Liquid Sauce Sachet Packing Machine: The Complete Buying Guide In 2025

Sauces are used in our daily life food taking from a cup of noodles to burger, pizza, and more. So, why not go for producing more tantalizing sauces and discovering ways for their preservation? Of course! If so, what will be the best option? Well, liquid sauces are all time preferable over other forms of sauces due to their instant use. As far as the packaging of these liquid sauces is concerned, so, single serving flexible packaging is what both the consumer and producers are looking for.

That's why, we have come up with a detailed buying guide about a new machine which is Liquid Sauce Sachet Packing Machine. This machine is a display of advanced technology and high automation where you will not be bothered to intervene manually in packaging but will get precisely finished liquid sauce sachets. Not only that, but its handling is extremely easy with precise structure and efficient performance. So, let's embark on the journey to know more about a Liquid Sauce Sachet Packing Machine!

1.What Is A Liquid Sauce Sachet Packing Machine?

Allpack APK-110 liquid sauce sachet machine

Liquid sauce is a free-flowing or viscous mixture added into food for enhancing their visual appeal, aroma and taste. That's why, most of the food industries are now delivering liquid sauces in handy packages and due to home delivery services for products like pizza, burger, and fries, single serving sachets are used for this purpose.

Similarly, a specific machine is manufactured to deal with the packaging of liquid sauces including ketchup, mayonnaise, soy sauce, and chilli sauce in small sachets. This machine is termed as liquid sauce packing machine. It is highly intelligent and effective in its performance of creating sachets and filling them with liquid sauces astonishingly. So, whatever the type of liquid sauces and seasoning you process, this machine is perfectly suitable.

2.Write Down The Eclectic Advantages Of A Liquid Sauce Sachet Packing Machine?

A liquid sauce sachet packing machine is an outstanding equipment designed with multiple features each having several advantages for your business. So, let's enumerate few of them for your information!

Ensure Protection

Stringently packed sachet

As a liquid sauce sachet packing machine comes up with compact and hygienic stainless steel body, it is fully safe to process your vary sauces and liquids. It thus ensures that the contact parts of filling material and packaging material are food grade to avoid any sort of contamination caused during operation.

Customizable

Customized mayonnaise sachets

In today's era, where customers are not only looking for relevant material but also attracted by beautiful and unique design packages, a liquid sauce sachet packing machine is very instrumental as it is highly resilient to support multiple packaging formats. For instance, you can employ it to create 4 side, 3 side, twin sachets, shaped sachets with vibrant sealing and cutting.

Fast Performance

Fast performance of liquid sauce sachet packing machine- Picture Courtesy: universalpack.it

Speed is what matters the most especially when it comes to packaging machinery. It is because machine replace human labor which not only reduce material waste but also enhance the packaging efficiency.

High Precision & Accuracy

Precisely packed tomato ketchup sachet

A liquid sauce sachet packing machine is fully automatic in technology, therefore, it realizes all the functions of sachet forming, filling, sealing, and cutting automatically. In this way, the electric sensors and other controlling components make sure that machine produce packages of similar size, shape, and material with consistent volume.

Cost-effective

Cost-effective icon

This machine is extremely reliable in terms of price and overall expenses of liquid sauce sachet packing. The reason behind is its user-friendly interface which support easy interaction of operator. Moreover, it does not require multiple labours for operation and offers cost-effective way for packing your liquid sauces in flexible sachets.

3.Enumerate The Popular Liquid Sauces Processed By A Liquid Sauce Sachet Packing Machine?

Well, a liquid sauce sachet packing machine is flexible enough to process all kinds of flat to granulated liquid sauces. However, here we well discuss some of the notable ones to shed light on its usefulness. These include:

Tomato Ketchup Sauce

Tomato ketchup- Picture Courtesy: nutritionrefined.com

Who will not be familiar with the most popular dipping sauce around the world? Of course no one! Tomato ketchup sauce is all time favorite liquid sauce taken with fast foods and food like chicken nuggets and others. It is made from fine tomatoes in combination with sugar, water, and some artificial food additives. As the use of ketchup is compulsory, its packing in sachets is inevitable.

Chilli Sauce

Chilli sauce- Picture Courtesy: kitchensantuary.com

Chilli sauce is another famous sauce we use in our daily cooking. It is in thick form as containing ketchup along with chilli and other ingredients. So, their preservation require safe and durable packaging means where freshness cannot be escaped and that is possible with a liquid sauce sachet packing machine.

Mint Sauce

Mint sauce- Picture Courtesy: carvedculture.com

Mint sauce is another common liquid sauce which we often prepare in our homes, but now it is also available in readymade form. It is a mixture of mint, water, chilli, and few other ingredients which can be used for flavor. So, to retain its freshness, sachet packing is preferred.

Soy Sauce

Soy sauce- Picture Courtesy: therecipecitric.com

The origin of this delicious soy sauce can be found in Chinese traditions where they used to blend the fermented soybeans with wheat and salt. But, now with globalization, we see how soy bean is becoming necessary for food like spaghetti, macaroni, and noodles etc., everywhere. That's why, liquid sauce sachet packing machine is crucial to enclose it for consumers.

Hot Sauce

Hot sauce- Picture Courtesy: wholefully.com

As the name illustrates, hot sauce is a thin liquid sauce used to add heat and flavor to food. It is a formulation of chilli pepper combined with vinegar and salt. Therefore, you can simply process it by a liquid sauce sachet packing machine for primary packaging.

Cranberry Sauce

Cranberry sauce- Picture Courtesy: themodernnonna.com

Cranberry sauce is a must have liquid sauce in America and United Kingdom especially during festivals like thanksgiving and Christmas. As the making of cranberry sauce is similar to that of cranberry jam, they are often termed interchangeably. Similarly, its packing can be easily carried out by a liquid sauce sachet packing machine.

4.What Packaging Formats Does A Liquid Sauce Sachet Packing Machine Support?

Liquid sauce sachet packing machine do support multiple packaging formats. These are shown below:

3 Side Seal Sachets

3 side seal sachet- Picture Courtesy: pakona.com

3 side seal sachets refer to sachets with three sides being tightly sealed and one left for providing additional space for liquid sauce. A liquid sauce sachet packing machine can beautifully create 3 side seal sachets for encasing liquid sauce.

4 Side Seal Sachets

4 side seal tomato ketchup sachet- Picture Courtesy: designerpeople.com

Such type of sachets are having all the four sides; two vertical and two horizontal sealed hermetically. They provide extra strength for products, therefore, most of the liquid sauces are packed in 4 side seal sachets which are accurately made by this machine.

Twin Sachets

Twin sachets- Picture Courtesy: smartymockups.com

Twin sachets are sort of double sachets being interconnected to each other through one side. These sachets are also very popular for delivering two different types of liquid sauces together in individual packs. That's why, a liquid sauce sachet packing machine is tailored to meet this need.

Shaped Sachets

Shaped chilli sauce sachet- Picture Courtesy: reddit.com

Shaped sachets are customized sachets with irregular shapes such as tomato, chilli, and other fruits. Shaped sachets fascinate much quickly to consumers' eyes than that of regular sachets. Ergo, a liquid sauce sachet packing machine is capable of offering such format.

Continuous Sachets

Continuous sachets

A liquid sauce sachet packing can also form continuous sachets which are interconnected to each other without having proper cutting but having perforation for separation.

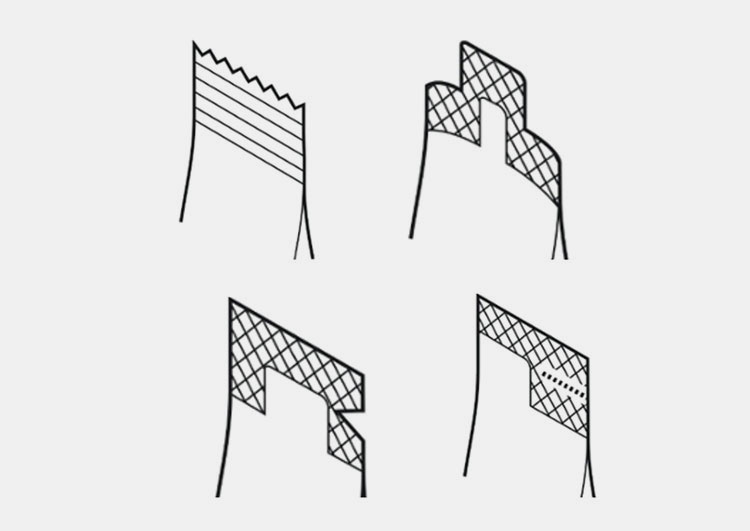

Designed Sealed Sachets

Various designs for sachet sealing

Sachets can be beautifully styled by simply incorporating unique design sealing such as diamond serrated, triangle, and square patterns into its sealing. And this machine is ideally perfect for carrying out these functions.

Designed Cut Sachets

Pickle sachet with zigzag cut- Picture Courtesy: Flipkart

You can also employ this machine to add vibrant design cutting into your sachets like zigzag cut, round cut, and flat cut etc.

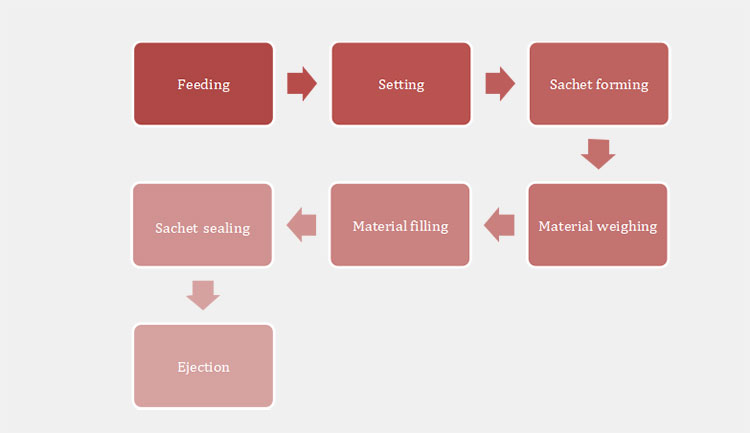

5.How To Operate A Liquid Sauce Sachet Packing Machine?

In order to operate a liquid sauce sachet packing machine, you need to follow the machine's manual. As, the manual may appear difficult to you, we have simplified it for your assistance. Its working process can be understood by looking into the underlying steps:

Feeding

Machine feeding

The machine needs to be loaded first for which the hopper is fed with large volume of any desired liquid sauce, while as, the roll frame is supplied with a film reel. As the feeding step is carried out, next phase is to set up the machine.

Setting

Here, operator is required to set the machine by contacting small computer device. Here, parameters such as the volume of liquid sauce to be filled in each sachet, the length and width of sachet, and temperature of heat sealing jaws are fixed into machine.

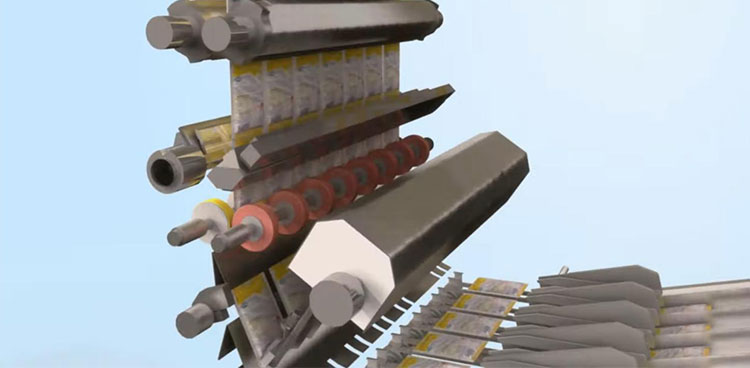

Sachet Forming

Sachet forming

Upon setting, a liquid sauce sachet packing machine is now ready to get started. As the machine is powered on, the sachet formation takes place. For this, the multiple rollers, and dancers arm begin unwinding film from roll. This film is then moved ahead and wrapped around the bag former. At the same time, longitudinal and bottom sealing of film is realized which result in the formation of sachet.

Material Weighing

In addition to sachet forming, material weighing is done simultaneously. For this, the integrated weighing system which is responsible for weighing liquid sauce, keep doing its work by taking commands from control system and accurately weighing the volume of liquid sauce.

Material Filling

Material filling

As the liquid sauce is weighed, the next step is its safe dispensing into sachet. To perform this task, measured liquid sauce is taken from weighing pump into the sachets through small filling nozzles. Depending upon the machine design, it can be done through volumetric filling, piston filling, or gravity filling system.

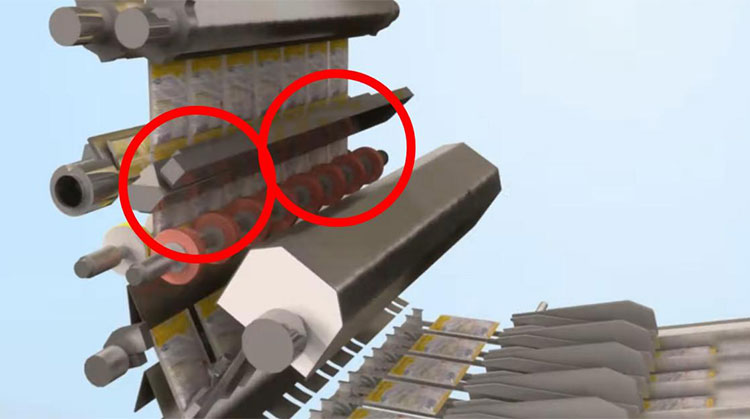

Sachet Sealing

Sachet sealing- Picture Courtesy: packwaymachinery.com

After filling, the most important step of sachet sealing is to be done. For this, the heated sealing jaws get closed which result in the formation of strong sealing of the top of sachet. Similarly, interconnected sachets are cut off from one another through knife.

Ejection

Sachet discharging- Picture Courtesy: packwaymachinery.com

At last, the finished liquid sauce sachets are ejected out of machine via conveyor belt either towards collection container or for further packaging in secondary packaging machine.

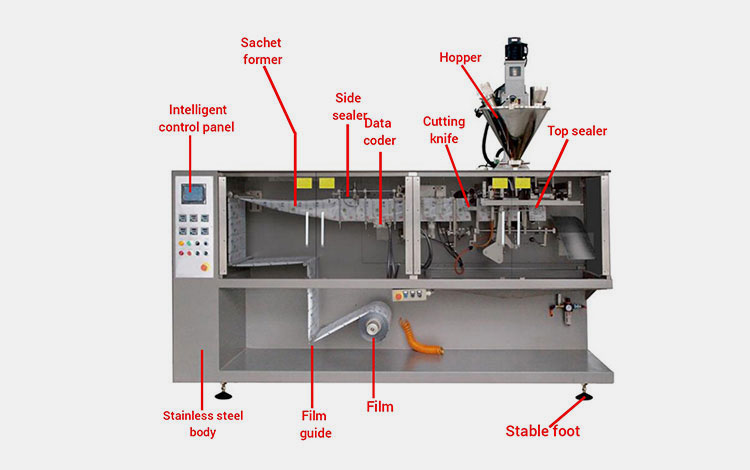

6.What Are The Major Components Of A Liquid Sauce Sachet Packing Machine?

A liquid sauce sachet packing machine is composed of several components. These are described below in detail:

Structure of Allpack- APK-130 Horizontal 4 side seal honey sachet machine

Intelligent Control Panel:It is a microcontroller device which controls the functioning of machine by storing the data set by operator. It has a human machine interface which allows user to interact with machine by contacting different settings which appears on the panel.

Stainless Steel Body:The body of machine is made from durable and compact stainless steel and all parts touching the filling material and packaging material are specially made from corrosion resistant and antibacterial stainless steel to avoid product contamination.

Film Guide:Film guide refers to multiple rollers located at certain intervals which help in the synchronized unfurling of film from roll.

Film Reel:Film reel is a stock of film which is in form of roll. It can be either plastic, aluminum, or laminated paper film.

Sachet Former:Sachet former is another crucial component of a liquid sauce sachet packing machine which is in form of a conical type of device. It is useful for turning the flat layer of film into sachet.

Side Sealer:Side sealer is also called vertical or longitudinal seal. Depending upon the type of sachet, either one or two side sealings are added to the sachet.

Data Coder:It is a printing tool which is integrated into the machine for imprinting necessary data like material production date, expiration date, and batch no etc., on sachets.

Cutting Knife:The machine has a fitted pair of fine cutting knife which is utilized for cutting the finished sachets by separation. The sharper the knife the precise will be cutting. Apart from this, the type and design of cutting knife vary as per the operator requirements of packaging formats like curve and flat cutting blades etc.

Stable Foot:A liquid sauce sachet packing machine has four stable feet located on its lower body which enable the machine to stand upright and work smoothly without any disbalance.

Hopper:Hopper is a large conical or pyramidal container situated on the top of machine. Here liquid sauce is poured before starting operation, so, that the machine will process it without any interruption.

Top Sealer:Top sealer refers to the horizontal seal. It consists of a pair of sealing jaws which close the opening of filled sachets.

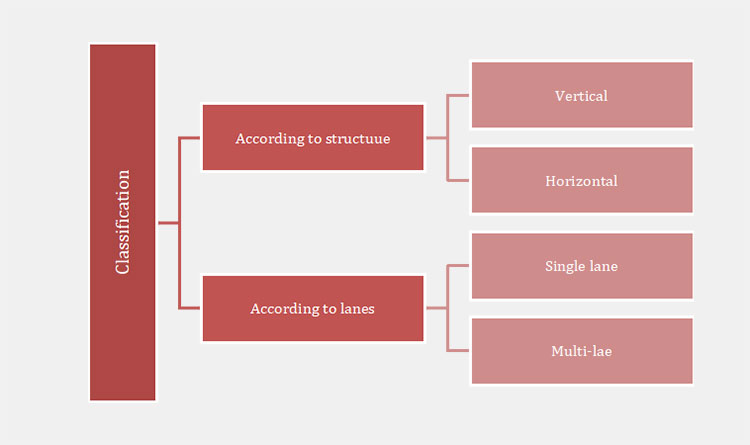

7.Are There Any Types Of A Liquid Sauce Sachet Packing Machine?

The answer to your question is definitely yes! A liquid sauce sachet packing machine do have multiple types. These types can be better understood by looking into their structure and working procedure. So, let's know about them!

According to Structure

Vertical Liquid Sauce Sachet Packing Machine

Vertical Ketchup Sachet Packing Machine- Picture Courtesy: cankey-tech.com

As the name indicates, this type of machine display a vertical body which occupies less space but give high output ratio. In vertical liquid sauce sachet packing machine, you will be offered to choose a single lane or multi-lane machine model, keeping in view your production line.

Structure

The body of machine is vertical with major parts encompassing a stainless-steel supporting structure with contact parts being made from antibacterial material. Along with that, it houses a workplace for the entire processing of liquid sauce sachet packing.

Working Process

It works on the easy working principles where packaging film is unwinded from a roll located on the top and undergoing it through forming, filling, and sealing in a vertical way. At last finished liquid sauce sachets are ejected out of machine.

Horizontal Liquid Sauce Sachet Packing Machine

Allpack- APK-130S/240DS premade pouch filling machine

Horizontal liquid sauce sachet packing machine is fully automatic packaging machine that can perfectly pack liquid sauces into single standard sachet as well as twin sachets depending upon the machine model. It is an ideal equipment in liquid processing industry like food, medical, and cosmetic industry etc.

Structure

It has horizontal structure, therefore, require a bit larger space than that of vertical liquid sauce sachet packing machine. It is composed of a sturdy main frame, control panel, electric cabinet, hopper, film roll stock, bag former, sealer, and cutter etc.

Working Process

It works by taking the layer of film from roll and then sealing its longitudinal sides to create sachet. Then the formed sachet is loaded with premeasured liquid sauce and closed from top for final discharge.

According to lanes

Single Lane Liquid Sauce Sachet Packing Machine

Single Lane Liquid Packing Machine For Sachet & Stick Pack- Picture Courtesy: samfull.net

Single lane liquid sauce sachet packing machine is small and compact machine that comes up with a single lane for forming, filling, and sealing sachet. The machine can be customized to create 3 side, 4 side, and irregular shape sachets. Moreover, its easy handling and cost-effectiveness make it reliable for low to medium scale industries in liquid processing area.

Structure

The structure of machine is compact and precise with a single lane being used for packaging of liquid sauce. The major parts constitute a hopper, packaging film, conical bag former, filler, sealer, and control system etc.

Working Process

It needs preloading and setting before starting operation. After these steps are carried out, the film is drawn from a reel via single lane and unwinded for sachet formation. Similarly, as the sachet is formed, pre-weighed liquid sauce is infused into it and the package is sealed and ready for output.

Multi Lane Liquid Sauce Sachet Packing Machine

Multi row four side sealing liquid packaging machine- Picture Courtesy: chengyipacking.com

Multi lane liquid sauce sachet packing machine features advanced technology and have an updated design to cater the modern needs of manufacturers regarding high packaging rate. Its lanes vary from 2-12, and it supports integration with secondary packaging machines such as sachet sorting machine and cartoning machine etc.

Structure

Similar to its name, the structure is also made up of multiple components which, by working together, enable the machine to carry out its function. They include multiple filling nozzles, a storage tank, weighing pump, bag unwinding, creating, and final closing system etc.

Working Process

The working process is simple with the machine unfurling film from roll and passing it through cutting step for splitting. Afterward, individual film layers are transformed into sachets through sealing and filled with liquid sauce. When filling gets done, the next step is to seal the openings of sachet and get them out of machine for further processing.

8.Differentiate Between Liquid Sauce Sachet Packing Machine And Powder Sauce Sachet Packing Machine?

As the nature and flow properties of liquid sauce and powder sauce are different, therefore, two separate machines are used for their packaging. Despite dealing with the packing of sauce, their applications and functions are different. So, let's know the differences that prevail between them!

| No | Aspects | Liquid Sauce Sachet Packing Machine | Powder Sauce Sachet Packing Machine |

| 1 | Definition | Liquid sauce sachet packing machine is used to process viscous and thin sauces by packing them into single serving sachets. | Powder sauce sachet packing machine is employed to deal with the particles of powder sauces by responsibly encasing them in sachets. |

| 2 | Weighing & filling system | It uses multiple weighing and filling system according to sauce properties such as volumetric filling system for thin liquid sauce and piston filling system for viscous and lumpy liquid sauce. | In contrast, the machine can be integrated with either auger filler mechanism for fine powder sauce and volumetric cup filling system for granulated powder sauce. |

| 3 | Sachet type | As it deals with liquid sauces, so, it is able to form 3 side, 4 side, and twin sachets with or without spouts for easy discharging of sauce. | While as, it can create 3 side, 4 side, and back side seal sachets without any spouts. However, these sachets may have a zipper for convenient handling. |

| 4 | Application | It is applicable for packing all kinds of liquid sauces including ketchup, soy sauce, mayonnaise, chilli sauce, and mint sauce etc. | It is eligible to process sauces available in powder form such as chilli pepper, salt, noodle seasoning powder, and mix condiment powder etc. |

| 5 | Picture |

Allpack- APK-130S/240DS premade pouch filling machine |

Allpack- APK-130 Horizontal 4 side seal small salt powder granule sachet machine |

9.Enlist The Applications Of A Liquid Sauce Sachet Packing Machine?

It is important for buyers of a liquid sauce sachet packing machine to know its worth which can be easily understand by looking into its applications which are given below:

Seasoning Industry

Various sachets of liquid sauces

The use of a liquid sauce sachet packing machine is inevitable in seasoning industry where the manufacturing and processing of products like vinegar, ketchup, soy sauce, and hot sauce is a routine practice. Because they are used as popular serving for fast food and instant food making. That's why, they need single serving and protected primary packaging for which the machine is used.

Beverage Industry

Various juice spouted sachets- Picture Courtesy: Behance

Another prominent application of a liquid seasoning packing machine is beverage industry. As we have seen that juices, drinks, jellies, and smoothies are now available in small size sachets, it is no exception that these liquids are processed by machine other than this one.

Medical Industry

Anti chafing cream sachet

Production and packaging of liquids is also very popular in medical industry. From injection water to cough syrup and ointment, liquids are commonly delivered in handy packages like sachets and stick packs especially for emergency purposes. Therefore, a liquid sauce sachet packing machine can be used for packing these essentials in safe packages.

Beauty Care Industry

Shampoo sachets

Beauty care industry is the fastest growing sector with rise in demand for products such as lotion, shampoo, facial mask, and hair dyes etc. Due to this reason, manufacturers tend to adopt new means of packing and delivering these liquids and most desirable which they found is flexible sachet packaging. Hence, a liquid sauce sachet packing machine can be employed here.

Pesticide Industry

Pesticides packaging- Picture Courtesy: fluidotecnica.com

Pests, pathogens, and insects are the enemies of crops and plants. To keep them away from crops, farmers used to spray pesticides and herbicides etc. Similarly, at homes, people also find it difficult to deal with these organisms for which they opt for pesticides sachets. Hence, to pack these liquid chemicals, a liquid sauce sachet packing machine is suitable.

10.What Is The Method For Checking Leaks Tests of Sachets Being Made By A Liquid Sauce Sachet Packing Machine?

Vacuum leak test of liquid sachets- Picture Courtesy: sanatron.com

Well, the common method being employed for assessing the presence of leaks in liquid sauce sachet is vacuum leak test. It is a non destructive method to check the leaks in flexible packages.

It simply begins with the placement of a sample in an evacuation test chamber. After placing the liquid sauce sachet, chamber is tightly closed and the tester is powered on for functioning. Now, vacuum is applied to pre-set level and the change in vacuum level over a predetermined period of time show the results of the test.

Conducting this test for your finished liquid sauce sachets will ensure safe packaging.

11.What Is The Preventive Maintenance Of A Liquid Sauce Sachet Packing Machine?

A well-maintained machine will uplift your production and will perfectly serve your targets for years to come. That's why, we are sharing a list of guidelines regarding the preventive maintenance of a liquid sauce sachet packing machine to help you make your business more lucrative. They are as follows:

Operator maintaining machine

Machine Inspection:Inspecting machine while during operation is of utmost importance as it enable you to keep recording the inconsistencies being occurred in machine. In addition, you can examine the noise of machine, the misbehavior of any part of the stagnation of any component which is further disturbing other sections from proper working.

Regular Cleaning:Cleaning is obligatory step to be conducted on regular basis. It ensures the safety and hygiene of your machine especially those parts which are in directly contact with material such as hopper, filling nozzles, and sealing jaws etc. For cleaning, it is necessary to use the means and methods as directed in the machine manual and make sure to properly remove out the residues from narrow parts.

Parts Changeover:Liquid sauce sachet packing machine has multiple parts, few with long term functioning while others may face frequent breakdowns. So, you need to be cautious of them and replace them timely in case of wear.

Lubrication:Lubrication is also very important to keep the movable parts of machine smooth running and avoid friction. So, use the recommended grease for lubrication.

12.How To Tackle The Sudden Issues Caused By A Liquid Sauce Sachet Packing Machine?

While operating a liquid sauce sachet packing machine, you may face spontaneous errors which have some technical background and can be easily solved. So, let's know the most common ones!

Machine is not starting

Control panel- Picture Courtesy: Utmost Pack

Cause

The power switch is disconnected with electric board.

There may be incoming power issue due to insufficient power availability.

Solution

Check and replug the power switch.

Make sure to provide sufficient voltage of power as per the requirement of machine.

The temperature of sealing bars is uncontrollable

Marked sealing jaws- Picture Courtesy: universalpack.it

Cause

The temperature sensor is faulty.

Heating device to sealing jaws is damaged.

Solution

Check and repair temperature sensor, replace it if damaged.

Change the heater for sealing jaws.

Improper film tracking during unwinding

Film unwinding issue- Picture Courtesy: Optima Packaging

Cause

Film reel is not placed in the center of spindle or film frame.

The splice tape may be trapped in sachet former.

The belts for unwinding film are settled inaccurately.

Solution

Reset the film and locate it in the center of spindle.

Remove the splice tae from sachet former and check if the former is titled causing film to stick.

Set-up the film pulling belts properly.

Bad vertical and horizontal seals

Bad vertical & horizontal seal

Cause

Inconsisten vertical seal is the result of improper installation of forming tube backstop and the presence of unparallel distance between film and sachet former.

Faulty horizontal seal is caused by the trapping of liquid sauce in seal space.

Solution

Reinstall forming tube backstop and reset the distance between film and bag former.

Readjust the fill and seal time to allow adequate time for liquid to settle in sachet.

13.Things To Know For Choosing The Best Liquid Sauce Sachet Packing Machine?

Every entrepreneur desire to have the best machine but when it comes to purchase a liquid sauce sachet packing machine, most of them get puzzle. So, we have brought for you some valuable tips to consider. These include:

Production Volume

Various liquid sauce sachets

Determining your current production volume is one of the pivotal factor to choose the compatible machine. It simply means to know whether you are running small size industry, medium size, or large size. Thus, it will help you know to choose for single lane or multi-lane liquid sauce sachet packing machine.

Packaging Style

It refers to the outlook of liquid sachet which is influenced by its shape, cutting, and sealing style. So, it you will know the type of packaging style you want to use for your liquid sauce packing, it will be easy for you to opt for the right machine. Moreover, packaging style also affect the selection of different parts such as cutting blades, sealing jaws, and bag former etc.

Quality

Quality icon- Picture Courtesy: mark1systems.com

Liquid sauce sachet packing machine is meant to deal with edible liquids. Therefore, it must be made from quality material. In this way, ISO, FDA, and GMP are the prominent quality standards which your machine should meet with.

Customer Support & Warranty

Warranty icon

Another significant fact to know is the availability of customer support on part of vendor and their warranty policy. After all you are making a big purchase. So, keep in mind these things while purchasing a liquid sauce sachet packing machine.

Conclusion

To put in a nutshell, Liquid Sauce Sachet Packing Machine is a spectacular equipment that perfectly deals with the primary packaging of liquid sauces into sachets. It features automation, convenience, and adaptability to cater vary needs of the businessmen. You can use it alone or integrate it with other machines to excel the output. However, it also requires responsible handling and regular maintenance which can be done by taking help from above provided information. Now, if you are eager to buy a liquid sauce sachet packing machine from reputable supplier then Allpack is the best option. For further details, visit our website!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours