Milk Powder Stick Packaging Machine: The Complete Buying Guide In 2025

Are you looking to enhance your production efficiency or improve your packaging without sacrificing the product’s quality? Do you need a machine that ensures precise filling, robust production, and efficient packaging? The right milk powder packaging machine can certainly help you achieve that!

Milk powder is a popular and widely consumed dairy product due to its extended shelf life, ease of use, and nutritional value. Quality packaging plays a crucial role in sustaining the milk powder’s freshness and longer shelf life. Stick packaging has become more common among packaging options since it is economical, efficient, and easy to use.

A milk powder stick packaging machine offers a modern solution, designed to automate the operation, guaranteeing accuracy, hygienic practices, and efficiency. For manufacturers, investing in the right equipment can significantly impact your business growth and market image.

This buying guide attempts to provide you with the necessary knowledge to select the ideal milk powder stick packaging machine that will meet your demands. So, stick to the guide till the end and understand the device better!

1.What is a milk powder stick packaging machine?

Allpack Milk Powder Stick Packaging Machine

You might be aware of the increasing market trend of milk powder stick packs due to their convenient usage and portable single-use product. A stick pack is a slender packaging format.

A milk powder stick packaging machine is a specialized device created to efficiently produce stick packs filled with powdered goods. It is an indispensable and valuable device that can significantly influence your business growth.

Apart from the food industry, the milk powder stick packaging machine can also be employed in other sectors, such as pharmaceuticals, chemicals, cosmetics, and herbal, to package powdered items effectively.

2.What are the advantages of a milk powder stick packaging machine?

With all of its incredible benefits, the milk powder stick packaging machine is a must-have for any industry looking for robust and efficient production of stick packs of powdered items. Here are some notable advantages of the milk powder stick packaging machine:

Major Advantages of the Milk Powder Stick Packaging Machine

Cost-Efficient

Cost-efficient

It is a fact that the milk powder stick packaging machine requires a huge investment initially. However, it can be cost-efficient in the long run by eliminating labor costs and potential human errors.

Easy to Maintain

Maintenance Ease – Picture Courtesy: Jochamp

Maintenance of industrial equipment is essential to keep it in top condition. Manufacturers always want devices that are easy to maintain to avoid heavy expenses and halted work for a long time. The milk powder stick packaging machine offers the advantage of easy maintenance and you will have no problem maintaining it.

User Friendly

User-Friendly Interface – Picture Courtesy: Levapack

The milk powder stick packaging machine utilizes advanced technology, which makes the equipment user-friendly. The device can be operated and regulated via a touchscreen interface which is easier to use and does not require extensive training.

Rapid Production

Rapid Production

The automatic milk powder stick packaging machine has the key benefit of rapid production without requiring manual assistance. The rate of production can vary based on different models. The device can help you achieve the desired production demands.

Efficiency and Accuracy

Efficiency & Accuracy

Another remarkable benefit of the milk powder stick packaging machine is the efficient packaging processing and accurate filling of stick packs. The precise filling is critical, particularly in the pharmaceutical sector, where the stick packs are produced to serve a unit dose of medications.

Improved Product Quality

Improved Product Quality

The milk powder stick packaging machine packages the product in a strict hygienic environment, ensuring minimal contamination and improving product quality and freshness. This property will ultimately extend the product's shelf life while retaining its inherent characteristics.

3.Which industries can utilize a milk powder stick packaging machine?

The milk powder stick packaging machine is a flexible equipment that can handle a wide range of powdered materials. Therefore, it is a favored device across various industries. Here we are enlisting some common industries that can utilize the milk powder stick packaging machine for various products:

Dairy Industry

Applications in the Dairy Industry

Dried milk powders are commonly used items and are most popular due to their convenient usage, longer shelf life, and nutritional value. These milk powders can be effectually packaged into stick packs using a milk powder stick packaging machine.

Food and Beverage Industry

Applications in the Food & Beverage Industry

Another popular industry that can adopt a milk powder stick packaging machine for packaging several powdered food items and beverages as ready-to-use stick packs. Examples include coffee powder, cocoa powder, powdered juices, chocolate powder, spices, and protein powder.

Pharmaceuticals Industry

Applications in the Pharmaceutical Industry

The milk powder stick packaging machine is utilized in the pharmaceutical industry to package powdered drugs. Various powdered drugs are now packaged as unit-dose stick packs for easy consumption by the patients. Moreover, stick packs of sample drugs can also be produced.

Chemical Industry

Applications in the Chemical Industry (Cinnamon Dye) – Picture Courtesy: The List

The milk powder stick packaging machine is employed in the chemical industry to package chemicals, such as pesticides, dyes, pigments, laundry agents, and other powdered chemicals.

Cosmetics Industry

Applications in the Cosmetics Industry

Several personal care and cosmetic products such as facial powders, baby powders, and talcum powder are also packaged in stick packages using the milk powder stick packaging machine.

4.Describe the structural components of a milk powder stick packaging machine.

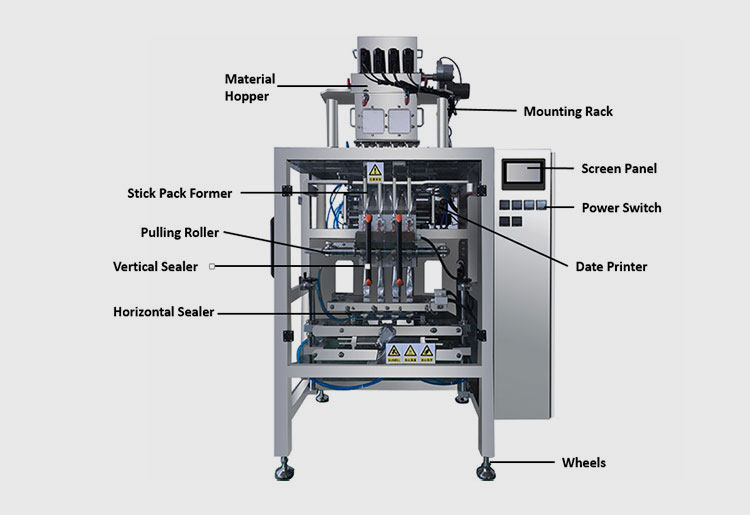

The milk powder stick packaging machine is structurally composed of various electrical and mechanical components. Here you will explore the basic components of the milk powder stick packaging machine and their description.

Components of the Milk Powder Stick Packaging Machine

| Components | Description |

| Material Hopper | The component is located at the top of the device and is responsible for temporarily storing the powdered materials and dispensing them into each stick pack. Its design and capacity can be varied in different variants. |

| Mounting Rack | It is responsible for tightening the film frame to avoid slipping the film reel. |

| Screen Panel | It is a touch screen used to monitor or regulate the processing parameters. |

| Power Switch | It connects the device with the necessary power supply. |

| Date Printer | It consists of the registration rollers that imprint the date on the packaging film. |

| Stick Pack Former | This section consists of shaping or forming tubes that are responsible for the fabrication of stick packs. |

| Vertical Sealer | The vertical heated sealing bars apply pressure on the film strips and produce vertical seals to form stick packs. |

| Pulling Roller | The pulling roller pulls the film and maintains the film's tension. |

| Horizontal Sealer | The horizontal sealer is a sealing clamp that seals the top and bottom edges of the consecutive stick packs. |

| Wheels | The universal wheels are responsible for conveniently transporting the device from one place to another. |

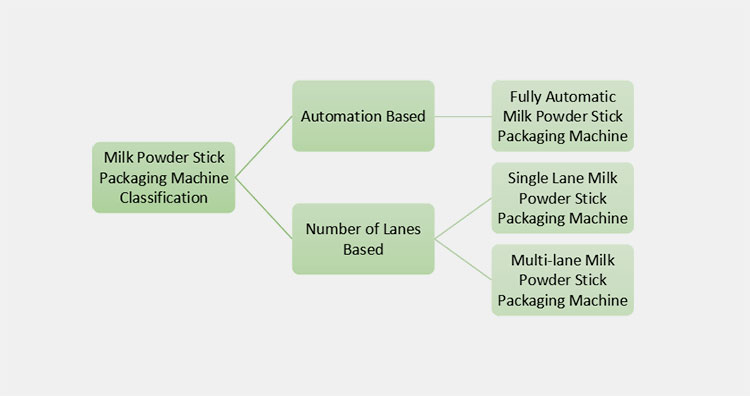

5.Classify the milk powder stick packaging machine.

It must be overwhelming to look at the heft of the variants of the milk powder stick packaging machine available on the market. Why fretting out? Here you will find different variants, each having distinctive features and benefits, classified on several aspects.

Categorization Based on Automation

Fully Automatic Milk Powder Stick Packaging Machine

Fully Automatic Milk Powder Stick Packaging Machine

It is the latest advanced form of equipment with multiple lanes functioning in the same fashion. It occupies a larger area and has incredible production efficiency. Companies with huge production demands add this equipment to their line.

The device uses digital technology to perform the entire operation with minimal human intervention.

Categorization Based on Number of Lanes

Single Lane Milk Powder Stick Packaging Machine

Single Lane Milk Powder Stick Packaging Machine

This device model is designed with a single processing lane, which processes a single stick pack at a time. It is often employed in laboratory-scale or medium-sized industries due to its limited productivity and easy maintenance.

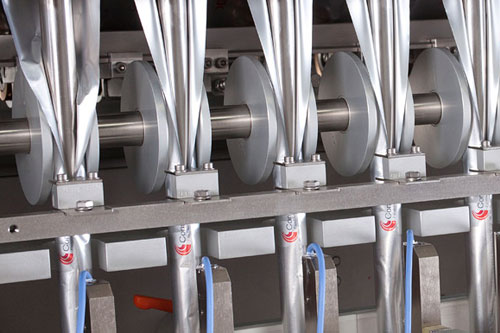

Multi-lane Milk Powder Stick Packaging Machine

Multi-lane Milk Powder Stick Packaging Machine

It is a large piece of equipment with multiple lanes in its design, working in the same fashion and producing multiple stick packs in each cycle (depending on the number of lanes). It is the best solution for large-scale industries with high manufacturing needs.

6.How does a milk powder stick packaging machine work?

The milk powder stick packaging machine is structured with several components for streamlined packaging. The basic steps involved in the functioning of this device are described below:

| Feeding of Powdered Material

The operation begins by feeding the hopper with the powdered material. The quantity of powder to be fed is ascertained by the hopper’s dimensions and capacity. |

|

| Placement and Unwinding of Packaging Film

A large film reel of recommended packaging material is placed on the film frame. The film is unfolded and directed towards the device. The unfolding process is facilitated by the cross-seal clamps. |

Picture Courtesy: Viking Masek |

| Printing

This is an optional step. If the device has the printing tool, the film is processed through a registration roller, imprinting the date and other imprints on the film. |

Picture Courtesy: Coretamp |

| Slitting of Film

The film tension is maintained while entering the slitting section, where the film is cut into strips using slitting blades. The number of strips produced and processed in each cycle relies on the number of lanes in the device. |

Picture Courtesy: Viking Masek |

| Formation of Stick Packs

The produced strips travel through many shaping tubes (one per lane). The strips get overlaid around the tubes such that it results in a stick pack with the overlaying of the two external margins. |

Picture Courtesy: Viking Masek |

| Filling and Sealing

Several heated vertical sealing bars (one for each lane) advance and come into contact with the vertical film overlay when the film stops moving. The bars press up against the tube to form a seal. A single lateral clamp then seals the top edge of one package and the bottom edge of another package. The precise amount of the powdered material is then fed into each pack. The filling mechanism for precise measurements can be varied in each model. |

Picture Courtesy: Viking Masek |

| Discharging of Finished Product

After the product filling and package sealing, the blades cut individual packs which drop down and are expelled from the device through the outfeed. |

Picture Courtesy: Viking Masek |

7.What filling techniques are employed in the milk powder stick packaging machine?

There can be various filling mechanisms installed in the milk powder stick packaging machine. The two frequently employed mechanisms are:

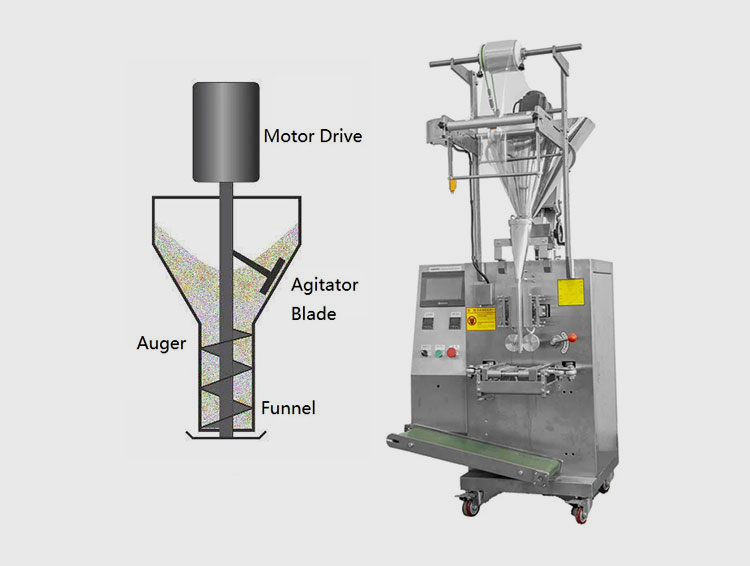

Auger Filling Mechanism

Auger Filler Milk Powder Stick Packaging Machine

In such types of fillers, an auger screw is utilized for the powders to be dispensed from the hopper. The screw gyrates at a specific speed and guides the precise powder quantity into each pack. By adjusting the screw rotations, the amount of powder to be dispensed can be regulated.

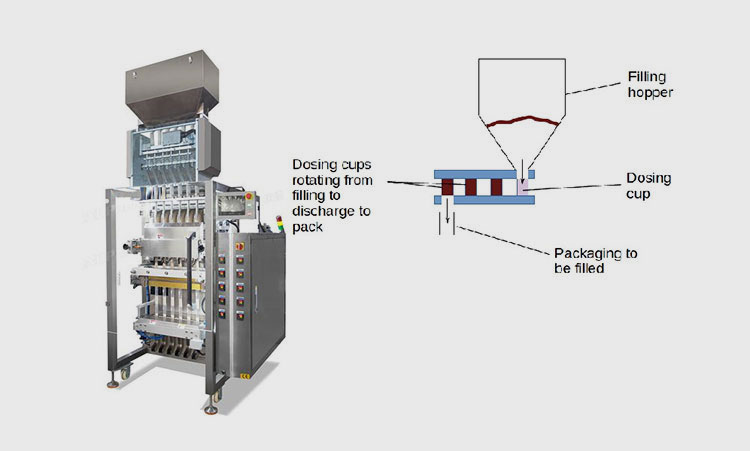

Vibratory Cup Filling Mechanism

Vibratory Cup Filler Milk Powder Stick Packaging Machine

The vibratory cup fillers offer a blend of speed, precision, and versatility. These are suited to linear feeders. They calculate the powders by weighing them and then distributing them into the packs.

8.How to maintain a milk powder stick packaging machine?

Maintenance Program

Machine breakdown might mean a large loss of money due to productivity loss. A machine that malfunctions due to poor maintenance won't be able to produce the quality product. The impact of device failure can be reduced by carrying out regular device cleaning and maintenance.

Here’s an overview of the maintenance procedure that can be followed to guarantee the smooth functioning of the device.

Maintenance Basic Steps

Lubrication

It is essential to periodically lubricate the dynamic parts of the device for their smooth functioning as continuous operation causes abrasiveness and friction that can lead to tear and damage.

Cleaning

Routine cleaning as well as periodic deep cleaning, are crucial for efficient performance of the device. Regular cleaning of parts such as sensors, nozzles, hopper, sealing station, and slitting assembly must be done to avoid dust and residue accumulation that can cause product contamination.

Inspection and Changeovers

Inspect the entire device for loose screws and bolts that can halt the operation. Moreover, examine the components for damage and tear and consider timely repair or replacement to avoid breakdown and permanent damage to the device.

9.Are there any safety guideline certifications required for a milk powder stick packaging machine?

Health and safety guidelines are developed to protect operators as well as customers. When safety regulations are followed throughout the production and processing, the product’s quality and safety is guaranteed. Here are the primary international standards that a milk powder stick packaging machine needs to comply with.

Food and Drug Administration (FDA): The FDA's clearance certifies the product's safety for use in consumer products manufacture and processing.

International Organization for Standardization (ISO): The ISO accreditation certifies that the product satisfies standard regulatory specifications and is safe and effective.

Current Good Manufacturing Practices (cGMP): The cGMPs are the legal requirements needed to properly develop the product. Its certification indicates that the product is safe to carry out the functioning.

European Conformity (CE): The CE marking indicates that the product complies with accepted safety and environmental standards.

10.Enlist the common problems encountered in a milk powder stick packaging machine and how to troubleshoot them.

The milk powder stick packaging machine has become indispensable to companies that deal in powdered goods. The device offers the packing process precision, uniformity, and efficiency. But just like any other equipment, the milk powder stick packaging machine might have issues that could compromise its functionality.

In this section, we will discuss some common issues encountered in the device and how to fix them.

Film Wrinkling

Film Creasing – Picture Courtesy: Synda Pack

The creasing or wrinkling of the film could cause multiple defects and halt the operation. The potential causes and their respective solutions are described under:

| Causes | Solutions |

| The film frame is loose.

The dancing rollers are damaged. Misaligned film roll. The pulling roller exerts extra pulling pressure. |

Firmly tighten the film frame.

Repair or replace the dancing rollers. Adjust the film reel into the center. Adjust the film pulling tension. |

Faulty Sealing

Defective Seal

The defects in sealing result in product spills and thus resource wastage. The possible reasons are:

| Causes | Solutions |

| Dirty sealing surfaces.

Inadequate sealing time or pressure. Improper temperature setting. Damaged sealing bars or clamps. |

Clean the sealing station.

Adjust the sealing parameters, such as time, pressure, and temperature. Replace the torn sealing bars or clamps. |

Stick Pack Size Variances

Stick Pack Size Variances – Picture Courtesy: Amcor

The non-uniformity in the size or dimensions of stick packs negatively impacts the brand image. The potential reasons and how to fix them are discussed below:

| Causes | Solutions |

| Defective slitter or forming tube.

Fault or obstruction in the film feeding. |

Replace the slitter or forming tube.

Clear the obstruction in the path of the film. |

Inconsistent Filling

Non-Uniform Filling

The inconsistency in the filling of stick packs is troublesome, particularly in the drug industry where stick packs offer precise unit-dose of medications. It must be timely resolved. The possible causes of this fault are:

| Causes | Solutions |

| The filling nozzle is blocked or damaged.

Fault in the material supply. Calibration or software errors. |

Clean the filling station regularly to avoid clogging.

Replace the damaged nozzles. Ensure the smooth supply of the material. Validate the calibration of the components. Update the software regularly. |

11.What are the major factors to consider before investing in a milk powder stick packaging machine?

Investing in the milk powder stick packaging machine requires a substantial amount. It is therefore important to choose the right equipment that can satisfy your demands efficiently. Some key factors that should be considered before buying the device could aid you in selecting the perfect equipment for your business. These factors are described below:

Production Capacity

Single Lane & Multi-lane Milk Powder Stick Packaging Machine with Distinct Production Capacity

It is an important factor to consider before selecting the device. You must take into account your desired production needs (current as well as future objectives) and then opt for the model that can assist you in a better way.

Budget

Budget

Before selecting a milk powder stick packaging machine, you need to make sure that your budget is well-defined. Consider both the initial cost of purchase and ongoing operational as well as maintenance expenditures for the machine.

Product Characteristics

Product Characteristics – Picture Courtesy: Best Health Magazine

The products you are dealing with will have certain unique characteristics. You must know about those properties and then opt for the device variant that can efficiently handle the products and satisfy your needs.

Filling Mechanism Installed

Auger Filler vs Vibratory Cup Filler

There are multiple mechanisms of filling, each developed for certain powders. Consider the device with the appropriate filling technique for your products installed in it.

Regulatory Compliance

Standard Certifications

Any company's top focus should be the wellness of its customers. A device, having the required safety certifications, is recommended to choose. Quality products and packaging will certainly help in the improved public’s trust in the firm.

Versatility

Versatility – Picture Courtesy: Medical News Today

It is recommended to choose the model that has the versatility feature and can handle a wide range of products. This feature will help you achieve your future objective of the extension of the production line without investing in multiple equipment.

Conclusion

For every manufacturer looking to increase productivity, reliability, and product quality, a milk powder stick packaging machine is an ideal and essential tool. Knowing the essential features of a milk powder stick packaging machine will make it easier for you to choose one that will unquestionably be ideal for your need. So, if you also want to get advantage from this incredible equipment by opting for a perfect variant, Allpack can certainly help you with that. Feel free to contact us for a perfect stick packaging solution!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours