Tube Filler:The Complete Buying Guide In 2025

Tube Filler:The Complete Buying Guide In 2025

Welcome to the ultimate guide to buy a tube filler in 2025! If you’re in the market for a tube filler, you’ve come to the right place. Whether you’re starting a new business or upgrading your current packaging machinery, selecting the right tube filler can be a daunting task.

That’s where this guide comes in – In this buying guide, we’ll take you through everything you need to know about tube fillers in 2025. From their various types and sizes to their features and functionalities, we’ll cover it all.

So, get ready to fill up on knowledge about tube fillers as we answer some of the most pressing questions about them, such as:

1.What is a tube filler?

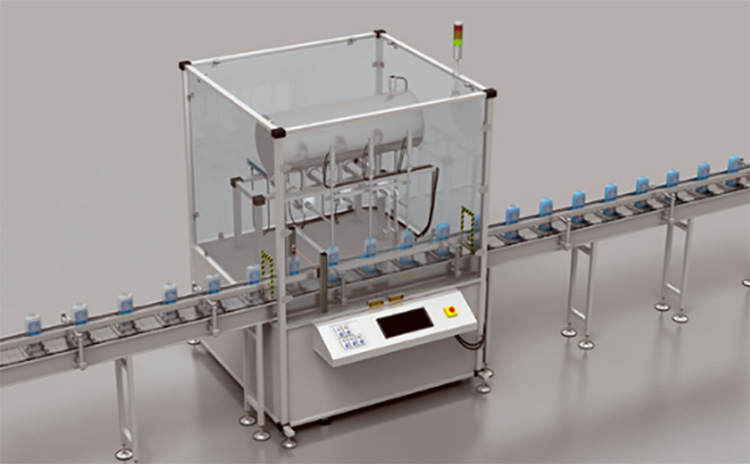

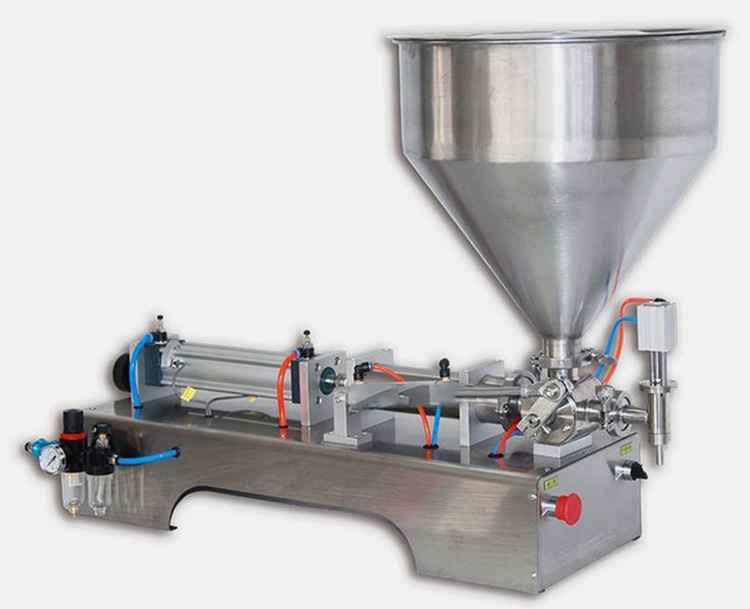

A tube filler is an innovative machine designed to carry out the function of filling various types of liquids into tubes such as toothpaste, cosmetic creams, and ointments.

It is capable of filling products of wide range having different viscosities and consistencies. Its precise and consistent filling ensures full accuracy.

In addition, tube fillers are frequently built with hygienic and sanitary characteristics to guarantee that the products being filled are not contaminated during the filling process.

This eventually makes the tube fillers crucial in industries who demands very high standards of cleanliness and product quality control.

2.How does the use of a tube filler benefit manufacturers?

The usage of a tube filler contributes several advantages to manufacturers, including:

Versatility:

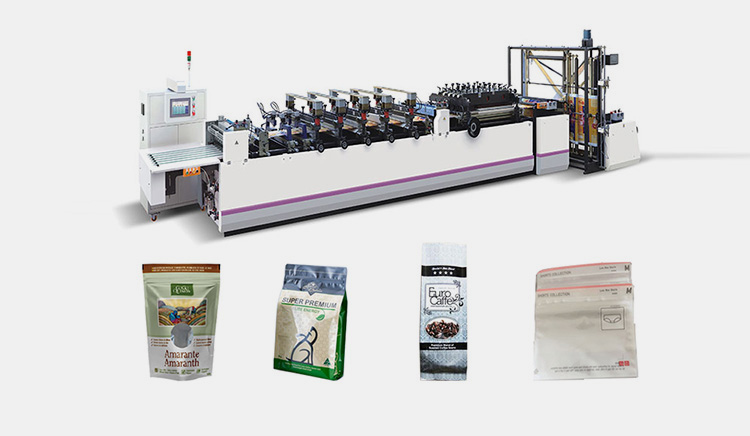

One of the major benefits of tube fillers is their area of jurisdiction. You can fill tubes of wide categories such as metal tubes plastic tubes or laminate tubes. In addition, there is no rigid system for same size tubes.

Easy to operate:

The machine is easily understandable once you have gone through the necessary precautions and initial steps. By using the touch screen display you can simply execute overall process.

Customization:

Manufacturers can meet the unique requirements of their clients thanks to the ability of tube fillers to fill tubes of all sizes and forms. By providing distinctive and specific package alternatives, this personalization can help manufacturers promote their brand.

3.In what industries or applications is a tube filler commonly used?

Some standard industries and applications where tube fillers are used include:

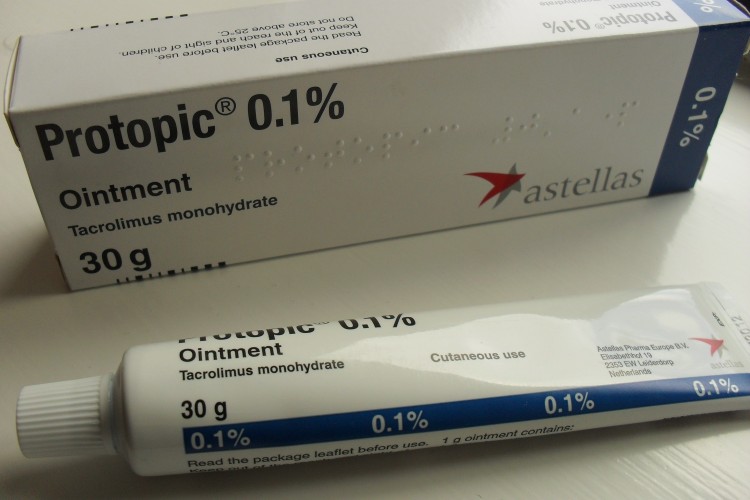

Pharmaceutical Industry:

Pharmaceutical industry is among the prominent sectors where tube fillers are used on large scale to fill tubes with creams, ointments, and other topical medications. Additionally, tube fillers are used to fill tubes with innovative products, such as transdermal patches, which deliver medication through the skin.

As pharmaceutical industry requires strict safety and hygienic standards tube fillers are here used which comply these safety regulations and fill the prescription medications, as well as over-the-counter products, such as pain relievers, anti-inflammatory drugs, and anti-fungal creams.

Pet Food Industry:

Tube fillers are used on large scale to fill the tubes with pet food, as pets can be easily provide with food through tubes. They can better fill tubes with various types of pet food, including wet food, soft food, and treats.

Tube fillers are ideal for packaging pet food products that require airtight seals to maintain freshness and prevent contamination.They are also used to fill tubes with unique pet food products, such as dental chews, vitamin supplements, and food toppers.

Cosmetics Industry:

Most of the cosmetics including cream, lotion, gels and other beauty products are commonly filled in tubes with the help of tube fillers. Tube fillers are also used to fill tubes with innovative products, such as self-tanning creams, anti-aging serums, and BB creams.

With the increasing demand for organic and natural beauty products, tube fillers are used to fill tubes with products made from natural ingredients, such as essential oils, plant extracts, and herbs.

Food industry:

Food industry is also taking the help of tube fillers for filling various products into tubes. The accuracy of dosage is especially considered during filling.

Paint industry:

In the paint business, tube fillers are frequently used to fill tubes with several kinds of paint, including water-based, oil-based, and solvent-based paints.

Chemical industry:

To correctly distribute chemicals into tubes for storage and delivery, the chemical industry uses tube fillers. The tube filler guarantees accurate chemical measurement and regulated dispensing, reducing the possibility of spillage and contamination.

4.What are the various types of tube fillers available on the market?

Semi-Automatic Tube Filler

Semi-automatic tube fillers are machines which requires manual intervention to complete the processing. The user load the material, tubes and fill them through the help of machine. The process of dealing tubes is done by using foot pedal.

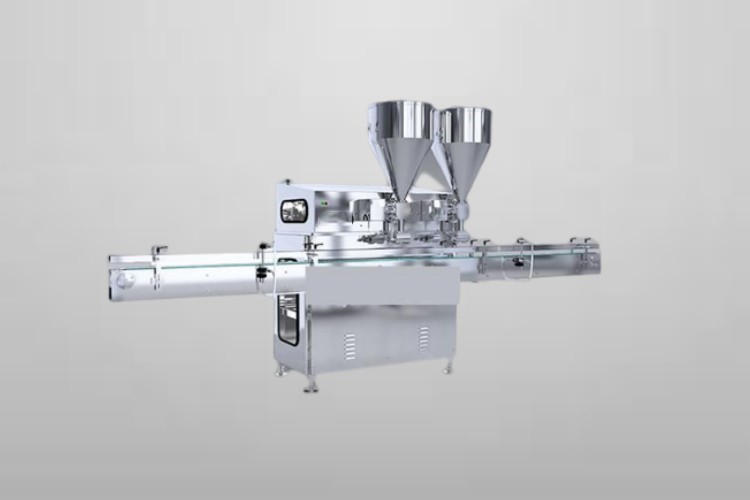

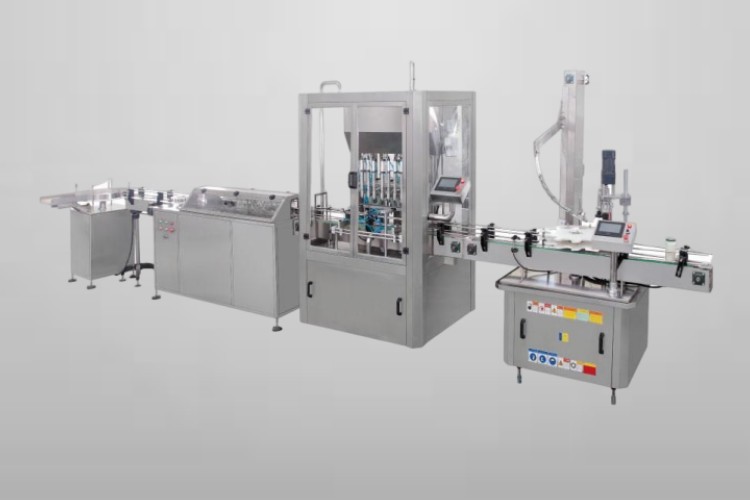

Automatic Tube Filler

Automatic tube fillers work independently without any manual intervention. They work with high consistency and give you higher output by running the entire mechanism of product loading, filling and sealing.

You can integrate your automatic machine to make the production for smooth filling of different viscous material into tubes.

Rotary Tube Filler

Rotatry tube fillers are devices that fill and seal tubes using a rotating carousel. Number of tubes can be carried on the carousel at once, and it moves them steadily through the filling and sealing procedure.

Rotatry tube fillers are useful for high-volume production since they can fill and seal hundreds of tubes per minute. They are frequently employed in the food, cosmetic, and pharmaceutical sectors, where effectiveness and speed are crucial considerations.

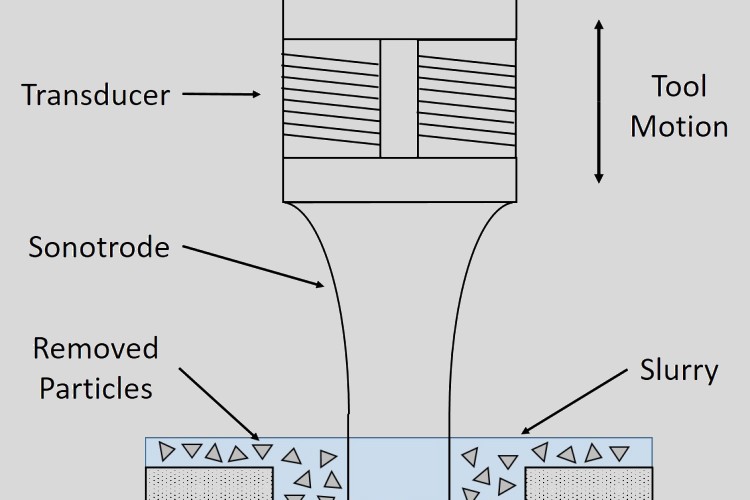

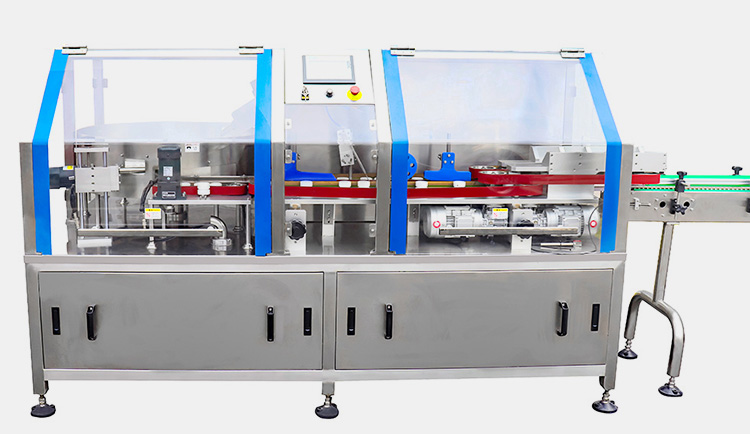

Ultrasonic Tube Filler

The ultrasonic tube filler is a technological marvel that revolutionizes the tube filling process by combining speed, accuracy, and efficiency.

This state-of-the-art apparatus uses the force of ultrasonic waves to quickly and accurately fill tubes, making it a vital tool for companies that need high-volume manufacturing.

Aluminium Tube Filler

The aluminum tube filler is equipped with advance features such as automatic tube loading and positioning, which reduces the need for operator interference. The operating procedure of the machine is simple as it reduces the learning curve and makes it a suitable choice for both small and large-scale operations.

One of the key benefits of the aluminium tube filler is its ability to handle a wide range of products. It can fill products with different viscosities, ranging from free flowing liquids to thick pastes.

5.In what ways does an automatic tube filler differ from a semi-automatic tube filler?

An automatic tube filler and a semi-automatic tube filler are two types of machines used for filling products into tubes. Here are some ways in which they differ. These are:

Operation:

The primary difference between the two is the level of automation. An automatic tube filler needs little or no human intervention, while as a semi-automatic tube filler demands manual input from an operator.

Speed:

Automatic tube fillers are skilled in filling a a considerable number of tubes consistently requiring less time, as they can operate continually without any interruption. Semi-automatic tube fillers, on the other hand, are slow in filling due to the manual operation involved.

Precision:

Automatic tube fillers are equipped with advanced sensors and controls, which assure thorough and uniform filling of each tube. Semi-automatic tube fillers, while still valid, may require more manual adjustments to provide constant filling.

Size:

Automatic tube fillers are mostly large size due to their vary components and integrated machines. On the other hand, semi-automatic tube fillers are precise and small in size.

Ease of use:

Automatic tube fillers are typically leisurely to use than semi-automatic machines. They have user-friendly interfaces and require minimal training to work. Semi-automatic machines may need more workout and experience to operate effectively.

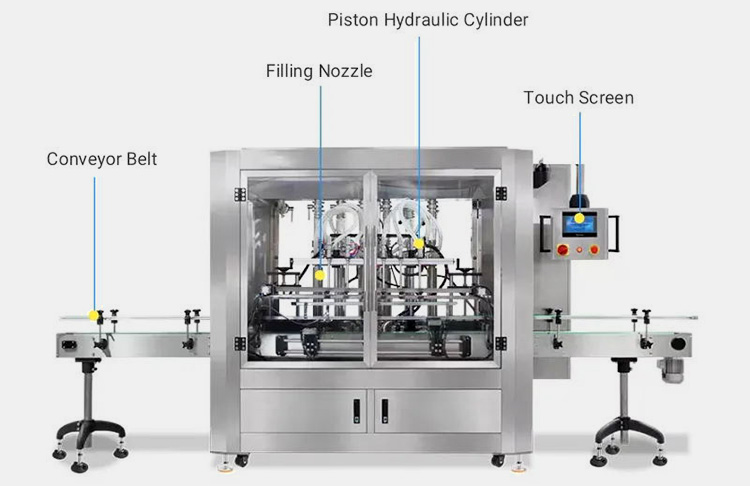

6.What are the essential components of a tube filler?

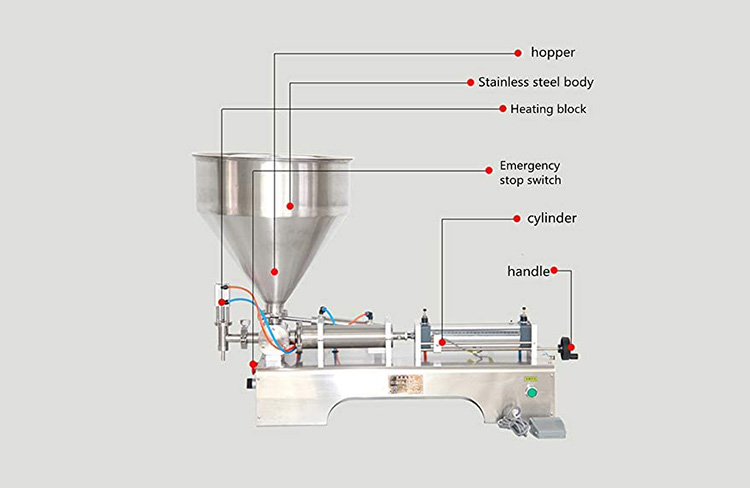

The essential components of a tube filler are following:

Dosing Pump:

The dosing pump is a critical component of a tube filler that accurately estimates and distributes the accurate dosage of material into the tubes. It is helpful in ensuring the consistency and uniformity of the filling process.

Coding Jaws:

The coding jaws are responsible for printing the manufacturing and expiration date, batch number, and other essential information on the tube during the filling procedure. It ensures the accurate labeling of the product and enhances traceability.

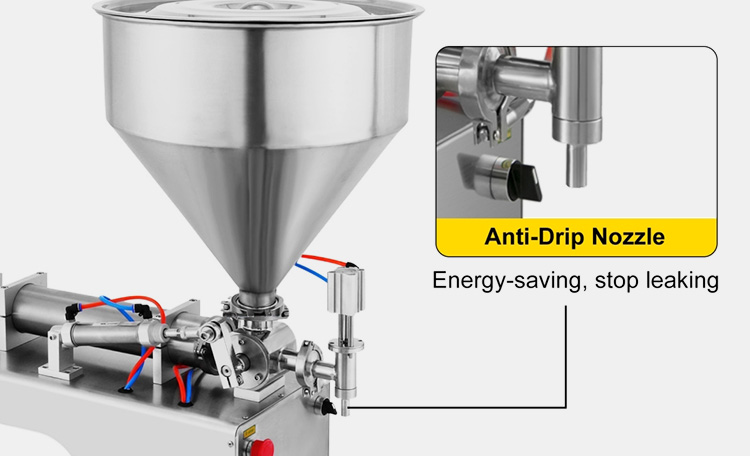

Filling Nozzles:

The filling nozzles are employed to distribute the product into the tube. They come in various sizes and shapes relying on the variety of product being supplied and the tube’s dimensions.

Frame:

The frame delivers the structural support for the whole tube filler. It is usually made of stainless steel and is organized to resist the stresses and vibrations of the filling technique.

Electronic Box:

The electronic box comprises of the control system, sensors, switches, and circuit boards that guarantee the precision and security of the process. It is responsible for executing the entire mechanism in a perfect and well maintained way.

Hopper:

The hopper is where the product is loaded into the apparatus before the filling process. It is the material holding tank which can be loaded either manually or automatically.

Tube Holders:

The tube holders sequentially holds the tubes during the filling process. They come in various sizes and shapes, depending on the type and dimensions of the tubes being filled.

Discharge Unit:

The discharge unit is responsible for removing the filled tubes from the device. It ensures that the filled tubes are adequately packed and labeled before they get discharged.

Safety System:

The safety system incorporates different safety elements such as emergency stop buttons, safety interlocks, and alarms that guarantee the safe and reliable operation of the tube filler machine.

Motor:

The motor supplies the energy for executing various parts of the tube filler. It is usually an electric motor that can be either AC or DC, depending on the machine’s design and application.

7.What are the working principles of a tube filler?

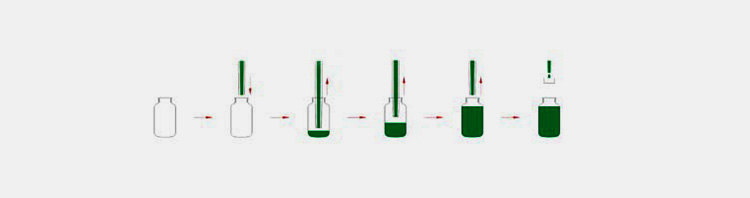

The working principle of a tube filler involves a series of steps that ensure accurate and efficient filling of the tubes. Here are the step-by-step working principles of a tube filler:

Tube loading: The first step involves loading empty tubes onto the tube filler machine. The machine has a tube magazine that holds a stack of empty tubes, which are automatically fed into the machine for filling.

Tube orientation: After loading the tubes, the machine automatically brings the tubes to right position so that the opening is facing upwards for filling. The orientation of tubes is carried out with the help of sensors.

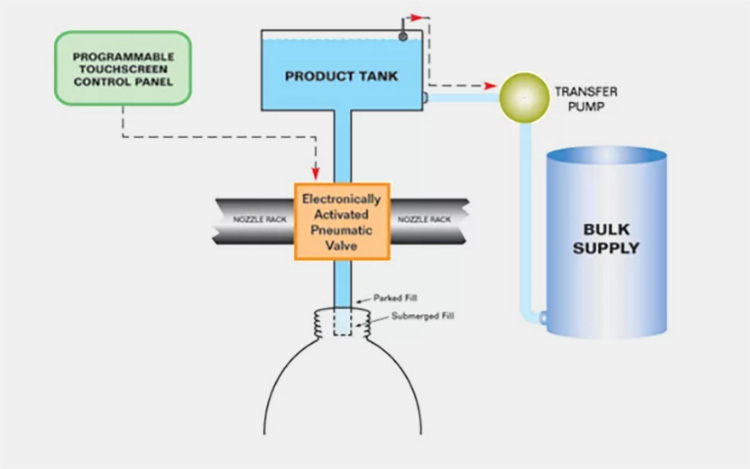

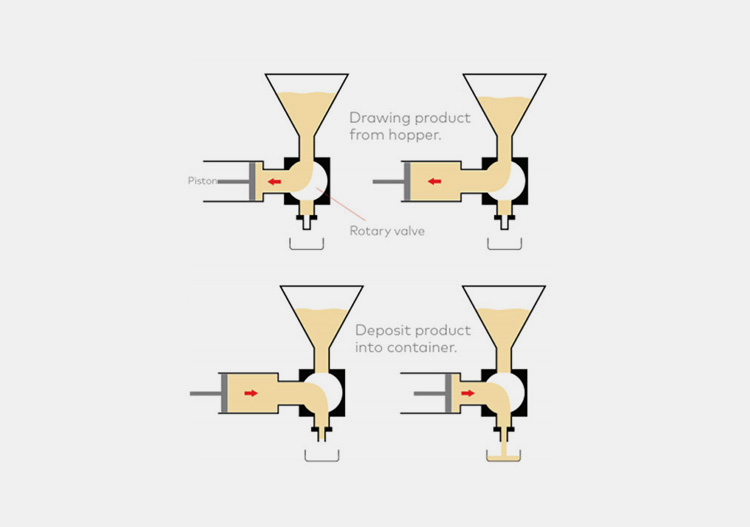

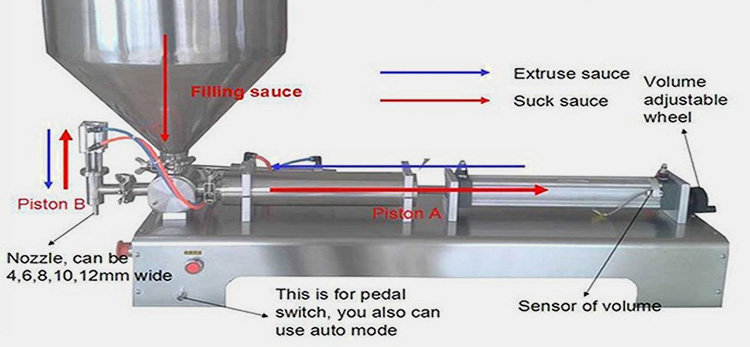

Filling:

Here the actual filling of tubes occurs, when the tubes are supplied with precise dosage of the product. The material is fed into a hopper that is attached to the filling nozzle. This process is done the help of piston which moves up and down taking the material for each tube.

Leveling:

Once the product is filled, the device levels the product inside the tube to confirm that the product is evenly settled in the tube.

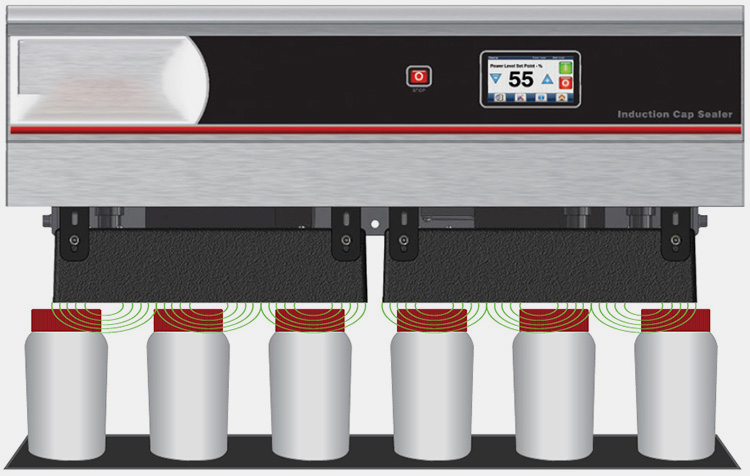

Sealing:

The sealing technique is essential to guaranteeing the product stays fresh and hygienic. The tube filler takes advantage of heat to seal the tube’s opening, which builds an airtight seal that prevents contamination.

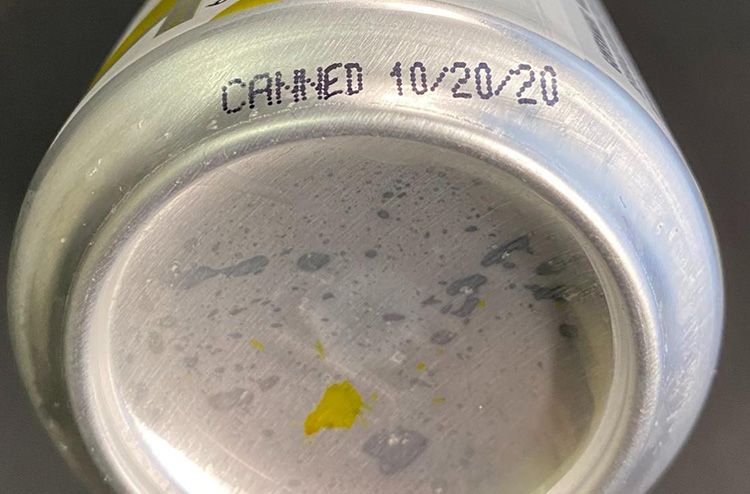

Coding and cutting:

After sealing, the device codes the tube with important information such as product details, expiry date, and batch number. The apparatus then cuts the tube to the desired length.

Tube ejection:

Finally, the filled and sealed tubes are removed from the machine onto a conveyor belt for further processing, such as labeling and packaging.

8.What type of materialcan be filled into tubes by using a tube filler?

Materials which can be filled into tubes by using a tube filler are listed here;

Creams and lotions:

Creams and lotions are the most common products which are filled in tubes for easy usability and the product discharge from tube. The products can vary in viscosity, from thick and heavy creams to light and watery lotions.

Gels:

Tube fillers are utilized to fill gels into tubes for packaging like hair gel, toothpaste gel, and even food-grade gels for edible products.

Ointments and pastes:

Tube fillers fill thick and sticky materials, making them ideal for filling tubes with ointments, pastes, and other similar products.

Adhesives: Industries associated with producing adhesive material like to use tube fillers for filling various types of sticky adhesives like epoxy, silicone, and acrylic into tubes.

Food products: Food products can be fill into tubes with the industrial tube fillers. It can fill a variety of products such as condiments, sauces, and spreads.

9.What are some common troubleshooting steps for a tube filler?

Common problems and their troubleshooting:

Uneven fill: If the tube being filled is uneven, you can check the fill volume and make adjustments as necessary. Also, inspect the filling nozzle for any blockages that could be causing the uneven fill.

Tube jams: If the tubes are getting jammed in the machine, check the tubing for kinks or damage. Also, make sure that the tubes are properly aligned with the filling nozzle.

Air leaks: If there are air leaks in the system, the machine may not be able to fill the tubes properly. Check the air pressure regulator and make sure that all of the connections are tight.

Slow filling: If the machine is filling the tubes too slowly, check the air pressure and correct it in case it needs adjustment. Also, inspect the filling nozzle for any blockages that could be causing the slow fill.

No filling: If the machine is not filling any tube, there might be issue in power supply. For this, you can check the power source and make sure that the machine is plugged in and turned on. Also, check the tubing and filling nozzle for any blockages.

10.What are some technical specifications to consider when buying a tube filler?

When purchasing a tube filler, there are several crucial factors to deem to ensure that the machine meets your production prerequisites and delivers the desired output.

Here are some key factors to keep in mind:

Tube size and compatibility:

The tube filler must be consistent with the size and shape of the tubes you plan to use. Also look into the capacity of tube

Speed and efficiency: No doubt, the reason for opting any tube filler is to increase the production speed and efficiency. However, it is only possible when you thoroughly examine the specifications which enables the capability of machine.

Accuracy and consistency: The tube filler should provide proper and consistent fill volumes to secure product quality and consistency.

Versatility:

Consider the scope of products the tube filler can deal with. Go for a machine which can deal different materials including viscous, semi-solid, and liquid products.

Operator security: Safety features must be your obligatory consideration for making sure that operator is free of harm. It will be analyzed by looking into the safety features like emergency stop and alarm etc.

Cost and ROI: Consider the upfront expense of the apparatus and the return on investment it can produce. Look for a machine that proposes good value for money and can help you reduce costs, gain production, and make better product quality.

Model:

There are different models available in market for filling tubes. You can get best one by evaluating certain factors as like speed, filling capacity, flexibility and convenience in usability.

Conclusion

In conclusion, tube fillers are a versatile and practical tool that can make the task of filling tubes with various products a breeze. Before making any decision, make sure you have understand all the points explained above. Along with that, make sure to go through the essential factors. If you have other problems, welcome to contact us.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tube Filler:The Complete Buying Guide In 2025 Read More »

Before buying sauce packaging for your sauces, one must consider some factors in order to determine which packaging would the most suitable for his industry. These factors are.

Before buying sauce packaging for your sauces, one must consider some factors in order to determine which packaging would the most suitable for his industry. These factors are.

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours