Lotion Filling Machine: The Complete FAQ Guide In 2025

Lotion Filling Machine: The Complete FAQ Guide In 2025

Many industries, whether small scale or large scale produce many products in the form of liquids. These products need to be stored in safe packaging which are then sent for shipping. In order to store these products, they need to be filled first. This filling is done by lotion filling machine which helps to fill the bottles with the liquid products. These filled products are then sent to their final destination.

Before buying this lotion filling machine, let us discuss in detail its features, applications, benefits and much more.

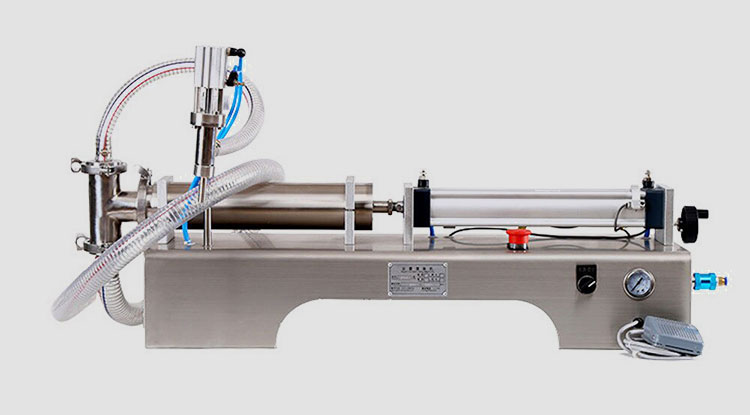

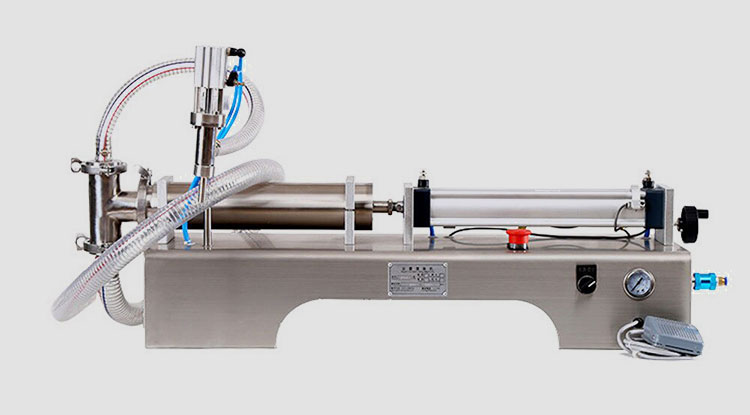

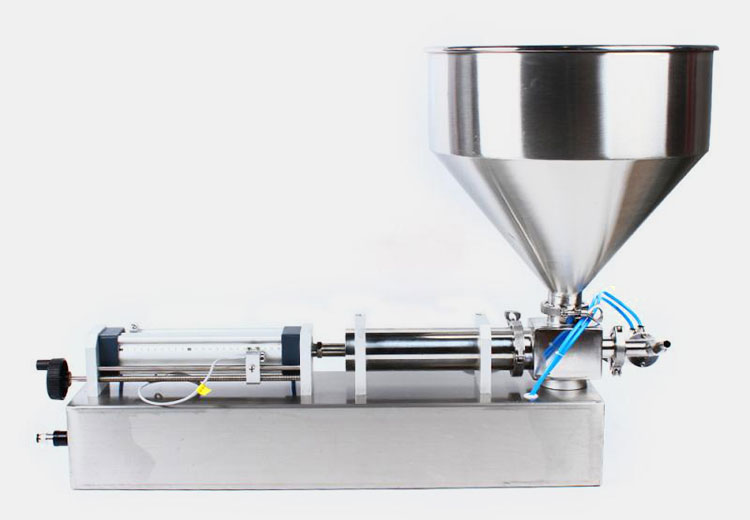

1.What is lotion filling machine?

Lotion filling machine, as the name suggests is used to fill lotion into bottles. This machine is used by several industries like pharmaceutical and cosmetic industries where they produce liquid products like lotion and fill it into bottles which are then sent for shipping.

All these industries need an efficient machine which would easily fill their liquid products in a safe and easy manner. For this reason they use lotion filling machine which is able to meet all the requirements given by these industries. Thus, this machine is an ideal option and its demand has been increasingly growing over the past few years especially due to a boom in cosmetic industry.

2.What is the working principle of lotion filling machine?

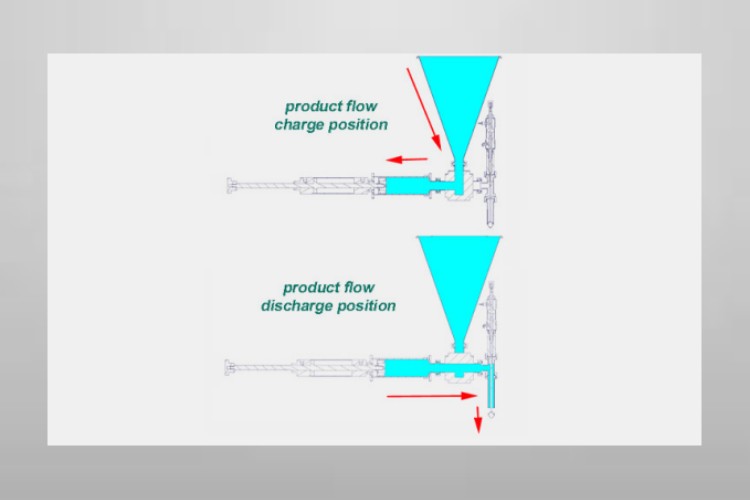

The working principle of lotion filling machine is dependent which type is being used to fill lotions in into the bottles or jars. The first and foremost task is to set the parameters with the help of control unit. This is specific to the company or the industries requirements. Next the tube/bottle is placed on the tube holder. After that, the machine pretty much does all the work given that the parameters have already been set. The machine then easily fills the lotion into the bottles, jars or tubes which is then transported to the next part of the production.

This working principle is almost same in all the types. However there are a few differences. In manual lotion filling machine, the operator would have to perform all the tasks manually. In semi-automatic lotion filling machine, he would have to place the tube in the tube holder. In automatic lotion filling machine, the machine does the whole work and the operator only has to monitor the whole process.

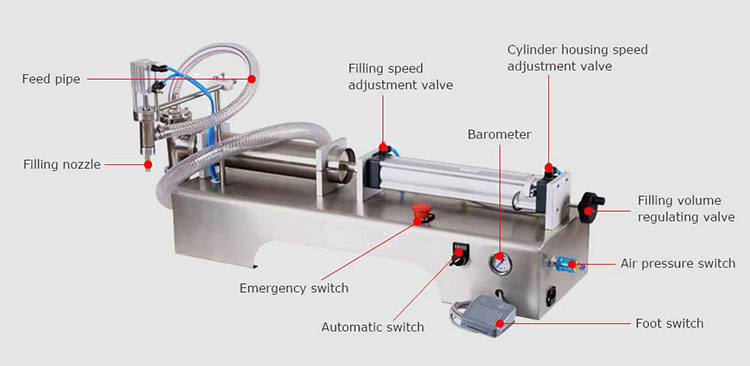

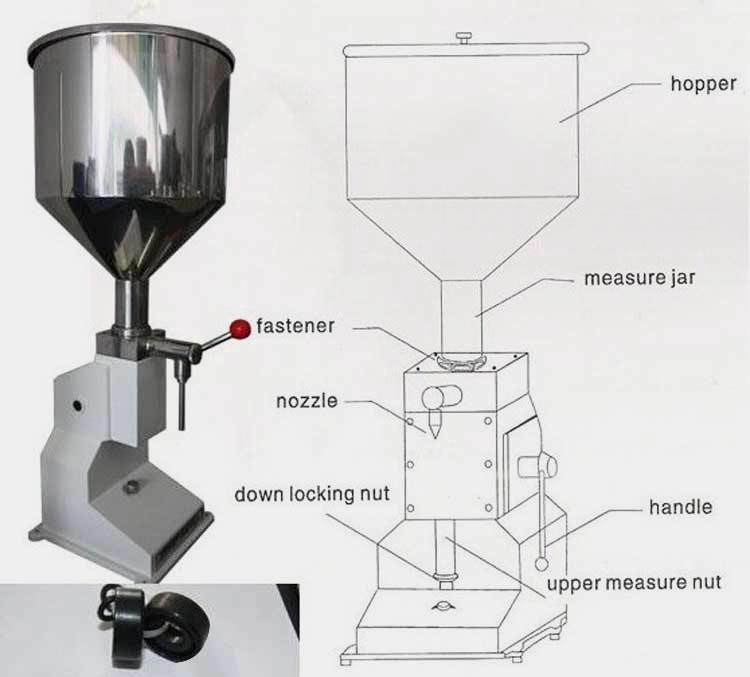

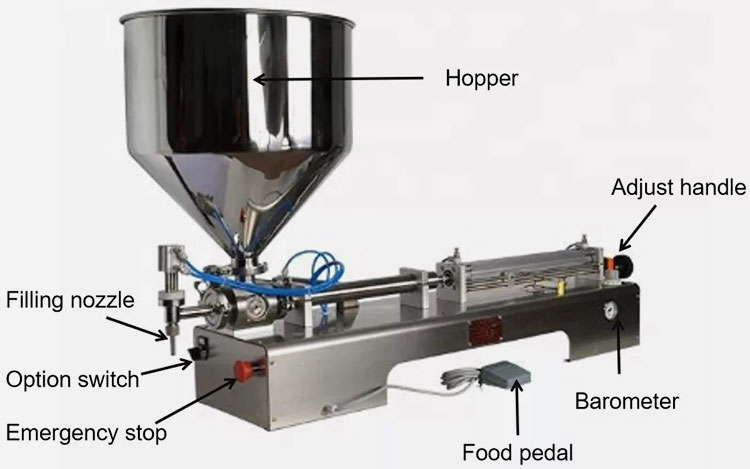

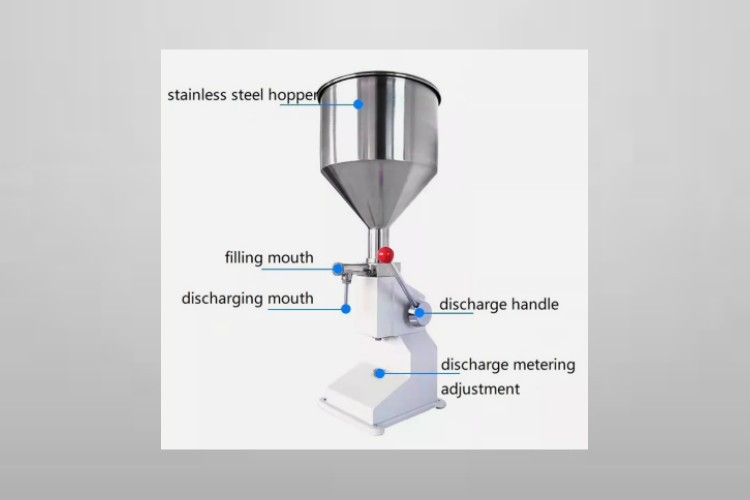

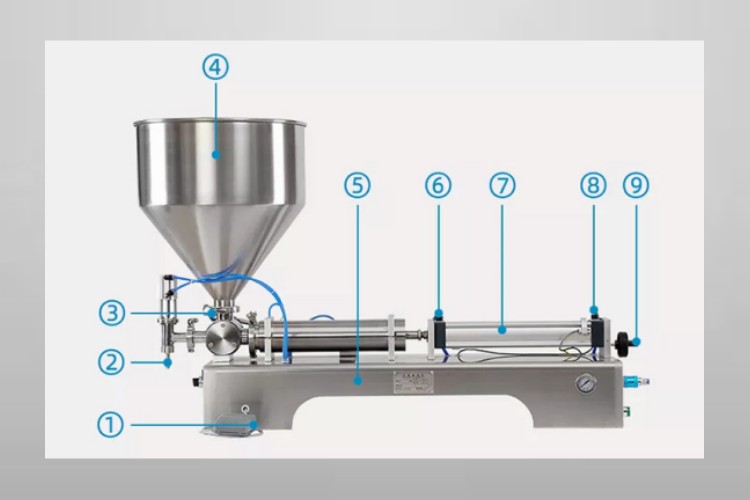

3.What are the components of lotion filling machine?

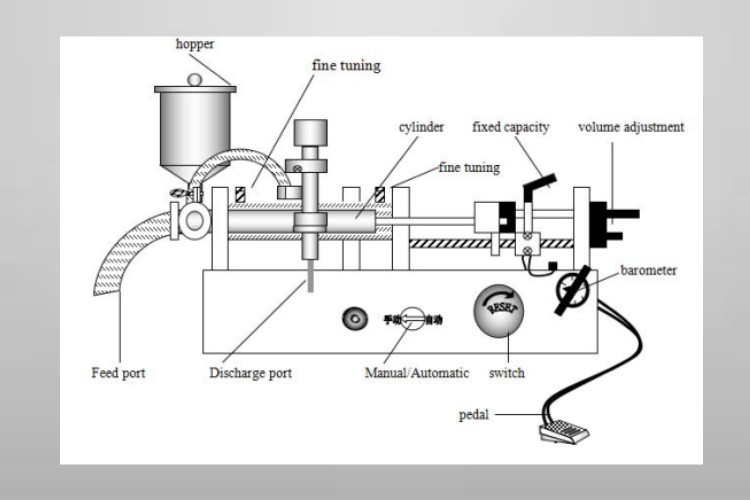

Lotion filling machines have various parts which are specialized to perform different functions. Let us discuss what each of these components do.

Frame: this is the main structure of the machine, without this, the whole machine would become non-functional. It holds and supports the internal components and also providessupport to the external components of the machine. It is made of stainless steel which protects it from corrosion or any damage.

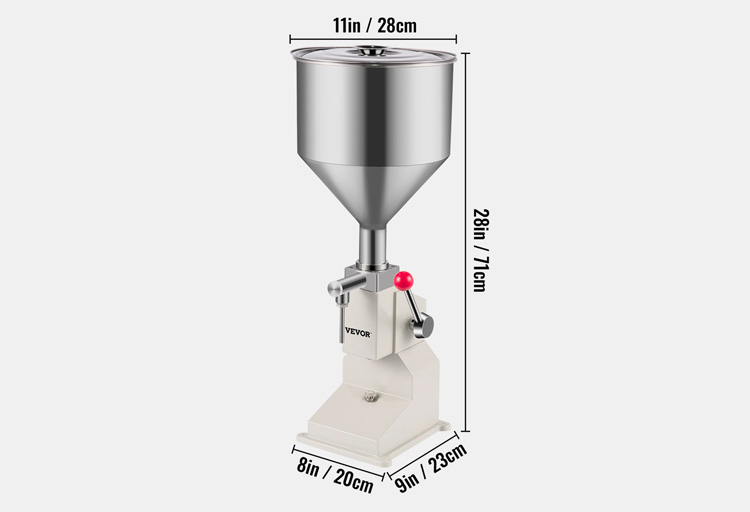

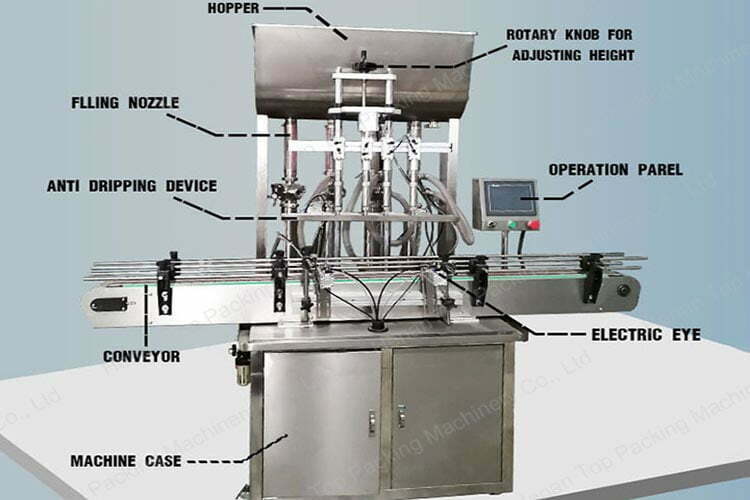

Tanks: Tanks are the main storage area where the lotion is placed before it is filled into bottles or jars. These tanks are placed higher than the machine so that during filling, the lotion can easily flow into the bottles due to gravity. They are customizableand can be manufactured in any design or size, depending on the customer’s requirements.

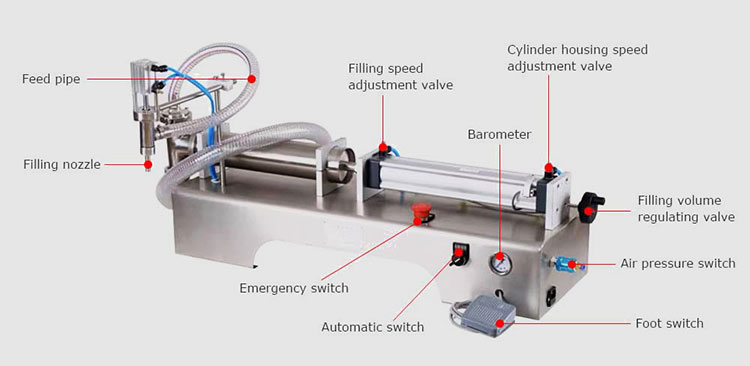

Filling nozzles:

Nozzles are used to direct the flow of the liquids from the filling machine into the bottles or jars for packaging. They must be designed according to the kind of liquid which is being filled since every liquid has its own surface tension and density, thus it requires specific nozzles.

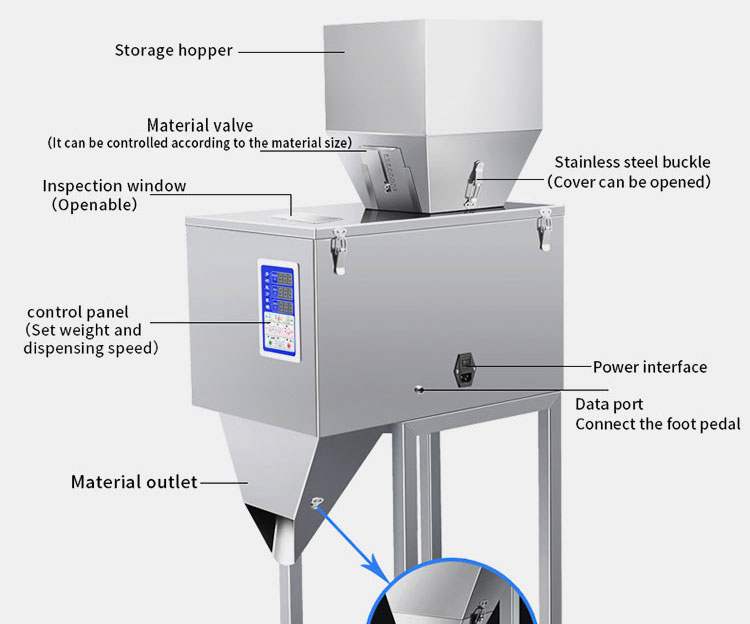

Control unit:

This is the main components which controls the whole process of lotion filling machine. It is an electronic based system on which all the parameters of the process are put ina trained worker who knows how to use the control unit is put in charge of it to monitor the whole process.

The coding jaws: these components are important in maintaining and readjusting the process according to the specific requirements. They help the machine in readjusting itself when different liquids are used to fill bottles of different shapes and sizes. They improve the overall efficiency and effectiveness of the machine.

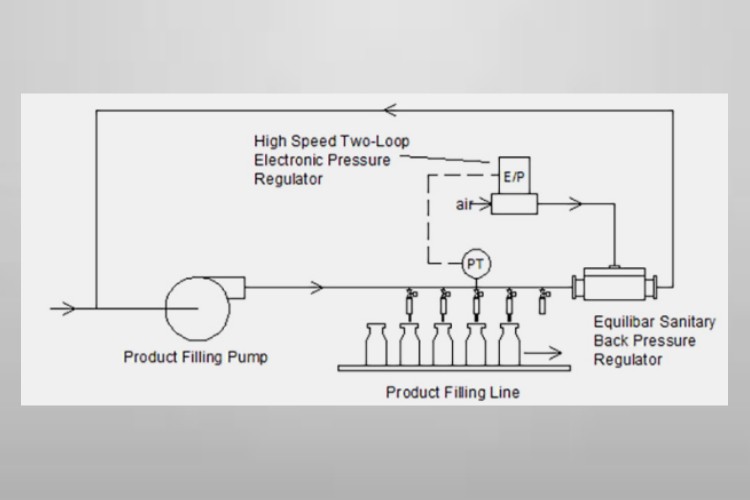

Discharge unit: this is one of the important part of machine which controls the amount of liquid which will be filled in the bottle, jar or tube. It decides how much liquid will be filled in the package, right from the tank till reaches the bottle for packaging.

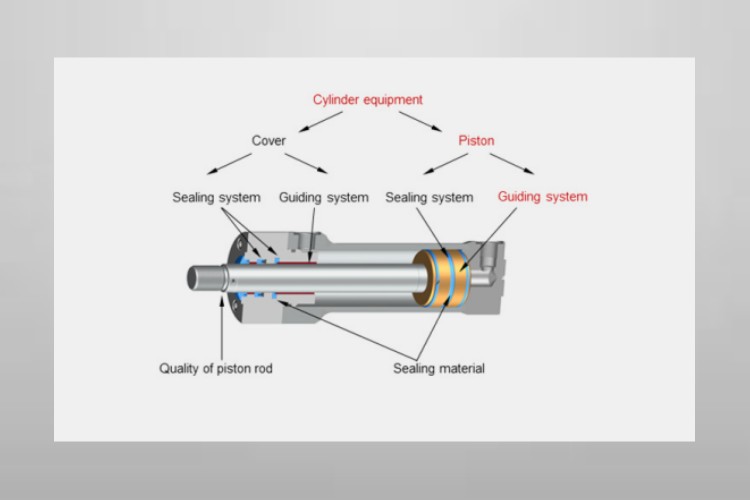

Dosing pumps: dosing pumps are a crucial part of machine which pumps the exact dosage of liquid into the bottle or tube. They control the rate of flow of liquid from the machine into the bottle.

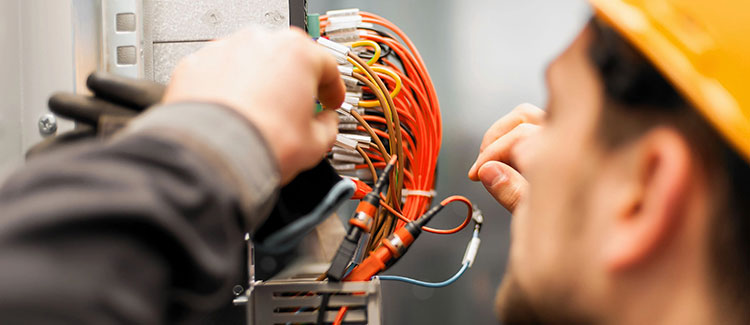

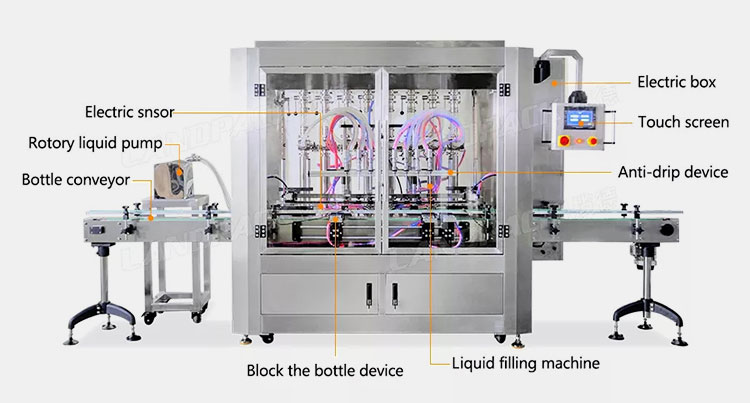

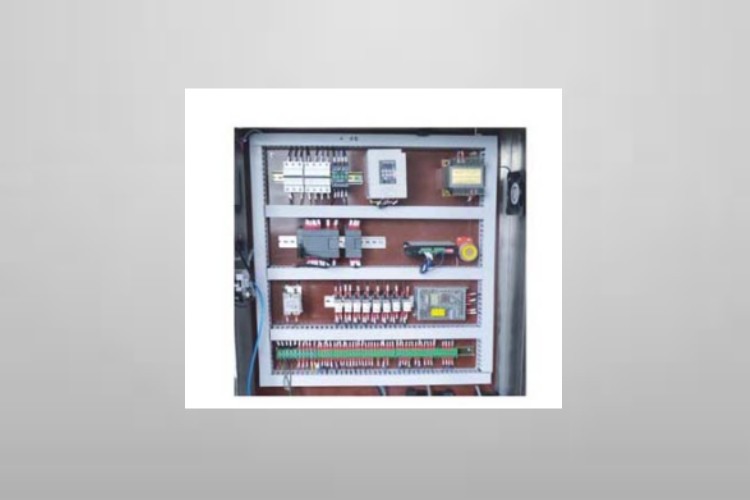

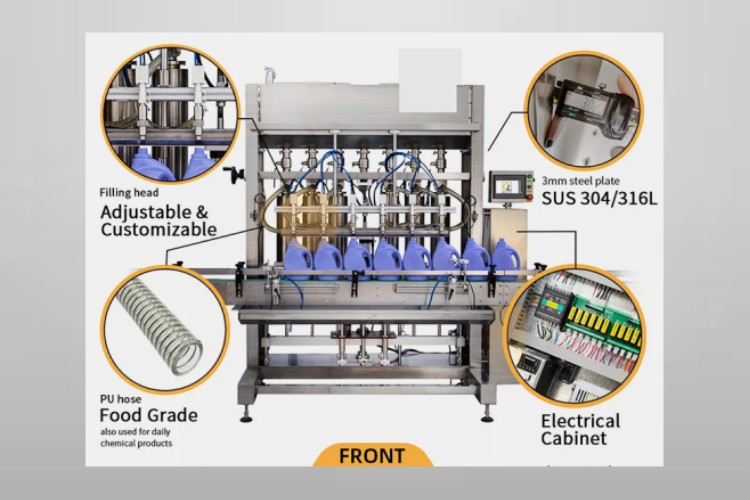

Electronic box:

Since the machine is powered with the help of electric current, it needs an area which can hold all the electric connections needed to run the machine. For this, the machine is provided with an electronic box which holds all these connections. Some of these parts are relay, air switch, transformer and PLC.

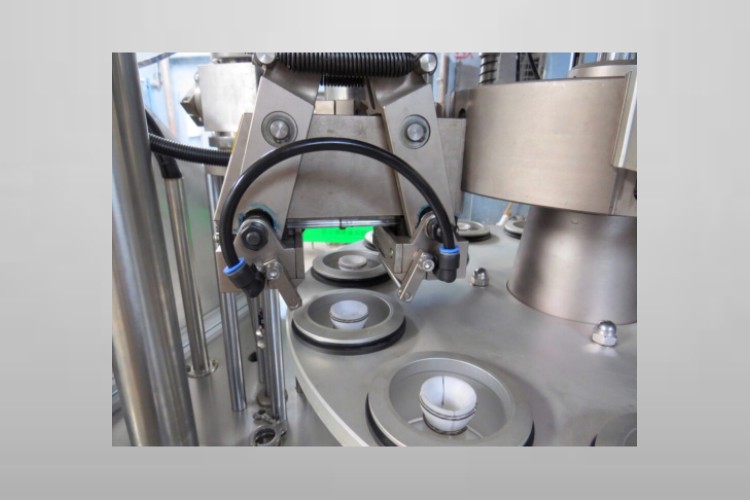

Tube holder:

As the name implies, this part is used to hold the tube or bottle in which the desired liquid will be filled. To ensure maximum efficiency of the filling process, the rotary speed of the machine can be adjusted which will rotate the tube holders accordingly.

Safety system: this part is essentially one of the most important one since it protects the machine and the operator from any harm by ensuring that the whole process is working efficiently and not pose any danger to the operator or the environment from getting damaged.

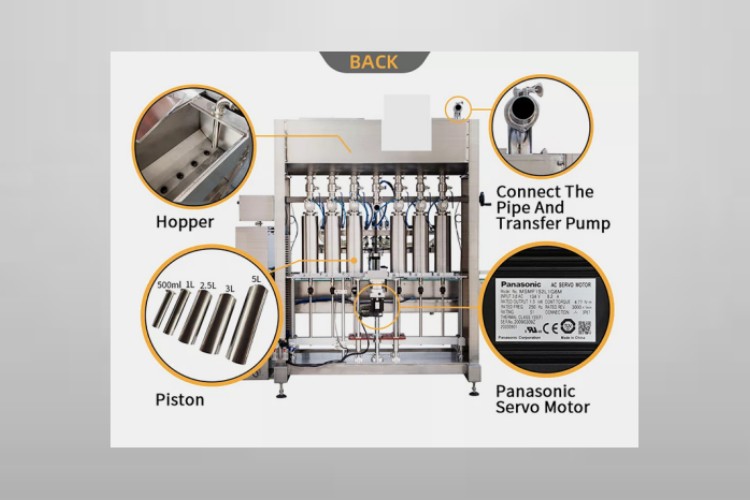

Motor: this is the most important components because it is the main force which keeps the machine operating. Without it, it will become non-functional. The motor is powered by an electric current which constantly supplies the energy to keep the machine running.

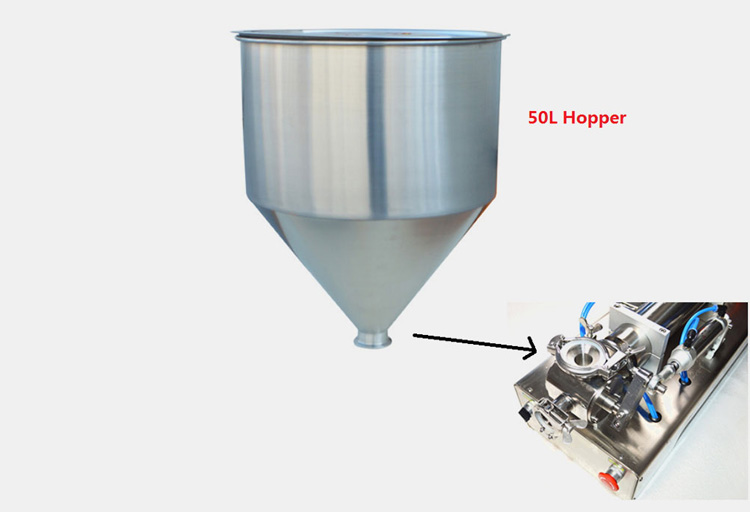

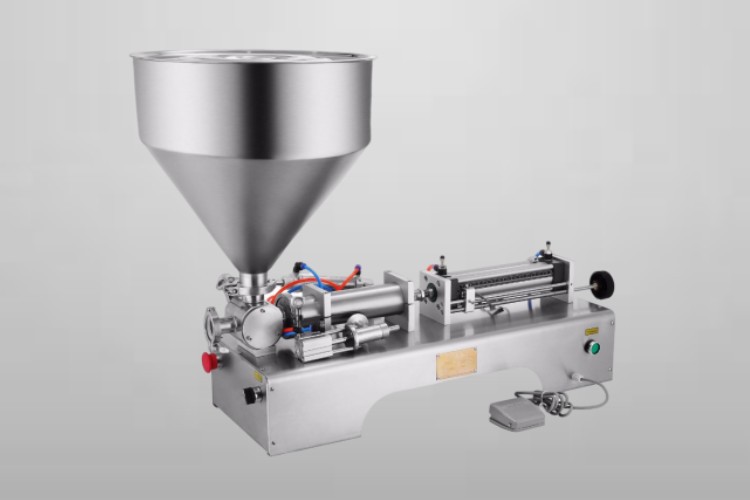

Hopper:

This part helps in mixing all the ingredients which then form the final liquid product.

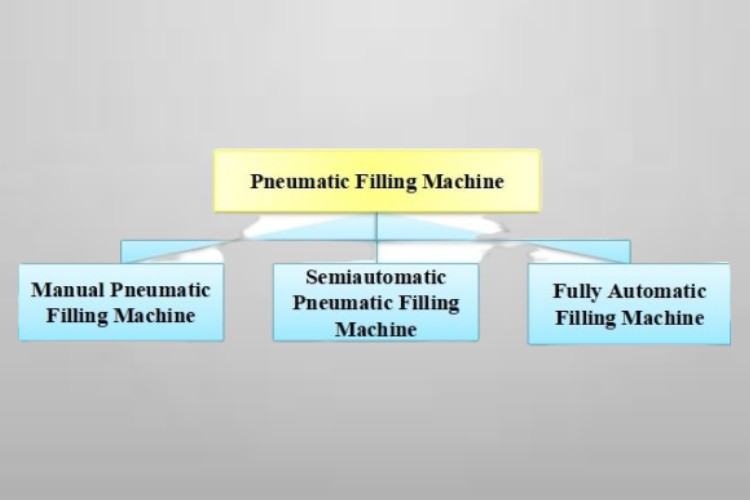

4.What are the types of lotion filling machine?

There are several types of lotion filling machines, each suited for specific purpose. Let us discuss each of these types below.

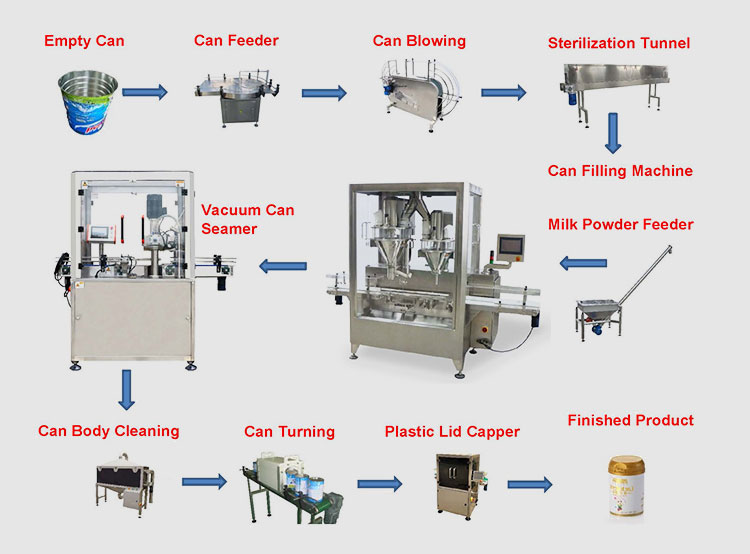

A)Fully automatic lotion filling machine

As the name suggests, this machine works almost on its own with very little involvement of manual labor. It is capable of controlling each aspect of the process. It automatically arranges the bottles in an orderly manner, fills them with the desired liquid, and closes them with specific lid and finally sends them for final packaging. The operator only has to monitor the process, using control panel.

Since the whole process is automated, this machine is able to fill thousands of bottles in a day, making the process extremely quick. They also prevent any kind of leakage during the filling process, showing the machines’ efficiency.

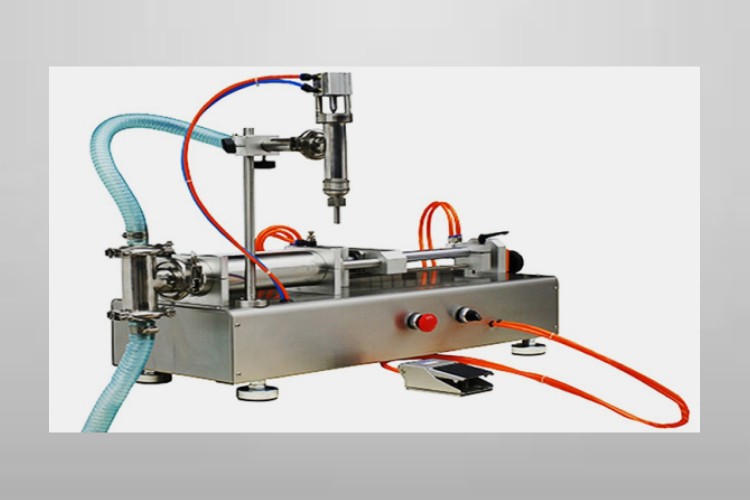

B)Semi-automatic lotion filling machine

This machine, as the name implies, is partly dependent on manual labor. Almost the whole filling process is automated. Manual labor is only required when the bottles need to be arranged in a specific manner so that the machine can fill them. The labeling of bottles also needs to be fixed by a worker.

C)Manual lotion filling machine

This machine, as the name suggests requires manual labor to operate the filling process. Although it is not automated, this machine is cheaper than the automatic or semi-automatic types and would be an ideal option for small scale business to install it in their production line.

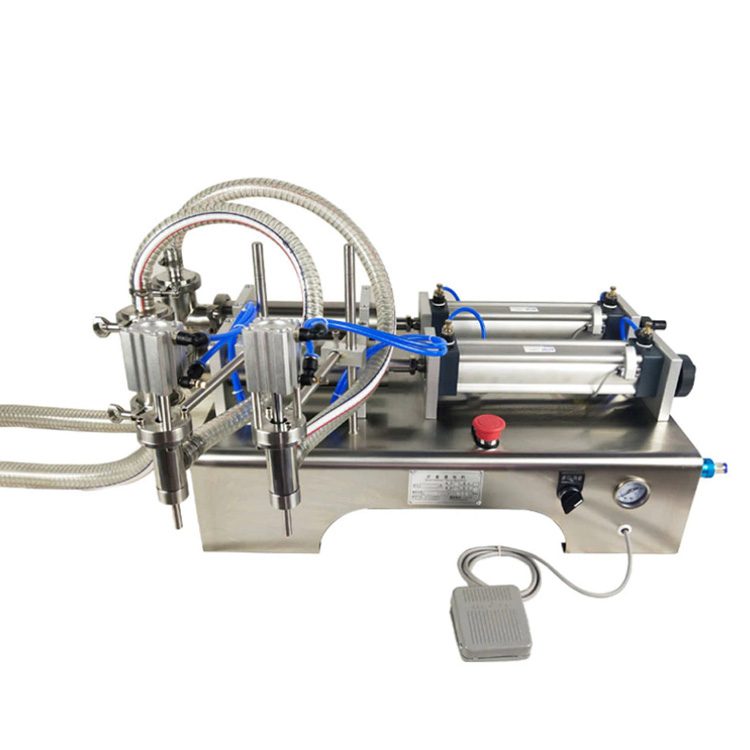

D)Twin head lotion cooler machine

This type of machine consists of two nozzles which are responsible for directing the liquid into the bottles. It enhances the efficiency and the production, increasing profits. It is ideal to use in large scale industries such as pharmaceutical, cosmetic, food, chemical industry etc. they are perfect for filling bottles with liquids such as milk, oil, soda drinks etc. moreover, they work pretty much on their own and do not need any human involvement.

F)Four head lotion filling machine

This machine has four filling nozzles and is ideal for filling those bottles which need accurate dosage and filling. The machine is run on a specific speed so that it is able to control the in feed and out feed.

G)Six head lotion filling machine

This machine has six filling nozzles which move around the conveyor belt. The bottles or jars which need to be filled are placed on the conveyor belt and the nozzles fill them with the desired liquid. The process is highly accurate and does not cause any kind of leakage.

Six head lotion filling machine is ideal for packaging viscous and semi-viscous liquids. It also needs involvement of manual labor and does not work completely on its own. The operator has to monitor the filling part of process through the control unit.

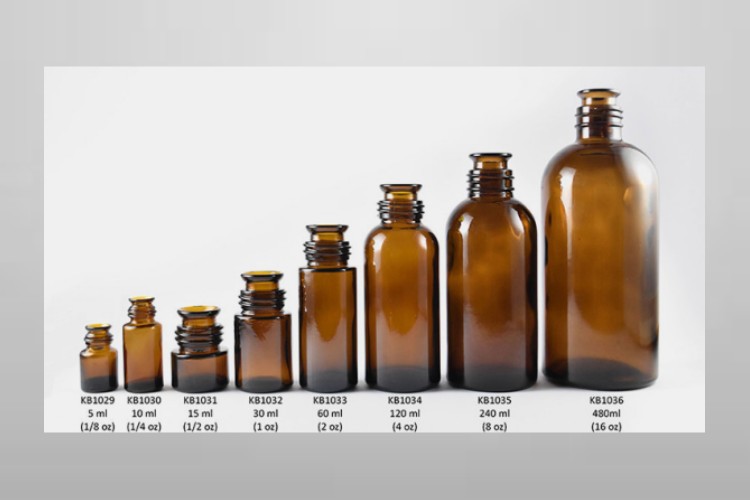

H)Lotion filling machine for vials

Lotion filling machine are also used to fill vials. These vials can be filled with various kinds of liquid in the form of viscous or suspension. They are perfect to use in pharmaceutical industries where medicinal liquids have to be filled with accurate dosage and prevent any spillage.

They are also used in industries like ophthalmic and animal health related industry.

I)Electronic lotion filling machine

As the name suggest, this type of machine is driven by electronic based system which require electric current to run. They are fully automated and are provided with various features like clutch brake, snap cappers, labelers, station cappers, turntables, conveyors etc.

5.Manual vs semi-automatic vs automatic lotion filling machine

Although the ultimate goal of these three types of machines is to fill the desired liquid into bottles, jars or tubes, they have a few differences as well. Manual lotion filling machine is the cheapest and the most reasonable one out of the three, thus it is ideal for small scale business or for those small scale industries who are looking for cheaper options.

Semi-automatic lotion filling machine lies in between the other two options. It costs more than manual lotion filling machine but is cheaper than automatic lotion filling machine. Thus it is ideal for those industries who are looking for an efficient machine with a reasonable cost.

Automatic lotion filling machine is the most efficient one and has the ability to fill the most bottles out of the other two. But it is the most expensive one among them, thus it can only be employed by large scale industries who would be able to afford it.

6.What are the advantages of buying lotion filling machine?

Using lotion filling machine comes with many benefits and one would not regret buying it and installing it in their industry since it has many advantages. Let us discuss them below.

Increased profit margin

Lotion filling machine has the capability to fill hundreds of bottles in a few minutes. This increases the overall production which is then quickly sent for shipping, thus increasing profits.

Easy to use

This machine is quite simple and doesn’t require complex methods in order to run, making it easy to use.

Accurate dosage

This machine accurately fills the desired liquid into the bottles or tubes. This factor is highly important in industries like pharmaceutical where accurate filling is critical to maintain the efficacy of medicines and prevent over dosage.

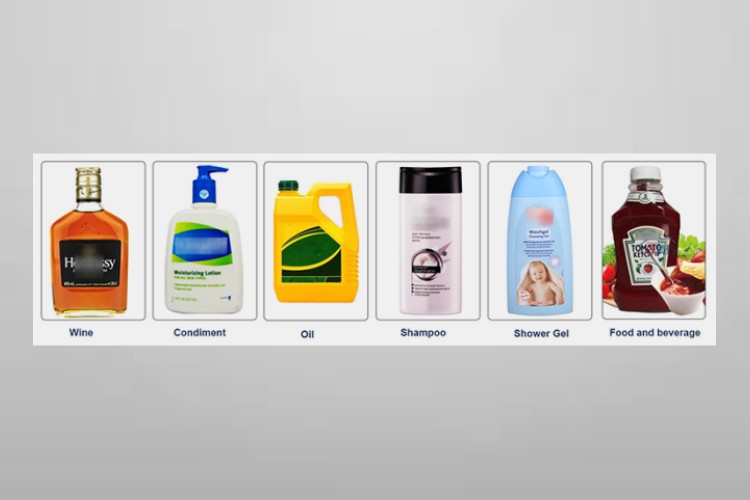

7.What are the applications of lotion filling machine?

Due to the number of features and benefits this machine offers, it is safe to say that lotion filling machine is a universal machine since it can be used in a number of industries. Let us discuss each of these industry below.

Pharmaceutical industry

This industry produces various medicines and drugs which are needed by the population either to cure their diseases or improve their lifestyles. Since it is a large scale industry, it produces thousands of medicines in a single day. Thus it needs a machine which would fill these medicinal drugs into bottles or tubes as quickly as possible in an efficient manner. Moreover, it also needs a machine which would safely complete this process in a hygienic way to maintain the potency of the drug and prevent it from contamination.

Lotion filling machine would easily meet all these requirements and fill the bottles as safely as possible.

Food industry

Food industry makes various food items like ketchup, sauces and ice creams which are filled into tubs, jars or bottles. Lotion filling machine is used for this purpose.

Chemical industry

This industry makes various chemical products like paints, solvents and other products which are then used in other industries. Lotion filling machine can fill these products into jars for final packaging.

Agriculture industry

Agriculture industry makes various compounds like herbicides, pesticides. This machine fills them in their desired packaging.

Cosmetic industry

This industry makes various beauty products like creams, lotion, serums and moisturizers. Lotion filling machine then packages these products into bottles, tubes and jars.

Veterinary industry

This industry provides medical treatment to animals and manufactures various medicinal drugs, creams, ointments and allergy creams for them. Thus this machine is used to fill them in bags and then sent to the markets for sale.

8.How to maintain lotion filling machine?

Just like every other machine which requires regular maintenance to work at maximum efficiency, this machine too needs to be maintained so that it works properly. Let us discuss what points need to be considered.

- Make sure you disconnect the machine when not using it so that it gets cooled down and can be used in future.

- Check every component of the machine like hopper, conveyor belt and discharge unit to see if they’re working properly.

- Lubricate the machine with oil to ensure proper working and prevent any friction.

- Check if the motor needs any fixing or not.

- Clean the machine thoroughly with brushes or cleaning fabrics. Remove any dust stains with soap and water.

9.Problems and solutions of lotion filling machine

| Problems | Solutions |

| 1) The motor is broken. | Replace the motor with a new one. |

| 2) Power supply has been disrupted, stopping the whole process. | Check if there is a broken electric wire and replace it with a new one. |

| 3) Conveyor belt has broken down. | Replace the belt with a new one. |

| 4) Some parts of machine such as hopper, filling nozzles, dosing pumps have been damaged. | Search for the new parts online or in market and replace it with the broken one. |

| 5) The speed of the machine is too high or low. | Adjust the speed to an appropriate level using control unit. |

10.What is the marketing strategy of lotion filling machine?

In order to attract customers into buying lotion filling machine, one needs to see what kind of features this machine offers so that it will easily convince the customer to buy it and install it in their production line.

Lotion filling machine is a very high speed machine, filling thousands of bottles in a single day. This will significantly increase the productivity, thus increasing the profit margin. It carries out the whole process in a safe and hygienic way, thus the customer doesn’t have to worry about his product getting contaminated, thus decreasing the possibility of losses. Moreover, it does not require complex maintenance and can be regularly with simple steps, thus reducing the cost of running this machine.

11.What quality standard should lotion filling machine conform to?

There are certain guidelines which need to be considered to ensure that the process is being carried out at highest quality level. These guidelines are:

International standard organization quality standard (ISO)

This gives the guidelines for quality control.

Food and drug admin quality standard (FDA)

This organization gives guidelines for public health protection.

Electronic quality standard (CE)

This ensures that the product being made is of a standard quality and is safe for public health and environment.

Current Good Manufacturing Practices Quality Standards (cGMP)

This ensures that the product which is being manufactured is made of high quality materials and it meets the current standards needed to pass the criteria which is issued by the organization.

12.What are the factors which need to be considered before buying the lotion filling machine?

Before buying lotion filling machine, one needs to check whether this machine would be able to meet all the requirements of the customer. These factors are:

Authenticity of the manufacturer

Before buying the machine from a particular manufacturer, check if that person is registered and has approved certification before finalizing a deal with them.

Space requirements

In order to decide which machine would be suitable for a particular business, the customer has to see what type of machine would be able to fit in his business. If he has a small workspace, manual lotion filling machine would be suitable for him whereas if he has huge workspace, he can easily install automatic or semi-automatic lotion filling machine in his production line.

Production capacity

Lotion filling machine has different types with different production capacity. Those who are looking for large production capacity should go for automatic lotion filling machine which can fill thousands of bottle in a single day, whereas those who are looking for small production capacity, manual lotion filling machine would be an ideal option.

Budget limitations

If a customer wants an affordable type of lotion filling machine, he should opt for manual lotion filling machine or semi-automatic lotion filling machine instead of automatic lotion filling machine which is the most expensive one among them and might be out of his budget.

Conclusion

After discussing in detail about lotion filling machine, we can easily say that this machine is totally worth the investment given the features and benefits it offers. It would be a great option to install this machine in your industry if you want to earn huge profits in a safe, secure, fast and efficient way!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Lotion Filling Machine: The Complete FAQ Guide In 2025 Read More »

Adaptability -photo credits: askingletterresume

Adaptability -photo credits: askingletterresume Oil Filling Machine -photo credits: vkpak

Oil Filling Machine -photo credits: vkpak