Multi-Lane Irregular Shape Bag Packing Machine: The Complete Buying Guide In 2025

Have you ever wondered how a large batches of irregular shape bags seemingly generates in a blink of eye? What technology is used to produce such bags? How helpful it is in today’s life?

A Multi-Lane Irregular Shape Bag Packing Machine is the answer. Though, it is just a flash about what we’re going to discuss. Yes! Planning to invest on machine? don’t worry just stay with us and read the blog to understand the basics about multi lane irregular shape bag packing machine.

1.What is Multi-Lane Irregular Shape Bag Packing Machine?

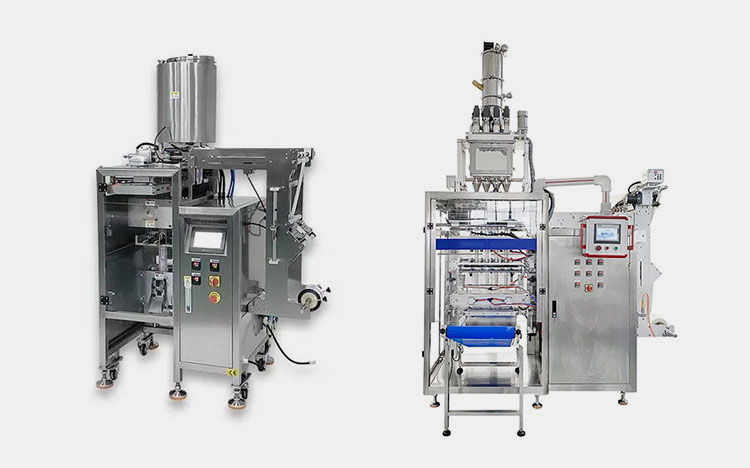

A Multi Lane Irregular Shape Bag Packing Machine

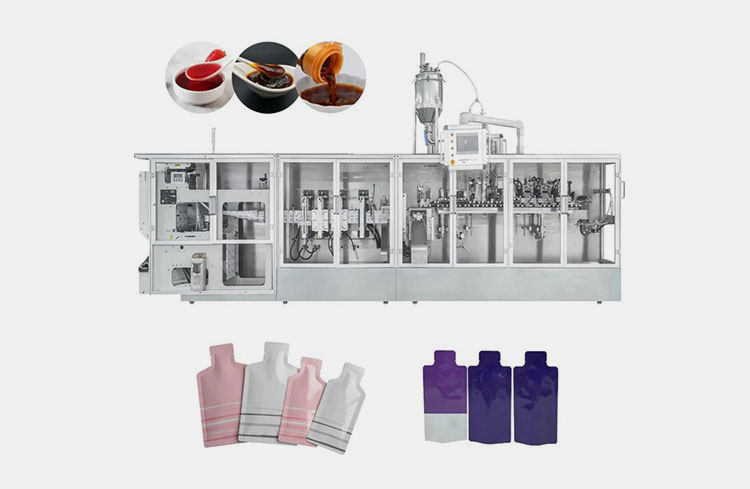

A multi lane irregular shape bag packing machine is an advance solution to form fill and seal unmatchable customized bags with variable sealing, cutting patterns.

Hence it is a great packaging solution in today’s competitive production market.

This machine is specifically designed with particular features that are concurrently capable of running multiple lanes that simultaneously help in the creation of a bag followed by filling and its final securing.

2.What are the Multi-Lane Irregular Shape Bag Packing Machine applications?

Applications Of Multi Lane Irregular Shape Bag Packing Machine

A multi lane irregular shape bag packing machine is the greatest solution for various industrial sectors.

That is simply due to its highly productive formation of bags with amazing customized irregular shapes, so it is adopted by many manufacturers just to make their brand’s identity. We have collectively mentioned the industrial applications of this machine for you with common examples.

Food and Beverage Industry

Multi-Lane Irregular Shape Bag Packing Machine in food & Beverages

A maximum ratio of using irregular shape bags is associated with the food and beverage industry and that’s why this equipment is displaying high market demand here. This can pack various formulations including flavored powders, juices, sauces, and sweeteners to represent an eye-catching product with various quantities and smart designs holding an accurate filling following diversified packaging that makes you grab it from store shelves.

Pharmaceutical Industry

Multi-Lane Irregular Shape Bag Packing Machine in Pharma

Pharmaceutical products like lozenges, suppositories some disintegrating tablets, and other semi-solid formulations require multi lane irregular shape bag packing machine. It gives you a specific order design that prepares individual and single use irregular shape bags considered essential hygienic packaging requirements in pharmaceutical industries.

Personal Care and Cosmetics

Multi-Lane Irregular Shape Bag Packing Machine in Cosmetics & Personal Care

The cosmetic and personal care industry benefits from irregular shape bag packing machine when they’re required to make specialized and customized shape irregular bags for certain products such as lotion, serums, facial masks, wet wipes, eye creams, etc.

The prepared sachet is so presentable and perfect for one-time use. Machines can make packaging products that user can easily adjust and carry for long periods of time in their bags anywhere.

Agricultural Industry

Multi Lane Irregular Shape Bag Packing Machine In Agricultural Industry

In the agriculture industry, for the packaging of one time use of various crops promoters, seeds, pesticides, insecticides, and other associated materials are preferably packed in using multi lane irregular shape bag packing machine. this machine is indeed giving you a specific amount of concentration which is commonly available in granular structures so a precise dosing is possible with this equipment.

Chemical Industry

Uses Of Multi Lane Irregular Shape Bag Packing Machines in Chemical Industry

Making and packing chemicals in specialized customized irregular shape bags is now very common in chemical industry. A multi lane irregular shape bag packing machine is basically used in to create and fill various specialized chemicals safely that are meant for specific uses. Such as one time use of chemicals i.e. buffers, bleaches, or reactive items.

Veterinary Industry

Uses in Veterinary Industry

You can noticed various colorful irregular shape bags containing animal’s related supplementary products medicines or food products that are presented with an improved shapes serving. Yes, vet industry formulation packaging is commonly done by using this machine hence showing its high demand.

3.What is Multi-Lane Irregular Shape Bag Packing Machine benefits?

The benefits of multi lane irregular shape bag packing machine are discussed below:

Adaptive Configuration

Promising Configuration

This machine allows you to produce multiple production of irregular shape bags simultaneously thus giving you a promising output and greater productivity.

Robotic Controlled Features

One Touch Robotic Features

The machine is smartly designed and features amazing driving parameters to process the production and packaging of bags with high accuracy and reduced chances of errors. You don’t need to stand alone and monitor the process, just set the protocol and leave on the machine to show its magic.

Promising and Presentable Packaging

Aesthetic Shapes

The machine is a fruitful result of well-engineered manufacturing in that it gives you surety to produce and pack bags with good quality with smooth edges and cut packs.

High-Speed Processing

Fast Functionality

Multi lane irregular shape bag packing machine is composed of various lanes which is meant to give a high speed processing because at one time machine is capable of producing hundreds of bags to meet production demand respectively.

No More Product Wastage

Precise Product Filling

This is proven to you that when the material is filled into each bag accurately, there won't be chances of any wastage; just, say bye to product wastage.

Wide Applicability

Broad Spectrum Industrial Usage

This machine has high applications in various industrial sectors as it allows enhanced features and multiple packaging options that won't compromise your investment in any production field and packaging purposes.

Cost-Effective Operations

Cost Effective Properties

Seamless working. high automation, and greater productivity of multi lane irregular shape bag packing machine can lead to high profitability and cost savings and minimizing extra cost of packaging

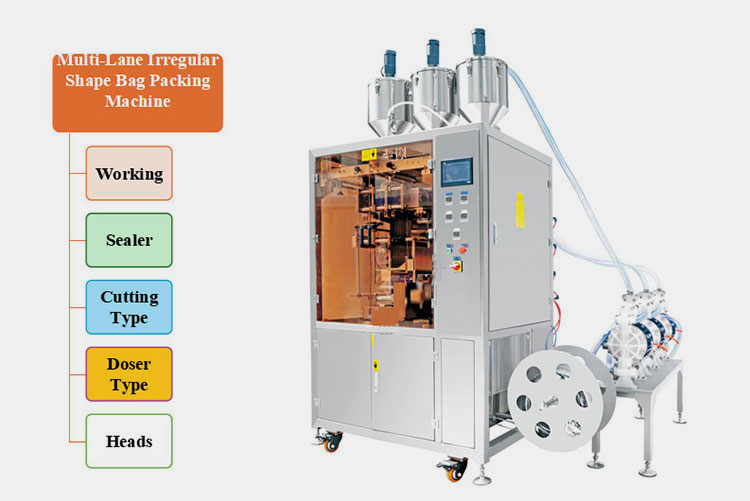

4.What are Multi-Lane Irregular Shape Bag Packing Machine types?

A multi lane irregular shape bag packing machine is featured with various common types that basically introduced in order to meet various demand by different fields of production and filling types. For your clear understanding, we have simplified the classification.

Classification of multi lane irregular shape bag packing machine

WORKING TYPE

A multi lane irregular shape bag packing machine is classified on the basis of its working type which demonstrates various functional characteristics of this machine. please see below to find more information.

| Vertical Form Fill Seal (VFFS) Multi- Lane stick packaging machine |

VFFS multi lane irregular shape bag packing machine This is very common and simple type of machine where entire processing take place in a vertical manner. For example, the unwinding, bag formation, bag filling and bag sealing, cutting, and discharging is accompanied by an upward to downward direction. This machine is undoubtedly designed in a compact structure therefore preferred in various production field with smaller installation space and high production demand. |

| Multi Lane Horizontal irregular shape bag packing machine

|

HFFS Multi lane irregular bag packing machine This machine is meant to form, fill, and seal bags with product and discharge them in a finish form following a horizontal pattern of processing. The machine is useful in various industries where large production batches are treated with positive outcomes. The machine is capable of forming customized shapes bags effectively. As compared to VVFS machine, this equipment requires a high space to installation. |

SEALER TYPE

Always remember, a multi lane irregular shape bag packing machine is featured with certain sealing types. Not every machine is meant to offer all different sealing types. So when you’re planning to design bag packing production, you must consider this property to get exact results you want. Let’s see what sealing type is offered by machine.

| Back Sealing |

This is also termed as a vertical sealing which is a straight simple seal that secure bag at the back which looks like a vertical in structure with a smooth surface preferred by many brands. |

| Stick Sealing |

This is also known as a center sealing offered by this machine featuring a longitudinal seal providing a symmetrical or middle sealing to your bag. This seal is mostly used when packing candies or toffees or any small products. |

| Three-Side Sealing |

This is most commonly used to pack beauty care product where three sides are sealed while one edge is opened offering a controlled presentation. Means a user can use the bag multiple time or small sachet bag with easy opening. |

| Four-Side Sealing |

Four-side sealing by this machine means you can get highly secure airtight packaging of bags sealed from all over sides. This sealing is preferred in electronic items packaging or medicinal products. |

| Gusset Sealing |

Gusset sealing as it name shows, sealing forms a gusset or pleats around the edge of bag forming a beautiful packaging for various bulkier items such as coffee, tea, milk, or other products. |

| Zipper Sealing (Re-sealable) |

Bag sealing with a small zip at the top edge is new and advance feature offered by this machine which allow customers to use bag again and again with greater freshness intact inside. |

CUTTING TYPE

Every machine is associated with different cutting type, this is based on specific cutters equipped in the machine which gives specialized cutting types to you. The cutting types are described below:

| Straight Cutting |

This is a common cutting type used by multi lane irregular shape bag packing machine which is the execution of straight and linear incisions of edges to form a well-defined and even corners. This cutting process ultimately offers a tidy and aesthetic presentation of the bag. |

| Zigzag Cutting |

This is an innovative and another commonly used cutting type offer by the machine where the top and bottom border of the bags are cut by irregular zigzag pattern edges that present a vibrant and pleasant appearance of the product. |

| Wavy Cutting |

This is a randomly used cutting types offering a wavy or spiral designing at the edges of the produced bag presenting an attractive appearance to your product. |

| Die-Cut Shapes |

This is mostly known for its irregular, customized, or abnormal shapes cutting accompanied by a die cut which crafts distinct shape patterns around the edges of the bag helpful in the creation of promotional or marketing samples. |

| Perforated Cutting |

This is an essential type that is mostly used for large bags which facilitates easy tearing without needing any supporting material to open them. A perforated incision line is stamped around edges uniformly with minute perforation which is quite a common irregular shape bag packaging method. |

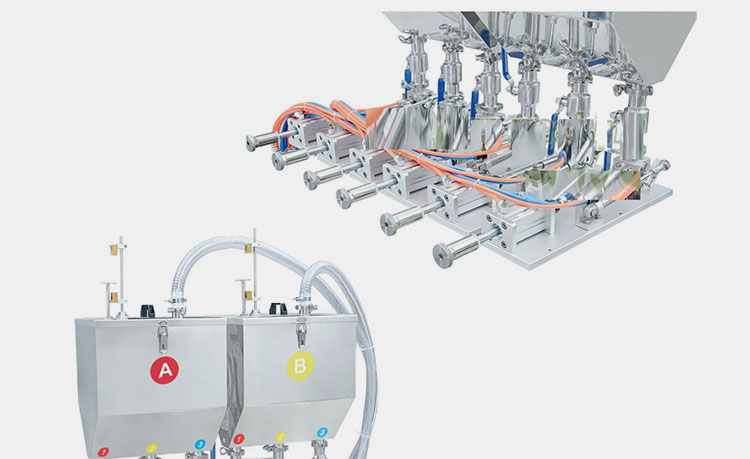

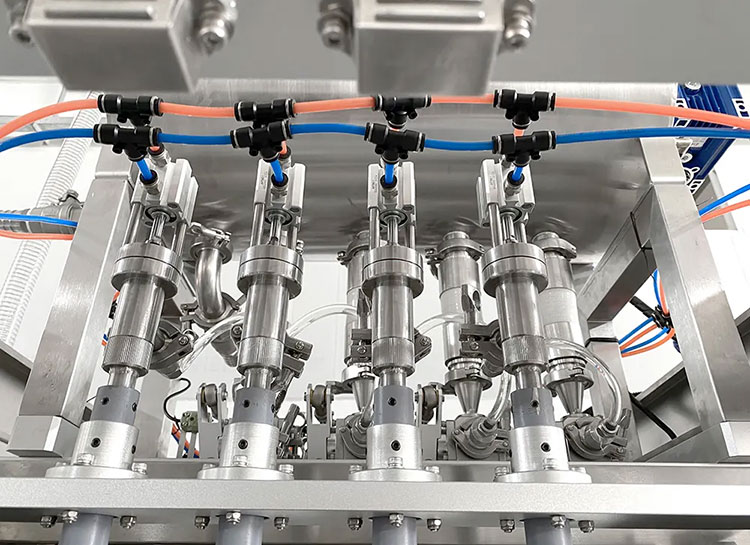

Type of Filler/Doser

A multi lane irregular shape bag packing machine is featured with various different dosers depending on the type or state of material to be filled in each bag. Such as:

| Multi-Head Weighing |

Multi head weighing A multi- head weigh filler or doser is involved when it comes to individually measuring or dispensing of products required in a large quantity based on desirable weights of formulation into each individual bag. |

| Volumetric Filler |

Volumetric Filler A predetermined volume of formulation, whether granules, free-flowing powders, or semi-solid items, it can easily be dispensed into each bag using a volumetric filler. |

| Piston Filler |

Piston Filler Multi lane irregular shape bag packing machine is build up with super innovation with piston filler that offers simple functioning. You can attain specific and precise amounts of product dispensing using a piston filler that is helpful in drawing exact quantity of product simultaneously. |

| Auger |

Auger Filler This is a specialized type of filler mainly offer to those customers who are associated with the packing of free flowing dry powders into each customized shape bags such as packing of spices, flours, milk powders, etc., An auger with inside agitator ensures fast and smooth flow of powders into each bag. |

| Peristaltic Pump |

Peristaltic Pump This is a type of filling where a set of peristaltic pumps are responsible for enhancing the flow of material from the hopper to each bag by generation of squeezing and circular motion. This is mostly perfect type of filler for products that are presented with high viscosity. |

Based on No. Of Heads

The number of heads in the machine mostly depends on the type of production capacity and the entire packing design where a greater number of heads are associated with a fast or rapid packing process. For example:

A Multi Lane Irregular Shape Bag Packing Machine with Various Number Of Heads

| Single Head Multi lane irregular shape bag packing machine | This machine is featured with multi lane film forming characteristics with only one head or storage tank. Here, you can consider it suitable for moderate production lines. |

| Multi- heads multi-lane irregular shape bag packing machine | Considering large production batches, a well-engineered production of multi head machine has emerged which is best fit for large production processes. It includes more than 1 head, such as dual heads, three-heads, four-heads. |

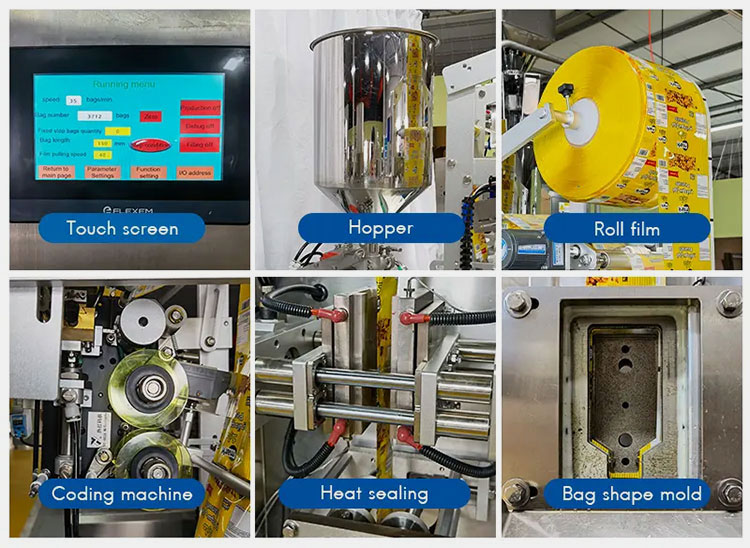

5.What are Multi-Lane Irregular Shape Bag Packing Machine parts?

Parts Of Multi Lane Irregular Shape Bag Packing Machine

| Hopper | The topmost and large hollow cylinder is designed to hold filling material and protects it against clumping or forming aggregates as it ensures uniform flow of material towards further packing process by using certain mechanisms such as vibratory, agitator, or simple gravitational force to maintain consistency. |

| Filling Tube | A set of narrow and straight tubes runs from top to bottom of machines helps in the transportation of products from hopper to bags maintaining an optimized flow and uniformity with no chances of spillage or product wastage |

| HMI Screen with Rotary Swing Arm | A touchscreen interface allows you to put processing essentials and operate the machine simply using touch screen keys, it includes speed of bags formation, its filling machine, troubleshooting, etc, The touch screen is integrated with a rotary swing arm which improves ergonomics and allow you to move according to your desirable direction. |

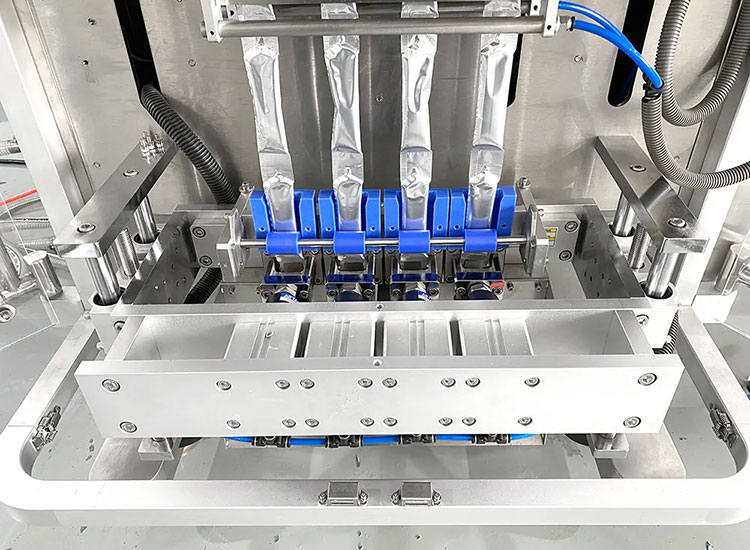

| Formers | This is the main component of the packaging machine where equipment is responsible for the formation of customized shape bags using a former as an assistance. This is narrow tube supporting an even and equal shape bag of specific sizes ensuring promising uniformity and aesthetics of each bag formed by the machine. |

| Vertical Sealer | To seal the bag, a vertical sealer is responsible for securing the straight vertical edges by exerting pressure of heated rods or bars. The temperature of each sealer is regulated by the machine, and it is depending upon material to material which is in fed by you before starting the procedure. |

| Film Pulling Unit | This unit is meant to sync the overall movement of the film to ensure uniform coordination between formation and filling of material in a respective time period. At this point, a strong connection between film movement and filling time must be aligned with each other to avoid spillage or film jamming. |

| Horizontal Sealer 1 & 2 | The topmost and bottom edges of the bags are secured by using two horizontal sealers which are concurrently working with vertical sealer to make bag closing simultaneously. Like, vertical sealers, these sealers also associated with temperature and pressure hence it is prime important to regulate these parameters in order to achieve desirable results. |

| Control Panel | This is a PLC unit where entire programming and controlled parameters are regulated using electronic components features of the machine. This is a compact structure inside the machine responsible for various centralized tasks and monitoring of the procedure including the transmission of process which is displayed on touchscreen ensuring a safe operation. |

| Cutter Assembly | Sharp knives or sets of cutters continuously engaged in separating the formed bags to discharge an individual finished bag outside the machine. The machine basically equipped with cutter assembly which is kind of blades to carry clean, uniform, and accurate separation of bag so it can give you a finest presentation. These cutters basically work by using sensory mechanism to detect the edges of the bag and mark a punch of cutters. |

| Waste Collect Conveyor Belt | This machine is a complete solution where production till end process entire wastage is collected in waste collect unit. This includes trimmed film or excessive material for uniform designing of irregular shapes bags. |

| Foot Cup | A smooth and vibrationless machine is basically due to presence of foot cup which acts like a shock or vibration absorber to provide a smooth and quiet work process and enhance quality of working conditions during operation. |

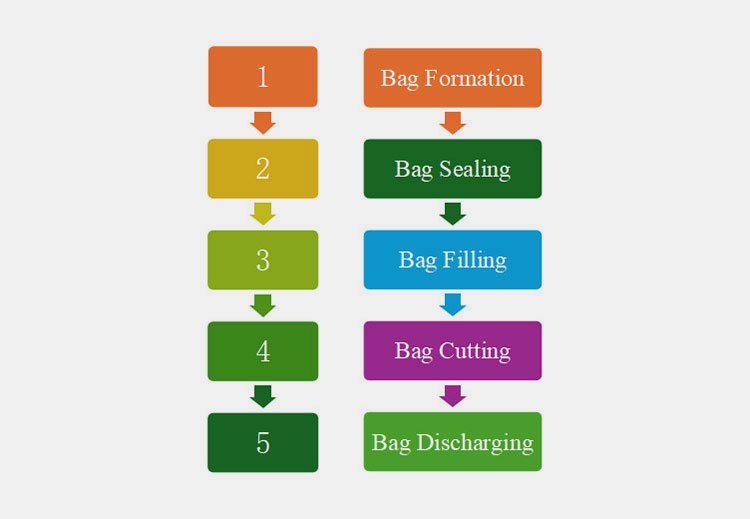

6.How Multi-Lane Irregular Shape Bag Packing Machine Work?

To understand the working principle, we have divided the process into four major steps:

Bag Formation

This is the first step where manual setting and adjustment of the film takes place on the machine. Upon initiation, the film starts unwinding slowing and roll around the former which gives a particular shape to the bag.

Bag Sealing

The formed shape of the bag is firmly sealed by using heat sealers which are presented in vertical and horizontal positions. These sealers gives you particular sealing at the edges of the film such as, at topmost, and side edges, back seal, fin seal, etc.,

Bag Filling

Once the bag is formed, the material comes inside the bag depending on the particular weight fed in the system. This include either liquid, semi-solid, or solid substances involved with various filler types discussed above followed by final sealing to secure material inside.

Irregular Bag Cutting

This is the fourth step; it is accompanied by utilizing of sharp blades or cutter which exactly punches the edges of the bag as it is required, also it allows separation from other attachments.

Bag Discharging

The formed bags are discharge outside by the presence of small outlet or conveyor which produce a finished formed bag.

7.What is difference between single lane & multi lane irregular shape bag packing machine?

The basic difference between single lane and multi lane irregular shape bag packing machine is described below:

Number of Lanes

The single lane machine is featured with the formation, filling, and sealing of customized shape bags but it utilizes a single channel for packaging process, whereas, in multi-lane, the formation, filling, sealing, and packing of bags option is broader as it is featured by multiple lane subjecting packing process utilizing its all lanes at one time.

Throughput and Efficiency

A single lane machine generally uses one channel to form a bag therefore it gives you a small amount of output. On the other hand, a multi-lane irregular shape bag packing machine is meant to deal with various lanes ultimately offering high throughput and greater efficiency. So it is suitable for larger production companies.

Versatility

A single lane machine is very simple and relatively considered as straightforward in the terms of operation. Whereas, a multi lane irregular shape bag packing machine is a mastermind production with high flexibility and versatility that can handle various sizes, shapes of bag formation concurrently.

Space Requirements

A single lane machine is compact in structure and can occupy a small space of installation. On the other hand, a multi lane irregular shape bag packing machine has larger footprint and may need a larger space for installation and work process.

Cost Considerations

A single lane irregular shape bag packing machine is very cost-effective and can be affordable to you with the smaller budget; while multi-lane is associated with higher investment.

8.How do you troubleshoot Multi-Lane Irregular Shape Bag Packing Machine

To troubleshoot a multi lane irregular shape bag packing machine, go through the following points below:

Uneven Filling

The common problem with using multi lane irregular shape bag packing machine is to find bag with inconsistent filling of product. To troubleshoot it is recommended to calibrate the system, inspect the type of obstruction and alignment of the film forming tube and film channel such as dancer arm.

Sealing Issues

You must have seen leakage of the bag which ultimately compromises the quality and integrity of the brand. To troubleshoot the problem, it is recommended to analyze the temperature and pressure of sealing bars (horizontal and vertical sealers). Plus, ensure the film forming material is compatible with temperature and pressure utilization.

Bag Misalignment

The formation of bags due to misalignment is packed incorrectly. To correct the problem, examine the ‘formers’ of the system, and assess if it is properly aligned to the system. Also, asses the alignment of the film pulling unit.

Cutter Issues

This is noticeable because the formation of the bag is not separated or cut cleanly. To solve the problem, it is suggested to replace dull or damaged cutters, check and correct the alignment of cutter and calibrate the sensors of the machine.

9.What Should You Consider When Purchasing Multi Lane Irregular Shape Bag Packing Machine?

Choosing the right multi lane irregular shape bag packing machine may be tricky, this is because there are several types of machine with various features. So go through the following points to asses what important factors you must know about the machine prior to purchasing.

Machine Filler Category

Determine Filler type

Knowing this thing will help you to choose the best machine, there are several categories such as irregular machine for viscous, free-flowing liquid or powder, or granules.

Production Rate

Assess your production capacity

How many numbers of irregular bags or sachets do you need per minute, knowing this point will help you to select a small or vertical machine or horizontal, single lane, or multi lane irregular shape bag packing machine.

Hopper Capacity

Determine Hopper Tank Capacity

Ensure that the head of the machine is perfect to hold the type of filling material and best fit for your production procedure. If not, you can see various other types available such as dual heads, three- heads, multi heads, to run the procedure.

Financial Budget

Estimate your affordability

You must estimate your budget before opting for the right choice, for that you can take help of a manufacturing company to find a suitable solution for your production needs.

Installation Space

Measure installation Space for Machine

Check installation space, and assess space and footprint of the machine prior to final purchase. This would help to select whether you should go for small size machine or the larger one.

Conclusion

A multi lane irregular shape bag packing machine is a one stop solution to get various shapes, designs and sizes of bags that can enhance your productivity and business. We hope, in this article, you have obtained the basics about the machine. Still have a question? Why not contact us directly? Allpack is an excellent place where you can avail world’s best packaging types of machinery with free customer services. Want to give it a try? Please contact us now to avail our incredible guidance program.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide