Mayonnaise Packing Machine: The Complete Buying Guide In 2025

Do you believe a cup of savorily delicious mayonnaise can differ your meal? Imagine being in a position where you can guarantee that the freshness and quality in every portion remain as constant as they would if you were in any location. This motive has given rise to innovative packing solutions that mostly aim at the convenience of the consumers, yet price cuts for producers and ecological awareness.

Mayonnaise packing machine with different types of mayonnaise packed

Step inside this mayonnaise packing machine. Such machinery allows for the saving natural taste and aroma of mayonnaise at the same time, increasing the efficiency of production. To get the full benefits of its capabilities let’s start with the components, functions, types, and control of the machine. This is about knowing enough to stand up for yourself when choosing mayonnaise with packing. Here, we will go in depth of the key points!

1.What Is A Mayonnaise Packing Machine?

A mayonnaise packing machine

A mayonnaise packing machine is a machine that is specifically designed to automate the process of filling different containers with mayonnaise. It has everything from jars, bottles, to pouches and sachets.

Mayonnaise which is the most common condiment made of oil, egg yolk, and vinegar or lemon juice has got fairly high difficulties to maintain its creaminess and exquisite taste. The machine improves production process efficiency and quality that are absolutely essential for the food processing and packing industries to achieve quality standards.

Automation of the filling and sealing unit will drastically decrease the manual work, raise the production speed and eliminate the human error. Therefore, it results in a well-coordinated process that ensures the product quality and safety during and after packing.

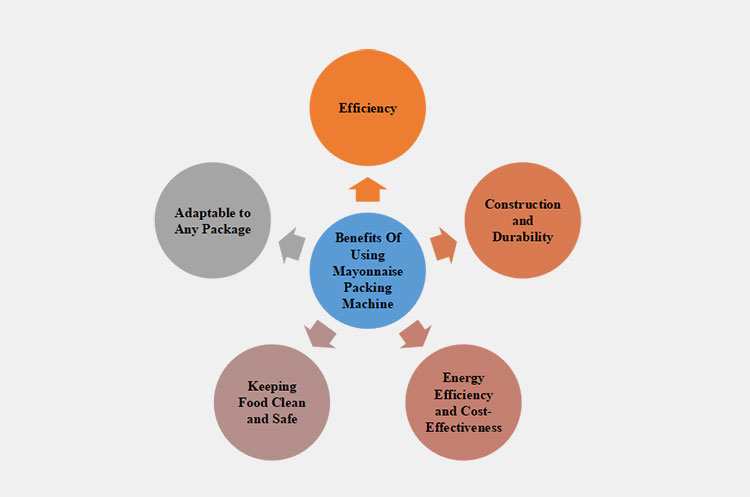

2.What Is The Benefits Of Using A Mayonnaise Packing Machine?

Mayonnaise packing products - Picture courtesy: food.ndtv

For sure, let's discuss mayonnaise. Hence, when it refers to mayonnaise packing machines, they're definitely unavoidable in the food industry, including when a condiment this popular is involved. These machines serve both small as well as big scale packing operations, which guarantee accuracy and efficiency and the packing process. Now we look into the benefits and popularity of mayonnaise packing machine which is discussed in details.

Benefits of Using Mayonnaise Packing Machine

A Mayonnaise packing machine is highly efficient

Efficiency: It is this very thing that makes these machines superheroes of efficiency. They are far more efficient than any human in the packing of mayonnaise and this is really crucial when demand is high and the number of consumers is huge.

Metals and alloys used for the construction of the Mayonnaise packing machine – Picture courtesy: IndiaMart

Construction and Durability: The mayonnaise packing machines are manufactured from durable materials such as metals and alloys to ensure long service life. The robust construction of these models tends to prolong their lifespan and hence makes them reliant on features in packing lines. The machines are designed aiming at provide both functionality and durability, thereby they will continue to be a good investment even over time.

Energy-efficient machine – Picture courtesy: scholleipn

Energy Efficiency and Cost-Effectiveness: Energy efficiency is one of the most essential parts of modern manufacturing today, and models of mayonnaise packing machines are no exception. These machines are perfect examples of energy-efficient appliances as they are designed to be energy efficient, which could result in lower operational costs. Moreover, this kind of machine is able to eliminate physical work and lower down costs of manpower.

A Mayonnaise packing machine keeps the clean and safe the mayonnaise and also maintains freshness – Picture courtesy: Stylecraze

Keeping Food Clean and Safe: Food safety is a big issue, and packing machines have a big influence on making sure that mayonnaise is safe to consume. Through the very limited interaction between the product and individuals, they contribute to the prevention of contamination, resulting in satisfied customers and regulators.

Different shapes and sizes of the packed used in the mayonnaise packing machine

Adaptable to Any Package: Whether you are packing mayonnaise in small sachets for fast-food chains or filling big jars for grocery store shelves, these are the machines that can handle the work. They, in a way, are the chameleons of packing equipment, easily accommodating whatever size or shape you give them.

Nowadays mayonnaise packing machines are gaining more attention due to some reasons such as:

Sandwich with mayonnaise – Picture courtesy:chefnotrequired

Convenience Craze: In modern society, people prefer to live their lives easily and at the same time quickly. People nowadays need a convenient way to prepare their meals, and mayonnaise serves as a multi-functional sauce that meets their requirements. By adding pre-packaged mayonnaise, you can turn your sandwiches, salads, or dips from normal to rich and creamy. You can eat them in no time.

Small size mayonnaise pack – Picture courtesy: Roy Plaza store online

Portion Control: In addition to that portion control is also a big driver of popularity of mayonnaise packing. With individual packets and sachets, keeping serving sizes under control is easy whether for school children's lunches or snacks for a road trip. First and foremost, they cut the costs of food and restaurants, reducing the amount of waste.

Mayonnaise small pack for serving

On-the-Go Lifestyle: Similar to this, many of our busy lifestyles have also pushed for increased mayonnaise packing. Whether you are in a hurry for a break time snack between meetings or just having fun with a picnic in the park, single-serve mayonnaise packets will serve as the best companion. They are portable and mess-free for convenience.

Packed mayonnaise for food safety – Picture courtesy: LandPack

Hygiene Awareness: With the growing attention placed on hygiene and food safety, there is now high demand for food products like ready-to-eat mayonnaise which is more convenient to purchase and eat outdoors. Indisputably packets eliminate the shared bowls and bottles hence reducing the risk of contamination and each pack is fresh and safe for consumption.

Creative look of the mayonnaise pack – Picture courtesy: behance

Creative Marketing: Marketing shouldn't be overlooked! Mayonnaise brands are becoming increasingly creative when it comes to the packing design and branding strategy in order to make their products catchy on store shelves, and at the same time, the brand enjoys popularity among consumers. From colorful designs to distinctive packing layouts, they create unique ways to catch our attention.

3.What Are The Applications Of Mayonnaise Packing Machine?

Mayonnaise packing machine have tremendous applications in different industries including food and beverage industries, hospitality industries, retail industries, etc. Not let’s have a look to check how it is applicable in different industries.

Mayonnaise packing machine use in food and beverage industry to pack mayonnaise – Picture courtesy: Reily Product

Food and Beverage Industries

Mayonnaise packing machines are fundamental in the food and beverage sector for packing mayonnaise in jars, bottles, pouches and tubes for retail, as well as in bulk for both restaurants and food manufacturing. They are also crucial in ready-to-eat meal kits, pre-packaged sandwiches, and portioning of fast food outlets.

Uses in hospitality industries – Picture courtesy: telegraph

Hospitality Industries

In the hospitality sector, these machines offer a range of services, including buffet service, room service, and meal service in schools and hospitals, capable of production of single-serve packets for hygiene and convenience.

Retail Industries

Mayonnaise packing machines are used by grocery stores and supermarkets for their shelf-ready products and private label packing to ensure that the products have been packaged efficiently and eye-catchingly.

Application in pharmaceutical industry – Picture courtesy: Rotzinger group

Pharmaceutical Industries

Pharmaceutical industries also use mayonnaise packing machines in packing of some pharmaceutical creams, ointments, and gels. They can be also used for materials which are similar in their viscosity to mayonnaise for the exact filling and sealing of tubes, jars or sachets. Further, such machines are useful in the production industry as they make processes easier, ensure better packing, and ensure adherence to strict quality standards for pharmaceuticals.

Application in cosmetic industry – Picture courtesy: unisourcepacking

Cosmetics Industries

Mayonnaise packing machines are used for packing various viscous cosmetic products including creams, lotions, gels, and hair care. This machines are suitable for cosmetics due to their ability to handle a high viscosity; these machines offer accuracy and eliminate wastage of the product.

Application in chemical industries

Chemical Industries

Mayonnaise packing machines are also used in chemical industry for packing viscous chemical products like adhesives, sealants, lubricants, solvents, and cleaners, etc.

Applicable to pack veterinary product

Veterinary Industry

Mayonnaise packing machines are also applicable in veterinary industry to pack filled pouches with the veterinary creams, gels, ointments, and supplements. The machines also improve packing efficiency and also boost packing production while ensuring that the packing is uniform and accurate for veterinary care products.

Application in stationary paint industry

Stationary Paint Industries

In the stationary paint industry, mayonnaise packing machines are used to pack all types of viscous paints, coatings, and sealants. This machine is beneficial because it helps protect the products from tampering, contamination, and counterfeiting during storage, transportation, and use, hence promoting product quality and customer confidence.

Mayonnaise as an ingredient for other foods – Picture courtesy: Adweek

Other Industrial Applications

These other industries make use of mayonnaise packing machines to pack mayonnaise as an ingredient for other food products thereby minimizing time and sustaining the quality of these products.

4.What Is The Working Principles Of The Mayonnaise Packing Machine?

Working principle of Mayonnaise packing machine

The working principle of mayonnaise packing machines depends on the materials used to pack mayonnaise.

| Working Principle of Pre-made Mayonnaise Packing Machine | |

Picture Courtesy: Rotarypacking.com |

To begin with, many pouches are loaded at a time on the magazine unit which transfers them with the help of gripper devices to the inflation section for opening. At the filling station, the specific volume of preprogrammed mayonnaise is dispensed into the inflated pouch. Lastly, at the sealing jaws heated bars or induction sealing is used to ensure a proper closure of pouches. |

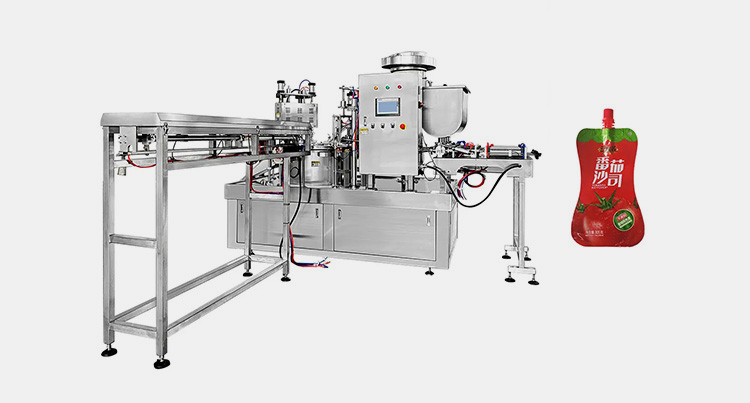

| Working Principle of Spout Pack Mayonnaise Packing Machine | |

Picture Courtesy: china-sealer.com |

The working principle of this machine is the same as a premade pouch mayonnaise packing machine. At the filling station, the pouch is opened mechanically and then vacuumed. This is done to the mayonnaise by first feeding it into the pouch and then sorting, heating, and welding spouts to the top side of the pouches. Therefore, heat sealing is made to seal pouches in a manner that they cannot be opened easily. |

| Working Principle of VFFS Mayonnaise Packing Machine | |

Picture courtesy: Soontruepacking.com |

Large batches of mayonnaise can be processed with ease through the unrolling of the packing film that is arranged on the holder. The rotation of the unwinding disk and rollers helps in the proper continuous unwinding of the disk and also maintains the correct tension on the film to avoid slipping off the disk which may lead to machine jamming. It later goes over rollers to a cone-like forming tube where the film is molded and packed into pouches. Subsequently, the filling machine dispenses a preprogrammed amount of mayonnaise into a pouch. The later stage is to cover the upper part of the pouch after it is filled. |

| Working Principle of Stick Pack Mayonnaise Packing Machine | |

|

This machine employs one film roll that is unwounded and placed on roller and dancer parts. These components maintain the film under equal stress. From rollers, the packing film is shifted to the slitting section where a single film is cut into many strips. Subsequent to cutting each strip is taken to a different forming station and shaped into a tube-like pack. Next, mayonnaise is poured into each stick pack and the top side of the stick pack is packed by the sealing jaws. |

| Working Principle of Sachet Mayonnaise Packing Machine | |

|

Initially the plastic or aluminum foil is unwound and folded and then as it passes through the rollers it comes to the forming section. This top cone-shaped part is helpful for folding and forming a small pack-like sachet. This ovalish-shaped sachet has an opening at one side and at the bottom and is then filled with thick vicious mayonnaise. Finally, horizontal sealing jaws sealed the upper part of the sachet by laminating, while cutting edges trimmed the joined sachets. |

| Working Principle of Bottle Mayonnaise Packing Machine | |

Picture courtesy: Landpack |

To start the operation, a large amount of mayonnaise is placed in a hopper that will dispense the mayonnaise later on. The containers are placed on the conveyors gradually, one after the other at the correct time interval. After the bottles reaches the filling head, a standard amount of mayonnaise is filled in the bottle or any other packing container and then the packing container moves towards the capping station where twist off caps, pre-cut lids or any other cap type for permanent sealing are placed on the container. |

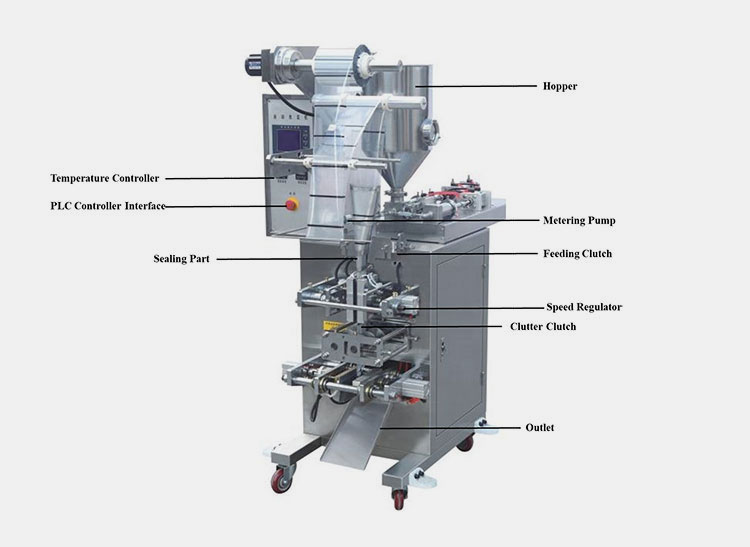

5.What Are Parts Of The Mayonnaise Packing Machine?

Components of mayonnaise packing machine

A mayonnaise packing machine can perform all functions like measuring the volume of the product, filling, packing, labeling, cutting etc. For proper functioning of this machine, it has some components such as stirring motor, hopper, mayonnaise metering pump, PLC controller interface, Feeding clutch, Vertical sealing, horizontal sealing, temperature controller, Cutter clutch, Speed regulator, Power outlet.

Let us explain each component one by one.

Hopper: The hopper is a container that is serving as the storage of the mayonnaise before it is released in the packing.

Metering Pump: The metering pump exactly measures the amount of mayonnaise that is put into each container. It guarantees that the corresponding amount of the product is filled every time that is necessary to keep the consistency and the conformity with the packing standards.

PLC Controller Interface: The Programmable Logic Controller (PLC) controller interface is the smartest part of the machine. It supplies an operator with the ability to program and control the different functions of the packing machine. The settings like fill volume, speed and sealing temperature can be adjusted and monitored through this interface.

Feeding Clutch: The feeding clutch is a control of movement of containers in the machine. It operates and shifts feed system to check if containers are located under filling nozzles properly so that they can be filled. The filling synchronization is assisted by this.

Sealing Part: Sealing part are of two parts, the vertical sealing involves closing the sides of a packing material to form a tube or a pouch shape. This part is the most significant for preparing the package that will hold the mayonnaise. Vertical sealing generally consists of a heat sealing process in which the edges of the packing materials are connected to each other. In the next step, the horizontal sealing part involve. When the mayonnaise reaches the top of the packing, the top and bottom seals join together in a horizontal way. This step guarantees the items are tightly sealed off, guarding against leaks and contamination.

Temperature Controller: The temperature regulator sets the temperature during the sealing process. It is significant to maintain constant temperature for the package neither to break nor damage the packing material. It makes sure that the seals are strong and even.

Cutter Clutch: The cutter clutch manages the cutting device that divides the individual packet once they are sealed. It guarantees that each packet is cut from the continuous strip of packing material neatly, this way the packets are uniform and well-cut.

Speed Regulator: The speed regulator enables an operator to adjust the speed of the machine. It is responsible for the speed of the filling, sealing and cutting operations. The speed needs to be adjusted to fill the required amount of product and to get the necessary quality when packing.

Power Outlet: The electric power outlet is responsible for the supply of electricity to the machine. It is the source of power for all the components and is thus the key for an efficient operation of the machine. Consistent power supply is a must-have for the machine to achieve its reliable packing performance.

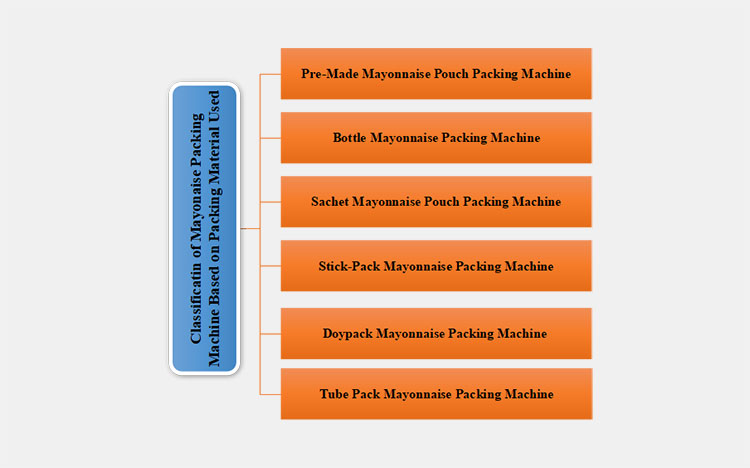

6.What Are The Classifications Of Mayonnaise Packing Machine Based On Material Used To Pack Mayonnaise?

The packing material used in mayonnaise packing to preserve mayonnaise for the long time includes; Pre-made pouch, bottles, sachet, stick-pack, doypack, tube pack. So, the mayonnaise packing machine use these materials to maintain the shelf life of the mayonnaise. Based on the materials used, mayonnaise packing machine further classified and represented as below. Let’s have a look one by one on each type of machine in details.

Various material used to pack mayonnaise in mayonnaise packing machine – Picture courtesy: Vemco

| Classification Based On Packing Materials With Its Applications | ||

| Types of Materials | Name of the Machines | Application |

Picture courtesy: https://www.khandryfruit.com |

Pre-made pouches mayonnaise packing machine | Pre-made pouches are always available and frequently used by people who want to carry something small for their breakfast or traveling. They are sealed by pre-made pouches mayonnaise packing machine to keep fresh and avoid leakages of the mayonnaise.A pre-made pouches mayonnaise packing machine automates packaging mayonnaise into pre-formed pouches. |

Picture courtesy: https://makwellmachine.com/ |

Bottles mayonnaise packing machine | Mayonnaise is often placed in glass or plastic bottles by manufactures. They allow durability and visibility at the same time, so consumers can watch the product inside. Bottle mayonnaise packing machine uses bottles to pack mayonnaise to maintain its shelf life. |

Picture courtesy: https://www.mustakshif.com/ |

Sachet mayonnaise packing machine | Single sachets work great for people who want to maintain their daily intake and consume their food on the go. They are lightweight, easy to open, and at the same time reduce the amount of waste. It is possible by using a sachet mayonnaise packing machine. |

Picture courtesy: https://www.ebay.com/ |

Stick pack mayonnaise packing machine | These standardly-sized, lengthened pouches are well-suited for servings per person. The sealing on both ends by stick pack mayonnaise packing machine is completely guaranteed freshness, so the contamination chances would be reduced. |

|

Doypack mayonnaise packing machine | Doypack mayonnaise packing machine used to pack mayonnaise in the doypack. This packing material is also known as stand-up pouches, they are meant to be convenient and easy for storing. |

|

Tube pack mayonnaise packing machine | The uses of tube pack for packing mayonnaise are the most convenient for squeezable mayonnaise. They are used for the measured dispensing and are commonly produced using soft plastic or aluminum. Tube pack mayonnaise packing machine is used to pack mayonnaise in the tube. |

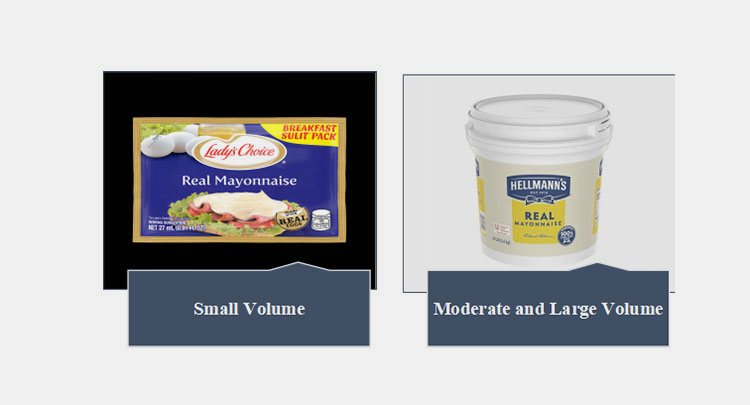

7.What Is Ideal Volume Managed ByMayonnaise Packing Machine?

Mayonnaise packing must be exported all over the world; hence little quantities must be packed side by side. This explains why the capacity of mayonnaise containers fluctuates greatly.

Volume used for packing

It includes a little sachet that holds 10ml to 30ml or more. It is appropriate for single servings as well as for promotional uses.

Moderate to large volumes

There are several container alternatives for common use, such as dressing, salad, and cooking, ranging in volume from 100 ml to 10+ liters.

8.What Are The Troubleshooting Required For The Mayonnaise Packing Machine To Function?

Troubleshooting during packing mayonnaise in mayonnaise packing machine

The mayonnaise packing machine is used to pack mayonnaise materials that are prepared during production procedure. The production procedure requires vacuum emulsifiers, which this equipment has. Making high-quality mayonnaise requires vacuum-mixing, emulsifying, and homogenizing.

After that mayonnaise need to be pack. Carelessness can lead to issues with starting and feeding materials, cleaning and cleaning supplies, feeding, environmental treatment, mayonnaise clogs or jams in machine while working, and foreign objects falling into emulsification. Here’s how you can resolve the problems:

| Problems Associated With | Solutions |

| Wrapping Material | In case of excessive damage, the roll must be discarded. As for the outer portion, it can be trimmed out and the rest of the roll can be used. It is also suggested to use minimum amounts of unwind breaking. |

| Dancer Roll Set Is Incorrectly | Set the dancer roll so that the web path is approximately the same angle as the former wings. |

| Poor Seals | If the temperature is too low, the seals will be either inadequate or nonexistent at best.

Ensure that the sealer temperature is at an appropriate level through using pyrometer and set it accordingly if it is not. Once sufficient time exists to allow change to take place, recheck the temperature. If no change is noted, then controls, wiring, heaters etc. have to be examined by a competent person. |

| Poor Package Cut-off | If knife is improperly adjusted, try to adjust the knife properly to proper package cutting.

It could be possible that knife become damage, if it persists then it is advisable that knife should be replaced with the sharpened knife. |

9.What Points You Should Need To Consider Before Buying A Mayonnaise Packing Machine?

Mayonnaise Packing Machine - Picture courtesy: Landpack.com

Before buying a mayonnaise packing machine, it is vital to assess numerous crucial factors to ensure that the machine meets your production requirements, financial constraints, and operational specifications.

| Here are some essential factors to take into account | |||

| Production Capacity Volume: Calculate the quantity of mayonnaise that has to be packaged per hour or day. Verify if the machine is capable of handling the desired production volume. | Type and dimensions of the packing:

Make sure the machine can handle the precise packing formats you need, such as jars, bottles, pouches, and sachets. To ensure that the machine can fit a wide range of object sizes and forms, assess its capacity to provide a variety of packing options. |

Filling Accuracy and Precision:

High precision is necessary to minimize waste and ensure constant product quality. Verify the consistency of performance and output to confirm that the quality standards are met. |

Compatibility of materials:

Mayonnaise has a thick consistency and is temperature sensitive. Please ensure that the machine is built to handle thick material and that the mayonnaise remains intact during the packing process. All components or parts in touch with the product must be made of nutritious substances that meet health and safety regulations. |

| Efficiency of Use and Maintaining Innovative User Interface:

The device should have a clear user interface with simple-to-use controls and straightforward instructions. Look for tools in the machines that are simple to maintain and clean. Take into account the ease of performing routine maintenance and the availability of replacement parts. |

Mechanization and Incorporation:

Assess what type of mechanization you want for your machine based on the number of employees and production needs. Choose between semi-automatic and fully automated machines. Ensure seamless machine integration into your existing production line and compatibility with other equipment. |

Competence and Lifespan:

Seek equipment constructed from durable, premium materials to ensure prolonged reliability. When choosing gadgets, selecting products from reputable manufacturers that have received excellent reviews and have a proven history of delivering consistent performance is advisable. |

Expenses and Financial Plans: Consider the machine's pricing in light of your budget. Consider regular expenses such as maintenance, electricity consumption, and potential periods of inactivity. Calculate the predicted ROI by considering the increased production efficiency and lower labor costs. |

| Features that ensure the safety of the product:

Ensure the machine has enough safety systems to protect operators from threats. Make sure the machine follows food safety laws to keep the mayonnaise safe from contamination. |

Assistance and Training. Tech Support:

Check the manufacturer's availability of dependable technical support and post-purchase service. Ensure the vendor provides extensive training to your employees so they can use and maintain the machine effectively. |

Regulatory Compliance Standards and Certifications:

Ensure the machine meets all required industry standards and certifications (such as FDA, CE, and ISO) for food processing equipment. |

Options for Customization:

Whether you have specific requirements, ask the manufacturer whether they can adapt the machine to meet them. |

Conclusion

In conclusion, the complete buying guide on mayonnaise packing machine in 2024 was a comprehensive guide that has covered the features, benefits, and vital factors to consider before making a decision on which model of the machine to buy. With the increased demand for efficiency, consistency, and hygiene, a modern mayonnaise packing machine is one of the vital elements for staying profitable and having an edge in the industry. To be more specific, by comparing the options and understanding the latest technologies, you will be able to make an informed decision that will bring maximum operations and long-term benefits. It is a great choice for those who are already eager to take production issues to more advanced level; consult industrial specialists and Allpack customers to find exactly what you need.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours