Merits And Demerits Of Double Cone Blender: What Do You Know?

Have you ever wondered how mixtures have uniform properties?

Blending is an effective process, responsible for producing consistent and homogenous mixtures in pharmaceutical, food, chemical, construction, and other industries. Do you know that manufacturing sectors are dependent upon mixing for distributing products with constant characteristics?

So, for this purpose, diverse types of double cone blenders are engineered and delivered across the globe for handling intricate feats of mixing. It forms a homogenous blend because of its practical design. Gentle handling and adaptability are the biggest benefits of the double cone blender,

In this blog post, you will seek answers to questions: why use a double cone blender, and what extraordinary advantages does this blender provide manufacturing sector? If you are in the process of seeking a double cone blender, then get ready for an enlightening ride. Let’s dive into the topic.

1.Definition of Double Cone Blender

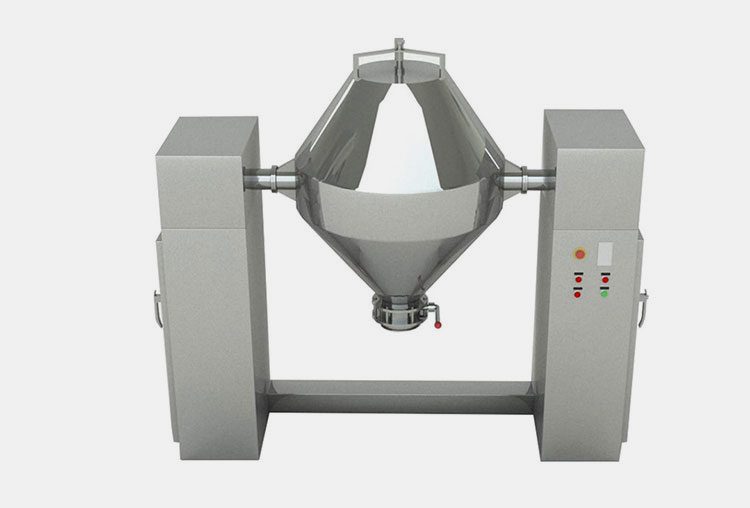

Allpack Double Cone Blender

Double cone blender is a subtype of tumbling blender, in which mechanical mixing occurs because of tumbling movement. With its rotation, materials are freely moved inside the machine. It is a heavy-duty blender and is perfect for blending dry powders, granules, and even moderate-viscosity liquids. It carries out mixing tasks on the principle of diffusive mixing.

This blender gets its name from its double cone design. It is engineered by welding the bases of cone-like structures with a slanting angle of 45°. The ends of the conical vessels are fixed on the central band. The device is supported by two trunnions that allow the blender to rotate. The transition space between the two cones prevents the mixture from moving across to sides of the blender and in turn, leads to the folding of the mixture over itself. This process has a vital role in consistent mixing.

2.Merits And Demerits Of Double Cone Blender: What Do You Know?

Merits of Double Cone Blender

Double cone blender is a great hit in the industrial sector because of its plethora of merits. It is a perfect balance of consistent blending with high-quality yield. It is a continuously sought-after blending machine due to its superb accuracy and high efficiency. Here, we are presenting common merits of the double cone blender that help you in searching for the ideal blender:

Uniform Blending

Uniform Blending- Picture Courtesy: intheweedsapothecary

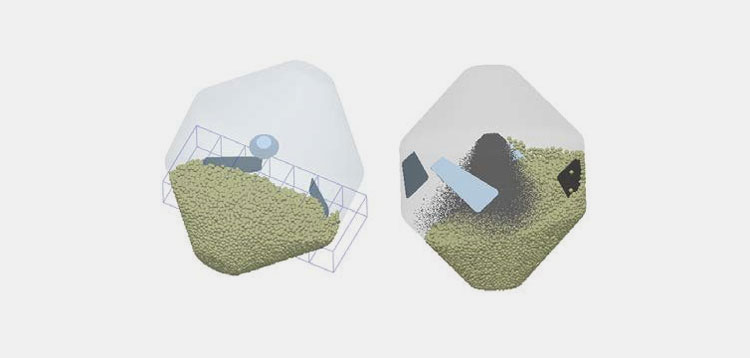

One of the most notable benefits of the double cone blender is its uniform blending. Its double cone design facilitates the random motion of the materials, leading to consistent blending.

This blender completely spins and rotates around its axis, aiding the tumbling and cascading of materials from one edge to another. This action promotes the even mixing of particles in the mixture. It is a completely enclosed device, a perfect fit for effective diffusive mixing.

Moreover, its unique geometry aids in the motion of feed in several directions- radially and axially, resulting in thorough mixing. Three-dimensional rotation of double one blender offers good material rolling and cross-mixing.

Easy Loading and Discharge

Easy Loading and Discharge- Picture Courtesy: Health By Mushroom

The ergonomic design of the double cone blender makes it easier to load and unload. It is typically fixed at a height or inclined angle that eliminates the requirement for extra lifting or complicated machinery. It features a wide input port at the top surface that provides convenient access for feeding the raw substances.

Furthermore, this machine is also equipped with a wide discharge port, located centrally at the lower part of the conical structure. This port allows the effortless discharge of materials via gravitational force. Therefore, products are quickly and completely emptied and transferred to the next processing step without much effort.

Large Processing Loads

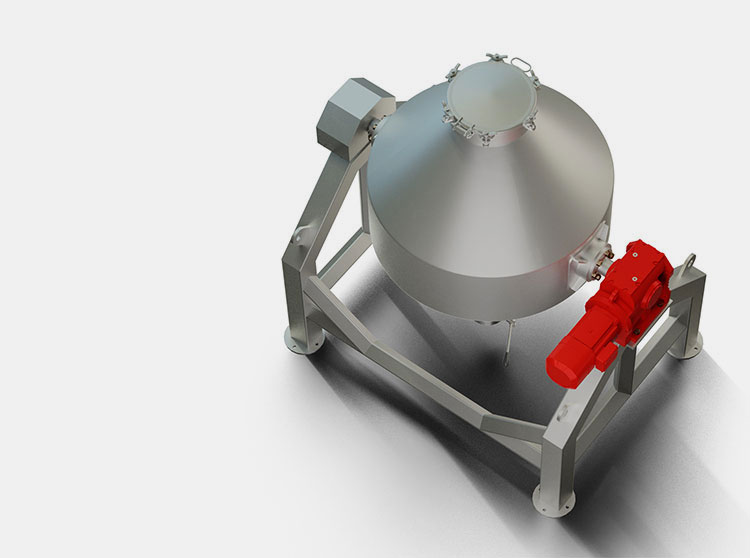

Large Processing Loads- Picture Courtesy: Soln Pharma

Mixing larger loads is one of the greatest strengths of a double cone blender, making it an ideal device for the blending industry. As compared to other blending instruments, this machine is a champion in handling a few hundred to thousands of liters of materials. For example, some industrial-sized double cone blenders can process up to 4500 liters or more of raw feed.

Its beneficial pro is because of efficient engineering. Its designs aid in the mixing of heavier loads in a single batch.

Versatility

Versatility- Picture Courtesy: Insta Food Industries

The adaptability and flexibility of the double cone blender play a pivotal role in deciding its use in different industrial sectors, for instance, chemical, cosmetics, and many more. It is a preeminent choice for solid-solid mixing and can handle a wide assortment of raw feed either in granular, powdery, or pasty state.

With its adjustable speed, it can effectively blend a diversity of materials. Moreover, this blending machine is distributed in different sizes, ranging from small laboratory machines or heavy-duty models, consequently, it is easier to scale up and down this machine. This feature adds to its flexibility, thus it is found in both research and development units and mass-scale businesses.

Gentle Handling

Gentle Handling- Picture Courtesy: steel GmBH

Double cone blender is well-recognized in manufacturing settings because of its ability to handle delicate and fragile items. Due to tumbling action, low shear forces are developed that minimize the chances of material attrition and breakdown. This gentle mechanism of the double cone blender is essential for blending sensitive items.

Contrary to high-shear blenders, double cone blender is not equipped with agitators, paddles, or baffles that can generate strong mechanical forces and lead to product damage. Therefore, this blender is widely used for blending friable or crumbled feed.

Moreover, due to its gentle process, there is little to no heat production during the blending cycle, which facilitates the processing of heat-sensitive materials. This averts their deterioration while upholding their structural integrity.

Short Cycle

Short Cycle- ResearchGate

A short blending cycle increases the uptime of production and results in higher yield. Double cone blender is a favored choice because of its rapid mixing time. It has a mixing time of 10-15 minutes for different applications.

Short mixing time is normally because of its slant geometrical design, which allows the material to swiftly mix by tumbling, consequently minimizing the time required for attaining a consistent blend. Alao, quick loading and unloading of materials minimize the downtime between batches, thus reducing the total cycle duration.

Zero Contamination

Zero Contamination

Double cone blender is manufactured to overcome the issue of contamination. Sterility, purity, and, zero contamination are crucial requirements in several industries, which are fulfilled by the enclosed compartment of a double cone blender. Hence, contaminants cannot enter the mixing vessel during the mixing cycle.

The opening inlet and outlet of this device are fully sealed to prevent interference of airborne or other foreign objects with the blending procedure.

Likewise, product mixtures are completely removed from it every batch processing, thus averting the risk of cross-contamination between batches.

Safety

Safety- Picture Courtesy: Hebrotek

The safety of the machine is integral in protecting the workforce and the quality of a product. Therefore, double cone blender comes with different safety features to ensure the health safety, and integrity of products.

Various double cone blenders are furnished with safety interlock features that stop the workforce from running the machine until every access door is fully closed. This prevents operators from coming into contact with electric and other mobile parts during the mixing process.

A statically stabilized double cone blender averts unnecessary force on the motor and gearbox. It also constitutes a motor overload protection mechanism that is essential in turning off the double cone blender if the motor encounters heavy load or overheating, which minimizes the wear of the system and the hazard of fire.

Clean Design

Clean Design- Picture Courtesy: PinkWhen

Sterility and hygiene are stressed in different manufacturing industries, especially pharmaceutical and food. A double cone blender is frequently utilized in productions because of its optimal clean design. It is constructed in such a way that it facilitates easier cleaning and maintenance.

It is constructed using high-quality stainless steel that not only offers the finest cleaning but is also corrosive and chemical tolerant. Moreover, the internal and external planes of this equipment are polished to provide convenience in cleaning residues after batch processing. This smooth finish is less likely to retain particles and prevent product adherence to walls, consequently, this blender is completely cleaned between batches.

Easy Integration

Easy Integration- Picture Courtesy: Healthline

A double cone blender offers easy integration by its compatible connection points, for instance, inlet and outlets, and utilities like power, compressed air, and water. This feature allows this device to be easily integrated into existing production lines without adapting or reconfiguring the whole production system.

Besides this, this blending device can easily accommodate several additional support parts, such as hoppers, loading, and spray assemblies for fast blending.

No Dead Zones

No Dead Zone- Picture Courtesy: JBM

This is one of the main advantages of a double cone blender that increases its standing among other industrial mixtures. No dead zone in this equipment is because of its exceptional design. Its cone construction helps in even mixing and therefore, there are no regions where raw feed stays stagnant or unblended.

This device follows a three-dimensional mixing pattern in which particles are continuously moved in multiple directions, promoting in-depth intermixing and removing dead zones. There are no sharp edges or changes in the construction of this blender, thereby preventing the buildup of materials in hard-to-access areas, which can otherwise cause dead zones.

3.Demerits of Double Cone Blender

Although there is a wide array of advantages of a double cone blender, there are also a few demerits to be taken into account, particularly when selecting a suitable device for certain uses. Here are some common limitations of the double cone blender:

Manual Intervention

Manual Intervention- Hanningfield

This kind of double cone blender is not completely automated; therefore, it needs manual intervention for the loading and discharging of materials. This can be troublesome and time-consuming for larger batches and dense materials.

Furthermore, the opening of the butterfly valve for off-loading products is carried out manually by the operators, resulting in increased downtime. Manual labor is also required for aiding the removal of mixtures and regulating their flow.

Large Space

Large Space- Picture Courtesy: The pharmaceutical tech

A double cone blender, chiefly industrial-sized has a larger footprint. They require considerable space in the industrial settings. This is a drawback in production facilities, where space is a significant asset.

Moreover, a double cone blender has a significant height when it is fixed on the stand. Its vertical headroom is an imperative concern in low-ceiling rooms. Furthermore, it requires enormous room for its 360° rotation. Therefore, this blender is not to be set up in smaller rooms.

Decreased Portability

Decreased Portability- Picture Courtesy: Pharmablender

It is challenging to move and relocate the double cone blender, which is quite taxing in settings where adaptability and mobility are vital. This immobility is due to the heavier and larger construction of a double cone blender, requiring the use of heavy-weight lifting mechanisms, including forklifts or cranes.

Several double cone blenders are engineered for permanent positioning and are grounded with heavy bolts to the floor. This arrangement lowers the portability because relocating them would need complete disengagement and reassembly.

High Segregation Chance

High Segregation Chance

There is a risk of segregation post-mixing, adding to the limitations of a double cone blender. Some substances like those with high particle size and density distribution may separate during their unloading and handling.

In a double cone blender, there is uneven fluidity of products during the offloading, with bigger particles unloading first and smaller particles staying behind. This will result in separation during device clearing. The architecture of the discharge port also contributes to segregation if proper care is not taken.

Particle Bias

Particle Bias

A double cone blender has some particle bias, so, it is not ideal for processing very fine particle materials. These particles can hinder the blending process by clogging the gaps between cones. Hence, the clumpy or stickier feed is not homogenously blended.

Moreover, particles with diverse sizes, including larger particles are not mixed efficiently by this device because of its low-shear. It operates solely by tumbling and offers delicate mixing. This is ineffective in mixing high-shear materials that require more force for their deagglomeration.

High Starting Cost

High Starting Cost- Picture Courtesy: Patriot Software

Double cone blender is a heavy-duty and state-of-the-art piece of blending equipment, made using superior quality materials to comply with rigorous hygienic regulations, which significantly impact the purchase cost of the equipment. Moreover, if this equipment is tailored with special features like thermal jackets or baffles, then its cost will increase substantially.

Its high starting cost is also because of its complex installation process, requiring considerable resources and efforts, including space preparation and fitting blender on site. Also, structural modifications to installation space add to in starting cost.

Limited Control Over Mixing

Limited Control Over Mixing

The mixing efficiency is chiefly estimated by the rotational speed and architecture of the double cone blender. These factors are adjusted to a certain extent but it is difficult to attain precise and complete control over mixing intensity for selected materials.

A timer is responsible for controlling the duration of the mixing cycle in the double cone blender, although it is appropriate for several functions, it might to let accurate alteration required for intricate mixing procedures.

Conclusion

In short, the significance of a double cone blender cannot be denied in industrial settings. It has a mountain load of merits, exclusively because of its remarkable architecture. Its enclosed design, smooth angles, welded joints, and 360° rotation promote its uniform blending, gentle mixing, cleanability, zero contamination, and, extreme safety. However, notable challenges like segregation issues and limited control over mixing need to be considered when opting for a double cone blender. By doing this, manufacturers acquire well-aligned equipment with business needs. If you are in quest of a high-quality double cone blender, then immediately click on our main webpage to attain Allpack's best promotions and deals.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide