Multi-Lane 4 Side Sealing Liquid Packaging Machine: The Complete Buying Guide In 2025

Are you a fan of coffee and juice sachet packaging? Do you want to know how this packaging is made? Multi-lane 4 side sealing liquid packaging machine is used for making and filling 4 side sealing liquid packaging.

This machine combines physics and computation to create custom 4 side sealing liquid packaging. Multi-lane 4 side sealing is a wonderful innovation, having diverse useful features and aspects, making it a perfect addition to different industrial sectors of the world. With the packaging revolution, now this equipment can fabricate chic packaging.

We have penned this buying guide to increase your understanding of the multi-lane 4 side sealing liquid packaging machine so that you can attain maximum benefit from this machine. Let’s dive into the wonderful world of about multi-lane 4 side sealing liquid packaging machine.

1.What Do You Know About the Multi-Lane 4 Side Sealing Liquid Packaging Machine?

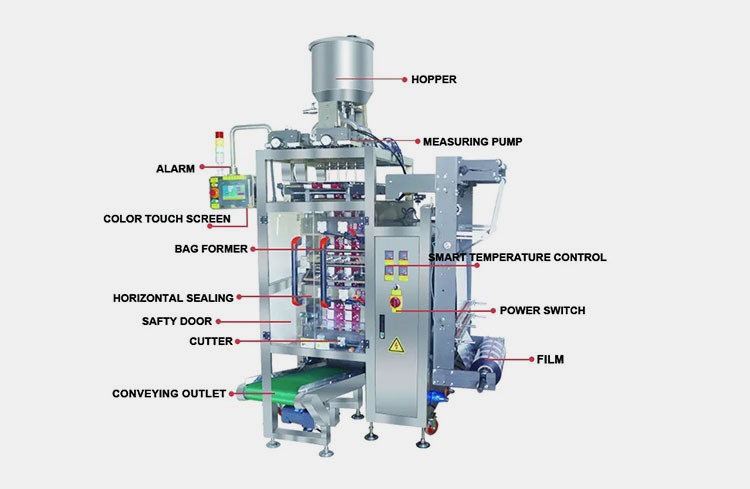

Allpack Multi-lane 4 Side Sealing Packaging Machine

It is an automated machine, that efficiently packs liquids in 4 side sealing sachets. It consists of multiple forming, filling, sealing, and cutting stations with which it can pack multiple 4 side sealing packs. It consists of multiple channels in which packaging operations occur in synchronicity.

This machine is referred to as 4 side sealing because it seals all four sides of the sachets (two vertical and two horizontal seals). It is manufactured to pack different types of liquids like sauces, condiments, ketchup, juices, and liquid coffee. It loads miscellaneous assortments of liquids in 4 side sealing packaging.

2.Why Is Multi-Lane 4 Side Sealing Liquid Packaging Machine Popular?

The multi-lane 4 side sealing liquid packaging machine is popular in different industrial sectors because it brings a multitude of benefits for the industries due to its increased speed, higher productivity, and extreme accuracy. Some of the benefits that contribute to the popularity of multi-lane 4 side sealing liquid packaging machine are detailed below:

Multi-Tasking

Multi-Tasking of Multi-Lane 4 Side Sealing Liquid Packaging Machine- Picture Courtesy: Behance

Multi-lane 4 side sealing liquid packaging machine is an all-in-one machine forming multiple packs in complete harmony. It performs different tasks like cutting, forming, filling, and sealing in one machine. This saves manufacturers from buying many machines.

Economical

Cost-Effectivity of Multi-Lane 4 Side Sealing Liquid Packaging Machine- Picture Courtesy: landpack

Manufacturers are always concerned about money and expense They are always in pursuit of saving money. Multi-lane 4 side sealing liquid packaging machine is significant in this regard as it saves operational expenses by reducing the need for human supervision. Furthermore, it efficiently uses packaging materials, lowering wastage and ultimately saving the production expense.

Improve Production

Improved Production by multi-lane 4 side sealing liquid packaging machine- Picture Courtesy: Out of Eden

One of the most significant characteristics of a multi-lane 4 side sealing liquid packaging machine is it boosts production capacity. It offers enhancement of manufacturing efficiency by simultaneously packaging multiple 4 side sealing sachets. It comes in fully automatic mode, thus reducing the time spent on packaging.

Versatility

Versatility of Multi-Lane 4 Side Sealing Liquid Packaging Machine- Picture Courtesy: Micoope

Another important aspect of the multi-lane 4 side sealing liquid packaging machine is its flexibility and versatility. It packs a diverse range of liquids differing in their physical characteristics like viscosities with easy change of parts. Moreover, with few adjustments, it can fill different ranges of volumes in the 4 side sealing sachet.

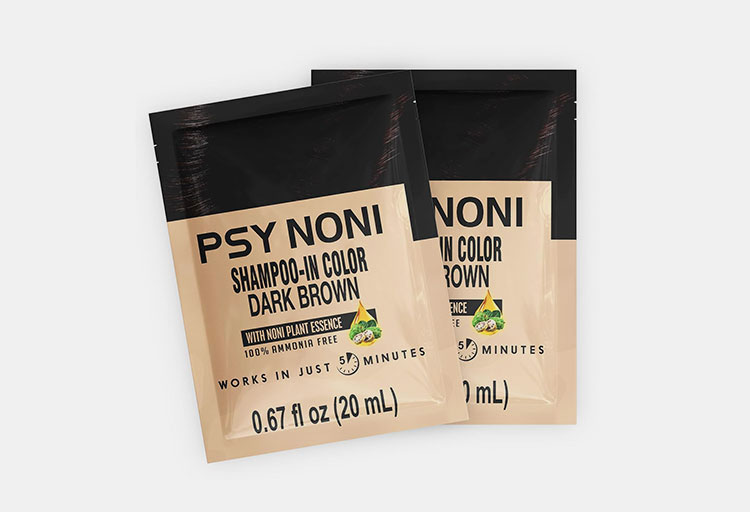

Branding

Branding By Multi-Lane 4 Side Sealing Liquid Packaging Machine

The first choice of customers is unique and stylish packaging. People are captivated by the noticeable packaging. This demand of the customers is fulfilled by the multi-lane 4 side sealing liquid packaging machine. It can create unique and chic single-serving sachets that boost impulse buying.

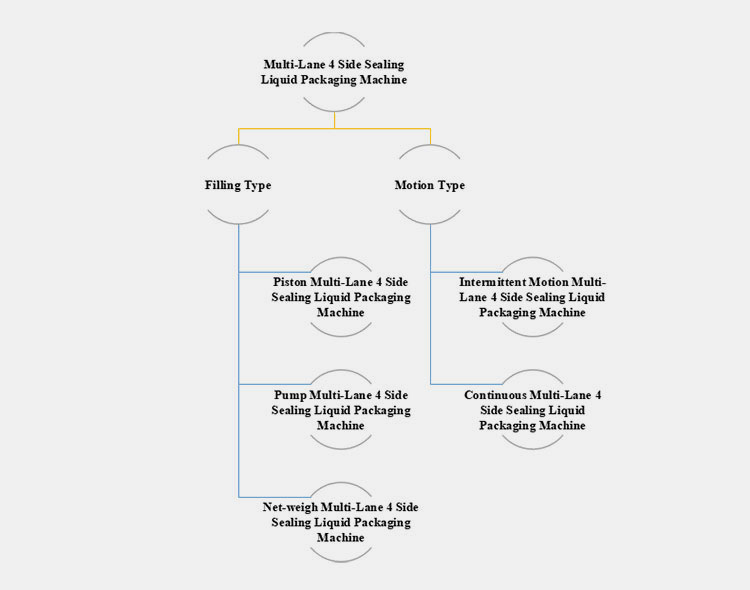

3.What is the Classification of Multi-Lane 4 Side Sealing Liquid Packaging Machine?

There are different categories of multi-lane 4 side sealing liquid packaging machines based on filling type and motion type. These types are penned below:

Filling Type

Piston multi-Lane 4 Side Sealing Liquid Packaging Machine

Piston multi-Lane 4 Side Sealing Liquid Packaging Machine

The dispensing of different types of liquids in 4 side sealing sachets is achieved by the motion of the piston. The forward and backward motion of the piston is essential in drawing the liquids from the hopper and pushing them into the filling nozzle. It is the most widely used type of multi-lane 4 side sealing liquid packaging machine.

Pump Multi-Lane 4 Side Sealing Liquid Packaging Machine

Pump Multi-Lane 4 Side Sealing Liquid Packaging Machine

As the name indicates, this type of multi-lane 4 side sealing liquid packaging machine has a pump to move the liquids of the hopper into the filling nozzles. There are different types of pumps, for instance, gear, lobe, cavity, etc., present in the pump multi-lane 4 side sealing liquid packing machine.

Net-weigh Multi-Lane 4 Side Sealing Liquid Packaging Machine

Net-weigh Multi-Lane 4 Side Sealing Liquid Packaging Machine

For precise weight filling, a net-weigh multi-lane 4 side sealing liquid packaging machine is used. This type of multi-lane 4 side sealing liquid packaging machine is the only machine that is used for filling liquids by weight. It is usually used for filling precious and expensive liquids.

Motion Type

Intermittent Motion Multi-Lane 4 Side Sealing Liquid Packaging Machine

Intermittent Motion Multi-Lane 4 Side Sealing Liquid Packaging Machine- Picture Courtesy: Landpack

This machine stops at each step in the working operation. The film moves intermittently during each cycle in this type of multi-lane 4 side sealing machine. This allows for higher accuracy in the liquid filling process. Moreover, it has flexibility in terms of liquid filling and the creation of sachets.

Continuous Multi-Lane 4 Side Sealing Liquid Packaging Machine

Continuous Multi-Lane 4 Side Sealing Liquid Packaging Machine

It is a sophisticated innovation in the multi-lane 4 side sealing liquid packaging lines. It has a continuous mode of operation and each step occurs simultaneously in this machine which is why it has increased operational speed and efficiency. This machine has lower wear and tear as it does not constantly stop and start.

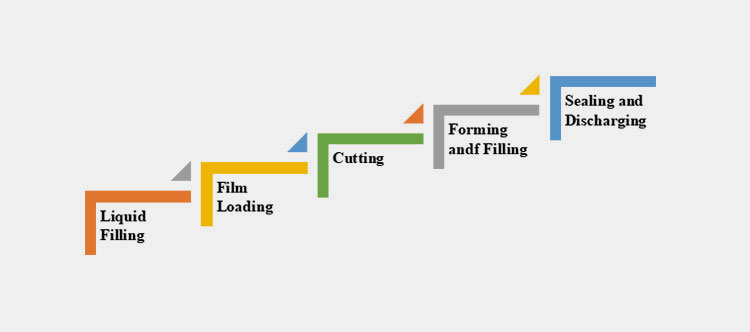

4.How Does Multi-Lane 4 Side Sealing Liquid Packaging Machine Work?

You should have a clear understanding of the working steps of a multi-lane 4 side sealing liquid packaging machine, otherwise, you cannot identify problems and troubleshoot them. So, read carefully these working steps.

| Liquid Filling

Liquid Filling |

In the first step, the liquid is filled in the top hopper by the infeed pump. This hopper houses the bulk volume of the products for the uninterpreted flow of liquids. |

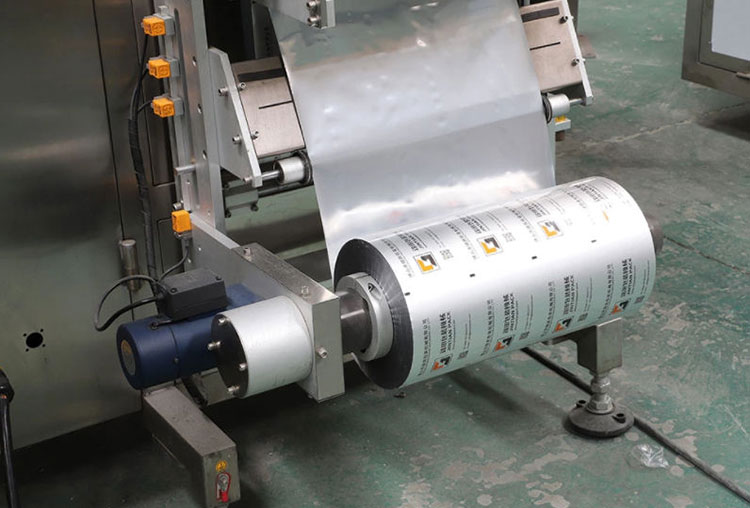

| Film Loading

Film Loading |

The large film roll is fixed at the unwinding roller. This film after passing over the rollers goes to the cutting station. |

| Cutting

Cutting |

The sharp cutters strip a large film sheet into smaller strips depending on the number of lanes. |

| Forming and Filling

Forming and Filling |

It is the main step in which strips of film are folded and doubled to form a sachet. The forming station wraps the film around itself and vertical sealing jaws seal the vertical or longitudinal seals of the sachet while the bottom side of the sachet is sealed by the horizontal sealing jaws. After that liquids are dispensed into newly formed sachets with the filling devices.

|

| Sealing and Discharging

Sealing and Discharging |

After filling, the next step is sealing of the top part which is carried out by the horizontal sealer bars using high pressure or heat. Afterward, two joining 4 side sealing packs are separated by the sharp cutter present in the centre of the horizontal sealer bars. The formed and filled 4 side sealing packs are discharged into the product chute or loaded on the product conveyor. |

5.Enumerate Industrial Applications of the Multi-Lane 4 Side Sealing Liquid Packaging Machine?

Due to its huge advantages, the multi-lane 4 side sealing liquid packaging machine has vast industrial applications which are emphasized below:

Food Industry

Application of Multi-lane 4 Side Sealing Liquid Packaging Machine - Picture Courtesy: Behance

A multi-lane 4 side sealing liquid packaging machine is always utilized in the food industry because of its accurate liquid dispensing. This machine fills a diverse range of liquids in the food industry like condiments, sauces, ketchup, pastes, dressings, liquid flavouring, liquid sweetener, honey, and extracts in small and compact sachets.

Beverage Industry

Application of Multi-lane 4 Side Sealing Liquid Packaging Machine in Beverage Industry

One of the prominent applications of the multi-lane 4 side sealing liquid packaging machine is the beverage industry. This machine is utilized for packing different beverages like juices, liquid tea, coffee, and extracts in portion-sized sachets.

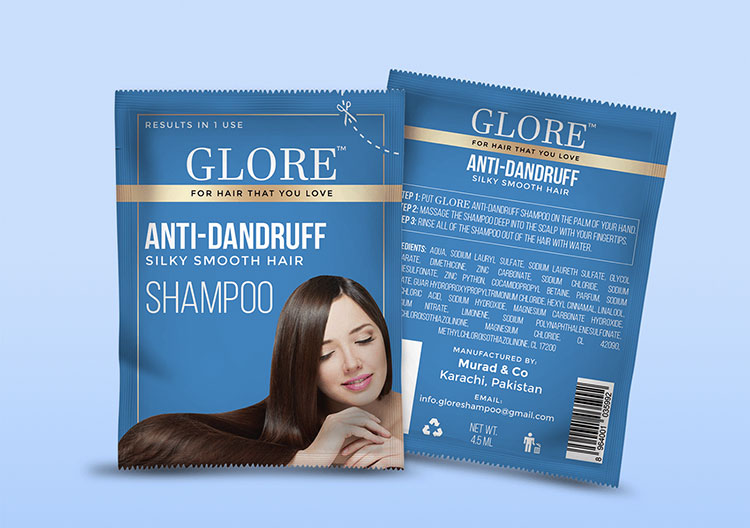

Cosmetic Industry

Application of Multi-lane 4 Side Sealing Liquid Packaging Machine in cosmetics Industry

There is no uncertainty that a multi-lane 4 side sealing liquid packaging machine is also employed in the cosmetic industry. This machine is used for packaging hair dyes, lotion, hair serums, creams, and foundations in small trial packs or travel-sized sachets.

Personal Care Industry

Application of Multi-lane 4 Side Sealing Liquid Packaging Machine in Personal Care Industry- Picture Courtesy: Behance

In addition to the cosmetic and beauty industry, this machine is also utilized in the personal care industry for packaging different hair products like shampoo and hair conditioner in small sachets. It also packs body washes, moisturizers, liquid soap, sanitisers, washing gels, and face wash in a one-time-use sachet.

Pharmaceutical and Herbal Industry

Application of Multi-lane 4 Side Sealing Liquid Packaging Machine in Pharmaceutical Industry- Picture Courtesy: Florex Pharma

A multi-lane 4 side sealing liquid packaging machine is also found in the pharmaceutical industry. Here it dispenses a large number of oral medications and liquid supplements like protein shakes, energy drinks, vitamin shots, sports drinks, etc in the sample or product sachet. It also loads herbal extracts and essential oils in the single-use sachet.

Chemical Industry

Application of Multi-lane 4 Side Sealing Liquid Packaging Machine in Chemical Industry- Picture Courtesy: B&Q

Yes, this machine is quite popular in the chemical industry because of its greater output rates and exact filling. The job of this machine in the chemical industry is to fill different kinds of chemicals like adhesives, sealants, varnishes, coating, paints, lubricants, automotive oils, and disinfectants.

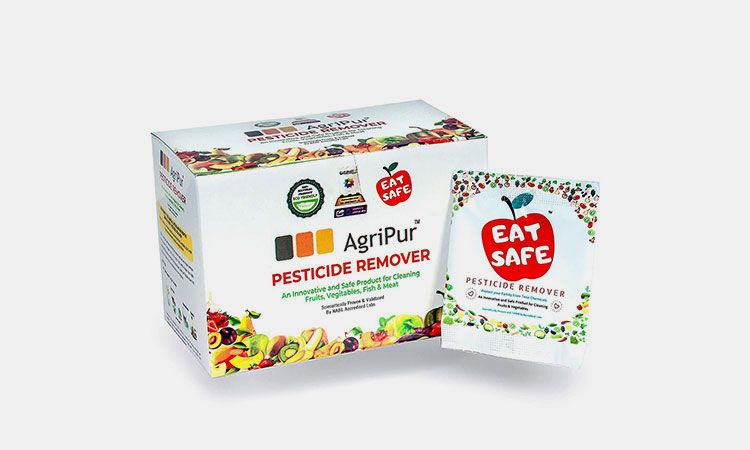

Agriculture Industry

Application of Multi-lane 4 Side Sealing Liquid Packaging Machine in Agriculture Industry- Picture Courtesy: Florex Pharma

This machine has found its use in the agriculture industry as well. Multi-lane 4 side sealing liquid packaging machine loads diverse volumes of agricultural products like pesticides, liquid fertilizers, and fungicides in the individual dose packaging.

6.What are the Basic Components Featured in Multi-Lane 4 Side Sealing Liquid Packaging Machine?

Different types of basic components make the multi-lane 4 side sealing liquid packaging machine special and technologically advanced. Knowing the different components of the multi-lane 4 side sealing liquid packaging machine aids in achieving maximum benefit from the said machine. Here is a list of basic components featured in a multi-lane 4 side sealing liquid packaging machine.

Parts of Multi-lane 4 Side Sealing Liquid Packaging Machine

Alarm System

It is a safety feature present in most of the multi-lane 4 side sealing liquid packaging machines. The alarm system produces a sound and lights up to communicate with the operators regarding malfunctioning or defects in the machine.

Color Touch Screen

This part of the machine is regarded as the brain of the machine because it is an intelligent and smart interface with which users can control and regulate the machine packaging by inputting various options like sachet length, sealing temperature, fill volume, and many more.

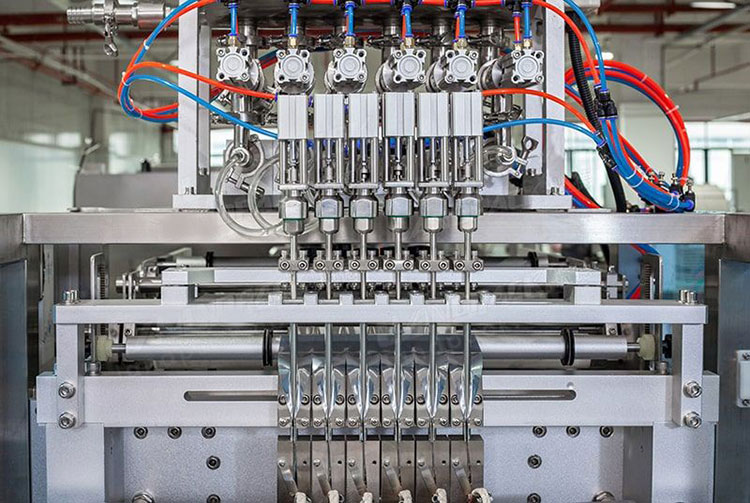

Bag Former

It is the central part of the multi-lane 4 side sealing liquid packaging machine. Multiple bag formers are present in this machine. It is a cone-shaped instrument around which packaging film is wrapped to produce precise-length sachets.

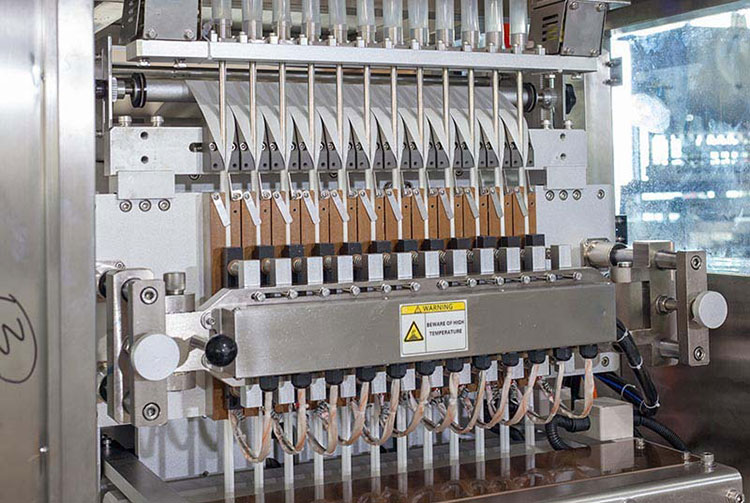

Horizontal Sealing

This includes horizontal sealing jaws that are the essential component of the multi-lane 4 side sealing liquid packaging machine. These are meant to seal the upper and lower seams of the 4 side sealing packs.

Hopper

The part of the machine, like other parts is constructed using stainless steel. It allows users to store bulk quantities of the liquids in it. It is a hollow rectangular device present at the upper side of the machine and supplies liquids to filling devices once the machine is turned on.

Measuring Pump

It is present beneath the hopper and is used for measuring the required volumes of the liquids. These pumps are the filling devices that connect the liquid hopper and the filling nozzles.

Safety Door

Multi-lane 4 side sealing liquid packaging machine has a transparent protected safety glass fitted on the front side of the machine. It is essential to uphold the safety of the operator while protecting the inner parts of the machine from dust, air, and humidity.

Cutter

It is yet another vital component of the multi-lane 4 side sealing liquid packaging machine. its job is to break apart two joined packs. It is located at the bottom side of the machine.

Smart Temperature Control

It is a high-tech sensitive temperature control device that allows one to attain precise temperature during the packaging stages.

Power Switch

It is the main red color conspicuous button present in the center of the machine control panel. Its function is to switch on the machine.

Film Holder

The film is a thinner elastic sheet made of plastic, aluminum, or composite materials and is used for forming 4 side sealing packs. The film holder is a cylindrical component that holds the film. It rotates to unwind the film.

Product Conveyor

It is a long film conveyor present at the end of the machine. the finished packs fall and are collected on the conveyor.

7.What is the Sealing Temperature of Multi-Lane 4 Side Sealing Liquid Packaging Machine?

Sealing Temperature- Picture Courtesy: Dribble

The sealing temperature generally depends upon the make and model of the machine, packaging material and liquid product. Different types of multi-lane 4 side sealing liquid packaging machines have their specific sealing temperature.

Thicker film materials like laminated and composite films require slightly higher temperatures to form a leak-proof seal. Their sealing temperature is above 140°C. Thinner film materials have low sealing temperatures because of their lower melting point. A low temperature of about below 130°C is utilised to weld these materials.

Sealing temperature also depends upon the viscosity of liquids. Thicker consistency liquids require high sealing temperature while lower viscosity liquids need less sealing temperature.

8.What Type of Sealing Technology Does a Multi-Lane 4 Side Sealing Liquid Packaging Machine Utilize?

This machine utilizes a different range of sealing technologies to ascertain seal integrity, robustness and protection of packed liquids. We are discussing some common sealing technologies for your understanding.

Heat Sealing

Heat Sealing- Picture Courtesy: Dribbble

It is one of the most frequently employed sealing technologies for sealing liquids in 4 side sealing liquid packaging machines. In this sealing technique, heat is applied to fuse the two layers of plastic materials, forming an airtight and hermetic seal.

Ultrasonic Sealing

Ultrasonic Sealing- Picture Courtesy: Behance

In this sealing technology, high-frequency ultrasonic waves are employed for heating the sealing area. Heat melts packaging material and bonds the two layers without requiring an external source. It is a quick and energy-saving method.

Cold Sealing

Cold Sealing- Picture Courtesy: Good Mockups

It is used for sealing heat-liable materials that may degrade upon application of heat. In this method, high pressure is applied to seal adhesive-coated materials.

Hot Air Sealing

Hot Air Sealing- Picture Courtesy: Dribbble

This technique guides hot air at the sealing area to melt the layers of packaging film. These melted layers are compressed together to create a strong bond. It is used for sealing materials at a high temperature.

9.How To Maintain Multi-Lane 4 Side Sealing Liquid Packaging Machine?

Maintenance of Multi-Lane 4 Side Sealing Liquid Packaging Machine

For a long operational life and effective working of the multi-lane 4 side sealing packaging machine, it is vital to maintain the machine regularly. We are giving a maintenance schedule for your consideration.

| Daily Maintenance | Visually check for any superficial problem in the machine like leakage, defective parts,

Gently clean the frame and interior parts like sealing jaws and cutting blades of the machine to get rid of product debris and dust. Oil the mobile parts of the machine for seamless working. |

| Weekly Maintenance | Check for damage in the drive belts and adjust the tension in the belts.

Check all the electric connections and reconnect them if the cables and wires are loose. Ensure that electric switches are in good working order. Ensure the cleanliness of air filters. |

| Monthly Maintenance | Check for leakage in a pneumatic system. Verify that air pressure in pneumatic systems is according to manufacturer recommendation.

Wash and clean the machine deeply, giving some attention to hard-to-clean areas. Test all the safety features like emergency stop buttons and safety alarms. |

| Yearly Maintenance | Examine the machine for rusting and corrosion.

Replace any damaged parts. Update the machine software if available. |

10.How to Troubleshoot Basic Problems in a Multi-Lane 4 Side Sealing Liquid Packaging Machine?

A systemic approach is required to detect basic problems in the multi-lane 4 side sealing liquid packaging machine. Some of the common problems and their troubleshooting are discussed below:

Uneven Filling

Uneven Filling- Picture Courtesy: landpack

There is variation in the filling volumes of the liquids.

| Cause | Solution |

| There is an error in the fill parameters.

Filling nozzles are unclean and dirty. Hindrances in the flow of liquid in fill devices. |

Readjust the fill parameters on the machine HMI.

Properly clean the filling nozzles. Check for blockage in the fill devices and remove it. |

Leakage in Seals or Incomplete Seals

Incomplete Seals

Liquids leak from the sealed packaging.

| Cause | Solution |

| Improper alignment of the sealing jaws.

Damaged sealing jaws. The sealing temperature is not within the recommended range. Sealing pressure is not sufficient. |

Properly align the sealing jaws.

Replace or repair worn-out or defective sealing bars. Adjust the sealing temperature. It should be within the advised threshold. Sealing pressure should be high to properly bond the film layers. |

Film Wrinkling

Film Wrinkling

Sometimes, creasing or folding is observed in the film.

| Cause | Solution |

| There is a blockage in the film path.

Misalignment of film over the rollers. High or low tension in the film. Improper placement of the film roll. |

Clear the blockage in the film path to avoid jamming.

Properly align the film oven rollers. Reset the tension settings so that the film unwinding is smooth. Properly mount the film over the film holder to ensure there is no tangling in the film. |

Non-uniform or Incomplete Forming

Non-uniform or Incomplete Forming

Sometimes, 4 side sealing packaging is not properly formed.

| Cause | Solution |

| Wear and tear of the forming collar could cause non-uniform forming.

Misalignment of the forming parts. Improper settings of machine forming parameters such as temperature, pressure, and speed. Incompatibility between machine parts and forming film. |

Fix the damage in the machine-forming collar.

Properly align and level the forming parts of the machine. Reset the forming parameters to attain uniform forming. Ascertain that forming material is well-suited to machine parts. |

Slipping of the Film During Cutting

Slipping of the Film During Cutting

The film moves during the cutting process and results in uneven or jagged cutting.

| Cause | Solution |

| Improper film tension.

Anti-slip devices are not used. Misalignment of film registration sensor with the cutting blade. |

Adjust the film tension so that there is consistency in the tension during the cutting stage.

Use anti-slip devices or grippers to keep the film steadily in place. Align the film registration sensor with the cutting blade. |

11.What are Buying Consideration Points for Multi-Lane 4 Side Sealing Liquid Packaging Machine?

Although you have a complete understanding of multi-lane 4 side sealing liquid packaging machine, some important consideration points should be carefully pondered before making a suitable investment. These important consideration points are:

Packaging Materials

Packaging Material Type- Picture Courtesy: Behance

There are different packaging materials like flexible plastic, aluminum, and laminated paper. Some types of multi-lane 4 side sealing liquid packaging machines can process versatile packaging materials while others are suitable for specific types of materials. Knowing your packaging materials will allow you to select a well-matched machine for your processing needs.

Liquid Type

Liquid Type

What liquid type do you favor? Liquids differ in their physical characteristics like viscosity and fluidity. Packaging conditions change depending on the type of liquids. So, first, choose your liquid type then your machine.

Filling System

Filling System

There are different types of multi-lane 4 side sealing liquid packaging machines based on the filling type like piston, pump, net weigh, etc. Hence, it is important to determine what type of filling system, you need to choose the appropriate machine.

Quality Certification

Quality Certification- Picture Courtesy: Newswire.com

The quality of the machine is what matters most to the manufacturer. So, select machines with quality certifications like GMP, ISO, CE, and others.

Budget

Budget

The purchase of a multi-lane 4 side sealing liquid packaging machine requires huge capital. You should not only consider the machine's direct cost but also keep in mind maintenance and repair costs, labour training, labour expenses, and purchase of parts. This will lead towards the accomplishment of business.

Conclusion

Let’s conclude this buying guide about the multi-lane 4 side sealing liquid packaging machine with some important takeaways. This machine protects the liquids by creating airtight and water-proof seals. It contributes towards the success of your business by its versatility, speed, customization, and efficiency. This machine serves various industrial sectors because of its wide-ranging applications. If you are interested in making a purchase, then explore Allpack's catalog of high-quality machines.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide