Melting Point Tester: The Complete Buying Guide In 2025

Nowadays, the development of the industries is directly influenced by the products’ quality. And, products’ melting point is related to the products’ purity. Many industries have use melting point testers to control the products’ quality and keep safe production.

Facing diverse melting point testers, you will get into trouble to choose a suitable one. Are you curious about what are the main types, parts and working principle of melting point tester. What should you understand and consider when choosing your desired device?

Well, let’s explore the complete buying guide of melting point testers together!

1.What Is the Melting Point Tester?

Melting Point Tester - Sourced: vtsyiqi

As the name shown, the melting point tester is a device to detect the melting point of the material. Melting point tester, also called as melting point apparatus, is widely used in many research.

Usually, when the substance is contaminated, its temperature detected by the melting point tester is lower than a pure one.

2.Why Is the Melting Point Tester Important?

Melting point tester has been widely used, and its importance has been displayed. Why is the melting point tester more and more important?

(1)Research and development

Research and Development - Sourced: Church & Dwight Careers

Melting point tester has been a significant role in the research and development in many industries. Scientists use this device to check the effects of the material.

(2)Quality control

Quality Control - Sourced: Medium

Melting point is mainly used to detect the purity of the substance and ensure the products’ quality. Once the operators find that the products are not purified, they can report this result to the related personnel to control other products’ quality.

3.What Are the Benefits of Melting Point Tester?

After understanding the importance of the melting point tester, do you know their benefits? What can this device contribute to your industry?

(1)Easy and fast detection

Easy and Fast Detect - Sourced: buchi.com

With specialized system, melting point tester can get the melting point easily and vastly. You can watch the changes in melting point data through display screens and video recordings. These data can be quickly managed through computer software.

(2)Accurate

Melting point tester can test the melting point accurately with compared to manual testing. Melting point tester can avoid errors caused by manual detection, and can more accurately identify the melting process and the temperature.

(3)Cost savings

Cost Savings - Sourced: Inc. Magazine

By using the melting point tester, the manufactures can detect unqualified products, and avoid the rework and delay of the products, so this device help the manufactures save a lot of cost.

4.What Are the Applications of Melting Point Tester?

Which industry can melting point tester apply? As long as the industries need test melting point, they will use this device, which will contribute a lot to them.

(1)Textile industry

Textile - Sourced: 123rf.com

Fiber is a common material in the textile industry, which adopts melting point tester to detect the quality and different types of the fiber. This device serves as a significant role in the textile production.

(2)Pharmaceutical Industry

Drug - Sourced: Wolters Kluwer

Active pharmaceutical ingredient is the core part of the drugs, and melting point tester is used to detect its quality. This process ensures the efficiency of the drugs and provide healthy support for patients.

(3)Food industry

Snack - Sourced: Sanctifly

Fats and oil are common material used in the food industry. Melting point tester is used to test the purity of these material, and evaluate its quality, such as detecting the degree of deterioration of oils and fats in fried foods.

(4)Scientific research industry

Scientific Research - Sourced: University of Utah

Researchers in universities, research institutes, and other institutions, use melting point testers to study the melting point characteristics of substances, and then investigate their physical and chemical properties, providing data support for the development and research of new materials.

5.How Many Different Types of Melting Point Tester?

How much do you know about the types of the melting point tester? Nowadays, with the technology, there are many shapes of melting point tester. Well, let’s learn four main kinds of this device.

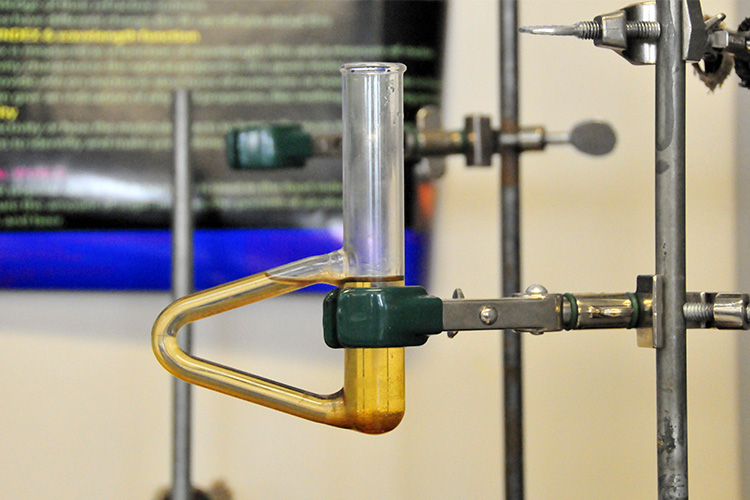

(1)Thiele tube

Thiele Tube - Sourced: Wikipedia

This device is mainly used to detect the melting point of liquids, and the operation is very simple. The operator only needs to pour the liquid into the tube and heat it with fire until the liquid boils.

(2)Fisher-Johns melting tester

Fisher-Johns Melting Tester - Sourced: Wikimedia Commons

This device does not use tubes, but instead uses small circular glass coverslips for detection. The operator places the material on a glass coverslip, turns on the device for heating, and can observe the changes in the material through a lens.

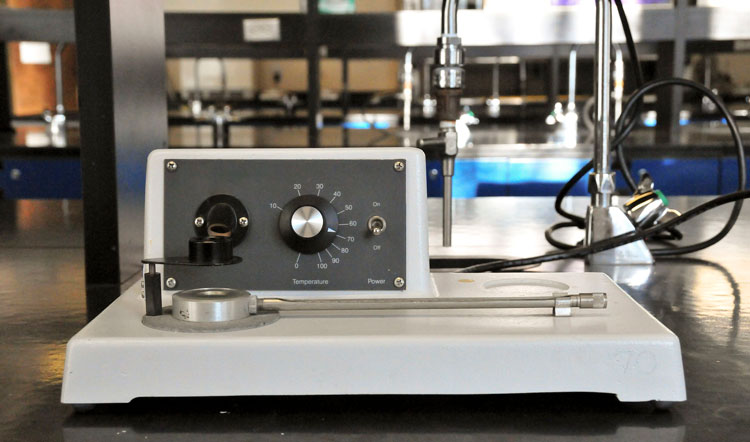

(3)Gallenkamp (Electronic) melting-point tester

Gallenkamp (Electronic) Melting-point Tester - Sourced: Eiscolabs

This type of device can be used to detect different types of materials. This device adopts mercury thermometer to detect the result, which can enhance its accuracy. It is capable of recording temperature changes during solid melting process.

(4)Automatic melting-point tester

Automatic Melting-Point Tester - Sourced: thomassci

Automatic melting-point tester is a common device used in many industries. This machine is equipped with an LCD display screen. Therefore, the operator can more accurately observe the changes and the range of temperature.

6.What Are the Key Parts of Melting Point Tester?

Although melting point tester is a small device, it is very important to understand its key parts. As shown in the picture below, the melting point tester is mainly made of four parts.

Key Parts of Melting Point Tester - Sourced: vtsyiqi

| Key Parts | Description |

| Capillary tube | Capillary tube is thin tube, which is made of glass. This part is adopted for holding the material to conduct melting point analysis. |

| Heating chamber | Heating chamber is used to storing the test material. This part is usually made of metal or glass that can be adapted to all kinds of material. |

| Magnifying lens | The function of a magnifying lens is to magnify the process of material melting, making it easier for operators to observe. Operators can clearly observe the melting process of the material through the magnifying lens. |

| Temperature screen display | Temperature screen display can record and display the initial and final results of the material melting, which make it convenient for operators to observe. |

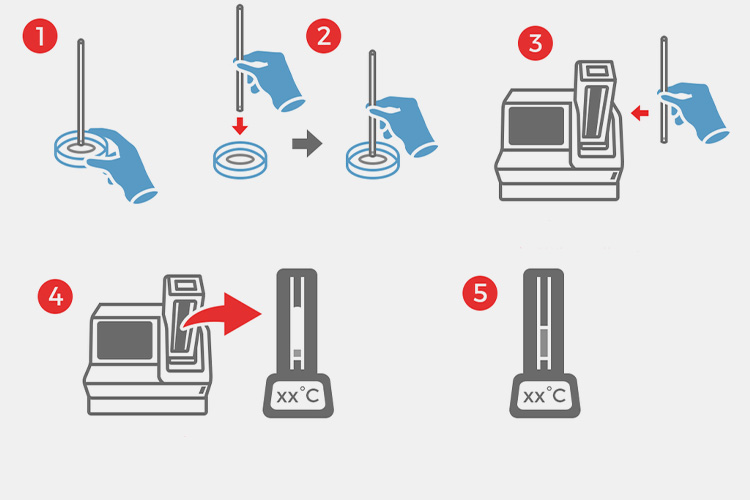

7.What Is the Working Principle of Melting Point Tester?

You will feel confused how to operate melting point tester. The working principle of the melting point tester will endure several stage. Looking at the following workflow, and you will understand it clearly.

Working Principle of Melting Point Tester - Sourced: labster

Step 1: Prepare material

You should prepare the material that you want to test. The material should keep dry, or it will influence the melting result.

Step 2: Put the material into the capillary tube

Capillary tube is a disposable tool. One end of the capillary tube is in a closed state, and the other end is in an open state. You need to load the material through the unsealed end.

Step 3: Turn on the device

After put the material into a new capillary tube, you should insert the capillary tube in the melting point tester and start the device to operate.

Step 4: Record the initial temperature

Once you turn on the device, you should record the initial temperature of the material when it does not melt.

Step 5: Record the result

After a period of time, the material melts gradually. When the solid completely melts, you should record the finial temperature.

8.What Are the Main Methods Used by Melting Point Tester?

Why does melting point tester can detect the melting point? Do you know its methods? The common method used by the melting point tester is the capillary method and microscopic melting point determination method

(1)Capillary method

Capillary Tube - Sourced: World Lab Supplies

This method will use capillary tubes. The operator loads the sample material into a capillary tube, places it in a hot bath, continuously heats it, observes the melting point, and records the initial melting and full melting.

(2)Microscopic melting point determination method

Microscopic Determination Method - Sourced: Optotune

This method uses a microscope to observe the process of material melting. The operator places the sample material on a glass slide, places the slide under the microscope of the melting point analyzer, and turns on heating to observe the process of material melting and record the temperature at which the material completely melts.

9.What Factors Will Influence Melting Point Tester?

The result of melting point tester is influenced by many factors. When we use this device, we should pay attention to this factors.

(1)The control of temperature

The Control of Temperature - Sourced: Flaticon

The temperature will influence the result of melting point tester. The rate of heating should not be too fast or too slow, and should be maintained within a reasonable range. The faster the heating rate, the higher the melting point.

(2)The type of bonding

The type of bonding between material will influence the melting point. If the material is equipped with ionic bonds, it will have higher melting points than those with covalent bonds.

(3)Impurity

Impurity in Liquid - Sourced: iStock

Impurity is a vital factor that influence the measure result of the melting point tester. If there are lots of impurities in the material, it will influence the result of the device. The more impurities in the material, the lower the melting point is.

10.How to Maintain Melting Point Tester?

Everything needs maintenance, and good maintenance can extend its lifespan. In order to ensure accuracy of melting point tester, you should pay attention to maintain it.

(1)Store properly

When you do not use melting point tester, you should put the device in a dry and clear place. Therefore, it can prevent the machine from being eroded or entering debris, which may affect the accuracy of the data.

(2)Cleaning

Cleaning - Sourced: pharmaguideline

The storage of machines inevitably generates dust or other impurities. You should clean the outside of the machine with a soft cloth every day to keep it clean. And cleaning the inside of the machine once a week with a cleaning agent while the machine is turned off.

(3)Report issues

Issues - Sourced: Pix4free

When you meet any issues about the melting point tester, including the unclear data display, you should not try to repair it by yourself, and you should report them to related technicians right now.

11.How to Choose A Suitable Melting Point Tester?

A suitable melting point tester play a significant role in the material detection. When you choose a desired a melting point tester, you should consider following factors.

(1)Accuracy

You should choose a melting point tester with accuracy suitable for your industry. Only choosing a high accuracy product, you can ensure your products’ quality.

(2)Material size

Material Size - Sourced: Yuga Organic

Melting point tester can contain different types and sizes of material. But you should according to your material size to choose a suitable melting point tester, so you can avoid the problem of unreasonable size.

(3)Material type

You should choose a melting point tester based on your material, including metal, glass and fragrances. Different melting point testers are adapted to different material types, and also you can choose a device that suitable for all material types.

(4)Temperature range

Temperature Range - Sourced: VectorStock

Temperature range is diverse among different melting point tester, so you should choose a melting point tester that required for your products.

12.What Is theFuture of Melting Point Tester?

According to the data, the global market value of melting point tester is about USD 56 million in last year. With the market demand, this number will continue to rise.

(1)Demand growth drives market development

Novel Drugs Development - Sourced: BioWorld

With the development of the society, more and more companies pay attention to the research and development of new products, and they need to test the material, especially in pharmaceutical and health care industry.

Withe the increase of chronic disease, many pharmaceutical companies continue to detect drugs to develop novel drugs for patients. Therefore, these demand drives the market development of melting point testers.

(2)The device will be more accurate

More Accurate - Sourced: Journeyfront

With the rapid development of technology, melting point testers will become increasingly advanced, display screens will be clearer, and content will be richer. Through various data analysis techniques, the detection results of the melting point tester will become increasingly accurate.

Conclusion

With its diverse benefits, melting point tester serves as a vital tool in many industries. After reading this article, you must have understand a lot about melting point tester. If you want to know more information about this device, you can contact Allpack at your convenience.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide