Mayo Packaging: The Complete FAQ Guide In August 2025

Mayo is a versatile condiment with many uses, for instance, dip for fries, dressing for salads, and sauce for sandwiches and burgers. The texture, taste, and appearance of mayo dictate various ways of consuming this condiment.

Its silky-smooth texture, milky white appearance, and salty flavor are only possible due to airtight mayo packaging. Environment-conscious mayo packaging solutions are integral in keeping mayo fresh throughout its retailing and consumption. Branding and product identification are other features of mayo packaging that prove fruitful for both brands and consumers.

Let’s dive into the flavorful world of mayo packaging to gain knowledge about advantages, packaging styles, shelf-life and so much more.

1.What is Meant by Mayo Packaging?

Mayo is very precious, tasty, healthful, and enriched with many nutritional values you always need. That’s why, every manufacturer wants to pack it in a way to preserve its entire potency via good mayo packaging.

Our experts describe it as, a production process where mayo is carefully stored in packaging to retain its stability, durability, and stretching effective shelf life. Thus, you can get maximum health benefits from these amazing packaging criteria.

The mayo packaging can be carried out by using a series of machines including a bottle unscramble till stacking machine for final transportation. The ultimate goal is to serve consumers with what they expect when spending money on well-being.

2.Why Has Mayo Packaging Gained Traction in Recent Years?

When going to the market and purchasing groceries; we bet you will definitely love grabbing mayo on the shelves. The Mayo packaging offers numerous benefits to sellers as well as buyers. Let’s see one by one.

Extending Quality

You can enjoy Mayo for long time

Mayo is enriched with phenolic substances that are helpful in promoting the longevity of the product but side by side, the presence of milky and creamy trace elements and high antioxidant levels are prone to inducing an oxidation process too.

The Mayo packaging prime aims to inhibit oxidation and offer you extended potency of the product.

No Room for Light and air Absorbance

Mayo Packaging with High Safety- Picture Courtesy: Simply Recipes

Mayo packaging is a specially designed product meant to strike back light, air, or external harmful factors to be absorbed and deteriorate it. Therefore, you can transport and distribute it worldwide with confidence.

No product Wastage

More Product with Zero Wastage- Picture Courtesy: Unilever Food Solution

Mayo constituents are so valuable, that every company as well as buyer strives hard to not waste even a single drop. Good mayo packaging helps you achieve product safety through proper storage and easy withdrawing.

Good marketability

Mayo packaging with promising presentation- Picture Courtesy: Trend Hunter

Mayo packaging is a successful way to improve its market value through an attractive display with nutritional value highlights and good graphics. This is considered the prime key to its success also.

Allows Various Concentration Dispensing

Mayo packaging offering various sizes and flexible presentation- Picture Courtesy: Caterite

This is one of the best products that is offered in various concentrations i.e. small to large cans, pouch to jars, mayo packaging allowing you to pack your product varying in size, shapes, and concentration.

Non-Reactive Packaging

The mayo packaging has improved mayo shelf life by 10 folds, making it easier for you to use it over the seasons. It not only gives protection from light and moisture but also against the microorganisms that hinder the quality. Keeping the temperature and quality intact.

3.What are Useful Mayo Packaging Formats?

Mayo contains viscous content with nutrition; so, its proper packaging is essential which is classified as flexible and rigid mayo packaging.

Flexible Mayo Packaging

Flexible mayo packaging- Picture Courtesy: Scholle

Flexible mayo packaging provides eco-sensible solutions that maintain the freshness of the mayo from the filling of the mayo to the end user. Due to flexible packaging, it can easily move from one place to another.

Rigid Mayo Packaging

Rigid mayo packaging- Picture Courtesy: A Plus Life

Rigid mayo packaging is another eco-friendly that can save the mayo freshness. It could be based on glass bottles that are stored in boxes or cartons, etc.

Besides the flexible and rigid mayo packing, some other popular packaging styles based on the materials used and the sealing types of the package include:

Mayo Packaging- Based on Types of Packaging Materials

Glass Mayo Packaging

Glass mayo packaging- Picture Courtesy: The Daily Meal

The glass bottle is widely used for packaging. It is now widely found in various styles and its choice depends on the requirement. It is popularly used in the kitchen to store and use mayo for various purposes.

Plastic Mayo Packaging

Plastic mayo packaging- Picture Courtesy: Epicurious

Plastic containers are non-reactive for mayo, and it is lighter in weight as well as non-expensive. So, plastic is another packaging material for mayo because it is easy to recycle, so it is also considered safe and eco-friendly for packaging mayo. Among all the plastic materials, polyvinyl chloride (PVC) is considered to be more popular. However, the polyethylene terephthalate (PET) container can be enriched with a UV absorber, so it protects mayo from the light.

Mayo Packaging- Based on Types of Sealing

2-Side Sealing Mayo Packaging or Stick Packaging

2-sided sealing mayo packaging

The 2-side sealing mayo packaging has another name such as the stick pack. The 2 sides of the sachet remained packed, and any open side was used to add mayo to the sachet. It is lighter in weight.

4-Side Sealing Mayo Packaging or Sachet

Four sided sealing mayo packaging

The four-sided sealing machine is properly sealed with four sides of the sachet. It is most widely used in airline companies, hotels, supermarkets, food delivery companies, and during traveling and catering services.

Heat Sealing Mayo Packaging

Heat sealing mayo packaging

Heat sealing is used to seal jars of different shapes and sizes. It is used to seal a jar tightly thus preventing it from leakage and contamination.

4.What are Frequently Employed Machines for Mayo Packaging?

Based on Automation

Manual Mayo Packaging Machine

Manual Mayo Packaging Machine

This machine involves a human operator for the packaging of mayo. The operator must manually place the container for filling the product, precise amount of product can be filled in container with the help of handle. For final packaging the container has to be removed manually.

Semi-Automatic Mayo Packaging Machine

Semi-Automatic Mayo Packaging Machine- Picture courtesy: Allpack

This machine includes manual loading of containers, then these containers are followed by automatic process for filling and sealing of mayo pouches. For precise filling cylinder and piston use mechanical contact to control the filling of mayo. In this way the operator can adjust the parameters for filling the mayo.

Automatic Mayo Packaging Machine

Automatic Mayo Packaging Machine-Picture courtesy: Allpack

This machine is used for quick and precise filling of products into containers of different sizes. The empty containers are loaded and forwarded for filling of product. This machine contains a full auto PLC control system for adjustment of volume. In this way operators do no need complicated adjustments.

Based On Packaging Material

Pre-Made Pouch Mayo Packaging Machine

Pre-Made Pouch Mayo Packaging Machine

This machine involves the precise filling and sealing of pouches of different sizes.

In this machine premade pouches are loaded on the machine, then these pouches are prepared for conveying to filling stations by use of vacuum system. It also contains a dosing and sealing system which controls the filling and sealing of pouches.

Bottle Mayo Packaging Machine

Bottle Mayo Packaging Machine

These machines mainly consist of conveyor, filling nozzle for efficient packing of mayo into the bottles. Empty bottles are placed on conveyor which forwarded them to filling stations for dispensing the product. This machine involves the capping system for sealing the bottles.

Sachet Packaging Machine

Sachet Packaging Machine

This machine is a sophisticated unit, playing a vital role in fast-speed packaging. It transforms large volumes of mayo into beautiful small sachets that are convenient during camping and hiking. It has a minimal floor space and is indispensable in production. It is designed with one or multiple lanes and its packaging speed is dependent upon the number of lanes.

The products are generally held in a wide hopper positioned on the top. The packaging roll is uncoiled and is directed to the forming station where the film is doubled and sealed to create a sachet. Then mayo is loaded inside the sachet. Sealing at the top occurs after filling and sharp blades trim two sachets.

Stick-Pack Packaging Machine

Stick-Pack Packaging Machine

Automation and efficiency are key features of stick-pack packaging and are a part of routine mayo packaging operations. It also operates in a vertical fashion similar to the VFFS machine. Its high throughput with space-saving feature brings huge benefits to production that have space constraints. Multiple lanes allow for high production capacity in stick-pack machines.

At first, the packaging material film is unfolded from the film roll stock and is cut into small strips that are delivered to the forming station where cross-sealing elements fuse the sides of the strips. Afterwards, the filler loads a precise quantity of mayo inside the tubular container. Upon filling, heated seals join two ends together.

Doypack Machine

Doypack Machine- Picture Courtesy: Allpack

The doypack machine offering flexible make up of standup pouches with spouted head over it. The machine works by unwinding a flat sheet horizontally where a spout is inserted followed by sealing of pouch from three sides. In the next step, the filling of mayo is carried out precisely and accurately due to the movement of the filling systems. Heating bars heat seal the top edges of filled pouches.

VFFS Packaging Machine

VFFS Packaging Machine

This machine is found in almost every production that involves packaging in pouches. It has efficiency and speed that brings production higher profit rates. It can use any type of packaging material whether it is plastic laminate or aluminum foil, cellophane or paper for creating tailor-made pouch packaging for mayo.

The forming film is guided over the roller after unfurling, ultimately reaching the forming tube where the forming collar creates a custom pouch by folding and wrapping. Upon fabrication of the pouch, an accurate quantity of mayo is loaded from the top where hopper and volumetric fillers are found. High-temperature sealer joins top edges by fusion. Sharp blades cut the edges of the filled pouch.

Tube Mayo Packaging Machine

Tube Mayo Packaging Machine -Picture courtesy: TENCO

This machine is designed for efficient filling and sealing tube with the product. Empty tubes are loaded on machine, once the amount dose is selected to be filled then the product is drawn from storage tank to the tubes without wasting the product. It consists of single, dual, and multi- cylinders that can work at same time independently.

Based on Orientation

Inline Mayo Packaging Machine

Inline Mayo Packaging Machine-Picture courtesy: VPACK

Inline mayo packing machines are used for efficient and large-scale production. This machine involves continuous processing of containers in production line. Empty bottles are loaded on conveyor system, then these bottles are filled with product and forwarded for capping and labeling system.

Rotary Mayo Packaging Machine

Rotary Mayo Packaging Machine-Picture courtesy: Pacific Packaging

In this machine, the rotary pump is integrated into the filling station for the filling of product accurately in a rotational manner. This machine can be easily operated due to its PLC and touch screen control system. It contains built-in sealing and printing features that automatically seal the pouches after filling the product.

Based on Packaging Size

Small Mayo Packaging Machine

Small Mayo Packaging Machine

These machines are designed for efficient and production at small rate. They are operated manually or semi-automatic and used for small packings. Small bottles are manually placed under the nozzle for filling the product. The product can be dispensed into bottles by using the handle or pedal.

Large Mayo Packaging Machine

Large Mayo Packaging Machine- Picture Courtesy: Carlo Migliavacca

These machines are designed for the production on high scale because they allow automated process for packaging of product. Bottles are loaded on production line, then these bottles go through different stages for filling through nozzles and for sealing through heating or capping process. An automated control system is integrated on machine for operating the production.

5.What are Volume used for Mayo Packaging?

For mayo packaging you need to trade it all over the world, therefore it requires to pack in bulk side by side in small amounts. That’s why you can find huge volume variation in mayo packaging.

Small Volume

Mayo Packaging Sizes

It includes a small sachet varying the smallest volume 10ml to 30ml or more. You can use it for single serving, and it is helpful in branding purposes.

Moderate Volume & Large Volume

Mayo Packaging Sizes

For general uses such as dressing, salad, and cooking; there are various packaging categories available with different range of volume sizes such as 100 ml, 500 ml,1000ml and 10+ Liters.

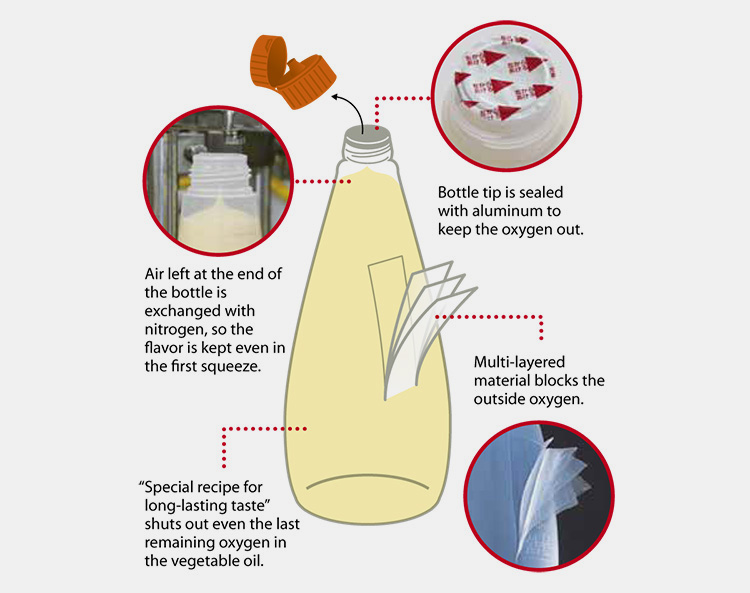

6.Why Inert Gases are Used for Mayo Packaging?

Inert gas saves product for long- Picture Courtesy: livekindly

This is the most essential question asked by many manufacturers. Using inert gases which displaces the presence of oxygen inside, it refers to the substance that has no role in altering the properties, taste, or activity of mayo.

The commonly used inert gas is nitrogen, somehow argon is also used during packaging processes. This step favors maintaining effectivity sensitive and useful constituents present in mayo such as cream, milk, vegetable extract, egg yolk, and others. Thus, it is advisable to use inert gas to protect mayo against rancidity and ensure a longer shelf life.

7.How Long Does Mayo Packaging Last?

Mayo packaging extends shelf life- Picture Courtesy: The packaging of the world

Mayo is prone to be affected by external factors such as UV absorption, High Temperature, Humidity, Oxidation and acidity that reaches unwanted end on its shelf life.

The demand from consumers and more awareness about mayo have raised the safety measurements to maintain the expectations of users. The proper containers act as a barrier to typical parameters and keep your product quality perfect for about 12 months in an unopened condition. Soon after opening, the excellence in it gradually decreases therefore you can keep it in the fridge for two to three months.

8.What basic Things to be Considered for Mayo Packaging?

To design mayo packaging you must take care of the following described points:

Air Displacement

Never ignore flushing nitrogen to displace oxygen; this step is essential to attain longer life and freshness in mayo.

Sealed Packaging

The sealed packaging must be done in a way that allow outrage of oxygen presence to minimize chances of microbial growth.

Multi Layer Packaging Material

The reason for multi-layer packaging is to offer a stable mayo packaging and making a strong barrier between product and environment.

9.What are global mayo packaging trends and what challenges do they face?

The huge consumer demand for mayo has created opportunities for producers to boost business. However, these trends also pose important challenges.

Finest Quality & Preserving Natural Content

Mayo Packaging Must be Responsible to Preserve Natural Ingredient- Picture Courtesy Gevity RX

To use product which is made up of natural ingredients is very much appreciated today. This is often referred to mayo as well. However preserving natural ingredients and maintaining its taste require premium mayo packaging.

For that mayo packaging has to be done with cost-effective materials and is expected to gain superior outcomes. For instance, using multi-layer materials that resist external factors. Selecting defines quality packaging gives you predictable and consistent quality product at every scale.

Health & Wellness

Healthy Product Poses Better Effects- Picture Courtesy- Scholle IPN

This is important growing issue where mayo is directly associated with health and its association with obesity. For example, high, mid, and low calorie mayo.

The producers are reformulating the mayo with pre-determined concentrations of fats, sugar, and ingredients with less fat-stimulating abilities. This new trend allowing more production of mayo and production line demand in food sector.

More Vegan & More Eco-Friendly

Safe product with environmentally friendly Packaging- Picture Courtesy: The packaging of the world

Today, vegans are booming industrialization as this change in eating has increasingly developed formation of new formulations, ingredients, and eco-friendly packaging styles. For example, using egg-free mayonnaise in an eco-friendly packaging.

Therefore, producers giving you benefits in a way that they offer mayo with right ingredients with recyclable packaging ingredients that is not health friendly but environmentally friendly.

Conclusion

Mayo lovers rejoice! Today manufacturer offers premium and promising products to their consumers with A Stars Satisfaction rate enlightening good taste, stability, safety, longer shelf life and more eco-friendly properties. Last but not least, innovative machines helps in the packaging of product without the risk of cross-contamination. We at Allpack offer you excellent technology and packaging machines to your product with great consumer experience. We provide the attractive and complete range of equipment that you need for mayo packaging. All our packaging machines are convenient, easy to operate, and cost-effective. Start your mayo packaging journey with us now. Please contact.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide