Liquid Packing Machine: The Complete Buying Guide In 2025

Delicious juices, energy drinks, and smoothies refresh us on hot summer days. But have you ever wondered how they are packed? These refreshing drinks and every liquid product are packed by a liquid packing machine.

Packaging plays a vital role in the commercialization of any liquid and no doubt liquid packing machine contributes a lot to branding and marketing any product production. This machine also bestows protection to liquid products. It brings several benefits for production due to its efficiency and speed.

Interested in integrating a liquid packing machine into your existing production line but first want to learn about this handy device, then read on to discover the fascinating world of the liquid packing machine.

1.What is Meant by a Liquid Packing Machine?

Liquid Packing Machine

A liquid packing machine or liquid packaging machine is a piece of equipment that encloses, contains, loads, or fills the liquids inside the container which are either flexible packaging like pouches, sachets, sticks, or rigid packing like jars, bottles, jerrycans, buckets, and drum.

It is an efficient and speedy machine that packs more containers per minute than it is filled by simple hand filling. It is utilized in every sundry industry like food, pharmaceutical, beverage, nutraceutical, chemical, cosmetic and many more.

2.What are the Useful Benefits of the Liquid Packing Machine?

Liquid packing machine comes in handy because of their flawless working, speed, and automation. Although buying this machine is a heavy investment, it generates more revenue in a short time. Here are some major useful benefits of the liquid packing machine:

Lower Cost

Highly Cost-Effective Liquid Packing Machine

Liquid packing machine has lower operational costs because it automates the liquid packing process, allowing productions to allocate labour resources elsewhere. This lowers labour expenses. Moreover, it also recoups its initial investment by saving packaging material.

More Efficiency

More Efficiency- Picture Courtesy: Packaging of the World

Liquid packing machine automates the packaging process and increases packaging efficiency. This means that it packs more product in less time, whereas, hand packing is more laborious and has lower packaging efficiency.

Remove Process Bottlenecks

Remove Process Bottlenecks

The hand packaging process can have more bottlenecks because of human mistakes. A liquid packing machine prevents these bottlenecks by removing the chances of human mistakes. This machine has fewer packaging errors and it easily keeps up with the production flow.

High Operator Safety

High Operator Safety

With the liquid packing machine, manufacturers ensure the safety of their workforce. By automatically packing the liquids, the risk of monotonous strain and work-related injuries is drastically reduced. This is because this machine works efficiently with less to no human intervention.

No Downtime

No Downtimes with Liquid Packing Machine

Human staff needs a break and hand packing stop when they are on break. This increases downtime. But the liquid packing machine operates 24/7 without needing a break. This significantly lowers the downtime and increases production efficiency.

Versatility

Versatility of Liquid Packing Machine

A liquid packing machine, whether packing rigid containers or flexible containers, can process a wide range of containers. In this way, it is ideal for industries dealing in different-sized and shaped liquid containers. With quick format change, the liquid packing machine is customized to handle different packaging containers.

3.What are the Industrial Applications of the Liquid Packing Machine?

Liquid packing machine has diverse applications in every industry that processes liquid products. These applications are penned below:

Food Industry

Use of Liquid Packaging Machine in Food Industry- Picture Courtesy: Dieline

In the food industry, a liquid packing machine is utilized to fill thinner and thicker consistency liquid products like pastes, dressings, sweet syrups, condiments, ketchup, mayonnaise, honey, etc., in bottles and pouches. With its computerized parts, this machine automates food production lines.

Beverage Industry

Use of Liquid Packaging Machine in Beverage Industry

Yes, the liquid packing machine has prime value in the beverage industry, because it loads different kinds of beverages, such as sodas, smoothies, fruit juices, water, and oils in attractive bottles and stylish pouches. This machine boosts the production efficiency of beverage filling lines.

Dairy Industry

Use of Liquid Packaging Machine in Dairy Industry

Liquid packing machine is also found in the dairy industry for packing milk, ice cream, butter, yogurt, and cheese in hard and flexible containers. This machine packs more dairy products in a short time.

Pharmaceutical and Nutraceutical Industry

Use of Liquid Packaging Machine in Nutraceutical Industry- Picture Courtesy: Dieline

In the pharmaceutical and nutraceutical industry, a liquid packing machine plays a significant role, as it packs syrup, emulsion, suspensions, energy mixes, protein mixes, and many more. Its speed in these industries exceeds the speed of handfilling.

Cosmetic Industry

Use of Liquid Packaging Machine in Cosmetic Industry- Picture Courtesy: Packaging of the World

A liquid packing machine is popular in the cosmetic industry, as it packs free-flowing as well as thicker viscosity products, for instance, perfumes, foundations, lipsticks, eyeliners, etc. in the bottles. It also fills cosmetic products in small pouches and sachets for sample and promotional purposes.

Personal Care Industry

Use of Liquid Packaging Machine in Personal Care Industry- Picture Courtesy: Packaging of the World

This machine is also utilized in the personal care industry to pack body mist, liquid soap, face wash, sanitizers, shampoo, sunscreen, etc. in jars, bottles, pouches, and sachets. This machine boosts production capacity in the personal care industry.

Chemical Industry

Use of Liquid Packaging Machine in Chemical Industry

In the chemical industry, this machine is utilized because of its quicker work efficiency and high productivity. Liquid packing machine packs a variety of chemicals like detergents, bleaches, disinfectants, adessives, glues, paints, liquid fertilizers, and many more in small and large capacity containers.

4.What Components Are Present in the Liquid Packing Machine?

A liquid packing machine consists of different parts, each capable of performing a particular role for seamless packing operation. These parts are discussed below:

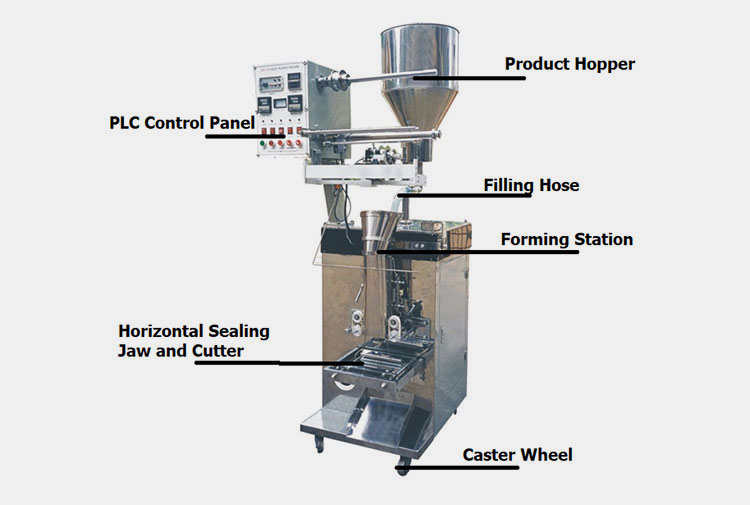

Both Pictures Represents Parts of Allpack Liquid Packing Machine

| Product Hopper | Bulk volumes of liquids are loaded in the product hopper located at the upper side of the liquid packing machine. |

| PLC Control Panel | It stands for programmable logic controller. It is a computerized panel that controls every process in the liquid packing machine. This panel has different buttons with which the machine is powered up. These buttons are also used for adjusting machine parameters. |

| Filling Hose | It is a plastic pipe-like structure that provides a passageway for the fluidity of liquids from the hopper to the filling nozzles. This hose connects the hopper to the filling head. |

| Forming Station | This is a cone-like structure, around which packaging film is folded and wrapped. This component transforms packaging film into a pouch or sachet. |

| Horizontal Sealing Jaw | This sealing bar melts and fuses the top and bottom edges of the pouch using heat or pressure. |

| Cutter | It is a sharp blade that cuts and trims the seams of the packaging pouch. |

| Caster Wheel | These are present at the bottom of the liquid packing machine and rotate to move the machine. |

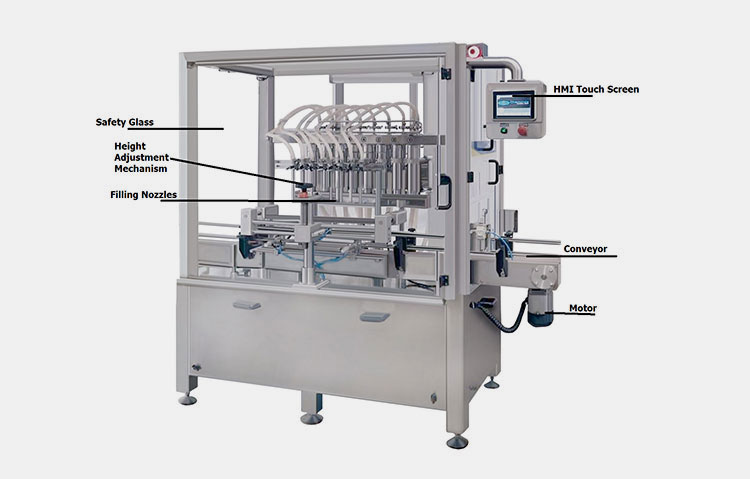

| Conveyor | It is a long transporting unit consisting of rollers, chains, and drive belts that move liquid containers to different machine areas. |

| HMI Touch Screen | It is a display screen using which operators can input machine parameters. |

| Motor | This is an electric component that powers the machine's HMI display screen, conveyor, and filling devices. |

| Height Adjustment Mechanism | It is a rotating handle with which filling heads are moved up and down to accommodate containers of varying heights. |

| Filling Nozzle | It is a cylindrical nozzle that allows liquids to gradually trickle down the container. |

| Safety Glass | This is a safety feature consisting of clear glass by which users can easily see the machine's operation without directly approaching the machine. |

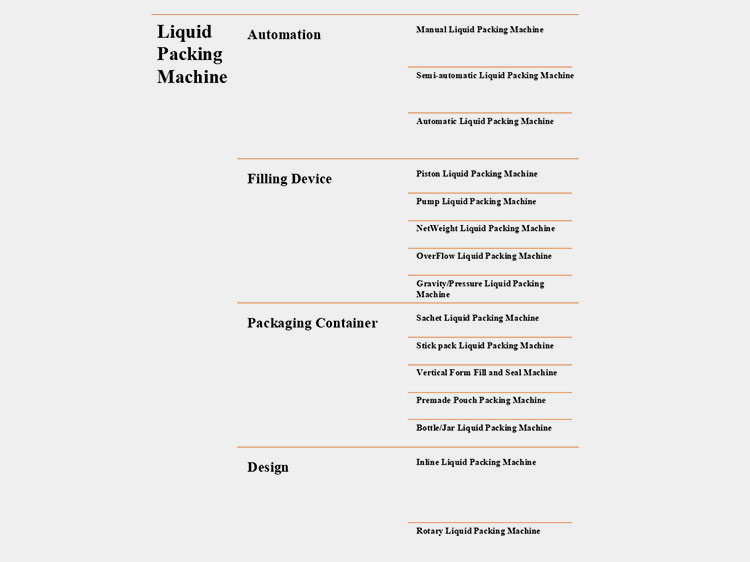

5.What is the Major Classification of the Liquid Packing Machine?

Liquid packing machine comes in all shapes and sizes. This machine is classified into different types based on automation, filling device, and type of container. A detailed classification is discussed below:

According to Automation

Manual Liquid Packing Machine

Allpack Manual Liquid Packing Machine

This machine is the most simplified form of the liquid packing machine that is easily accommodated on the desktop. It has handles and levers that are used to manually pack the liquid inside the containers. Moreover, operators have to load and unload containers physically under the filling nozzle. It is mostly found in small industries and homes.

Semi-automatic Liquid Packing Machine

Allpack Semi-automatic Liquid Packing Machine

This machine has a compact configuration. When it comes to functionality, it is between the manual liquid packing machine and the automatic liquid packing machine. It is an automated filling process due to its computerized controls while loading and unloading of containers is labor-intensive.

It has medium-sized productivity and is often seen in medium-sized industries.

Automatic Liquid Packing Machine

Automatic Liquid Packing Machine

This machine automates production with its seamless working and high speeds. Its packing speed is far faster than a semi-automatic liquid packing machine. With its up-to-date technology, it packs thousands of containers per hour. It is integrated with robotics and automated systems that load and unload containers to and from the machine.

It is more costly than its counterparts and has a modular configuration.

According to Filling Device

Piston Liquid Packing Machine

Piston Liquid Packing Machine

This machine utilizes the opposite movement of the piston in a cylinder to draw liquids from the hopper into the container. Piston movement forward fills the cylinder while its backward movement pushes the liquid into the filling head. It can easily fill liquids having both a thinner and thicker consistency. The piston liquid packing machine has accurate filling.

Pump Liquid Packing Machine

Pump Liquid Packing Machine- Picture Courtesy: Algomtl

This machine is equipped with different kinds of pumps like gear, rotor, cavity, and, lobe. This pump system rotates to move liquids from hoppers to filling heads. It is one to more filling nozzles and each filling nozzle has its own pump for efficient liquid packing. It loads both viscous and free-flowing liquids into containers.

Net Weight Liquid Packing Machine

Net Weight Liquid Packing Machine- Picture Courtesy: Accutek Packaging Equipment

While other liquid packing machines, fill liquids by their volume, the net weigh liquid packing machine loads the liquids into the packaging container by their weight. It is more accurate than a volumetric liquid packing machine. Measuring load cells in this machine monitor the in-filling weight and signal the PLC system to pause filling once the required weight is attained.

Over Flow Liquid Packing Machine

Overflow Liquid Packing Machine

This machine is different from other types of liquid packing machines as it fills containers to a required level instead of volume. The sensors monitor the progress of the liquid and once it reaches the desired level, the filling stops. The extra liquid is sent back to the hopper via overflow nozzles.

This machine is suited for packing transparent containers that have a conspicuous presence on retail shelves.

Gravity/Pressure Liquid Packing Machine

Gravity/Pressure Liquid Packing Machine- Picture Courtesy: VKPAK

This machine uses natural gravitational force or pressure to pack the container. Liquid flows down the filling nozzles via gradational force or pressure difference between the hopper and filling nozzle. It operates on the principle of time-based filling which means that once the desired time has passed, liquid packing stops.

According to Packaging Container

Sachet Liquid Packing Machine

Allpack Sachet Liquid Packaging Machine

This machine packs small sachets or bags with the liquid. It usually seals sachets at three sides (top, bottom, and one side) or four sides (top, bottom, and 2 sides). It is best for packing a one-time serving of liquids. The Sachet liquid packing machine has a smaller size.

Stick pack Liquid Packing Machine

Allpack Stick pack Liquid Packing Machine

It also packs single-serve liquids but its packaging container is longer and has a smaller width. It seals the stick packs on three or four sides. It also creates a back-seal on the stick pack. It has one to twenty lanes and its output capacity usually depends upon the number of lanes.

Vertical Form Fill and Seal Liquid Packing Machine

Allpack Vertical Form Fill and Seal Liquid Packing Machine

It is the most popular liquid packaging because of its cost-effectivity, versatility, and smaller size. It forms, fills, and seals pouches instead of using already-made pouches. It can pack diverse kinds of liquid pouches like standup, Doypack, gusset pouches, flat bottom pouches, etc.

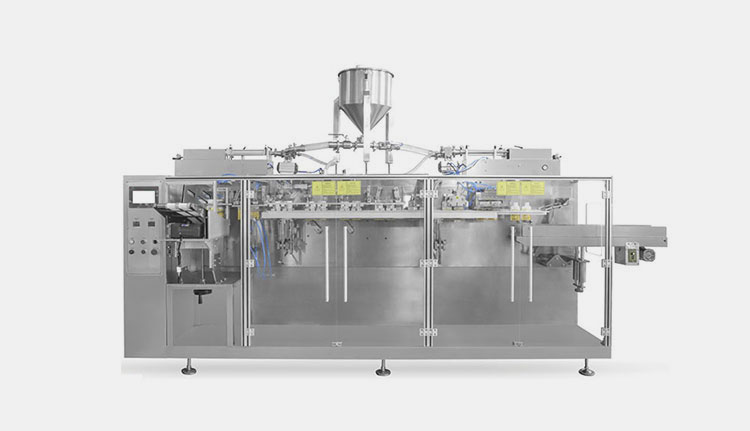

Premade Pouch Liquid Packing Machine

Allpack Premade Pouch Liquid Packing Machine

This machine uses already-made pouches instead of making them by itself. Hence, the premade pouch packing machine has more productivity than the VFFS machine. It is rotary turntable thus, can process multiple pouches simultaneously. It operates at a consistent speed to pack liquids in different pouches.

Bottle/Jar Liquid Packing Machine

Bottle/Jar Liquid Packing Machine

This machine fills liquids inside diverse container types such as jars, bottles, jerry cans, and drums. It has long conveyors on which containers are placed for filling. These conveyors are essential in guiding and loading liquid containers. Bottle/jar packing machine comes with one or more filling heads that boost production efficiency.

According to Design

Inline Liquid Packing Machine

Inline Liquid Packing Machine

It has a straight-line design like the letters L, U, and Z and bottles travel in a single line on the conveyor belt of this machine. It has a long conveyor. The conveyor pauses during the liquid filling in this machine. It has a lower speed than its rotary counterpart.

An inline liquid packing machine is ideal for small and medium productions. This machine has a lower footprint. The inline liquid packing machine is budget-friendly. It is quite flexible and format change is quickly managed.

Rotary Liquid Packing Machine

Rotary Liquid Packing Machine

The rotary liquid packing machine has a circular design. It has a small conveyor and starwheel turntable. The machine does not pause while the containers are filled. It can fill multiple containers at a time.

The rotary liquid packing machine has more production speed than its inline counterpart. It is more suited for large productions. It requires more floor space. It is more expensive. It has less flexibility and processes limited bottle types.

6.How Does the Liquid Packing Machine Work?

The liquid packing machine works seamlessly to carry out precise liquid filling. The working principle of different types of liquid filling machines is discussed below:

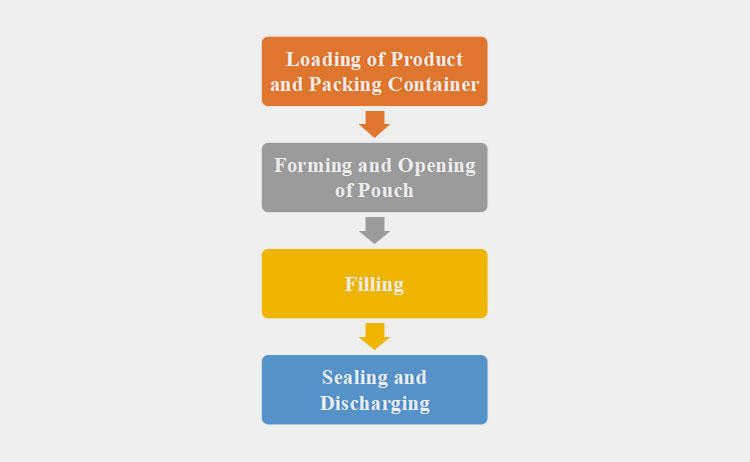

Liquid Pouch Packing Machine

Liquid Pouch Packing Machine

Following are the working steps of this machine:

Loading of Product and Packing Container

Before the beginning of the machine operation, the product is poured inside the liquid hopper located at the top. The operators place packaging film or empty pouches in the loading area.

Forming and Opening of Pouch

The packaging film unwinds, folds, and wraps around the forming station to fabricate the pouch while in the premade pouch machine gripper opens and compressed air inflates the empty pouches.

Filling

Upon detection of the pouch under the filling nozzle, liquid in the hopper flows to the filling nozzle by the rotational and vibrational motion of the filling devices.

Sealing and Discharging

After filling, the sealing element uses pressure, heat, and ultrasonic waves to fuse the top edges of the pouch. Ultimately, these finished liquid pouches are discharged in an outfeed chute.

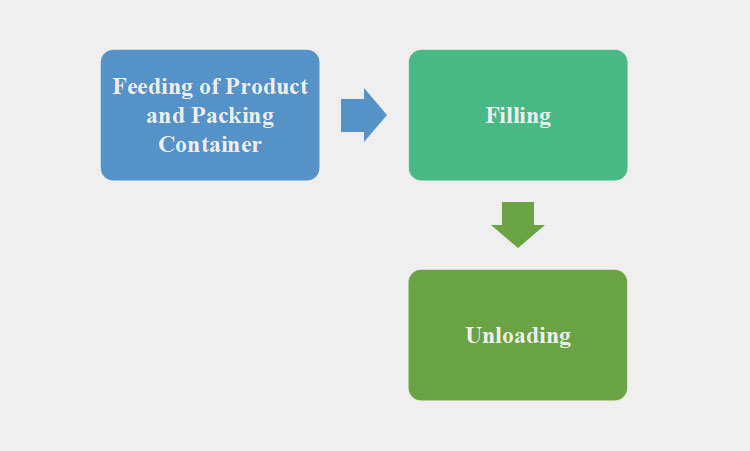

Bottle/Jar Liquid Packing Machine

Allpack Magnetic Force Pump Liquid Filling Machine

The working of bottle/jar packing machine is divided into three main steps:

Feeding of Product and Packing Container

The bulk quantity of liquid products is loaded inside the hopper.

Filling

When the container is detected under the filling heads, The liquids flow from the top hopper into the filling heads and then they gradually dispense into the packing container.

Unloading

Once the required fill volume, fill weight, or fill level is attained, the filling process stops and containers go to capping and sealing stations.

7.What Packaging Materials are Processed by Liquid Packing Machine?

The type of packaging materials processed by the liquid packing machine usually depends upon its type. Here are some examples of packaging materials processed by the liquid packing machine:

Polyethylene Film

PE Film Pouch

Liquid packing machine processes multiple types of PE films like LDPE, LLDPE, and HDPE, to create strong and protective pouches and bottles. These films have strong environmental element resistance and are puncture-proof.

Polypropylene Films

Polypropylene Films

This machine also handles PP film to fabricate pouches and sachets with more shelf appeal. These films are transparent and usually offer clarity. Moreover, they are tough and have better chemical resistance.

Metalized Film

Metalized Film

These films are formed from aluminium layer deposition on the plastic film. This creates a shiny metallic effect that attracts high-end customers.

Glass

Glass Bottles

It has a tough impermeable material, forming a more durable glass bottle. It has higher barrier resistance than other materials. The clarity of the glass allows users to view packaged products.

Metallic Cans

Metallic Cans- Picture Courtesy: Dieline

It is formed from aluminium and tinplate. These materials offer strong moisture, temperature, and, air protection. Liquid packing machine uses metallic cans to fill beverages and juices.

Rotary Liquid Packing Machine- Picture Courtesy: Datong Machinery

8.How To Maintain a Liquid Packing Machine?

Maintenance of Liquid Packing Machine

Proper maintenance of liquid packaging is a certain way to increase its operational life. Maintenance of machines is a must for gaining maximum benefit from it. Here are some useful maintenance tips for the liquid packing machine:

| Daily Maintenance | Visually examine the liquid packing machine for any loose belts, nuts, screws, and bolts.

Examine leakage in components. Clean every surface of the machine, especially the filling nozzle. Maintain proper product level in the hopper Check machine HMI for any error notification |

| Weekly Maintenance | Lubricate and oil mobile parts and joints.

Properly clean the clogged nozzles. Adjust the tension of the drive belts. Clean and calibrate machine sensors. |

| Monthly Maintenance | Replace worn-out clogged air filters to maintain correct airflow.

Thoroughly clean the machine from the interior. Recalibrate the filling devices to ascertain steady liquid flow. Examine and properly tight loose electric components. Inspect the alarm system. |

| Yearly Maintenance | Back up the machine data.

Lubricate gearboxes and motor. Check the working order of safety devices like guard rails and interlock doors. |

9.What are the Basic Problems of the Liquid Packing Machine? How to Rectify Them?

The Liquid Packing machine has a central place in the liquid filling line; however, it can encounter occasional problems that lead to production downtime and inaccuracies in liquid packing. Here are some basic problems and their possible solutions:

| Cause | Solution | Image |

| Tipping and Breakage of Bottles | ||

| Non-uniform conveyor belt tension

Uneven speed of the conveyor Poor positioning of guide rails Old conveyor belt |

Adjust the tension of the conveyor

Correct the speed of the conveyor Realign guide rails Replace old conveyor belt |

Tipping and Breakage of Bottles- Italianfood.net |

| Uneven Liquid Fill | ||

| Old or faulty fill nozzles

Clogging in filling nozzles Poor calibration of filling devices Non-uniformity in liquid consistency The presence of air in the filling pipes |

Replace old fill nozzles

Properly clean fill nozzles with cleaning agents Recalibrate the filing devices Ensure that there is uniformity in liquid viscosity Remove the air from the fill pipes |

Uneven Liquid Fill |

| Leakage of the Liquid | ||

| Old or defective gaskets and seals

Loose pipe connections Worn-out O-rings |

Replace or replace worn-out gaskets and seals

Properly tight all the fill pipes Repair or replace O-rings |

Leakage of the Liquid- Picture Courtesy: ALPS Inspection |

| Blockage of the Packaging Film | ||

| Faulty or worn-out photosensors

Hindrance in the film path Inaccurate positioning of film rollers |

Replace worn-out film sensors

Remove the blockage in the film path Correct the positioning of film rollers |

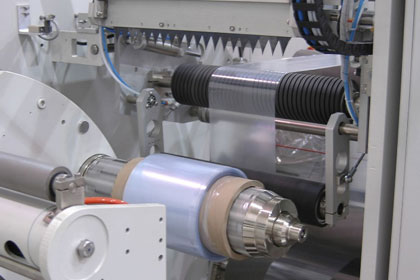

Blockage of the Packaging Film- Picture Courtesy: DirectIndustry |

| Poor Sealing of Pouch | ||

| Non-uniform sealing pressure

Dirty sealing jaws Worn-out sealing elements Inaccurate seal temperature |

Ensure that seal pressure is even

Clean the dirty sealing jaws Replace old sealing elements Adjust the seal temperature |

Poor Sealing of Pouch |

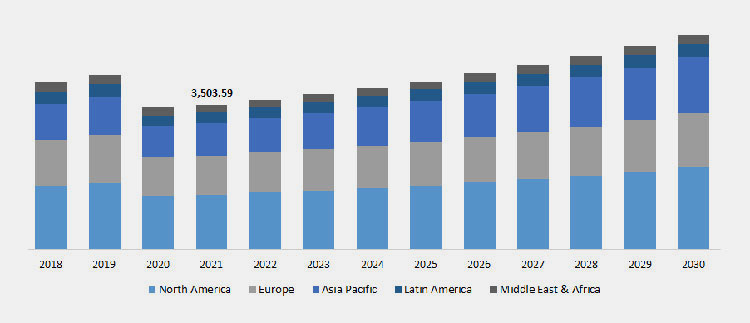

10.What are the Future Prospects of the Liquid Packing Machine?

Future Prospects of Liquid Packing Machine- Picture Courtesy: Polaris Market Research

The liquid packing machine market is on the rise and making a deeper impact all over the world. It is determined that the market value of the liquid packing machine was USD 3,503.59 Million in 2021. It is expected to grow with a CAGR of 4.6% and is expected to reach a market value of USD 5,205.78 in 2030.

The liquid packing machine market is witnessing a high growth rate because of the reliability of a liquid packing machine, it delivers quick packing results without compromising the product quality. Due to this growth, manufacturers modify their liquid packing machines so that they can meet the increased production demand.

The latest liquid packing machine is fabricated using artificial intelligence and internet-of-things. Manufacturers are modifying their liquid packing machines by incorporating Industry 4 protocols. These technologies will allow the liquid packing machine to smart pack liquids and make real-time decisions with data analytics.

Moreover, the futuristic liquid packing machine would be more eco-friendly, lowering carbon emissions and decreasing packaging waste.

Conclusion

A liquid packing machine is the best solution to pack liquids efficiently, accurately, quickly, and precisely. Hopefully, now you are well-versed in this machine by reading our informative buying guide. Now if you are planning to purchase a liquid filling machine then visit our dedicated Allpack website, as it is our motto to provide the best-quality machine that will skyrocket your business. If you are confused about the selection process then you are more than welcome to message us and we will guide you in picking a superb-quality machine.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide