Liquid Seasoning Packing Machine: The Complete Buying Guide In 2025

Just a couple of liquid seasoning can enhance the color, taste, and aroma of your food. So, no space is there for spending hours to give your cuisines the savour you want! But how to preserve the quality and freshness of liquid seasoning itself? The answer is simple, a Liquid Seasoning Packing Machine!

Liquid Seasoning Packing Machine is spectacular equipment brought into the field to responsibly pack liquid seasonings into rigid and flexible packages. The machine is highly resilient, efficient, and hygienic to meet all the specific needs required for processing liquid seasonings. It supports multiple packaging formats, having a simple operational procedure with a compact body. So, let's begin exploring all of its aspects one by one!

1.What Is Liquid Seasoning Packing Machine?

Allpack- APK-338-2 High-speed liquid vertical sachet machine

Liquid seasoning packing machine refers to an equipment tailored with advanced features to process liquid seasonings such as soy sauce, chilli seasoning, and ketchup etc., into rigid and flexible packages.

The machine is highly safe with its body being made from 304 stainless steel which is corrosion resistant and antibacterial. Its structure is food grade and thus it fully ensures the sensitivity and hygiene of liquids being processed. The machine has automatic technology which independently administer the liquid seasoning packing. Hence, it is also suitable to be used in industries beyond seasoning.

2.Enlist The Advantages Of A Liquid Seasoning Packing Machine?

You will find multifarious advantages of a liquid seasoning packing machine in the upcoming paragraphs:

Multi Functioning

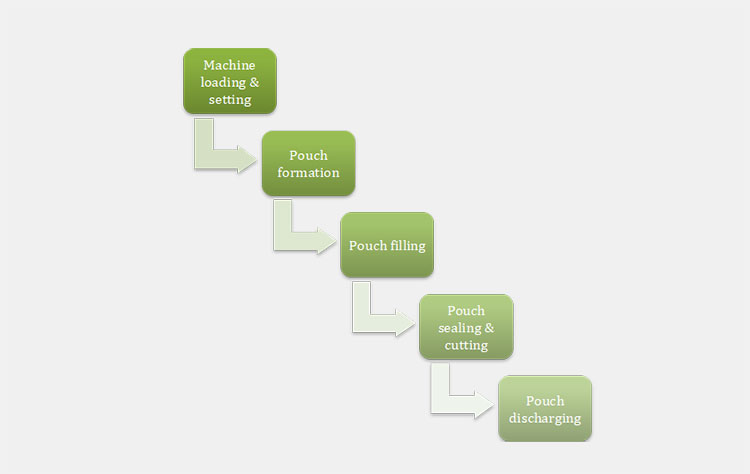

Bag forming process

Liquid seasoning packing machine has gained proficiency in undertaking all the tasks automatically in one run. Initiating from bag formation to liquid seasoning weighing, filling, and bag sealing, it intelligently carries out liquid seasoning packing.

Convenient Handling

The machine offers extremely easy way for handling throughout operation and after operation maintenance. For instance, by displaying all the necessary information and option on machine interface, it allows user to set the parameters in machine and thus control its functioning with few clicks. Moreover, the detachable filling system makes it so easy to clean and disinfect it from residues.

Enhanced Productivity

Multiple types of liquid seasoning packs

Liquid seasoning packing machine is fully automatic in its performance that's why it gives you extremely high production output. Its advanced technology and structure support the integration of secondary packaging machine like that of counting machine and cartoning machine for enhancing production efficiency.

High Precision

Precisely packed soy sauce sachet

Another most powerful feature of the machine is its outstanding accuracy which it shows in packing. In essence, by taking the help of intermittently located sensors, the machine makes sure to form bags of same sizes and length as fixed by the operator. In addition to it, liquid seasoning packing machine also dispense precise volume of seasoning in each bag to avoid inconsistencies and errors.

Customization

Customized ketchup sachet

In today's world, the most popular word you will listen from active consumers is customization and same goes for their preference during shopping. So, a liquid seasoning packing machine enable you to create the packages of your choice by altering the bag format, sealing shapes, cutting designs, and adding easy tear for customers' attraction.

3.What Type Of Other Food Liquids Are Packed By A Liquid Seasoning Packing Machine?

A liquid seasoning packing machine is capable of packing all kinds of liquid seasonings and other liquids such as sauces, syrups, and edible oil etc. These are described below:

Liquid Seasoning

Various liquid seasonings

This machine can easily pack liquid seasonings of various nature such as free-flowing seasonings and seasonings with particles. Therefore, it may use piston filling or volumetric filling system for liquid seasoning packing.

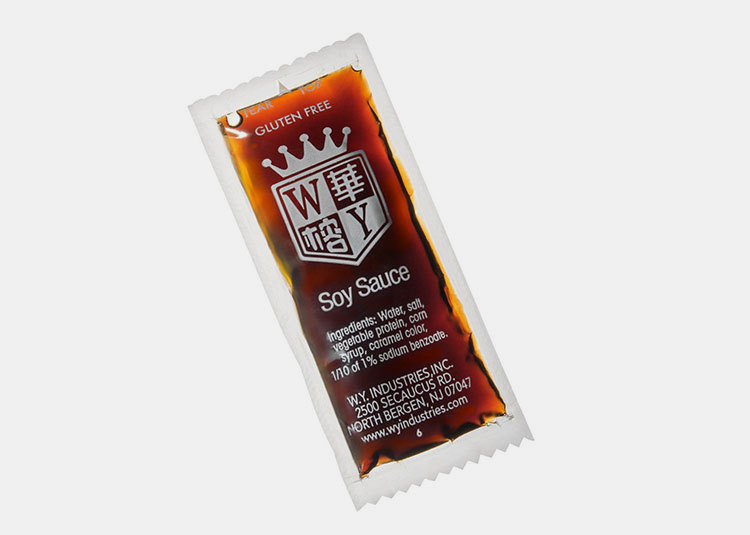

Soy Sauce

Soy sauce

Soy sauce is another popular food used as liquid seasoning or additive for adding flavor into various dishes such as chicken, spaghetti, and other food. It is popularly delivered in small flexible sachets to rigid bottles.

Chilli Sauce

Chilli sauce

Chilli sauce is one of the most famous liquid seasonings derived from chilies and combination of other ingredients like vinegar and sugar etc. Therefore, chilli sauce can be found in spicy to sweet form. So, a liquid seasoning packing machine can better retain its quality and essence by enclosing it in beautiful, protected packages.

Vinegar

Different types of vinegar in bottles

Vinegar is a sour liquid used as an ingredient to add taste to food. It is obtained from the fermentation of alcoholic liquids and other food materials like fruits. All these vinegars are carrying potential health benefits. Therefore, a liquid seasoning packing machine can easily pack them.

Ketchup

Ketchup presentation idea

Ketchup is a thick paste of tomato combined with other essential ingredients. It is the most favored dressing often spread on fastfood like pizza, burger, and roll etc. So, there is no doubt that a liquid seasoning packing machine can pack ketchup in various types of packages.

Edible Oil

Cooking oil in jug

Edible oil is also known as cooking oil which is extracted from plants, seeds, and animals. A liquid seasoning packing machine is proficient in packing these edible oils into different style packages while reducing waste and inaccuracies.

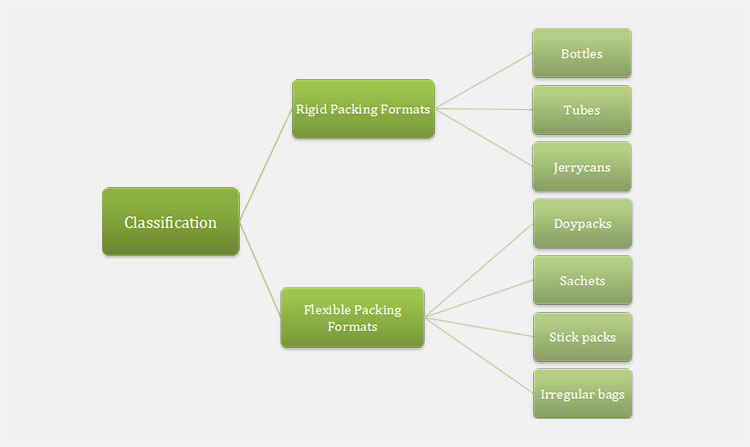

4.Write Down The Various Packaging Formats Supported By A Liquid Seasoning Packing Machine?

A liquid seasoning packing machine support myriad of packaging formats encompassing both rigid and flexible packages. Let's know them under following headings!

Rigid Packaging

Bottles

Various liquid seasoning bottles

Bottles are small to medium size containers with cap for closing. They are often made from plastic, glass, and occasionally from metal. The taste, color, and freshness of liquid seasonings can be better preserved in bottles, and they offer easy way for closure once opened. Hence, this machine can fill various liquid seasonings into bottles.

Tubes

Various liquid seasoning tubes

Another popular rigid packaging type is tube. Tubes are cylindrical shape containers with tapered edges. They are easily squeezable, therefore, most of the sauces like chilli sauce, ketchup, and mayonnaise are delivered in tubes with the help of a liquid seasoning packing machine.

Jerrycans

Soy sauce jerrycan

Jerrycans are rectangular shape containers which can hold large volume of liquid seasoning and other food like cooking oil, dressings, and sauces etc. With recloseable lids and handle for carrying, they are better for storing liquids for long time.

Flexible Packaging

Doypacks

Various liquid seasoning doypacks

Doypacks are also known as standup pouches due to their ability to stand tall on surface without any external support. They are good for holding medium size volume of liquid seasoning and provide strong barrier against light, heat, and moisture. So, a liquid seasoning packing machine can form or process readymade doypacks for packing liquid seasoning.

Sachets

Liquid seasoning sachet

Sachets are small size pouches with standard flat and rectangular or square shape. They are easy-to-use and, therefore, used for encasing low volume of liquid seasoning. The common example of liquid seasoning sachet packing is the delivery of liquid seasoning with a noodle pack.

Stick Packs

Various stick packs encasing liquids

Stick packs are narrow tubular shape packages resembling sticks. They are best known for delivering single serving liquid seasoning, dressings, and sauces. Hence, a liquid seasoning packing machine can create beautiful stick packs with eclectic design sealing and cutting.

Irregular Shape Bags

Irregular shape bags of ketchup

Irregular shape bags have no fixed shape rather their shape and format is determined by the manufacturer. As the customization on part of consumers is growing, irregular shape bags are becoming more popular and have a good demand. So, a liquid seasoning packing machine can be better used for making irregular shape bags for liquid seasoning packing.

5.Explain The Working Process Of A Liquid Seasoning Packing Machine?

Working process of a liquid seasoning packing machine depends upon the type of machine. Hence, in upcoming paragraphs, you will be shown the working principles of a premade liquid seasoning packing machine and form, fill, and seal liquid seasoning packing machine. So, let's get started:

Working Process Of A Premade Pouch Liquid Seasoning Packing Machine

Machine Loading & Setting

Hopper loading

Firstly, the loading phase is supposed to be carried out for which bundle of premade pouches are supplied to the magazine of a machine and along with that, the hopper of machine is loaded with liquid seasoning. Afterwards, the operator, by contacting human machine interface, set the basic parameters for machine execution such as data for printing, amount of liquid seasoning, and sealing temperature etc.

Pouch Opening & Filling

Pouch opening & filing

Secondly, when the machine is powered on, automatic pouch grippers come into action, grab an empty pouch from the rack, and open it by pulling the opposite sides of pouch. Similarly, the optional coding step is carried out where necessary data about material is printed over the pouch and pouch is moved ahead for filling.

Here, the machine start dispensing the pre-weighed amount of liquid seasoning into opened pouch. During this time, the integrated filling system strictly administer the filling to reduce overfilling and under-filling.

Pouch Sealing & Discharging

Pouch sealing & discharging

Finally, when pouch is filled, the next step is to seal it properly for which heated sealers come together and create airtight stringent sealing. Hence, the finished liquid seasoning premade pouches are discharged one by one from the machine in a collection container or adjoined machine for further packaging.

Working Process Of A Form, Fill & Seal Liquid Seasoning Packing Machine

Machine Loading & Setting

Before starting operation, it is significant to load the hopper of machine with liquid seasoning and most importantly supply the machine with a rollstock of film. After machine loading, basic setting of machine is fixed by the operator through touch screen penal.

Pouch Formation

Pouch formation

Now, the machine is switched on and the very first component which comes into action is the film roll wheel. It starts moving in backward direction which results in the unwinding of film. This film is then pulled and guided by rollers. Afterwards, by adding vertical and horizontal seals, the layer of film is turned into pouches.

Pouch Filling

Pouch filling

Moving forward, the formed pouches are now filled with liquid seasoning. However, before filling, the amount of liquid seasoning is properly measured by the machine with the help of concerned filling system such as piston filler or volumetric filler.

Pouch Sealing & Cutting

Pouch sealing & cutting

Upon filling, the filled pouches are pushed forward where a strong sealing is added into each passing pouch. Similarly, the sealed pouches are further beautified by the addition of distinct cut style which varies according to the type of cutting blades being used. Hence, finished pouches are separated from one another through cutting.

Pouch Discharging

Pouch discharging

At last, pouches are ready for outlet and, therefore, they are ejected out of machine for further processing.

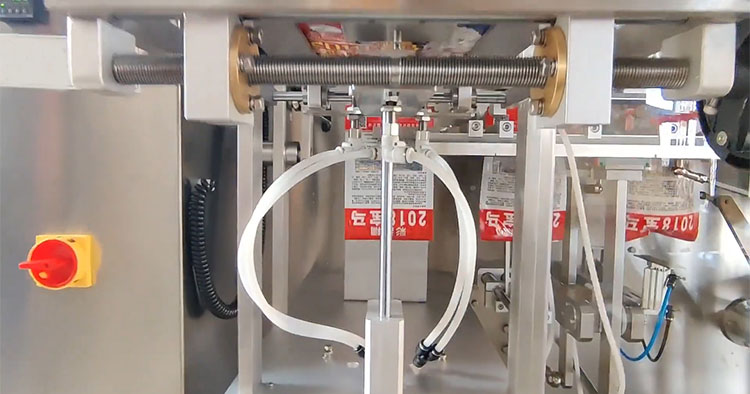

6.Describe The Structure Of A Liquid Seasoning Packing Machine?

The structure of liquid seasoning packing machine varies from one type of machine to another; however, the basic components are similar and can be found in every type of machine. Below, we have described the structure of a multi-lane liquid seasoning packing machine:

Structure of 4 side sealing multi-row liquid packaging machine

Hopper

Hopper is the storage tank of machine. It is made from 316 corrosion resistant and antibacterial stainless steel to hold large volume of liquid seasoning inside it and supply the machine liquid seasoning during operation for smooth running.

Weighing Pump

Weighing pump is another crucial component located under the hopper. It is used to measure the volume of liquid seasoning for pouring into each bag. Therefore, it is connected with filling nozzles in its lower side.

PLC Touch Screen

Programmable logic controller touch screen is a human friendly device and a type of small computer placed in the machine. It is solely responsible for noting the parameters setting fixed by the operator. It also displays over it, multiple type of information regarding machine, so, that the user will control machine by interacting with this part.

Filling Nozzles

Filling nozzles are also known as filling heads which are long narrow tubes attached to weighing pump. With the help of these filling nozzles, liquid seasoning is precisely injected into bags.

Bag Former

Bag former is another important tool of a liquid seasoning packing machine. It is responsible for turning the flat layer of film into bags through its specific shape conical heads around which film is wrapped.

Horizontal Seal

The machine has a set of horizontal seal which makes the bottom and top of bag through heat sealing. In addition to horizontal seal, there is a pair of vertical seal which constitute the longitudinal seals of bags during bag formation.

Cutting Device

Cutting device refers to the tool located under the horizontal seal. It is placed in a liquid seasoning packing machine to separate the connected bags into individual packages and also the cutting blades of different shapes and designs are employed for modifying the cutting styles like zigzag, flat, and round etc.

Conveyor

Conveyor is a transmission device attached to the main machine for purpose of mobilizing finished liquid seasoning bags from machine into a collection container or adjoined machine for further packaging.

Main Frame

Main frame constitutes the support body of machine which is made from 304 stainless steel. It is very helpful in keeping all other components together and ensuring smooth performance of machine.

Control Board

It is the brain of machine comprised of several knobs including emergency stop, start button, and temperature regulating button etc.

Control Cabinet

Control cabinet is an electric enclosure with a door. Here the electrical connections of machine in form of wires, boards, and fuses are placed for safety purpose.

Film Roll

Film roll is a stock of film and is also called a film reel. It is supplied to the machine for making bags.

Film Unwinding Unit

Multiple rollers or pulleys which help in film unwinding and guiding are collectively known as film unwinding unit.

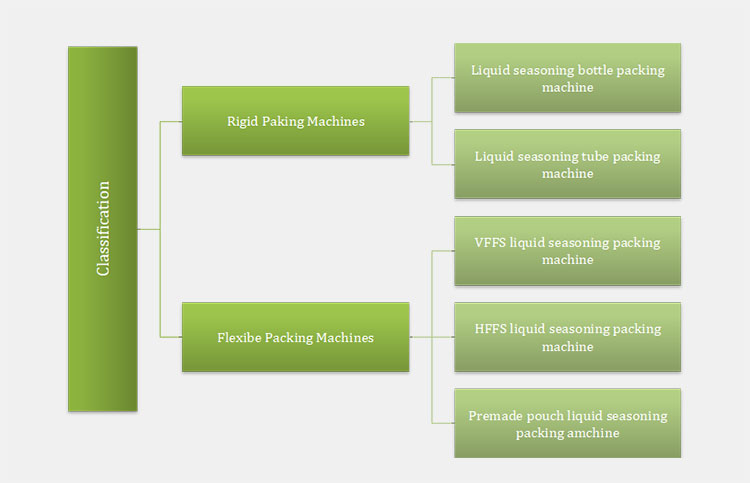

7.What Is The Classification Of A Liquid Seasoning Packing Machine?

Liquid seasoning packing machine can be classified into different types which are explained below:

Rigid Packing Machine

Liquid Seasoning Bottle Packing Machine

Ketchup filling machine

Liquid seasoning bottle packing machine is the latest new automatic machine employed to deal with the ever-increasing demand of liquid seasoning packing in bottles. The machine has multiple filling nozzles and a fitted piston filling system to ensure nonstop consistent packing. By adjusting its structure, bottles of various sizes and shapes can be processed by it.

Structure

The structure of machine is composed of several parts including a stainless steel body, electric cabinet, PLC touch screen, filling heads, a piston filler, and a conveyor belt.

Working Principles

The machine start working when bottles are fed onto conveyor belt. When these bottles reach the filling station, the machine detect their presence and filling heads start discharging liquid seasoning into bottles until the desired level is reached. Now, bottles are conveyed for capping and labeling.

Liquid Seasoning Tube Packing Machine

NF-60 Automatic Plastic/Laminated Tube Filling & Sealing Machine

Liquid seasoning tube packing machine is unique design automatic machine tailored to pack liquid seasoning into tubes through filling and sealing. This machine is specialized in packing free-flowing and thick liquid seasoning. It is multi tasking with the same machine performing tube orientation, filling, sealing, coding, and trimming. It has fast production output with finishing up to 50 tubes per minute.

Structure

The machine is an assembly of several small to large parts including a stainless-steel body, four stable feet, electric enclosure, tube magazine, material hopper, control panel, and a rotary turret for tube filling, sealing, and cutting etc.

Working Principles

The working principles of the machine are simple with tubes feeding into a machine where tubes are fitted on a rotary turret. This turret then start rotation and take pauses after intervals which result in tube filling, sealing, printing, and final ejection from machine.

Flexible Packing Machine

Vertical Form Fill & Seal Liquid Seasoning Packing Machine

Allpack- APK-338-2 High-speed liquid vertical sachet machine

Vertical form fill and seal liquid seasoning packing machine is an excellent machine with small footprint. It can beautifully create bags of various sizes and length with vibrant sealing and cutting formats. It allows you to increase production and reduce downtime by combining the bag filling and sealing into single step.

Structure

The body of machine is vertical in its construction; therefore, it is quite easily manageable and can be mobilized conveniently from one place to another. It consists of a side hopper, bag forming mechanism, electric enclosure, vertical and horizontal seals along with control system and film roll.

Working Principles

It carries out the function of liquid seasoning packing by unwinding film from roll location on the top side of machine. This film is then drawn downward in vertical direction and is sealed from bottom and sides. Afterwards, the bag is loaded with liquid seasoning, sealed from top, and ejected from machine after cutting.

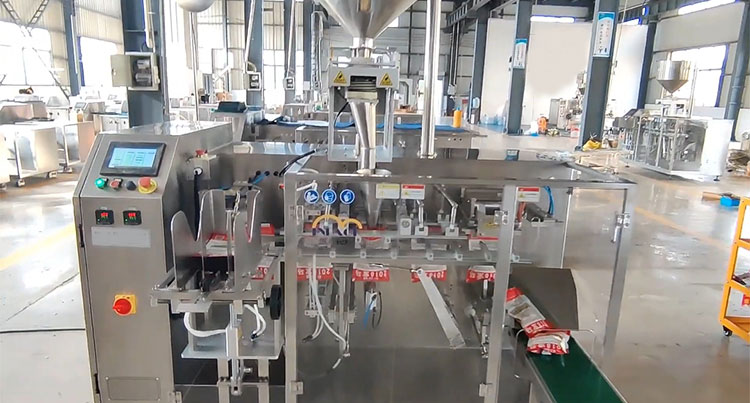

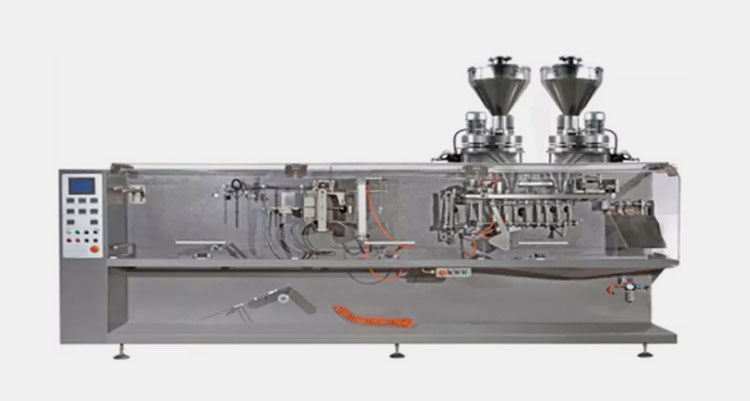

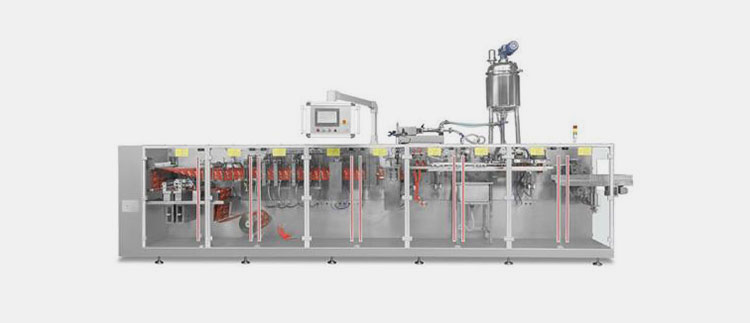

Horizontal Form Fill & Seal Seasoning Packing Machine

Allpack- APK-240D Horizontal honey ketchup sachet machine

Horizontal liquid seasoning packing machine is characterized by its horizontal body which proficiently carry out multiple tasks of bag forming, filling, and sealing. The machine support twin bag formulation with 3 or 4 side seal and having a good production output with packing up to 100 bags per minute.

Structure

The structure of machine is horizontal covering more workspace. Its major parts include a main frame, double hopper, control system, bag forming system, material weighing and filling system and sealing system etc.

Working Principles

It works by unwinding film from roll which is then passed through guiding rollers. The film is then turned into bags through folding and sealing. Similarly, the material is measured and then filled into bags. At last, ready liquid seasoning bags are taken out of machine via discharge chute.

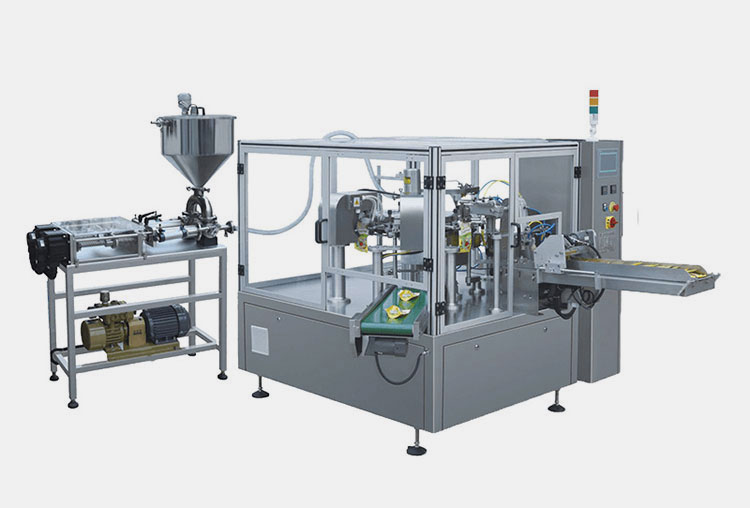

Premade Pouch Liquid Seasoning Packing Machine

Allpack- Rotary liquid premade pouch filling machine

Premade pouch liquid seasoning packing machine is designed to meet extremely high production targets; therefore, it is used to just fill and seal the readymade pouches with liquid seasoning. The machine has an attached piston filling system which can be altered with other filling system depending upon the material need.

Structure

The structure of machine is heavy-duty but compact with two major parts including filling system and pouch processing unit. The main components are motor, support body, pouch magazine, bag processing channel, control system, and conveyor belt.

Working Principles

The working principles of machine are simple with the first step involving pouch picking from magazine. After that, the grippers hold the pouch, open it, and get it filled with liquid seasoning. Similarly, the pouch is sealed and ready for delivery through conveyor belt.

8.Differentiate Between Liquid Seasoning Packing Machine And Solid Seasoning Packing Machine?

In the table below, you will know about the differences that prevail between a liquid seasoning packing machine and solid seasoning packing machine:

| No | Factors | Liquid Seasoning Packing Machine | Solid Seasoning Packing Machine |

| 1 | Definition | Liquid seasoning packing machine is a specialized equipment designed to pack all kinds of liquid seasoning into bags and containers. | On the other hand, solid seasoning packing machine is used for packing solid seasoning into packages. |

| 2 | Type of filling system | It uses volumetric filling system, piston filling system, or gravity filling system for liquid seasoning packing. | While as, this machine takes help of an auger filler, volumetric cup filler, or basculating filler for dealing with solid seasoning intricacies. |

| 3 | Type of bag | Such type of machine is capable of packing stick packs, spouted doypacks, and flat pouches. | In contrast, this type of machine can easily pack pillow bags, gusseted bags, and retort pouches. |

| 4 | Type of material | It is capable of packing liquid seasonings in all its thin to thick and highly viscous form. | Contrary to that, solid seasoning packing machine is proficient in packing powdered and granulated seasonings. |

| 5 | Application | It is best suitable for processing soy sauce, chilli sauce, ketchup, mayonnaise, yogurt, and other liquid seasoning. | This machine is perfect for packing powered condiments and seasoning like salt, pepper, chilli powder, and cumin seed etc. |

| 6 | Picture |

Allpack- APK-130S/240DS premade pouch filling machine

|

Allpack- APK-130 Horizontal 4 side seal small salt powder granule sachet machine |

9.Highlight The Uses Of A Liquid Seasoning Packing Machine?

A liquid seasoning packing machine has wide range of applications in almost every industry where there is processing of liquids. Few of the prominent sectors have been taken into context in the underlying paragraphs:

Seasoning Industry

Various liquid seasoning and sauces in bowls

The very first application of a liquid seasoning packing machine is itself a seasoning industry where products like sauces, dressings, liquid seasoning, and food additives are produced and processed. That's why, this machine can better perform packing of all these products.

Edible Oil Industry

Edible olive oil pouch

Edible oils are obtained from plants, vegetables, and animal sources. They are used in industrial food manufacturing and home cooking throughout the world. Therefore, their demand is quite high. To meet this end, liquid seasoning packing machine is used to efficiently pack edible oil into handy spouted pouches, bottles, and sachets.

Medical Industry

Cough syrup packaging

The use of a liquid seasoning packing machine can be also realized in medical industry where different types of pharmaceutical, nutraceutical, herbal, and veterinary liquid medications and supplements are prepared in liquid form. Therefore, the machine is used to safely pack these materials in packages.

Cosmetic Industry

Liquid hair dye sachets

Another notable application of a liquid seasoning packing machine is cosmetic industry. Here products like shampoo, conditioner, hand washing gel, hair dye, and lotion etc., are safety packed into small and large size packages by taking help of this machine.

Pesticide Industry

The use of pesticides, herbicides, and insecticides is very important for protecting crops from insects, weeds, pests, and other fungal diseases. Therefore, pesticide industry has now expanded its production so as packaging. Similarly, you will see that a liquid seasoning packing machine can be used here to pack liquid pesticides into small and large size packages.

10.How To Ensure Leak Free Packing With A Liquid Seasoning Packing Machine?

It is very essential to make sure that all the packages you pack by using a liquid seasoning packing machine are free from leaks. If not paid heed, the presence of leaks can ruin your production and result in huge losses. Therefore, to ensure leak free packing with a liquid seasoning packing machine you just need to employ a proper leakage test for finished packages.

Leaked liquid sachet

For this, vacuum leak detector is required where a finished pack of liquid seasoning will be placed inside the detector. Now, operator is required to observe the change that take place inside the water filled chamber of vacuum leak detector where package is laying.

If there appear bubbles and the pressure start dropping it means that package has a leak. However, if the pressure remains constant with no change being recorded inside the chamber, then your package is free from leaks and your business is at safe side.

11.How To Maintain A Liquid Seasoning Packing Machine?

Maintenance is very crucial for keeping your liquid seasoning packing machine on right track. It helps you in extending the working life of your machine as well as its working pace. In this way, we have explained some tips for your ease under following headings. So, read them carefully:

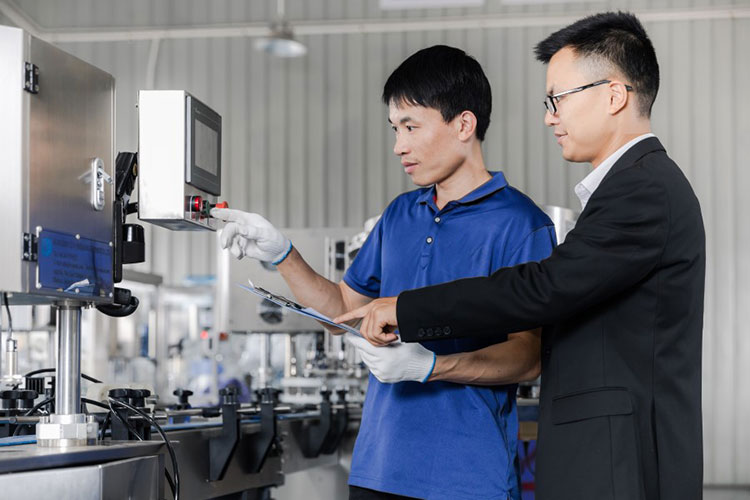

Operator maintaining machine

Preventive Maintenance

It refers to the regular maintenance of machine which is conducted for the sake of avoiding failures and sudden breakdowns. Therefore, operator is required to keep inspecting the different parts of machine during operation, lubricate the movable parts, carry out the cleaning of hopper, filling heads, and machine, and most importantly adjust the structure of machine before operation.

It also includes the noticing of parts performance and replacing them timely before they result in any breakdown. Moreover, the resetting of internal parameters of machine is also very significant to make sure that machine works properly.

Breakdown Maintenance

Such type of maintenance is carried out after any part of machine stop functioning due to failure or damage. In such case, it is crucial to repair that part and if the tool is out of order replace it with new functioning one.

12.Troubleshoot The Common Errors Of A Liquid Seasoning Packing Machine?

It is impossible that you operate a machine, and it will function smoothly without any error throughout its working life. Same goes with a liquid seasoning packing machine. Therefore, we have highlighted some of the common problems caused by this machine along with its possible reasons and solutions. They are as follows:

Machine does not power on

Operator checking machine

Causes

- There is error in incoming power.

- The power is insufficient.

- Connection between machine and electricity is disconnected.

Solutions

- Check the incoming power.

- Make sure the voltage of power is sufficient for machine.

- Reconnect the machine by replug.

Film tracking error

Film unwinding error

Causes

Film roll is not placed in the center of spindle.

Accumulation of dirt on brake roller.

Inaccurate tension on film.

Solutions

Place the film roll in center of spindle.

Clean the brake roller for accurate functioning.

Release parallel tension on film from both sides to avoid film unwinding error.

Bad vertical and horizontal seals

Highlighting bad vertical & horizontal seal

Causes

The space between bag former and film is inaccurate.

Sealing jaws are not properly aligned and resulting in wrinkled sealing.

Temperature inaccuracies cause weak or burned sealing.

Solutions

Adjust the distance between forming tube and film.

Align the horizontal sealing jaws for perfect sealing.

Make sure to keep the temperature of sealing jaws at suitable level and in accordance with film properties.

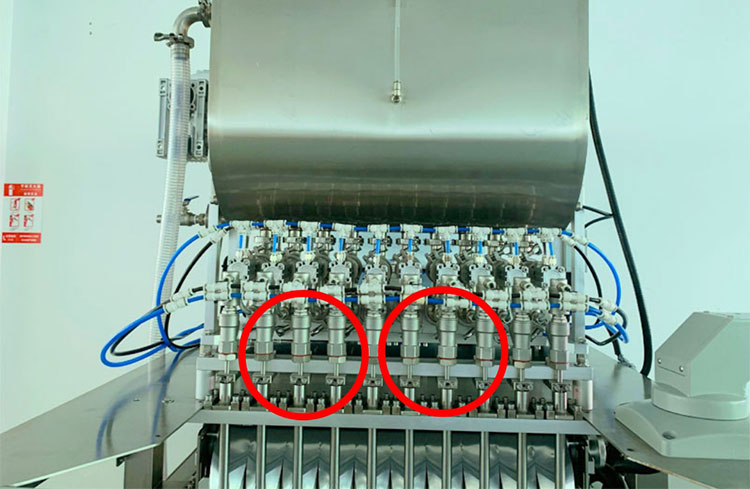

Liquid seasoning filling inconsistencies

Blocked filling nozzles

Causes

The integrated filling system is incompatible.

The filling nozzles are blocked due to residues accumulation.

The machine is not evenly placed on surface.

Solutions

Attach the filling system as per material requirement.

Keep the hopper and filling nozzles clean after daily task to ensure smooth flow of material.

Place the machine on even surface.

13.Factors Responsible For Choosing The Best Liquid Seasoning Packing Machine?

When choosing a liquid seasoning packing machine certain factors must be considered for making a sound purchase. These include:

Machine Specifications

Machine specifications

The buyer should check the specifications of machine including its speed, accuracy, and customization at which it pack the liquid seasoning packages. It will be helpful in a way that the machine will meet the basic needs of manufacturer including its production target and packaging formats.

Machine Quality

Quality control icons

Checking the quality of a liquid seasoning packing machine is another pertinent aspect to consider. It simply includes the examination of machine's compliance to local and international quality standards such as GMP, FDA, and ISO etc. It ensures that machine is highly safe and relevant for processing food products.

Price

Calculating price

The overall cost of machine along with its installation and maintenance cost must be estimated to keep yourself fully prepared for purchasing. Otherwise, your unawareness regarding the price of machine might lead you to money and time loss.

Installation & Warranty

Warranty card benefits

Ask your vendor for installation and after-sale services if any. Along with that, considering the warranty policy of the supplier is another most important factor which will help you determine the quality and assurance of machine.

Conclusion

To sum up this detailed buying guide about a Liquid Seasoning Packing Machine, it is now clear that demand of this machine is growing, and manufacturers are concerned about choosing the best one. That's why, we have thoroughly discussed the features, working process, structure, and types of a liquid seasoning packing machine, so, that you will be able to choose the best for you. If you are still confused or want to have topnotch liquid seasoning packing machine, then contact Allpack which has an amazing inventory of packing machines with one year of warranty. For further updates click on the given link!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide