Milk Powder Filling Machine: The Complete Buying Guide in 2025

Do you know why milk powder packaging is very important to you? As you know the milk powder is a substance that constitute important nutrients that are healthy for wellbeing. Primarily, the milk powder is very sensitive to your environment; this is because in the atmosphere, you are encountering with oxygen, light, moisture, microorganisms, and many other elements that you can’t see. But the milk powder is certainly prone to react them and affects its nutritional value with time.

The milk powder filling machine is a state of art solution that helps in the packaging process to store them in the finest way till the end user. The market value of this machine is rising leap and bound. If you’re planning to add this robust machine into your production line then don’t worry! This blog is especially designed for those consumers who are looking to find important answers of their questions. Let’s read out!

1.What is Milk Powder? Why does it Require Specialized Packaging?

The specialized milk powder filling and packaging

A milk powder is a convenient way of consuming milk for those who’re unable to get fresh milk. This is commonly prepared by evaporating the amount of moisture from the regular milk and reducing it into concentrated powdered form which requires astringent packaging for very effective shelf life and nutritional values.

This is in fact considered as a healthier option for those who’re really conscious about their health. Therefore, it is delivered in a specialized packaging way due to certain reasons. Firstly, the absorption of humidity in the milk powder can significantly affect the nutritional content of the milk powder so the prime purpose of the packaging is to keep it away from invasion of moisture and make it effective for a longer time against lumpiness, cakey, or structural alteration such as oxidation or enzymatic reaction.

Secondly, to keep water activity less than 0.6 which is known for optimum against progression of microorganisms. The water activity for milk powder should be around 0.25 (low) to 0.35 (high) while for skimmed milk powder varies from 0.32 to 0.43. Therefore, specialized packaging is able to keep them intact to preserve milk powder characteristics stable.

2.What is a Milk Powder Filling Machine?

The milk powder filling machine

To be very frank, this is the type of machine that could be used in the packaging industry forever! The milk powder filling machine is a one-stop-solution for filling and packaging milk powder in specialized manner where manufacturer should not be worried about any cross- contamination or any sort of error.

This machine is basically relying on auger fillers where filling powder milk powder is so confined and accurate without forming dust into your production facility.

The milk powder filling machine is just a click away to begin the process by itself. You just need to add the amount of product to be filled and that’s it. The rest of operability will be done by the machine which is made up of a finest sleek material that’s superb for sensitive products like milk powder so your valuable consumers can get 100% safe and hygienic products packed either in zip-lock, canister, pre-made huge pouches and other.

3.Why Milk Powder Filling Machine is So Important?

Beyond the filling of milk powder, the milk powder filling machine is a versatile solution to offer unlimited benefits to manufacturing companies; the significance of milk powder filling machine is discussed below.

Milk Powder Filling Machine Offering Broad Scope

Milk Powder filling machine has broad Applications.

Whether running scientific, or non-scientific production lines. The milk powder filling machine is an absolute equipment best fit for various purposes around the globe. Therefore, the machine is ideal in offering large benefits in the various fields of production businesses.

Quick Monitoring and Picks the Errors Immediately

A highly modern milk powder filling machine

The milk powder filling machine is extremely innovative equipment that featured with high PLC touch screen system with visual monitoring and detecting tools inside that helps you to scrutinize and alert about the errors via monitoring and alarming notifications. This is a helpful assessment to evaluate the effective approach in reducing error and delivering accurate and precise filling of milk powder followed by a uniform and consistent batch production.

Highly Effective for Small to Large Production Batches!

The milk powder filling machine large production batch

The milk powder filling machine is a modern equipment that offers uninterrupted workflow as you dream for. The machine is entirely based on operating with automation and highly vigilant sensors that help to minimize the error. So, why are you worried about it?

The milk powder filling machine is a great option to run small, medium and large batches with no room for error. You can fill hundreds to thousands of packaging materials in a very short time.

Say Bye to Cross-Contamination!

If you see the makeup of the milk powder filling machine it is made up of stainless steel with highly smooth surface where stickiness of remnant is impossible moreover it is easy to clean after every use. You can flexibly use this machine for delicate and sensitive product like milk powder, infant milk powder protein powders etc., So, for every filling product you should be free- of -mind about cross-contamination or any sanitary option as machine itself is excellent device of filling product.

4.Where Milk Powder Filling Machine is used?

Due to several innovative features, a milk powder filling machine has offered a broad industrial application to its users belonging to various industrial fields, such as:

Nutraceutical Industry

The role of milk powder filling machine in the nutraceutical industry

This is the most common industry that utilizes a milk powder filling machine for the filling and packaging of protein powders, milk powders, energy powders, instant energy boosters, vitamins powder, re-hydrating powders such as glucose, energy salts, probiotics, enzymatic products, fibers, proteins, sports formulas, infant formulas, and other relevant supplements used by geriatric and pregnant ladies to sustain health.

Pharmaceutical Industry

The Role of Milk Powder Filling machine in the pharmaceutical industry

The milk powder filling machine is essential element for packaging of pharmaceutical products such as antibiotics, extemporaneous products such as topical powder or raw ingredients used in the formation of tablets, capsules, syrups, etc.,

Food Industry

Milk powder filling machine in the food industry

A milk powder filling machine is used in food industry due to offering enclosed system packaging that helps in the formation of dust spreading around the vicinity of food labs. This is achieved by using an auger filler where sugars, baking powder, flours, coffee powders, milk powders, spices, confectionery items are filled.

Chemical Industry

A milk powder filling machine uses in the chemical industry

In the chemical industry, you’re encountering with various hazardous chemicals such as alkaline or bases used in the making of solutions such as neutralizing pH, and HPLC solvents, such, similarly, this industry is associated with salts, acidic substances etc., to fill them in their respective packaging types, the milk powder filling machine is used to bring this job safely and flexibly.

Cosmetic Industry

A milk powder filling machine in the cosmetic industry

Filling of cosmetics products needs milk powder filling machine which is used to pack products like dusting powder, beauty powders, glitters, loose blush on, etc. in respective jars, containers, pouches, etc., this job is amazingly brought by milk powder filling machine.

Construction Industry

A milk powder filling machine uses in the chemical industry

The filling of substances such as types of cement, gypsum, limestone, coal, ash, mineral powders, etc in the construction industry is very common. The milk powder filling machine is worthwhile equipment that brings these tasks effectively; that’s the reason it is popular choice in this industrial sector.

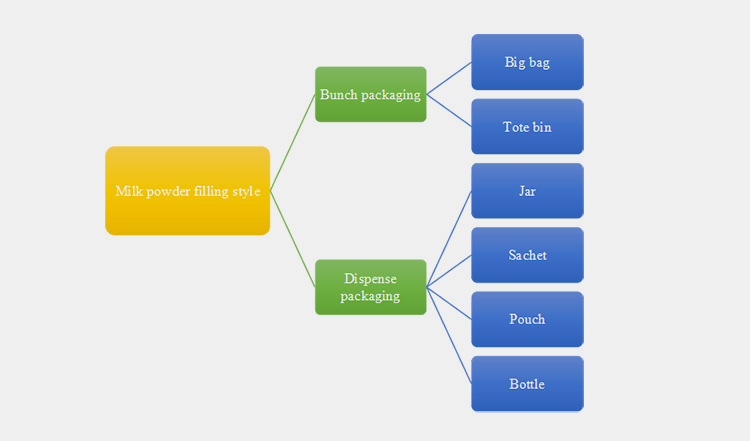

5.What are Different Milk Powder Filling Styles?

To save milk powder, different packaging styles are available. The packaging could be either bulk packaging or retail packaging depending on the requirements.

Bunch Packaging

It is further categorized into two types based on the filling styles, such as big bags and tote bins.

| Big Bag: A huge, multi-layer bag of polythene with milk powder is held together by constructed plastic in this packaging design, which has considerably exceeded tote bins. They are a very affordable filling and packaging technique. |  |

| Tote Bin: A Tote bin is perfect for shipping for moving bulky items. They can be used to store milk powder weighing between 800 and 1000 kg. Moreover, it assists in cutting costs compared to stainless steel by roughly 50%. |  |

Dispense Packaging

| Jar: The plastic jar is most commonly used for powder filling because it offers a sustainable packaging method. They prevent the packaging product from environmental deterioration and keep the rich nutrients included in milk powder fresh because they are airtight. The main advantage of a jar is that it is of lighter weight and can be easier to transport. Plus, the jar packaging provides good sealed protection and robustness in maintaining the shelf life of the product. |

|

| Sachet: It is convenient to use sachet packs. price. Consumers can utilize the small-sized package if they just need a small bit of the product for a single use or if they can only afford a small purchase price.

They can also conveniently transfer and carry them. It is classified into: Stick pack sachet where milk powder packaging comes in sleek design of plastic wrapping which is served for convenience and single use purpose. It allows controlled amount dispensing and has long shelf life. |

|

| Bottle: It is made up of rigid materials and used to store large amounts of milk powder features with capping option that allows the user to reuse the milk powder when needed |  |

| Pouch packaging: The pouch packaging for milk powders is the most commonly used packing style. It offers a filling and packing of milk powder that a user can reuse as they’re featured with resealing properties such as zip-lock, sliders, and zippers that give fantastic product presentation. |  |

| Gusseted bags: These type of bags offer bulk quantities of milk powder filling for packaging as they are spacious and have box bottom configuration. Gusseted bags have side panels and offer wide display of brand’s graphic designing to attract consumers attention |  |

| Multiple sealed pouches: Pouches that are centrally sealed , side sealed or two, three or four sides seal packaging offers maximum protection to milk powder and have the benefit of being quickly filled for further processing. Sealed pouches also have the option for resealable closure such as zipper feature, easy tear notch and hole hanging for prominent display. |  |

| Stand up pouches: Stand-up pouches are the most common forms of packaging milk powder. They can carry small and retail consumable quantity of milk powder that makes it easier for transport, storage and customer preference. |  |

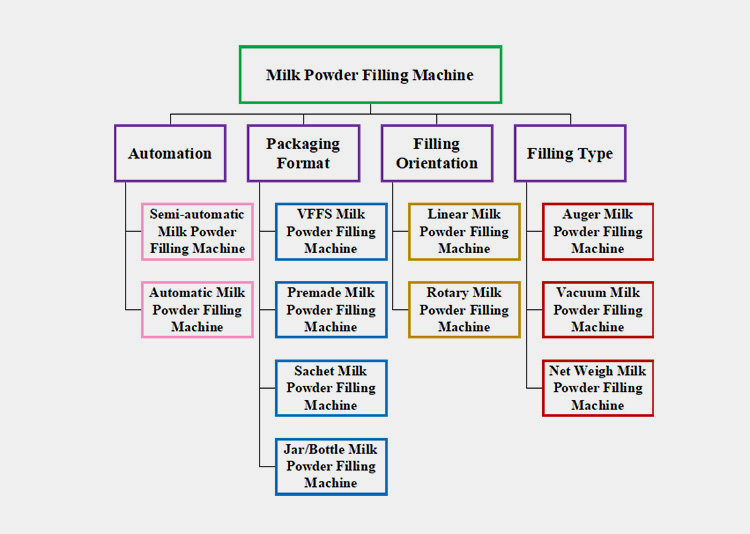

6.What are the Different Milk Powder Filling Machine?

TYPES OF MILK POWDER FILLING MACHINES

There are various types of milk powder filling machines based on the following categories:

ACCORDING TO AUTOMATION

In this category, you’re concerned about machines belonging to various automaticity. Such as:

Semi-Automatic Milk Powder Filling Machine

A semi automatic milk powder filling machine

This is the type of filling machine where the filling procedure needs human intervention during loading and unloading the packaging material. While the rest of the operation is performed by the machine itself.

This type of machine is basically recommended to run moderate to large batch production. The output capacity of the semi automatic milk powder filling machine is average it gives hundreds of containers per hour.

As compared to manual machine, semi automatic milk powder filling machine is time saving and the economical option offering much accuracy and precision.

Automatic Milk Powder Filling Machine

An automatic milk powder filling machine

This machine is mostly involved with automatic control over the filling procedure of milk powder. The user just needs to infeed the protocol in the machine while the filling task is performed by the machine itself.

The machine has ability to take over entire procedure automatically including notifications and alarming the situation and emergency Stop/OFF. You can visualize the filling process by touchscreen interface.

Also, it has ability to run large production batches day and night as this machine can’t get tired too short. That’s why every large industry is equipped with automatic milk powder filling machine for running bulk processes without requiring constant manpower or worrisome of errors.

ACCORDING TO FILLING FORMAT

The milk powder filling machine is offering filling solution depending upon different filling formats. Such as:

VFFS Milk Powder Filling Machine

A VFFS machine- Picture Courtesy: Propac

A Vertical Film Forming and Sealing machine has ability to fill milk powder into the packets that are formed by a very scratch such as a flat and thin sheet of plastic. The prime working of the forming, filling, and packing of milk powder takes place in a vertical fashion that’s why this is known as VFFS machine.

The machine itself occupies very less space generally preferred in a small working spaces but it gives out tremendous production capacity.

Premade Pouch Milk Powder Filling Machine

A premade pouch milk powder filling machine

This is the fast mode of filling milk powder where the machine is subjected to the bunch of premade pouches fitted into the rack or bag magazine where gripers pick each pack and pumped the milk powder by using air inflators to open the bag and places exact corrected measurements of the milk powder into each premade pouch.

The gas flush which helps in the displacement of oxygen from inside the bag and filled with blast of nitrogen to prevent progression of microbes.

Sachet Milk Powder Filling Machine

A sachet milk powder filling machine

This machine is widely used to pack milk powder in small energy bundles where user can only use them for single or individual serving each time. This machine is commonly used to form sachets either with three-sides, or four-sides sealing ultimately forming a minimal presentation. The working of this machine is very simple you can fix the film roll which is unwounded by rotary disk allowing a formation of film where milk powder is positioned by auger filler and later sealed by hot sealers and separated by cutters.

Jar Milk Powder Filling Machine

A jar milk powder filling machine- Picture Courtesy: LUWICO

Milk powders are commonly filled and transported in beautiful and presentable jars, and containers where manufacturing companies use jar milk powder filling machine that works by either linear or rotation filling patterns.

This is a compact machine that is integrated with a conveyor to carry containers or jars effectively into the machine where auger filler drops a measured amount of milk powder into each filling type then they leave the machine toward the next unit including capping, induction sealing, etc.,

ACCORDING TO FILLING ORIENTATION

The milk powder filling machine works in a different orientation as well. What orientation suits you must be decided by keeping the type of packaging material and area specification in mind. The types of milk powder filling machines based on filling orientation are discussed below:

Linear Milk Powder Filling Machine

Linear Milk Powder Filling Machine

As the name suggests, the filling procedure inside the machine takes place linearly; the packaging material smoothly towards the filling station where a number of filling heads are there to draw the milk powder into each container.

The linear milk powder filling machine is featured with ‘Z’ and ‘L’ designs which promotes ease of filling procedure. The machine working is fast in the corporation of conveyor unit that ensures speedy and uninterrupted filling.

The filling process in this machine is further based on intermittent and continuous filling where intermittent also few sections of packaging material followed by others, whereas continuous also seamless filling of milk powder.

Rotary Milk Powder Filling Machine

A rotary milk powder filling machine

The filling of milk powder in rotary milk powder filling machine is based on circular or rotational configurations where unfilled packaging material is subjected towards filling station which is featured with a number of filling nozzles.

Upon filling the material, the final product leaves the unit in a rotational fashion simultaneously. The machine is ideal for small or concise working spaces that work at a time without any break. That’s why the machine is also recommended as the best option to run large production batches.

CLASSIFICATION BASED ON FILLING TYPE

The milk powder filling machine is available in various filling types that is also based on the user’s compliance and requirements. Let’s see one by one.

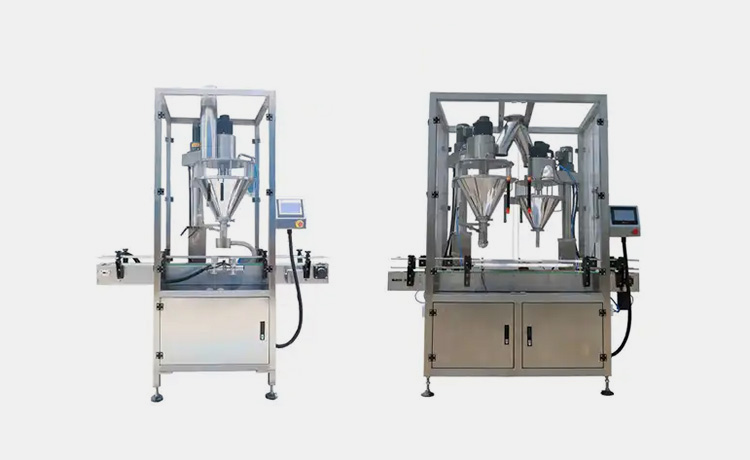

Auger Milk Powder Filling Machine

An auger milk powder filling machine

Think of powder filling brings auger in everyone’s mind. Because this is a great option where milk powder is concisely introduced into the filling jars, pouches, containers, etc in an accurate manner. The hopper in this type of machine is mainly presented at the uppermost part of the unit to allow ease in flowability depending on the force of gravity.

The machine works perfectly when filling material comes in contact with filling nozzles where machine guide prevents the milk powder spillage and allows accurate volume filling into the jars/container/pouches.

The machine is equipped with sensory devices that sense the presence of material and notify the user in case of any alarming condition. So, this is a perfect solution to add to your milk powder production facility.

Vacuum Milk Powder Filling Machine

Vacuum Milk Powder Filling Machine

This is the most significant filling machine which is mostly preferred to fill and pack delicate and sensitive products that are more prone to react with the environment and lead to degradation and alteration in structural and functional integrity.

The machine works by sucking the oxygen inside the packaging material and creates a vacuum which is useful in maintaining the shelf life of the milk powder for a longer duration. Once the powder is filled and the vacuum is maintained, it is simultaneously packed tightly and transferred to further packaging sections.

Net Weigh Milk Powder Filling Machine

Net Weigh Milk Powder Filling Machine- picture courtesy: weighpack

The net weigh milk powder filling machine is mainly used to fill bulk containers or bags such as tote bags. The machine basically relies on the measurement of the milk powder and then estimating the weight prior to positioning into it.

This is an ideal machine carrying large production processes and suitable for granular and irregular particle filling as it has no room for inconsistencies or inaccuracies. The machine is designed with a large structure where a hopper offers the dropping of powders into packaging materials; once the material is filled it is sent to further process units.

7.How to Check if Milk Powder Filling Machine Has Given Perfect Packaging?

The milk powder filling is indeed a sensitive filling process as your health mainly depends on its good quality. That’s why after filling the packaging is assessed by quality control unit to evaluate whether it is filled correctly or not. The discussed below methods are commonly used to assess the quality such as:

Water Bath Leakage Test

Water Bath Leakage Test- Picture Courtesy: wittgas

In this method, packed material is simply immersed in the water bath where the possibility of the air is eliminated from the water surface with the help of a venturi nozzle. The packaging material becomes contracted inside the water due to absence of water.

So if the progression of air bubble are observed it will depict the presence of leakage in the packaging but if there’s no air bubble means product is okay to market.

Trace Gas Leakage Test

Trace Gas Leakage Test

This is the most sensitive and extremely astringent assessment method ensure user to detect tiny or minute possibilities of leakage. The trace gas such as hydrogen, and helium is subjected to the packaging material which is placed inside the vacuum chamber.

If there’s any leakage in the pack the trace gases become escape to give you a pressure difference graph of the trace gases. The test is so accurate that helps you in finding the exact position of the leakage present in the packaging.

8.What are the basic challenges and Solutions of a Milk Powder Filling Machine?

During the milk powder filling machine procedure, you may encounter with certain unwanted situations that you must know how to troubleshoot them. Please find below issues and their solutions.

| Cause | Solution | Picture |

| Improper Cutting of the Pouches | ||

| This is an unwanted problem which is caused by inappropriate separation of individual packaging material which does not give a finished look to your product. | This problem is mostly occurred by malfunctioning of sensors that is unable to detect the correct cutting position. For that we recommend reinstalling the program setting and clear the photoelectric detectors. |  |

| Inaccurate Filling of Milk Powder | ||

| This is the condition where the weight of each pack is different from other packaging material. This problem is unacceptable for the packaging material to proceed the further production hence this is rejected. | To avoid product wastage and save your time. You need to re-calibrate the weigh unit, auger filling device and monitor the setting and reset them. Once you assure everything is properly adjusted try to run a test method and proceed the production. |  |

| Too Much Dust Formation | ||

| This is a condition where working facility becomes dusty and user become unable to inhale properly. This is of course an unwanted condition cause by machine. | To avoid dust, keep using guard valve that helps you in the controlling of dust. Try using compact and enclosed milk powder filling machine where filling process take place in a very close system. Also, install dust removal device to eliminate the chances of progression of dust during production |  |

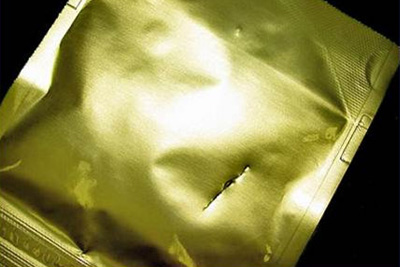

| Leakage of Milk Powders Filling | ||

| This is the condition where a filled product becomes leaked and cause product wastage. | Due to inadequate settings of the machine the sealers become too warm that cause poor sealing results in poor packaging and leakage. To correct them you need to reset the sealers and repair the unit if it has worn out. Correct the temperature setting and re-run the test. |

Picture Courtesy: IFSH |

9.What are the Future Prospects of the Milk Powder Filling Machine?

Milk Powder Filling Machine Future Prospects

The milk powder filling machine is an automatic addition to the production world relevant to various industries due to its high consistency and reliability. The machine itself is a cost-economical solution with almost no wastage therefore it is considered a tool of success toward enhancing productivity.

The milk powder filling machine has witnessed tremendous growth in the production market in recent years. The increasing demand for milk powder in health, infant formulations, old people, and pregnancy diets has brought the boom in the driving fast trade from various manufacturing countries such as China, Germany, USA, France, etc, which has fuelled the competitive market.

In terms of trend, it is expected that it market will grow a CAGR of 11% steadily considering the period from 2021 to 2031. That’s why manufacturing focuses on bringing high technology to fast production and more adoption by adding AI smart technology in the milk powder filling to gain more attraction and real-time visualization and on-time maintenance and troubleshooting when needed.

Conclusion

The milk powder filling machine is an absolute solution that must be brought into the production line for timely filling and packaging of the product without hurdles, product wastage, manual working, or tiresome routines. Our experts consider this excellent tool to be the gateway of your business success. If you are planning to purchase this machine, then always analyze your requirements first. We would recommend choosing your product dealer wisely to save your time and money. Allpack is a promising company that offers you unlimited filling and packaging equipment worldwide in a cost-effective way! So, what are looking for? We’re here to guide you and offering free product consultation and guide manuals to make you understand to choose the best one for yourself! Please contact us now.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours