Most Experienced Liquid Packaging Machine Manufacturer

- Servo Motor Driven

- Pneumatic Pump Dosing

- Intelligent Temperature Controller

Liquid Packaging Machine

Liquid Packaging Machine is suitable for filling and sealing various liquid products such as beverage, sauce, shampoo, etc. It is equipped the advanced device, electrical equipment, long-distance control system, and pneumatic control technology. This machine has the characteristics of filling reposefully, high speed, liquid level control, capping reliably, frequency conversion timing, and controls less material loss. It is the preferred equipment for the medium beer and beverage plant. The whole machine adopts stainless steel structure and adopts a single piece of polyethylene film, or two-layer and three-layer co-extrusion. The film is used as a packaging material. With an intelligent temperature controller, the temperature of horizontal and vertical sealing, so that the sealing is firm, the sealing performance is good, the bag shape is flat, and the packaging efficiency is high.

Liquid Packaging Machine

DXDY-1000AII Liquid Packaging Machine

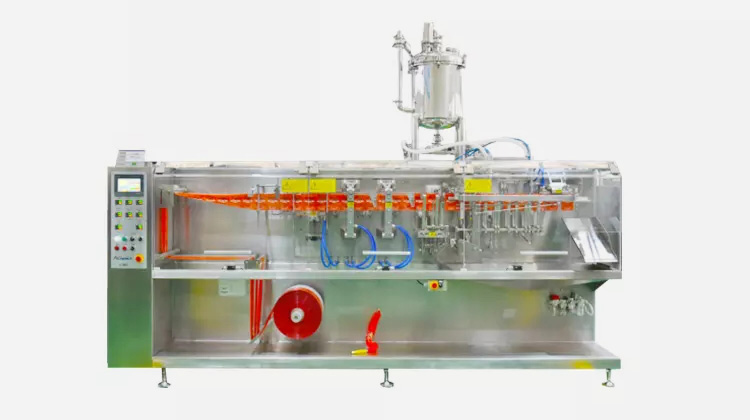

Allpack DXDY-1000AII liquid packaging machine is widely used in the packaging of various liquids such as milk, soy milk, various beverages, soy sauce, vinegar, yellow wine and white wine. Packing procedure: UV sterilization, bag forming, date printing, quantitative filling, sealing and cutting are completed in one time. The product is beautiful and reliable. The whole machine adopts stainless steel structure, adopts single piece of polyethylene film, or two-layer and three-layer co-extrusion. The film is used as a packaging material.

Economical design

Bag making/metering/filling/sealing/cutting/counting/printing complete at one time

Dust Proof&hygienic

DXDY-1000AIII Liquid Packaging Machine

Allpack DXDY-1000AIII liquid packaging machine can automatically complete a series of actions,such as bag making,filling,forming,date printer,sealing and cutting.It has Chinese and English display screen control system, stainless steel frame, only need to set the required parameters (filling amount, bag length, etc.) in the displayable settings, and the control system will automatically optimize and match, so as to achieve the best packaging speed. With intelligent temperature controller, to control the temperature of horizontal and vertical sealing, so that the sealing is firm, the sealing performance is good, the bag shape is flat, and the packaging efficiency is high.

Advanced intelligent photoelectric tracking system

Stepless adjustment of packaging speed

Automatic registration of double-sided printing patterns

DXDY-1000BNII Liquid Packaging Machine

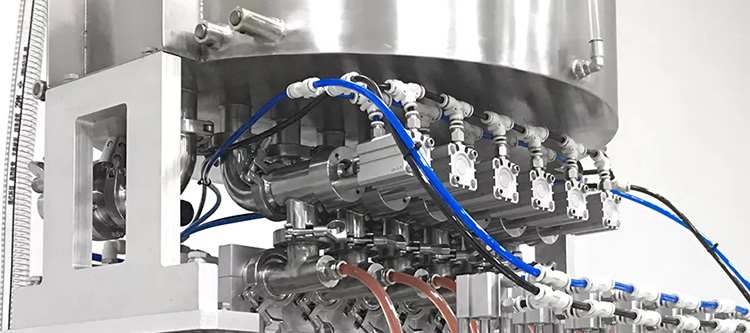

Allpack DXDY-1000BNII liquid packaging machine can pack liquid, viscosity product. If the machine has two feeding devices working at the same time, it can achieve twin pouch packing; three feeding devices for triple pouch packing.The machine are equipped with one set of vertical sealing roller, one set of horizontal sealing roller and one set of sealing roller for strengthen. The vertical sealing roller is completed, continuous grain vein with leak-resistant line. The horizontal sealing roller is grain vein with leak-resistant line or plain sealing with leak-resistant line.The whole set of machine combines forming -vertical sealing--filling -horizontal sealing -horizontal strengthen sealing--notching-cutting together.

PLC control

Operation on HMI panel

Servo motor driven pouch length adjustable

DXDY-100BNII Liquid Packaging Machine

Allpack DXDY-100BNII liquid packaging machine is suitable for packing all kinds of liquid or paste products such as water, juice, oil, cosmetic cream, jam,butter,tomato paste, ketchup, olive oil, honey,sauce, shampoo, lotions, etc.All the machine electronic components adopt international famous brand excluding motor, which use regular domestic brand.The raw material of the products adopts stainless steel Mitsubishi PLC control system.With noiseless stepping motor to improve steady working condition and decrease vibrator and noise.

Easy to operate and maintain

Wide application range

Weight accuracy&efficient&convenient

DXDY-20BNII Liquid Packaging Machine

Allpack DXDY-20BNII liquid packaging machine is suitable for all kinds of liquid and paste, such as ketchup, soy sauce, vinegar, honey,etc. Its suitable film material are plastic film, aluminum foil. Suitable industries are food, beverages, cosmetics, daily chemicals, etc.It has high degree of full automation,can automatically complete the bag-making, filling, sealing, cutting and counting.Controlled by microcomputer and simple buttons.The granule is easy to operate.The machine body is made of stainless steel, which is durable and food grade.

Stable performance and high precision

Easy to operate

Pneumatic pump metering device

DXDY-500BNII Liquid Packaging Machine

Allpack DXDY-500BNII liquid packaging machine is a high precision packing machine and the most advanced liquid compound packing machine in china, which is standing, three side sealing and intermittent. It can automatically complete bag-making, filling, sealing, printing, cutting and counting .Controlled by microprocessor and automatic photocell. It is widely used to pack all kinds of liquid without gas, especially soy, wine, vinegar, juice, soybean milk, oil, mineral water and liquid chemical products.

Electrical control system

Reliable, hygienic& safe

Smooth&accurate film pulling assembly

DXDY-50BNII Liquid Packaging Machine

Allpack DXDY-50BNII liquid packaging machine is suit for automatic filling and packing liquid/paste/sauce/cream item, such as milk, juice honey, hair shampoo, tomato paste, salad dressing, jam etc. The granule packaging machine also adopts the pneumatic pump dosing unit which have the machine advantage of suit for viscous liquid item with high efficient and reliable performance. The most important is the machine equip with small horizontal ribbon blender mixing machine, this will make the machine much suit for seasoning paste/sauce, such as chilli paste, for the mixing machine will have the paste evenly packaged with less deposite.

Photoelectric and tracing system

Adjustable mixing speed

Frequency conversion speed regulation

The Buyer's Guide

Liquid Packaging Machine: The complete FAQ guide in 2025

Liquid packaging machine is a type of machine for both filling and sealing for liquids. With wide applications, you can fulfill various liquids with liquid packaging machines. This FAQ guide can help you with all those information about liquid packaging machines, and please follow me right now!

1.What Is Liquid Packaging Machine?

Liquid packaging machine is a kind of equipment specially used for filling and sealing liquid products, and liquid packaging machines conclude beverage filling machines, dairy filling machines, viscous liquid food packaging machines, liquid cleaning products and personal care products packaging machines, etc.

2.What Are the Applications of Liquid Packaging Machines?

Liquid packaging machines are widely applied in the food industry, chemical industry, pharmaceutical industry, agriculture industry.

Food Industry

Liquid packaging machines are widely applied in filling and sealing the beverages, dairy products, condiments, sauces, such as fruit juices, various beverages, soy sauce, vinegar, ketchup, milk, yogurt, etc.

Chemical Industry

Liquid packaging machines are widely applied in filling and sealing the shampoo, shower gel, hand sanitizer, disinfectant, alcohol, body lotion, hair conditioner, laundry detergent, hand cream, glue, etc.

Pharmaceutical Industry

Liquid packaging machines are widely applied in filling and sealing the alcohol, oral liquid, syrup, cooling oil, disinfectant, iodine, cold medicine for children, mouthwash, various sprays, liquid preparations for external use, ear drops, glycerin, lavage, etc.

Agriculture Industry

Liquid packaging machines are widely applied in filling and sealing the liquid formulations of various pesticides and insecticides. Such as herbicides, paraquat, fungicides, insecticides, etc.

3.What Are the Features of Liquid Packaging Machines?

There are seven main feature of the liquid packaging machines including machine design, PLC computer control system, embedded closure, closed mechanism, external film release, malfunction, and bag length control.

Machine Design

The liquid packaging machine has a compact and firm structure design with a reasonable and simple appearance design, and is suitable for manual operation, inspection and maintenance. It is very maneuverable.

Closed Mechanism

The whole liquid packaging machine adopts a closed mechanism, which can well prevent dust from entering the machine content during the packaging process. Able to guarantee the aseptic process of the entire packaging.

External Film Release

The liquid packaging machine adopts an external film release design, which makes the replacement of the packaging film easier.

Multifunction

Liquid packaging machine can complete the whole process from liquid metering, filling, bag making, date printing to finished product in one go.

Bag Length Control

Liquid packaging machine can control the adjustment of the length of the packaging bag through the computer. There is no need for you to change the gear of the machine or the length of the bag.

4.What Are the Main Components of Liquid Packaging Machines?

The liquid packaging machines are main consisting of liquid filling device and liquid sealing device.

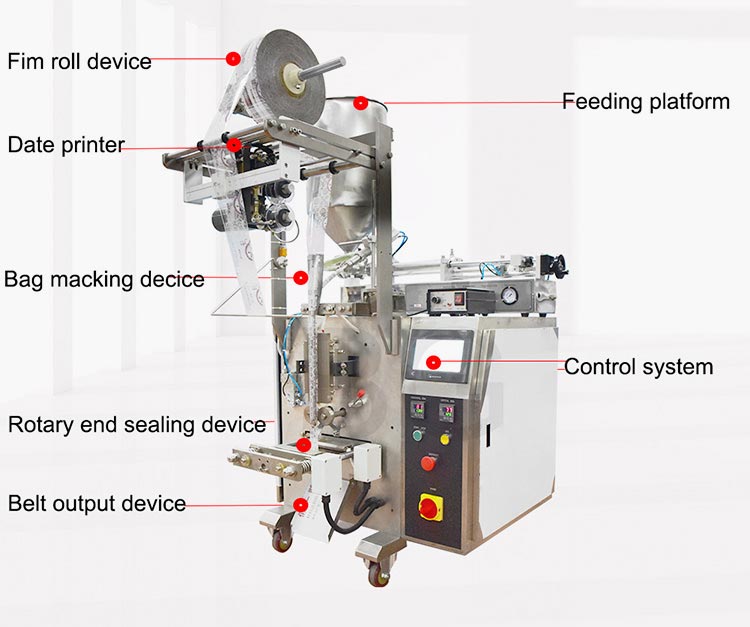

Structure of Liquid Packaging Machine

There are seven main parts of the liquid packaging machine including film roll device, date printer, bag making device, rotary end sealing device, belt output device, control system, feeding platform.

Control System

The control system also called as the touch screen panel, is designed for controlling the startup, stopping, the automatic mode, self-test, self-cleaning, self-maintenance, etc.

Feeding Platform

The feeding platform also called as the feeding hopper, is designed for feeding the liquid materials for packaging.

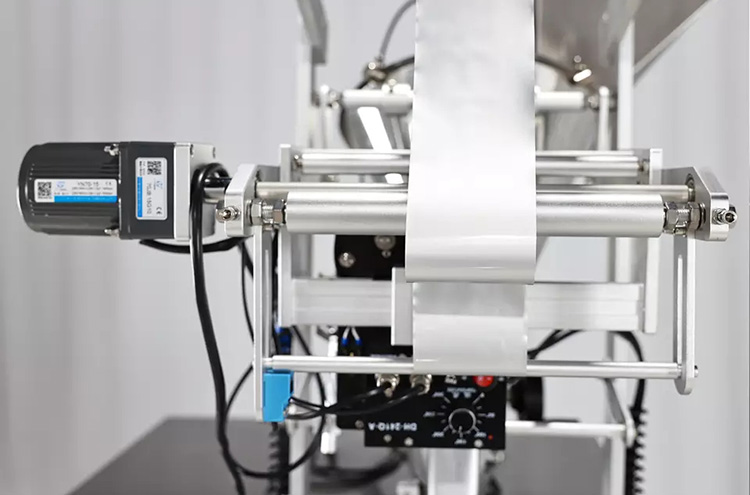

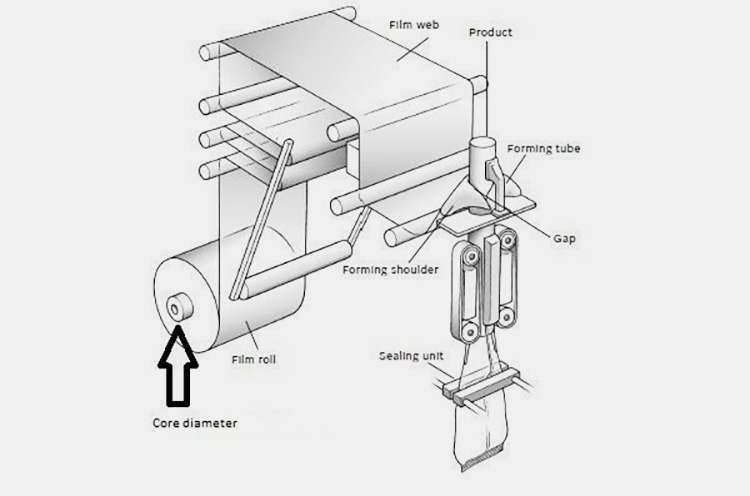

Film Roll Device

Film roll device also called as automatic film roll, is designed for controlling the up and down of the rolls for making up the bag for the liquid filling.

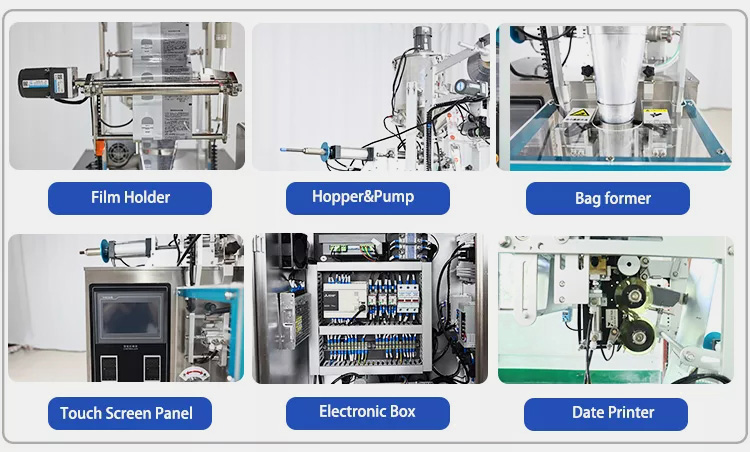

Components of Liquid Packaging Machine

Date Printer

Date printer also called as inkjet printer, is designed for printing the product information like production date and expiration date in the roll film.

Automatic Metering Pump

The liquid packaging machine adopts the cylinder stroke measurement, and the data can be linked with the distributor.

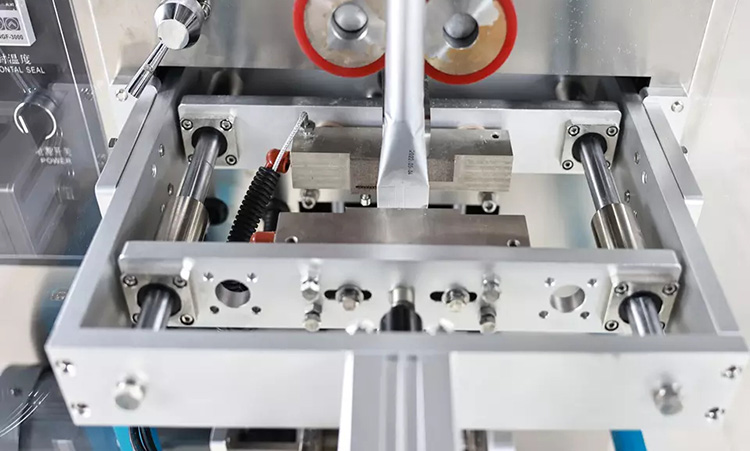

Bag Making Device

Bag making device is designed for making the roll films into the bags like sachets or pouches to fill and seal the liquids.

Rotary End Sealing Device

Rotary end sealing device also called as the sealer is designed for firmly and nicely sealing the liquid sachets and pouches and this is the last step for the liquid packaging machine.

Belt Output Device

Belt output device also called as output hopper, is designed for outputting the finished product by the liquid packaging machines.

The parts of liquid packaging machines are fine designed which is easy for you to operate and maintenance.

There are other machine components of the liquid packaging machines.

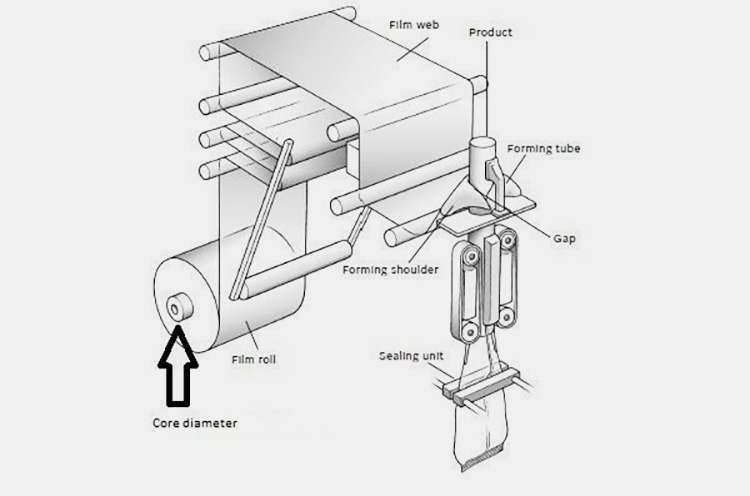

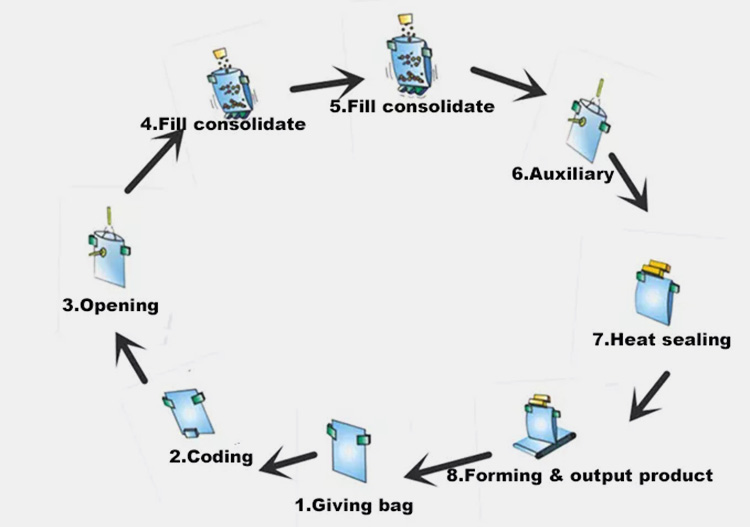

5.What Are the Working Principles of Liquid Packaging Machines?

The whole working process of the liquid packaging machine is automatically controlled and no human intervention. The key working principle of the liquid packaging machine is feeding, mixing, packaging, sealing and cutting, output.

Working Process of Liquid Packaging Machine

Liquid Packaging Principles

The liquid packaging machine mainly relies on the monitoring and control of the flow, pressure, temperature and other parameters of the liquid material itself, and then supplies the packaging materials to the packaging station through an automated centralized supply system to complete the filling and packaging of the liquid.

Feeding

Liquid filling can be divided into atmospheric filling, pressure filling and vacuum filling. Liquid packaging machine mainly adopts the way of normal pressure filling.

Mixing

The Liquid packaging machine introduces the liquid material to be packaged into the silo of the liquid flexible packaging machine by using a pumping device and mixes it.

Packaging

Liquid packaging machine uses pneumatic ball valve to quantitatively flow out the liquid material, so that the liquid material comes to the cylindrical bag through the plastic film and bag making machine. In the end, the liquid is filled by its own gravity.

Sealing and Cutting

When the processed liquid material is automatically filled into the bag, the packaging bag passes through the heat sealing device according to the set procedure. The heat sealing device seals the liquid-filled packaging bag strongly by heating the sealing strip.

Following the working principles, finally the liquid packaging machine output individually packaged products.

6.What Are the Types of Liquid Packaging Machines?

From the view of machine design, there are vertical liquid packaging machine and horizontal liquid packaging machine.

Vertical Liquid Packaging Machine

The vertical design of the liquid packaging machine has multi-functions including filling, labeling, sealing, counting, bag making. With the production capacity of 20bag/min, 40bag/min, 25bag/min, 50bag/min, 30bag/min, it can fulfill the pillow sealing, stand-up sealing, and punching.

Working Principles of Vertical Liquid Packaging Machine

The liquid and pastes will be uploaded into the feeding hopper. The liquids will be sucked into the cylinder by the piston pump. The film will be formed a bag and sealed by the bag former with the vertical sealing device, and liquids will be weighed and injected into the bag. The bag will be sealed and cut by the horizontal sealing device. The finished product will be transferred from the output.

Horizontal Liquid Packaging Machine

The horizontal design of the liquid packaging machine can make the three or four sides liquid pouch filling and sealing. With the production capacity of 20bag/min, 40bag/min, 25bag/min, 50bag/min, 30bag/min, it can fill different liquid, paste, and cream products such as water, oil, milk, juice, ketchup, tomato sauce, peanut butter, honey.

Working Principles of Horizontal Liquid Packaging Machine

When the horizontal packaging machine starts to operate, the weighing control system of the machine starts to automatically add materials. This machine has fast and slow feeding methods for you to choose. At this point, the bag-making device of the system starts to operate, and the made packaging bags start to be clamped. The weighed liquid material starts to be packed into the prepared bag automatically. After the heat-sealing device seals the packaging bag, the packaging bag will automatically fall off to the conveyor belt.

From the view of filling forms, there are sachet liquid packaging machines, and doypack liquid packaging machines.

Sachet Liquid Packaging Machine

Sachet liquid packaging machines are specially applied for filling and sealing the liquid sachets or small pouches or small bags. With little volume each time, sachet liquid packaging machines are more accurate for weighing and packaging liquid materials.

Working Principles of Sachet Liquid Packaging Machine

The liquid packaging machine mainly relies on the monitoring and control of the flow, pressure, temperature and other parameters of the liquid material itself, and then supplies the packaging materials to the packaging station through an automated centralized supply system to complete the filling and packaging of the liquid.

Doypack Liquid Packaging Machine

Doypack liquid packaging machines are specially applied for filling and sealing the liquid pouches or stand-up pouches. This machine can make the doypack and complete the filling and sealing process at the same time with high efficiency.

Working Principles of Doypack Liquid Packaging Machine

Doypack liquid packaging machines automatically print the date and batch number related information on the film through the printer, and use heat-sealable packaging materials to automatically complete the bag making. The finished product bag is a stand-up bag. Different forms of filling machines are selected to automatically fill liquid materials. The filled material is sealed by a relatively independent sealing system.

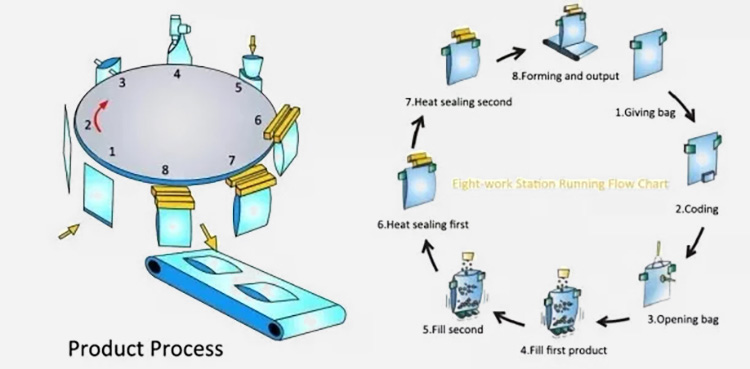

From the view of packaging ways, there are rotary liquid packaging machine.

Rotary Liquid Packaging Machine

Rotary liquid packaging machines refer to the machine can complete the liquid filling process that the packaging container rotates at a constant speed along the circumferential direction. Rotary liquid packaging machine can finish the filling and sealing of stand-up pouch, premade pouches.

Working Principles of Rotary Liquid Packaging Machine

The rotary liquid packaging machines adopts the continuous perfusion, and sealing the liquids and pastes. The giving bag will be coding at the first step, and then the bag will be opened for the filling. During the filling process, the packaging bags rotates at a constant speed along the circumferential direction, and the filling are completed at the same time during the movement. After that, the bag will be sealed by the heat sealing unit. Finally, the bag will be formed and transferred to the output conveyor.

With all those types of liquid packaging machines, there must be one type can suit your needs.

7.What Kind of Film Materials Can Be Applied for Liquid Packaging Machines?

There are various films that can be applied to pack the liquid materials. Most of them are cheap price and good quality, non-toxic and food grade.

PP

PP also called as polypropylene, is a polymer made of propylene through addition polymerization. PP has excellent heat resistance, high-strength mechanical properties and good high wear-resistant processing properties, etc., and is an excellent packaging material.

PE

PE also called as polyethylene, is a kind of thermoplastic resin obtained by polymerization of ethylene. Polyethylene is odorless, non-toxic, feels like wax, has excellent low temperature resistance, and has good chemical stability. PE is often used to make films and packaging materials.

PVC

PVC also called as polyvinyl chloride. PVC are widely used in building materials, industrial products, daily necessities, pipes, wires and cables, packaging films, bottles, foaming materials, sealing materials, fibers, etc.

PET

PET also called as polyethylene terephthalate, creep resistance, fatigue resistance, friction resistance, good dimensional stability. This material is very suitable for use as packaging material.

PVDC

PVDC also called as polyvinylidene chloride, has the characteristics of flame resistance, corrosion resistance and good air tightness. PVDC can be made into sheets, pipes, moldings, films and fibers, and is often regarded as an excellent type of packaging material.

OPP/CPP

OPP also called as o-phenylphenol, is an important fine organic chemical product. OPP is mainly used as packaging material in the food industry.

With all these film materials, you have plenty choices.

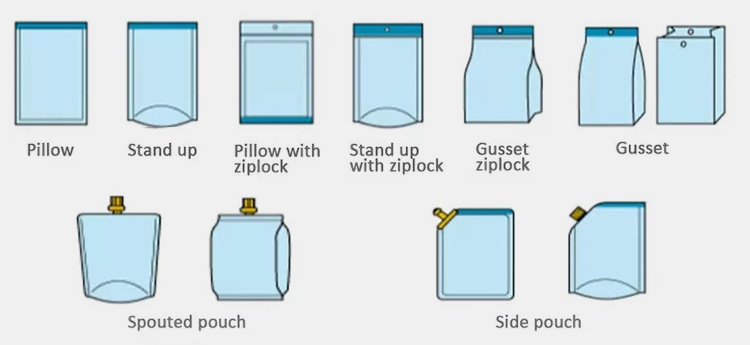

8.What Are the Packaging Forms By Liquid Packaging Machines?

The packaging forms includes packaging types, sealing types and cutting types. Different packaging forms have different uses.

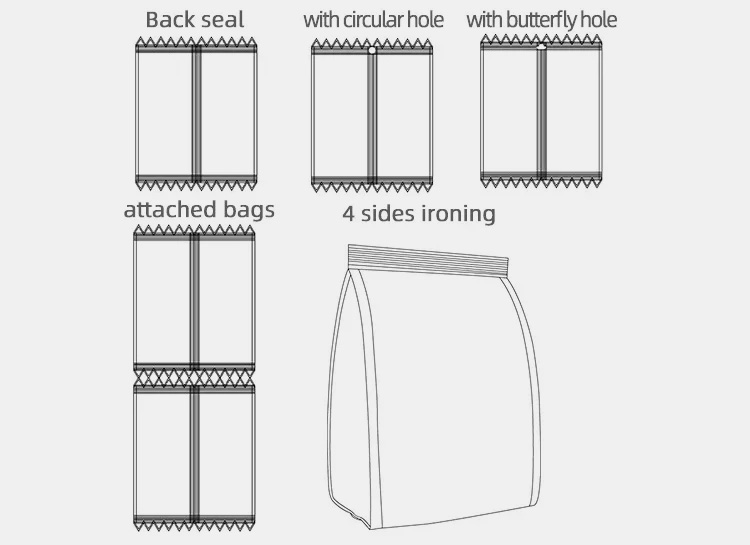

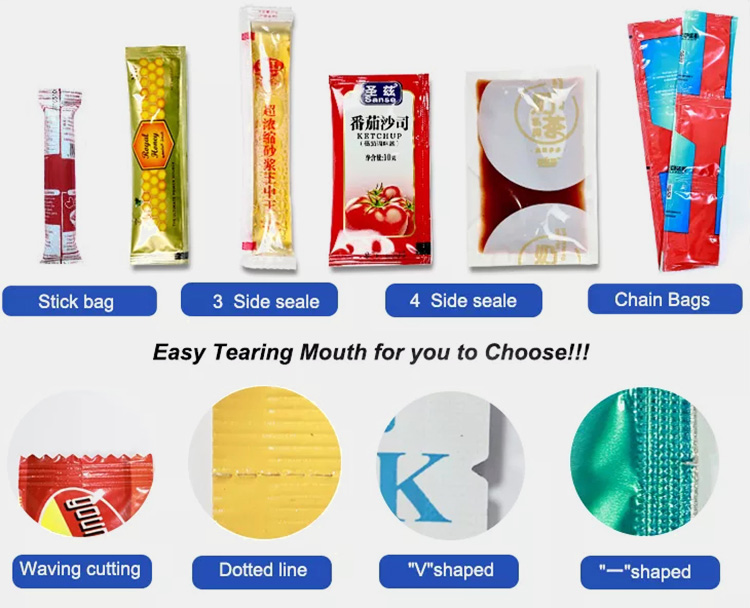

Packaging Types

From the view of bag packaging ways, there are bag packaging types of pillows, stand-up pouches, pillow with ziplock, stand-up with ziplock, gusset with ziplock, gussets, spouted pouches, side pouches.

Bag Packaging Types

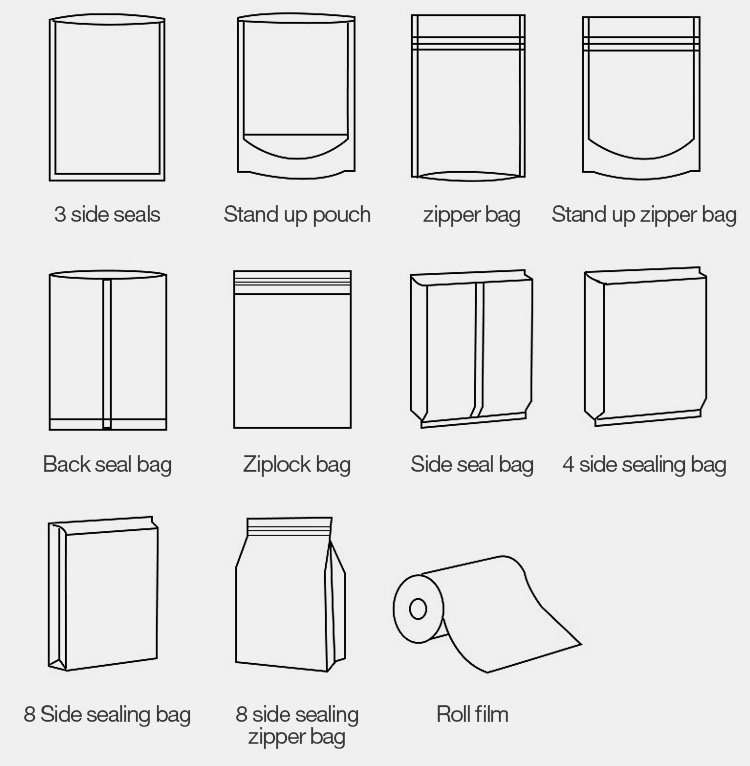

Sealing Types

From the view of sealing ways, there are bag sealing ways, there are 3 side seal, stand-up pouch seal, zipper seal, stand-up zipper seal, back seal, ziplock seal, side seal, 4 side seal, 8 side seal, 8 side seal zipper.

Bag Sealing Types

Cutting Types

From the view of cutting ways, there are back seal with circular hole, back seal with butterfly hole, back seal with attached bags.

There are waving cutting, dotted line cutting, ‘V’ shaped cutting for you to choose.

Cutting Types

There must be one packaging type, sealing type, and cutting type that will suit your need!

9.What Are the differences Between Liquid Packaging Machines and Powder Packaging Machines?

There are various differences between liquid packaging machines and powder packaging machines, and they are machine design, machine function, machine structure, machine working principles.

Machine Design

Liquid Packaging Machine

Liquid packaging machine is mainly consisting of liquid filling and liquid sealing. Liquid filling is mainly consisting of atmospheric filling, pressure filling and vacuum filling.

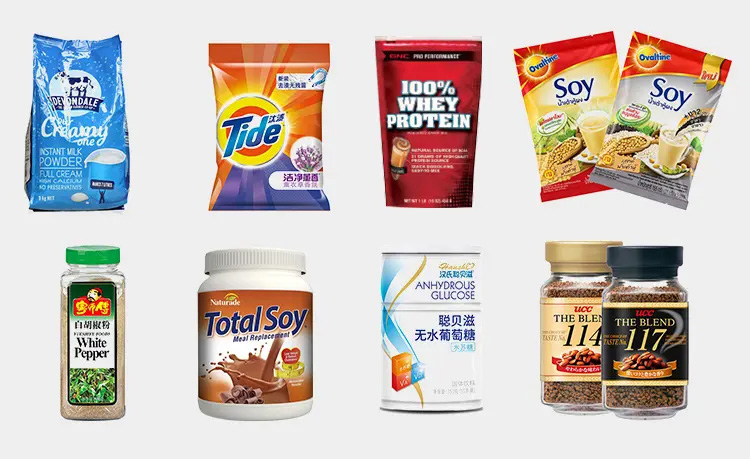

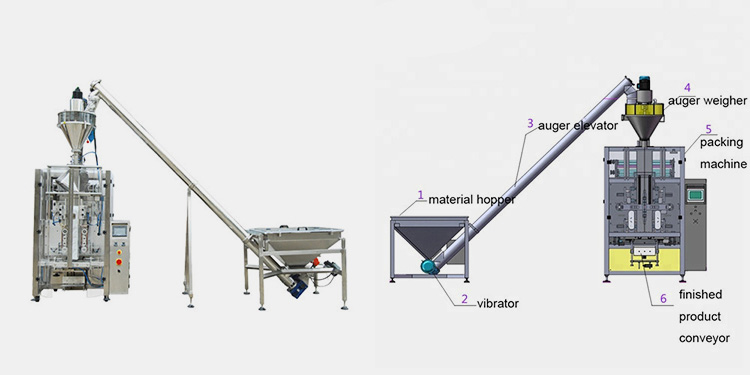

Powder Packaging Machine

Powder packaging machine is mainly consisting of powder filling and powder sealing. Powder filling is mainly consisting of screw powder filling, vacuum powder filling, and net weight powder filling.

Machine Function

Liquid packaging machines are mainly applied for filling and sealing liquid products such as fruit juices, various beverages, soy sauce, vinegar, ketchup, milk, yogurt, etc.

Liquid Packaging

Powder packaging machines are mainly applied for filling and sealing powder products such as powdered medicines, sugar, coffee, fruit, tea, monosodium glutamate, salt, seeds, desiccant, etc.

Powder Packaging

Machine Structure

The main structures of liquid packaging machine are consisting of film roll device, date printer, bag making device, rotary end sealing device, belt output device, control system, feeding platform.

Main Structure of Liquid Packaging Machine

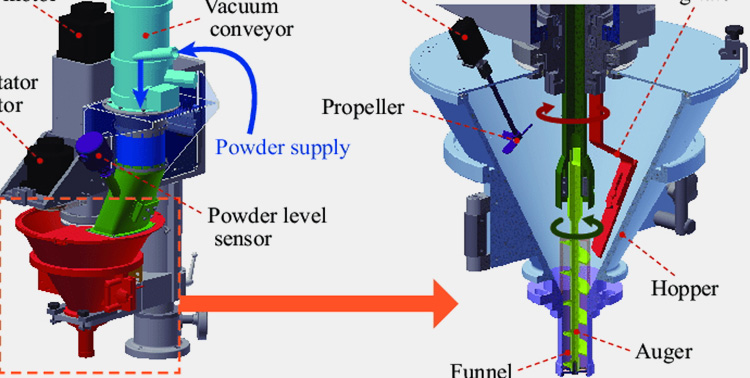

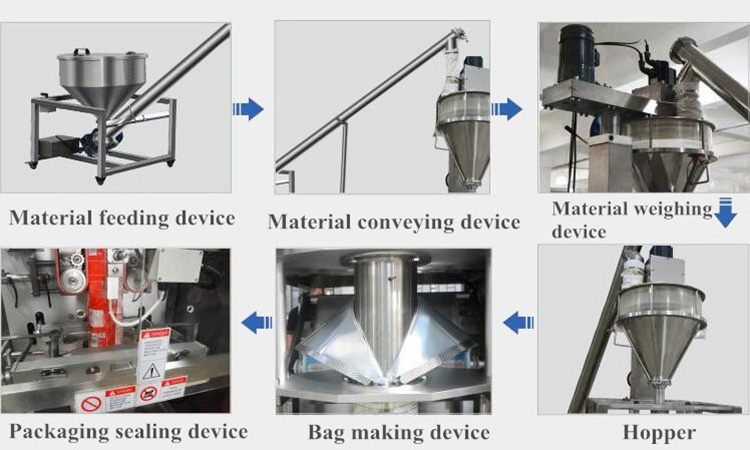

The main structures of powder packaging machine are consisting of material hopper, vibrator, auger elevator, auger weigher, packing machine, finished product conveyor.

Main Structure of Powder Packaging Machine

Material Filling Way

The liquid filling way of liquid packaging machine is by the liquid’s own gravity, atmospheric filling, pressure filling and vacuum filling.

The powder filling way of powder packaging machine is by the auger filler. The auger filler is equipped with the weighing sensor which can weighing the powders precisely.

Powder Filling

Machine Working Principles

The working principles of liquid packaging machine are feeding, mixing, packaging, sealing and output.

The working principles of powder packaging machine are powder dosing, powder filling, bag forming, bag sealing and cutting.

Working Principles of Powder Packaging Machine

The liquid packaging machines can not applied for packaging powders, and the powder packaging machine also can not applied for packaging liquids.

10.What Are the Precautions Should Be Taken When Operating Liquid Packaging Machines?

When operating the liquid packaging machine, you need to notice the precautions and conduct the power-on inspection carefully.

Clean the Machine

You should check all parts of the machine for foreign matter or oil and dust. Before starting, you should clean and wipe down the airframe.

Check the Machine

Before starting the machine, you should carefully check whether all parts of the machine are in the correct position. Whether the connection between parts is firm.

Adjust the Machine

You should check and adjust the pressure adjustment knob, air inlet fitting, air pressure gauge, drain valve, support, feed tank, etc.

Power Ups

You should connect the power cord of the packaging machine to a power supply with AC220V, 50HZ, and a good and reliable grounding device.

Set Packing Speed

You should set and adjust the packing speed as soon as the machine is powered on.

Check the Bag

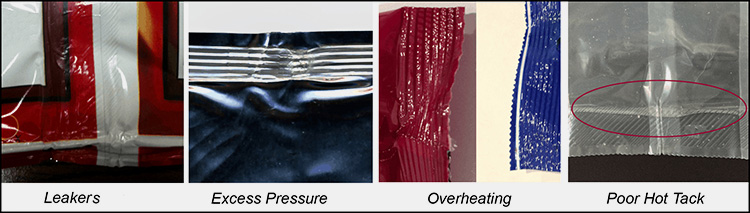

After the machine is working normally, you should randomly check the sealing quality, measurement accuracy, pattern and integrity of the finished bag at any time.

Check the Printer

After sampling the packaging bags, you should check the clarity of the printed production date or batch number on the packaging bags in time.

Regular Boot

When the equipment is not used for a long time, it should be restarted to run the machine every 30 days.

You need to learn all these precautions before you running the liquid packaging machines.

11.What Are the Error and Its Remedies During the Liquid Packing Machine Working Process?

Any machine will have errors if it is not operated properly. The liquid packaging machines are no exception. Therefore, you will learn about the following problems that liquid packaging machines will encounter during the specific operation process and its remedies.

Sealing Silicone Rubber Strip Damaged

![]()

Reason: The vertical and horizontal sealing silicone rubber strips were scratched by sharp objects, resulting in damage to the protective strips.

Remedies: You should replace the teflon tape on the silicone rubber strip regularly to ensure the sealing quality of the finished package.

Fuse F1 Is Blown

Reason: Short circuit between the heating wire and the horizontal head

Remedies: You should check for a short between the heating wire and the crosshead. If there is a short circuit, use Teflon tape for insulation.

Poor Quality of Vertical Sealing

Reason: The longitudinal sealing pressure is too large or the longitudinal sealing pressure is too small.

Remedies: You should adjust the vertical sealing pressure accordingly, and adjust the vertical sealing pressure to a moderate size.

Poor Quality of Horizontal Cutting

Reason: The heating effect of the heating wire cut off by the packaging bag is not ideal.

Remedies: You should adjust the electric pulse setting value in the heating wire, and set the electric pulse heating in the heating wire to a suitable value.

Liquid packaging machines have a long life with good and regular maintenance, but the sealing part receives the most tear and wear. So you need to pay a lot attention to this part.

12.What Are the Advantages of Liquid Packaging Machines?

Liquid packaging machines are corrosion-resistant, wear-resistant, and can work continuously.

316 Stainless Steel

The parts of liquid packaging machines in contact with materials are made of 316 stainless steel. Such a material design can overcome the influence of the corrosion of the machine when packaging pesticides.

PLC Control System

Liquid packaging machines use the touch screen technology of the PLC control system. This design can facilitate the staff to control the machine.

High Capacity

Liquid packaging machines are all automatically designed, there is no need for manual operation with high capacity. The average capacity can up to 60-100 bags per min.

Material Safety

Liquid packaging machines are fully self-filling and packaging, without the participation of staff throughout the process. This can greatly ensure the hygiene and safety of materials.

Cost Saving

Liquid packaging machines are fully self-filling and packaging, without the participation of staff throughout the process. This can greatly save manpower and material resources.

Wide Application

The liquid packaging machines can be applied in packaging the food liquids, chemical liquids, pharmaceutical liquids, and agriculture liquids.

There are so many choices to meet your needs.

Conclusion

With wide application and use, the liquid packaging machine can pack many different types of liquids. There are plenty types of liquid packaging machines for your choice. If you have any questions or problems about the liquid packaging machine, or you want to know more other types of packaging machine, you are always welcome to come to us.

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours