaning and Maintenance Of Machine

It is important to note that proper cleaning and maintenance of the multi lane special shape bag granule packing machine is crucial to achieve the best results and long service. Daily or weekly cleaning and checkup of all those parts that are likely to develop loose such as nuts, gears, and bearings are recommended to avoid mechanical breakdowns.

Greasing and oiling of every joint in a mechanical structure are paramount in minimizing frictional build-up which may cause severe wearing off of the moving components. Proper lubrication provides a hassle-free and enhances the durability of the machine’s part.

Software upgrade is equally important in maintaining the machine as it ensures that all the components of the machine are updated with the latest software. Routine software updates guarantee that the machine runs with current enhancements and updates.

All the parts of the machine are supposed to be serviced often to help in the general good running and use of the machine. Parts that are no longer serviceable should be replaced as quickly as possible to minimize downtime and loss of productivity.

8.What Are The Troubleshooting Required For Proper Functioning Of Multi Lane Special Shape Bag Granule Packing Machine?

Troubleshooting of multi lane special shape bag granule packing machine

There are several detailed troubleshooting requirements to ensure the proper operation of the multi lane special shape bag granule packing machine. These steps help identify and resolve common issues that could disrupt the machine's performance and efficiency:

| Inspecting Film Roll: | It is essential to check that the film roll is clean and has no signs of tears, or wrinkles, and most importantly, it has been wound correctly. Further, it is important to make sure that you load the film properly to the machine and get it placed in the right alignment so that the film does not feed wrong. Film being incorrectly aligned or damaged in some way can be costly due to time spent re-positioning and lack of product output. |

| Examining the Wrapping Material: | The material used for the wrapping should be compatible with the content that needs to be packed. It should be of an appropriate thickness and characteristics so that it is suitable for packing without getting torn or stretching too much. |

| Aligning Cutting Blades: | The first thing that the operator should do is inspect the cutting blades to ensure that they are sharp enough and correctly positioned. |

| Inspecting Sealing Jaws: | Inspecting the sealing jaws on a regular basis for signs of wear and the buildup of residue material. Some of the tips when using the jaws include; cleaning the jaws to ensure that you get a good grip on each of the bags and maintain them for efficiency. |

| Monitoring Seal Temperature: | Make sure that the sealing temperature matches the material specifications. Extreme temperatures may cause poor seals or melting of the material used for the film. |

| Ensuring Proper Film Tension: | Ensure that the level of tension in your film is set appropriately. Uneven tension may lead to the formation of wrinkles, tearing, or misalignment of the wire when wrapping. Tensioning leads to proper feeding and accurate wrapping which means that there are few instances where packages are misplaced. |

| It is noted that, in this way, the common problems in the multi lane special shape bag granule packing machine shall be effectively solved so as to keep the machine running stably, with high packing quality, and without any long interruptions. | |

9.How Do You Select The Best Multi Lane Special Shapes Bag Granule Packing Machine?

Selection of perfect multi lane special shapes bag granule packing machine – Picture Courtesy: ft-pack.com

When choosing the best multi lane special shapes bag granule packing machine, you must consider some essential elements to ensure that it fits your production requirements while providing the appropriate effectiveness and quality.

Here's a detailed guide that will help you make an informed decision:

Determine your particular needs: Make sure the machine can process the granulated product you're packaging (for example, coffee, sugar, salt, or seeds). Analyze the product's functions and whether particular characteristics (static-proof or open-ended) are required. Choose what kinds and quantities of bags you require (such as pillow bags, gusseted bags, and unique forms). Ensure

that the machine is compatible with the packaging materials you intend to employ.

Manufacturing Size: Check the machine's speed (bags per minute) to guarantee it can match your manufacturing volume needs. More lanes often increase productivity but should correspond to your manufacturing scale.

Quality and Effectiveness:Choose equipment with high-precision filling systems to reduce product waste and ensure uniform package weights. Ensure the equipment has strong, trustworthy seals to keep the product clean and intact.

Ease of Use and Service:A touch-screen-enabled control panel makes operation and modifications easier. Select equipment known for its dependability and ease of care. Look for features that make it easier to clean and repair components.

Mechanization and Implementation:Increased automation can lower labor costs while increasing efficiency. Include continuous feeding, filling, sealing, cutting, and labelling. Ensure the machine works seamlessly with your existing manufacturing line and software platforms.

Flexible and Multipurpose:The ability to easily change the machine to handle various bag sizes and types without requiring significant downtime. A machine that can handle a variety of products and packaging types can offer better versatility in the future.

Pricing:Think about your financial capacity and the expense of the machine. Evaluate long-term running costs, such as energy usage, servicing, and alternative components. Evaluate whether the machine will make up for itself through improved efficiency and lower labor costs.

Conclusion

In conclusion, this comprehensive guide on the multi lane special shapes bag granule packing machine has been designed to provide you with all the essential information on features, benefits, and considerations to help you select the best model in 2024. This advanced machine is crucial for any packaging line, ensuring a more efficient and accurate packaging process. Its capability to operate multiple lanes simultaneously enhances productivity while maintaining high-quality standards, making it a cost-effective investment for businesses aiming to accelerate their operations. If you are ready to elevate your production capabilities, reach out to our customer care team of allpack for the most advanced solutions and expert assistance tailored to your needs.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide