Mixed Nuts Counting Machine: The Complete Buying Guide in 2025

Are you sick of the traditional methods of manual counting and packing mixed nuts? Do you find it difficult to ensure accuracy and uniformity in each package? Envision an answer that guarantees accuracy and efficiency while expediting your packing procedure.

Have you ever wondered how much time and money savings the counting and packing automation could provide? What if you could enhance product quality and customer satisfaction by dispensing uniform and precise packages every time?

Introducing the mixed nuts counting machine - the best option for companies trying to improve their packing processes. Whether you own a food business or a chemical, pharmaceutical, agricultural, cosmetics, or veterinary manufacturing unit, this device will help you achieve your desired results and improve your business growth.

Continue reading this comprehensive buying guide to learn how this cutting-edge technology can revolutionize your industry and increase output. Bid farewell to manual counting and welcome a more productive and economical business method.

1.What do you mean by the mixed nuts counting machine?

Mixed Nuts Counting Machine

The mixed nuts counting machine is an advanced apparatus developed for precise and swift counting of nuts of varying sizes. The device can count thousands of nuts each minute while maintaining incredibly high accuracy, which eliminates the fuzziness of most existing counting methods and thus saves cost.

It is an ideal solution for major industries that pack large numbers of nuts packages. Apart from the mixed nuts counting, the device is also able to count multiple items accurately.

2.How the mixed nuts counting machine can benefit your business?

The manual counting method was used over the years for counting items until technology advanced and the mixed nuts counting machine came into play. Utilizing this incredible device for counting items provides numerous benefits over the traditional methods. The following paragraphs will expand on the major benefits of this mixed nuts counting machine.

Efficiency

Efficient Processing – Picture Courtesy: All-Fill

The mixed nuts counting machine automates the process and can count loads of nuts and other granular items efficiently and swiftly, reducing the time consumption and labor requirements.

Precision

Precisely Counted Packages – Picture Courtesy: Nut Shop

The device utilizes advanced sensors for counting items, which ensures the precise count each time, eliminating the error factor and maintaining quality consistency.

Affordability

Economical & Affordable – Picture Courtesy: the nut shop

The device is an economical solution along with higher productivity. Process automation and accuracy can significantly reduce your overall operational costs through quick packaging and minimal labor needs.

Operational Ease

Operational Ease – Picture Courtesy: health and food

The mixed nuts counting machine has a user-friendly interface and simpler operational protocols. It doesn’t require extensive training.

Versatility

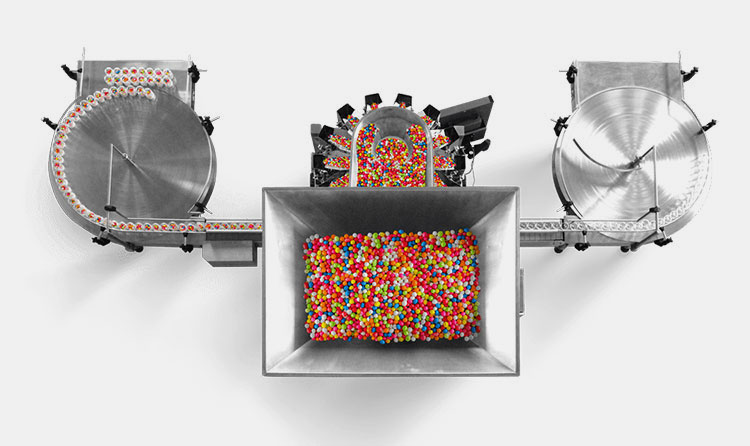

Versatile Equipment

Another interesting benefit of the mixed nuts counting machine is that it is a flexible device and can process multiple items other than nuts, such as pills, candies, and pellets, enhancing its utility.

Improved Quality

Improved Product Quality

The device ensures consistency in product packaging, resulting in enhanced customer satisfaction and brand image. The minimal human intervention reduces the chances of cross-contamination, leading to improved product quality.

3.What types of businesses benefit most from using a mixed nuts counting machine?

The mixed nuts counting machine is extensively used across various industries. It is popular for its robust and accurate functioning, not only in the dried fruits industry but in numerous other sectors as well. Some major industries that utilize the mixed nuts counting machine are:

Dried Fruits Industry

Applications in the Dried Fruits Industry

The mixed nuts counting machine is primarily employed in the dried fruits industry for counting and packaging nuts, such as peanuts, pistachios, cashews, walnuts, pine nuts, almonds, and hazelnuts, in various packages.

Food Industry

Applications in the Food Industry

In the food industry, the device is used for counting food items, such as beans, candies, chocolate balls, gums, and other food pills.

Pharmaceuticals Industry

Applications in the Pharmaceuticals Industry- Picture Courtesy: NiceRX

In the drug industry, the accurate quantity of drugs, such as tablets and capsules, in each package is crucial due to the expensive nature of the drugs and precise drug doses for convenient usage by the patients. The mixed nuts counting machine can be used for accurate dispensing.

Nutraceuticals Industry

Applications in the Nutraceuticals Industry

The mixed nuts counting machine can also be employed in nutraceutical firms for precisely counting dietary supplements (vitamins and minerals pills)

Cosmetics Industry

Applications in the Cosmetics Industry

In the cosmetics industry, multiple products are manufactured for personal care and hygiene that can be packed in different materials. The mixed nuts counting machine can be used for counting and packaging accurately.

Chemicals and Agricultural Industry

Applications in the Chemicals & Agricultural Industry

Several solid chemicals and agricultural goods, such as fertilizers, pesticides, naphthalene balls, and other chemicals are accurately packaged using the mixed nuts counting machine.

Veterinary Industry

Applications in the Veterinary Industry

Yes, you read that right. The mixed nuts counting machine can be utilized for packaging multiple veterinary products, such as pills, pellets, and feed.

Hardware Industry

Applications in the Hardware Industry

The device can also be used in the small hardware industry for counting screws, nuts, bolts, and other hardware products.

4.What essential components make up a mixed nuts counting machine?

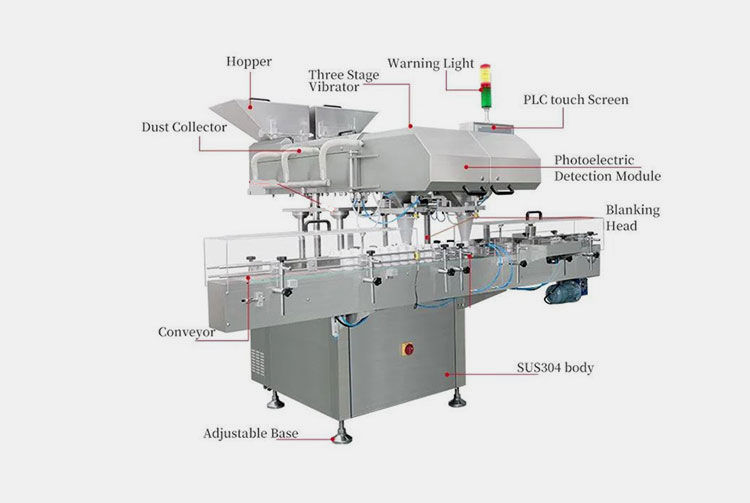

Components of the Mixed Nuts Counting Machine

The mixed nuts counting machine has a simple composition. All the components are easy to clean and maintain. The description of the components is as follows:

Hopper

It is a hollow structure positioned at the top through which the product is introduced for counting. Its capacity and shape vary with different models. The product feeding can be done either manually or using an automatic mechanism. It ensures a controlled supply of items for counting.

Three Stage Vibrator

It is made up of vibrating plates and is one of the most important components of the apparatus. It holds the tablets in place and facilitates the tally using the vibrating mechanism.

Nuts or other items are transferred to the primary counting mechanism with the help of controlled vibrations.

Dust Collector

The dust collector is designed to eliminate dust and other tiny particles produced during the product counting. It maintains a clean working environment and helps in improving product quality.

Conveyor

It is responsible for directing the packaging containers to be filled with the processing items. It is synchronized with the counting process to ensure that the right quantity of product is released into the container at the right time.

Warning Light

It is responsible for alerting the operators about any faults or errors during the process.

PLC Touch Screen

It is an essential component through which the process can be monitored and regulated accordingly.

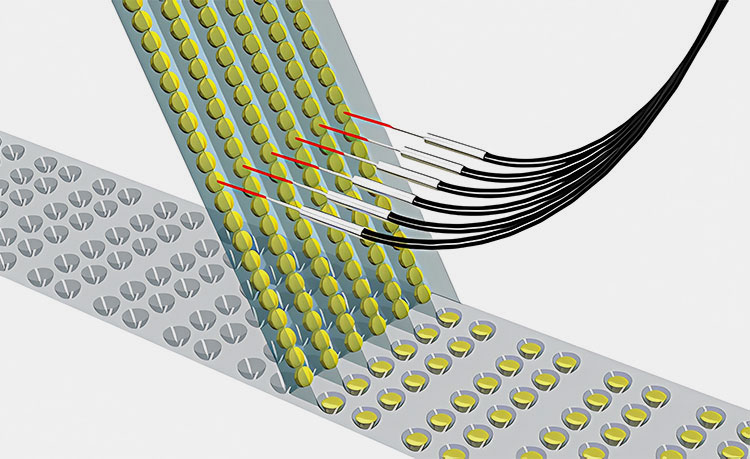

Photoelectric Detection Module

It is one of the most vital components of the device. It is situated beneath the vibrating plates and uses photoelectric sensors to detect and count the products as they pass through the counting area. It maintains accuracy and reliability in counting.

Blanking Head

It directs the counted nuts into the packaging containers. It can be adjusted according to the container’s size and shape.

SUS304 Body

It refers to the stainless steel material (SUS304) used for the device’s construction.

Adjustable Base

The base is used for firm placement of the device and adjusting the device position as well.

5.How does a mixed nuts counting machine work?

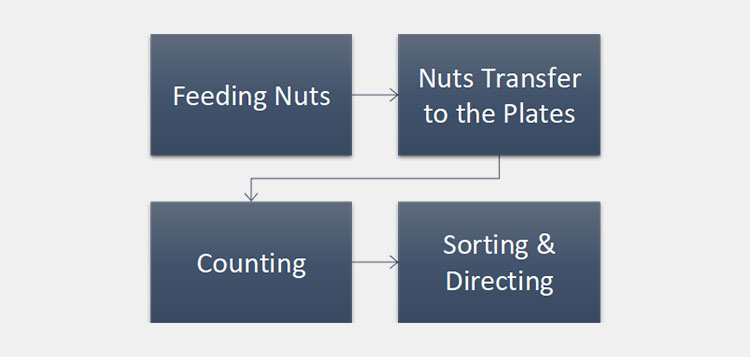

The mixed nuts counting machine operates in synchronized steps and components to ensure precise counting and packaging. A detailed rundown of the device's basic operation is provided below:

Working Steps of the Mixed Nuts Counting Machine

Feeding Nuts

Nuts are loaded into the hopper, temporarily holding them before directing them to the counting mechanism. The feeding step is done manually or using an automatic tool.

Transfer of Nuts to the Plates

The hopper directs the nuts to the vibratory plates, which evenly spread and align them for counting with the help of a vibrating mechanism.

Counting

The nuts are then transported to the counting area. The vibration ensures a steady flow. As nuts pass through the counting area, the photoelectric detection sensors detect and count the nuts. The detection sensors detect the interruption of a light beam or intensity caused by the nuts.

Sorting and Directing

After counting, the nuts are guided toward the packaging containers by the blanking head, which ensures the precise dispensing of the counted nuts into the supplied containers by the conveyor.

6.Describe the classification of the mixed nuts counting machine.

There are several types of mixed nuts counting machines available in the market. Several qualities set them apart. These devices fall under several different categories. Let's examine the different variants of mixed nuts counting machines without further delay.

Classification Based on Automation

The mixed nuts counting machine can be divided into 2 categories based on the level of automation.

Semi-Automatic Mixed Nuts Counting Machine

Semi-Automatic Mixed Nuts Counting Machine

Semi-automatic mixed nuts counting machines, as the name implies, are automated to some extent but still require human involvement. Tabletop versions of these devices are frequently employed.

Using a semi-automated process requires manual loading of nuts and positioning of bottles. Automated tasks done by the device include counting by photoelectric sensors and filling the containers. These devices have a greater productivity rate as compared to manual devices.

Mixed nuts counting semi-automatic machines can greatly enhance counting precision and productivity. These devices may be adjusted to handle different sizes and shapes of products. These are well-liked options for enterprises that are small to medium-sized.

Automatic Mixed Nuts Counting Machine

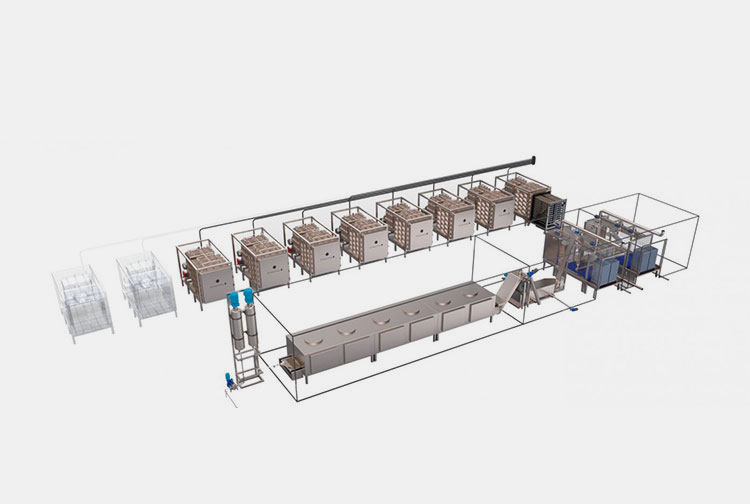

Automatic Mixed Nuts Counting Machine

Mixed nuts counting fully autonomous machines are sophisticated gadgets. Conveyors, photoelectric sensors, and other automated systems are installed in them. These elements reduce errors and guarantee accurate counts.

These devices are tailored with a user-friendly touch interface, enabling the workers to surveil and regulate the process settings.

The high automation level allows for processing large quantities of products in a short span, making it ideal equipment for large production industries.

Classification Based on Counting Mechanism

The mixed nuts counting machine can be divided into two categories based on the operating mechanism.

Vibratory Mixed Nuts Counting Machine

Vibratory Mixed Nuts Counting Machine – Picture Courtesy: Kenwie

These devices utilize a vibratory mechanism for the alignment of materials. They are structured with one or more vibratory channels that produce vibratory movements to align the processing materials and facilitate the counting. They are typically employed in large processing sectors.

Rotary Mixed Nuts Counting Machine

Rotary Mixed Nuts Counting Machine

These particular devices employ revolving discs with holes to hold the tablets individually. The rotating disc causes the materials to distribute into the spaces which are then directed towards the counting system.

Although they are versatile and easy to use, their comparatively smaller output capacity makes them unsuitable for large-scale operations.

7.What type of sensors can be used in the mixed nuts counting machine?

Different Types of Sensors- Picture Courtesy: Turck Banner

Various sensors can be used in the mixed nuts counting machine for detection and accurate counting.

Since opposed-mode sensors are unaffected by the color or reflectivity of processing items, they often provide the most dependable sensing method (also referred to as through-beam sensors).

Nevertheless, depending on your application needs, you could take into account alternative sensing choices.

You can adjust the sensitivity and coverage over the sensing region with fiber optic arrays. Incorporating microprocessor technology can also improve output capabilities and sensitivity.

8.How to manage dust build-up from the processing materials in the mixed nuts counting machine?

Regular Cleaning & Maintenance to Avoid Dust Build-up

Dust accumulation from the processing materials on the sensors can impact the signals, reducing the product’s accuracy. Schedule regular maintenance programs to guarantee the sensors are dust-free.

Advanced sensors contain effective optical surveillance systems to detect the optical level. These functions inform the sensor to adjust its gain level to keep it operating longer or send out an alert signal for repair before the sensor becomes unreliable.

9.How do you maintain a mixed nuts counting machine?

Maintenance of the Mixed Nuts Counting Machine

Regular maintenance is essential for any industrial equipment to have a long lifespan. The mixed nuts counting machine is generally simple to maintain, but to extend its life, it needs to be inspected regularly. The following procedures should be followed to maintain the machine effectively:

Cleaning

Mixed nuts counting machine

Regular cleaning and dusting are necessary to keep the device in top condition. Schedule thorough cleaning procedures to remove any residue. The cleaning can be done using a soft fabric with water or any recommended detergent. Components such as hopper, vibratory channels, nozzles, and other mechanical parts must be cleaned carefully.

Inspection

Mixed nut counting machine- Picture Courtesy:SED

Conduct periodic inspections of the device. Disassemble the apparatus and carefully inspect the parts for damage or tear. Consider repair or replacement (as necessary) to keep the device in optimal working condition and avoid breakdown.

Lubrication

Picture Courtesy: C.E King

Regularly lubricate the moving parts to maintain smooth motion because the machine's constant operation may cause them to operate more slowly.

10.What problems might you encounter while using a mixed nuts counting machine and how to troubleshoot them?

Owing to its constant operation, the mixed nuts counting machine could have some issues that need to be evaluated and fixed quickly to ensure proper operation. This section discusses some common problems encountered in the mixed nuts counting machine and how to resolve them.

Product Jamming

Product Jamming

The high-speed operation might cause the nuts and other processing materials to get clogged and stuck in certain machine parts.

Solution: make corrections in the feeding rate and speed of vibratory channels.

Counting Defects

Counting Defects- Picture Courtesy: optexfa

The potential reasons for over-counting or under-counting (counting errors) are incorrect timing, vibratory channels not properly sorting the material, and faulty sensors.

Solution: adjust the timing and operation speed. Repair or replace the vibratory plates. Examine the sensors for proper functioning.

Misalignment of the Packaging Containers

Misalignment of Packaging Containers – Picture Courtesy: Altrimex

The problem could occur from mistiming the containers or from the dropping nozzle not aligning properly with the bottle opening.

Solution: replace or adjust the dropper section. The conveyor belt's rail spacing should be adjusted.

Spillage

Spillage due to Conveyor Defects

The material spillage may occur due to improper functioning of the conveyor rail or defective blanking head.

Solution: align or repair the conveyor built. Repair or replace the blanking head (as necessary).

11.What factors should you consider when buying a mixed nuts counting machine?

When purchasing a mixed nuts counting machine, there are various factors to consider, both in terms of the device and your requirements.

Capacity of Production

Production Capacity – Picture Courtesy: TOMRA

The most essential factor is the production capacity of the device. Different models have varying capacities and you must opt for the device with the desired capacity for production and can satisfy your needs efficiently. The production capacity is crucial for determining the operation scale (bigger capacity; greater scale).

Processing Material Type

Type of Material to Be Processed

There are various mixed nuts counting machines available. You must choose a device that is compatible with your products. It is an important factor to get the most out of your device. If the device is unable to efficiently process the products you are dealing with, then it will be a waste of your investment.

Budget

Budget – Picture Courtesy: AIA

It is a crucial factor that needs to be taken into account before purchasing a mixed nuts counting machine. Evaluate the finances and the device's total cost, including the cost of acquisition, use, and upkeep. Pick a solution that will effectively meet your demands. The type of equipment you opt to purchase will depend on your operational budget.

Customization

Flexibility & Customization

Opt for the mixed nuts counting machine variant that is easily customizable and can handle various products with minimal adjustments.

Quality Compliance

Quality Compliance – Picture Courtesy: Conformance1

Each device you intend to utilize needs to adhere to the necessary quality requirements. Make sure any machine you intend to purchase meets the required quality standards. Spending money on unstable machines is nothing but a waste.

Integrating Compatibility

Integrating Compatibility

It is advised to select equipment that can be easily incorporated with other processing machinery. This property allows for streamlined operation while neglecting the chances of errors.

Conclusion

Mixed nuts are demanding products in the market. Customers always look for consistently filled and quality packaging. The mixed nuts counting machine is a reliable solution in that context as it offers a swift, accurate, and efficient operation, enables you to achieve the desired outcomes, and helps your business to grow. Selecting the right device that can satisfy your demands, is crucial and you must contact a reputable manufacturer for assistance. If you are also looking to invest in this incredible device or need further assistance, contact Allpack. You will be guided better!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide