Milk Filling Machine: The Complete Buying Guide In 2024

Milk Filling Machine: The Complete Buying Guide In 2024

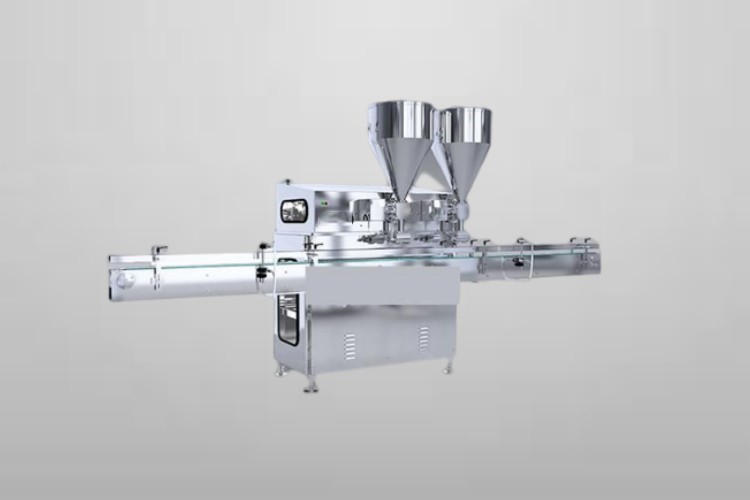

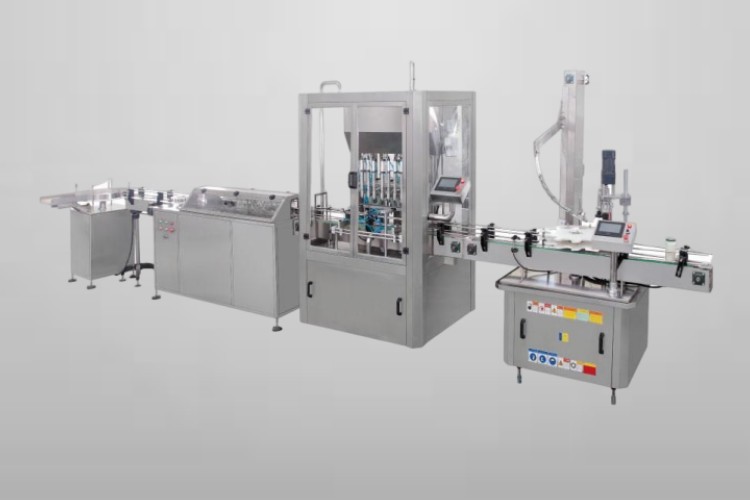

With increasing population and global requirement, it has been a challenge to fill milk manually. Milk filling machines are one of the modern ways of filling milk in different sizes of cans, bottles and jars. It supports in accurate filling of milk product in food and pharmaceutical industry. The milk remains fresh for a longer period as it is sealed and packed with airtight sealing feature.

With drastically growing demand of milk filling machine, many manufacturers have started to produce their own type of machine. Allpack is also one of the leading manufacturers of milk filling machines and provides best solutions to its customers. This buying guide assists in selecting the best milk filling machine for your setup and will give you all related information. So let’s go!

1. What Is A Milk Filling Machine?

Globally liquid milk and dairy products are now packed in specific bottles, containers and jars. For filling of these products, milk filling machines are used by many of the manufacturers as it gives accurate filling results irrespective of what shape or size it has to fill.

A milk filling machine can be used to fill natural milk, pasteurized milk or flavored type milk. Milk is first inserted into huge storage containers and from it is carried to the filling nozzle which dispenses accurate amount of milk. Milk filling machines are mostly used in food, dairy, pharmaceutical and also sometimes in distribution industry where milk is automatically filled to produce thousands of bottles in a single day.

2. What Are The Applications Of A Milk Filling Machine?

Some of the applications of milk filling machines are

- Food Industry

Milk filling machines are mostly used in food industry as multiple types of milk are packed in containers and bottles of different sizes and shapes. Both liquid and powdered milks are being filled using this type of machine. Flavored milk are globally consumed in large quantities and milk filling machine supports food industry to fulfill the requirements by quick and efficient results.

- Dairy Industry

Dairy Industry is also one of the sub types of food industry but it totally depends on the products related to dairy farms. Nowadays large number of dairy industries are present and using milk filling machines to speed up their productivity and lie of customers’ expectations. Pouches, bottles, containers are filled with dairy products like milk, flavored milk, fresh creams and yogurt with pleasant packaging results.

- Pharmaceutical Industry

Pharmaceutical industries are also one of the leading users of milk filling machines. Milks produced in this type of industry are usually composed of several vitamins, calcium’s and other ingredients that are necessary to fulfill human body requirements. These types of pharmaceutical milk products are also packed using milk filling machines.

3. What Are The Advantages Of A Milk Filling Machine?

As milk products ease in the reproduction of bacterial growth, it is always a challenge to maintain its purity and freshness. Milk filling machines have several advantages in this regard and some of them are

- Hygienic Filling

As milk filling machines are easy to clean and wash therefore it guarantees contamination free filling of milk and keeps product freshness alive. This type of milk can be used for a much longer period.

- Consistent Filling

As the construction of a milk filling machine, there are proper photo and pneumatic sensors that are used to sense the container and fill an accurate amount of product. The consistency remains throughout the process and gives unique results even in large batches.

- Improved Productivity

Industries that are involved in production of bulk quantity milk products use milk filling machines to enlarge their production capacity. Large batches can easily be produced using these machines and with quality results.

- Time and Energy Saving

Production of milk filling machine involves less manpower and this ensures a greater saving of time. Also the machines consumes less utilities during the operation and thousands of packed products are carried with less power consumption. This makes the process easy and economical.

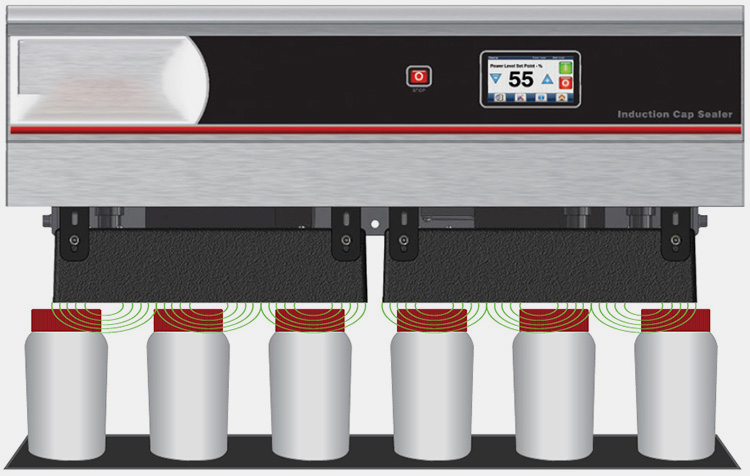

- Pleasant Packaging

A milk filling machine also has an ability to package milk products into bottles and cans in an efficient manner. The labeling process be incorporated within a milk filling machine that gives pleasant looking designs and attracts customer towards it.

4. What Is The Working Principle Of Milk Filling Machine?

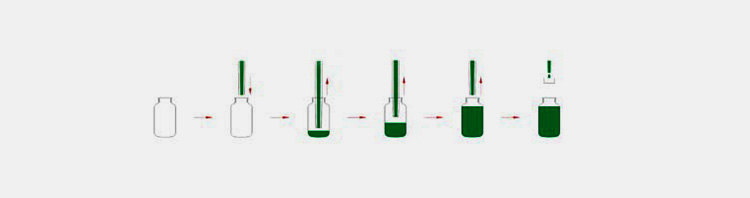

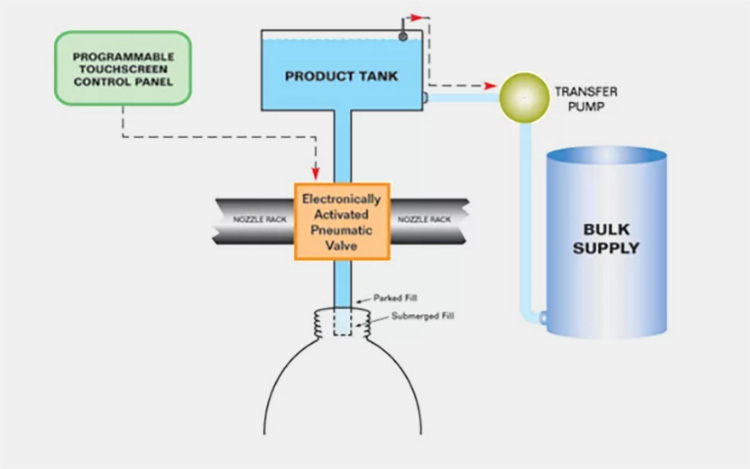

A milk filling machine has a complex structure but operates in a simpler way. It depends upon the volume and weight of the milk product and works accordingly. The common steps involved in the operation of a milk filling machine are

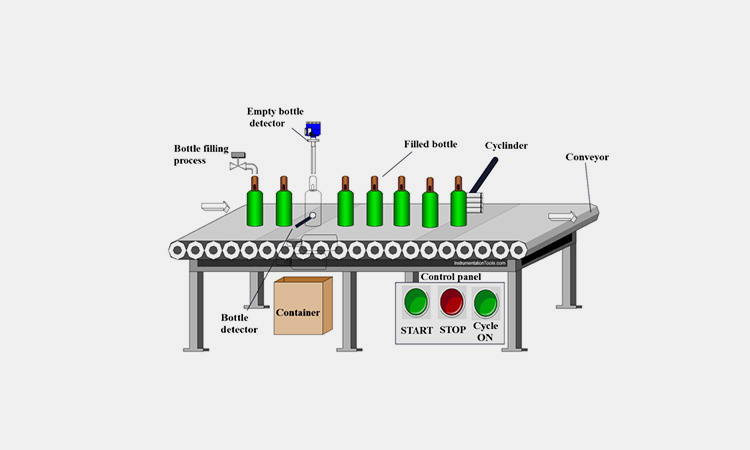

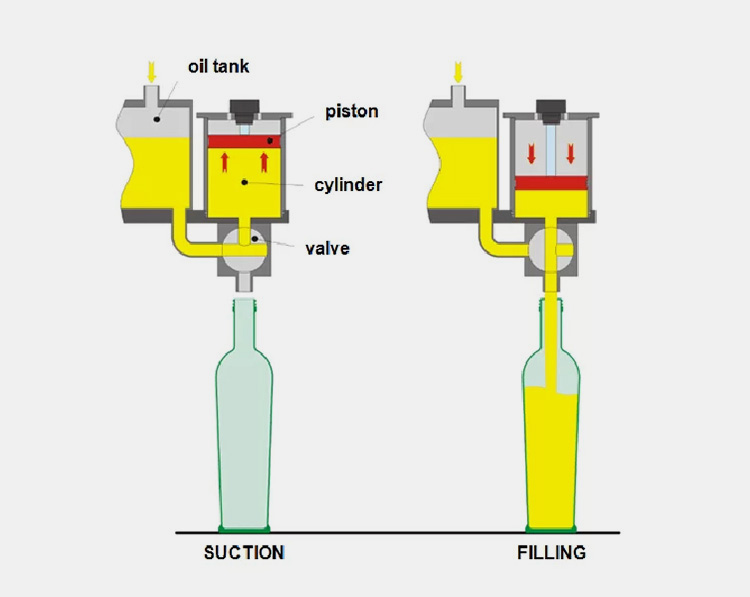

- Initially the container or hoppers are cleaned properly to avoid contamination and then filled with milk product that is to be packaged.

- In the second step the filling bottles, cans or containers are placed manually under the filling nozzle or automatically using conveyor belts.

- The filling packaging once detected by the sensors present in a milk filling machine direct the system to start the outflow of milk product.

- As the system gets its signal, it opens the valve of filling nozzle and allows the continuous flow of milk.

- The machine uses both volumetric and weighted feature that once the bottles are filled the system automatically shuts the valve and stops the flow.

- Accurate and desirable amount is filled into the packaging material without any tolerance and wastes. After filling of milk into packaging material, it is further moved where capping, labelling and coding processes are carried out.

- The finished products are moved onto the same conveying system and at the end they are packaged in their respective packaging form.

5. What Are The Main Components In Milk Filling Machines?

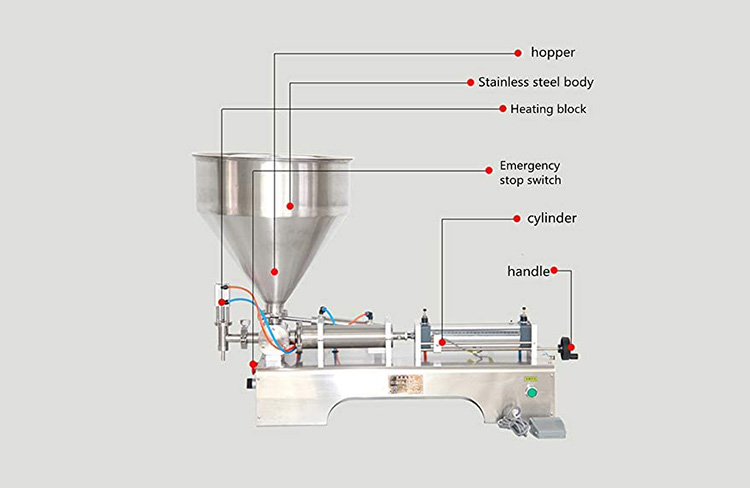

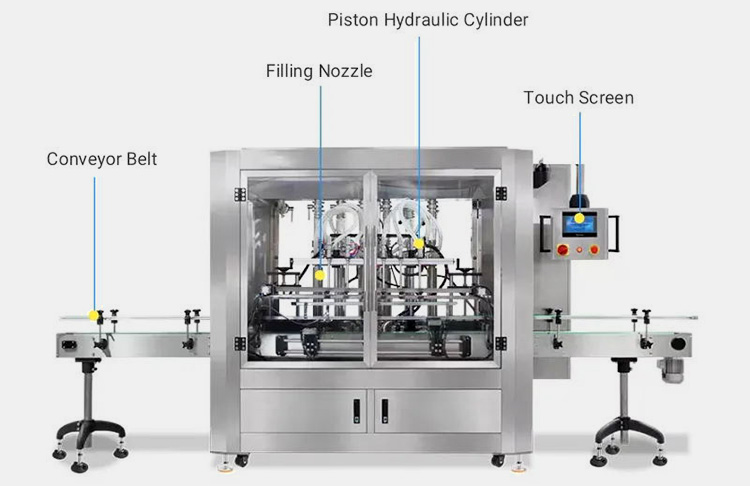

The main components in a milk filling machines are

- Monitoring System

A monitoring system in a milk filling machine allows the operator to see complete machine operations. Monitoring system also helps in setting the filling parameters of machine like pressure, volume, conveyor speed and etc. Also, in case of any abnormality or unusual activity this monitoring system displays the fault and also identifies the affected area.

- Feed Hopper

Feeding hopper or containers are the regions where the milk is filled that is to be packaged. These containers sometimes carry raw milk that is flavored, pasteurized or mixed is further containers and us prepared as final packaging product. There is also a small hopper ahead of small milk filling machines which are used for low production setups.

- Sensors

Sensors are the main security concerns that are built-in in a milk filling machine. These sensors are used for identification of bottles or containers that whether they are placed exactly under filling head or not. After confirming the presence by these sensors, the system allows the filling head to release milk product present in the hopper or feeding area.

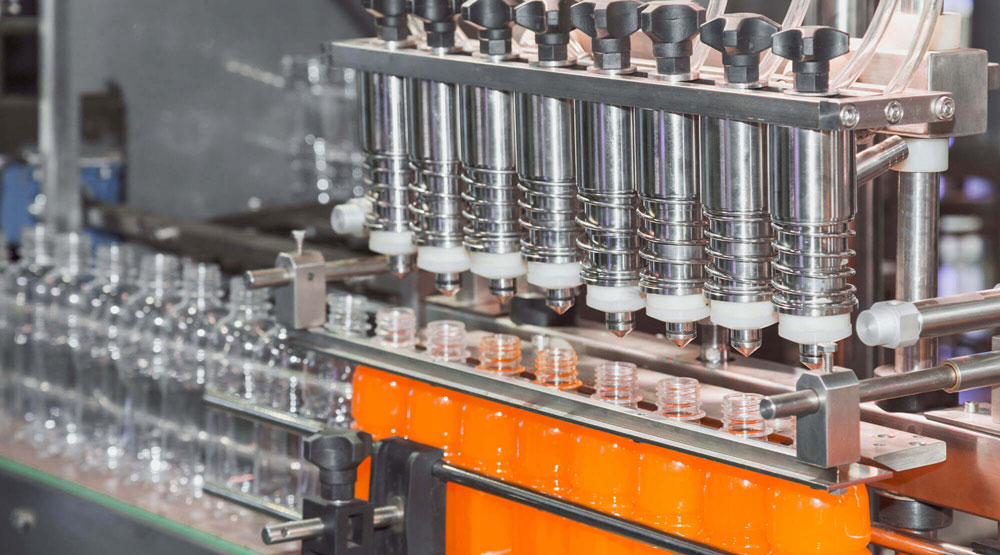

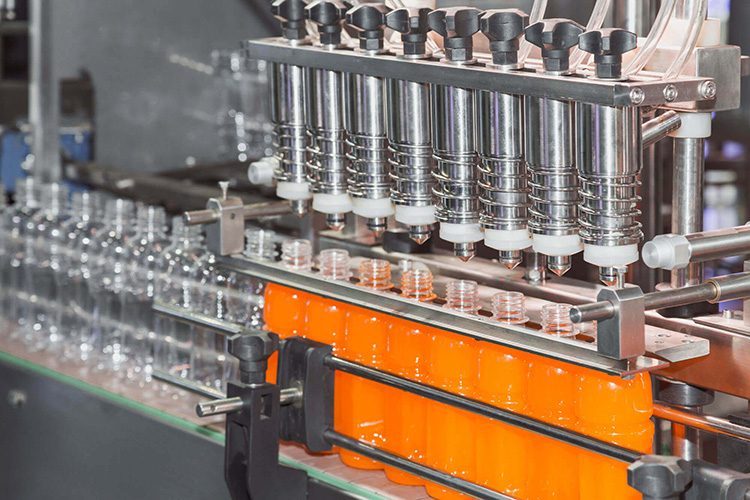

- Filling Head

Filling heads are the one from where the milk product is released into the bottles or conveyors. These filling heads are made up of stainless steel that never allows as contamination or rusting. Filling heads are also easy to remove and clean and are available in different opening sizes depending upon the packaging product.

- Mechanical Drive System

A mechanical drive systems is the main mechanism controller that includes all motors, actuators and gears. This mechanical system ensures proper movement of all these mechanical parts during operation and helps in smooth productivity. Also the milk released in bottles is maintained by these mechanical drivers to ensure unique packaging process.

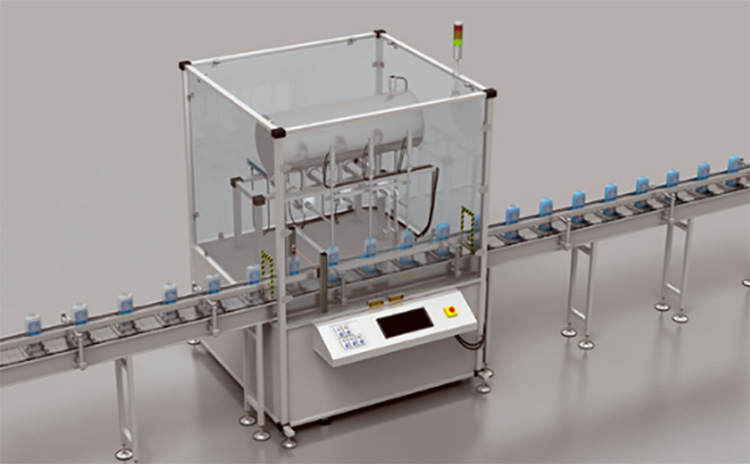

- Conveyor

Packaging bottles, containers and jars are moved through all the stages of a milk filling machine by the conveying system. This conveying system includes both loading and offloading side conveyors. Human security is also ensured when products are moved on these conveyors and come out as finished goods. Synchronization among systems can also be managed by using an efficient conveying system.

- Controlling System

Controlling system is actually a whole panel or box carrying relays, circuits and programmable controllers that are responsible for milk filling machines operation. This controlling system is sometimes present at the start of machine or at the back. Machines emergency switches are also incorporated in this controlling system.

6. What Are The Different Types Of Milk Filling Machines Available Globally?

There are several types of milk filling machines depending upon the automation level and filling requirements. Some of the types of milk filling machines are

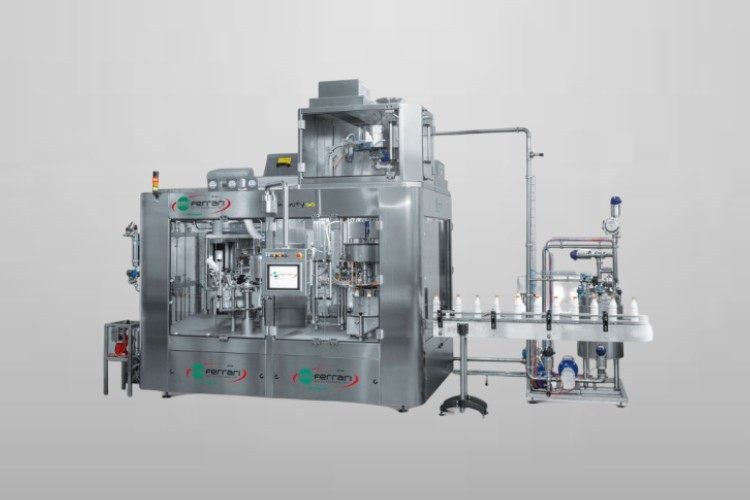

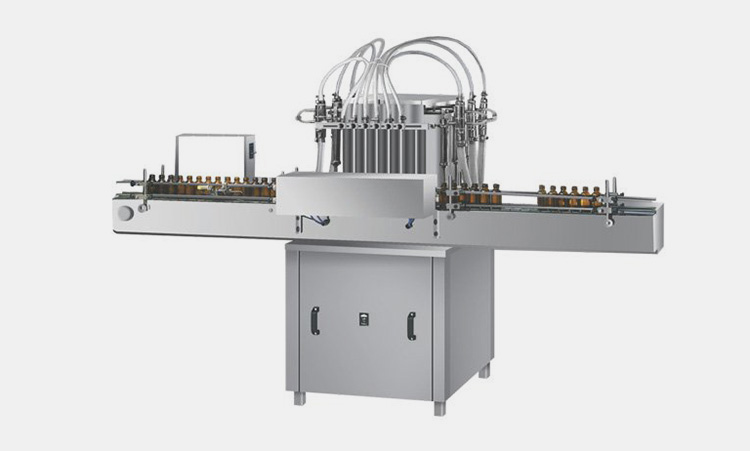

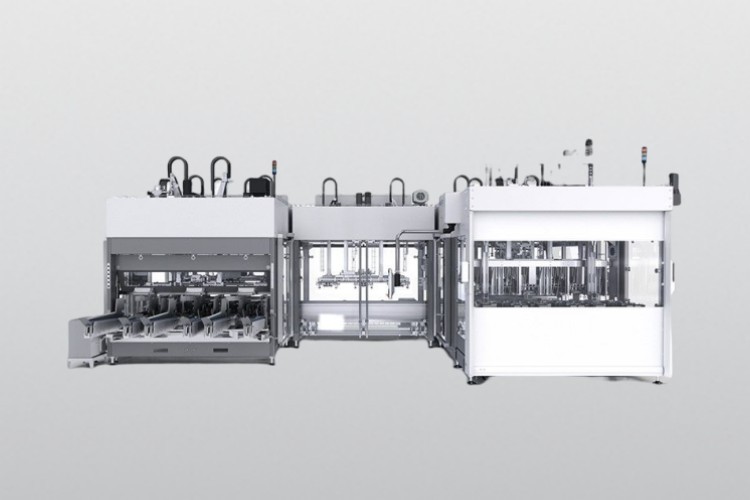

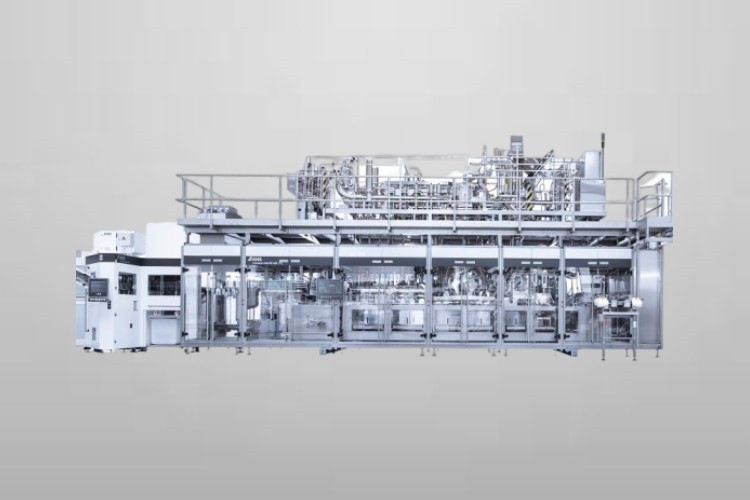

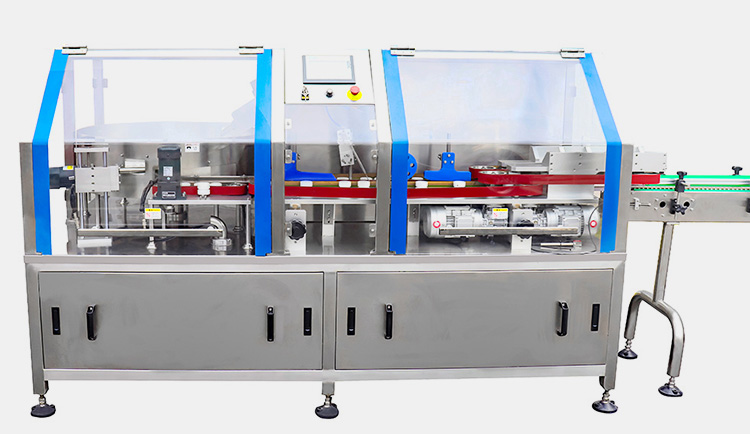

- Fully Automatic Milk Filling Machine

Fully automatic milk filling machines are completely based of automatic processes and no human involvement is present. Machines work directly from the picking of packaging material to the filling of it and then final packaging stage, all the stages are performed by fully automatic milk filling machine itself. This ensures high production volumes with greater human-machine safety.

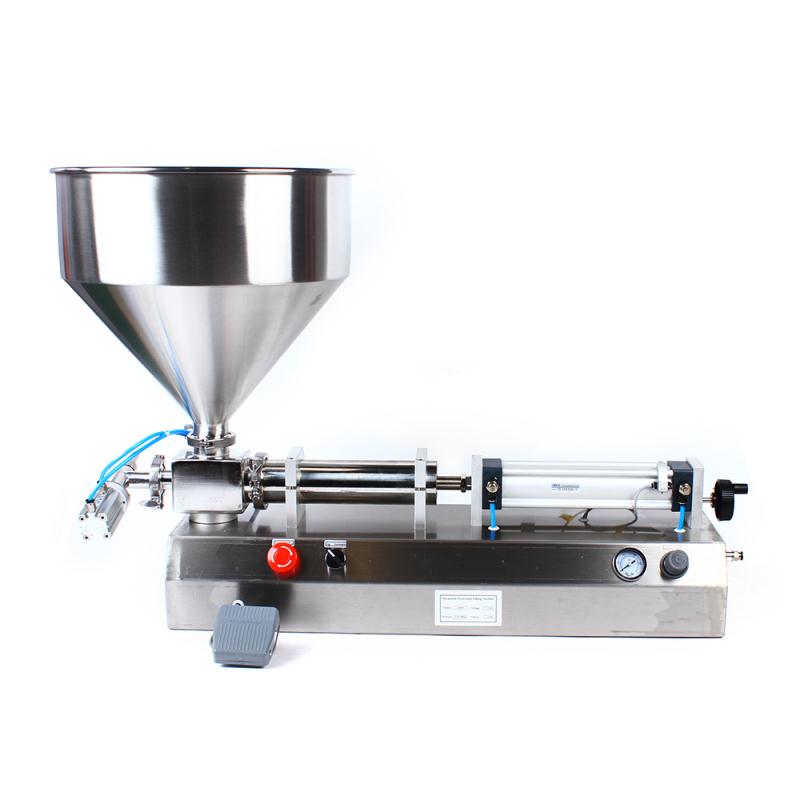

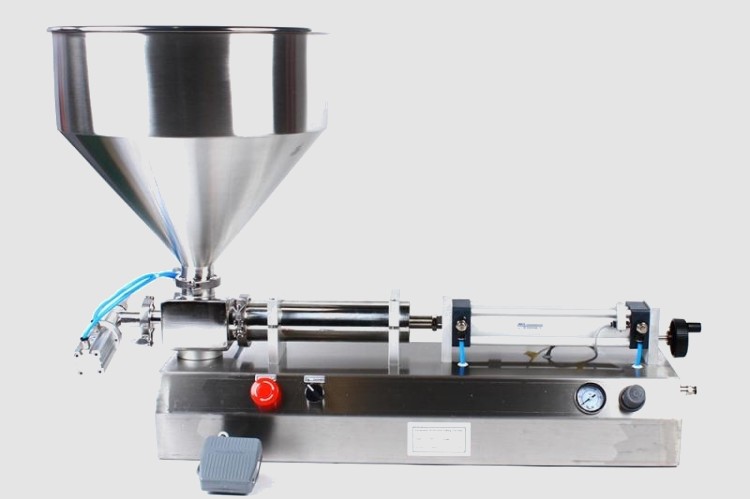

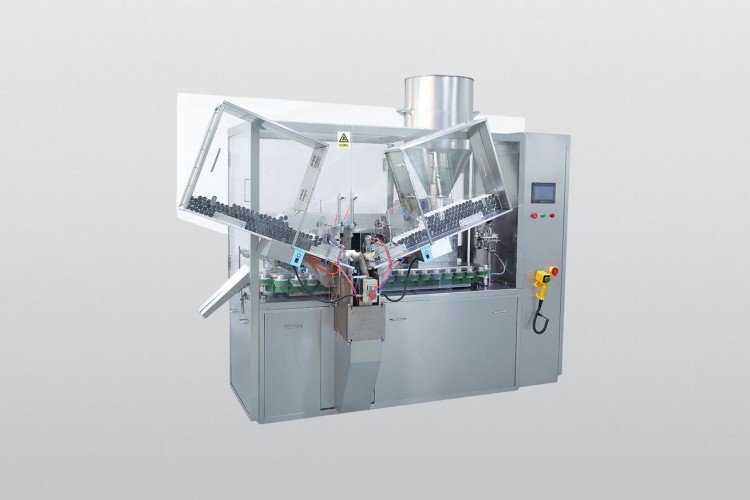

- Semi-Automatic Milk Filling Machine

Semi-automatic milk filling machine has a human-machine interface and involves both features in its process. The operator is first responsible for placing the product into the system and then involves at the final stages for picking it up. The center process is performed automatically by the machine and fills bottles, cans, containers and jars at an accurate level. Semi-automatic milk filling machines are mostly used in small and medium scale industries where production requirements are not that much high as large scale industries.

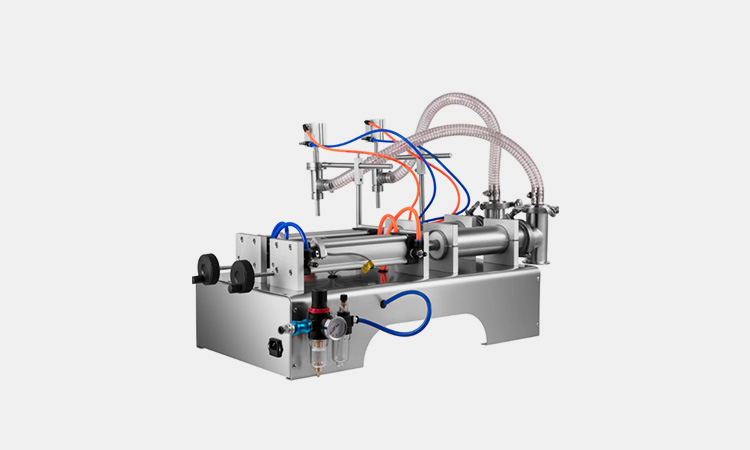

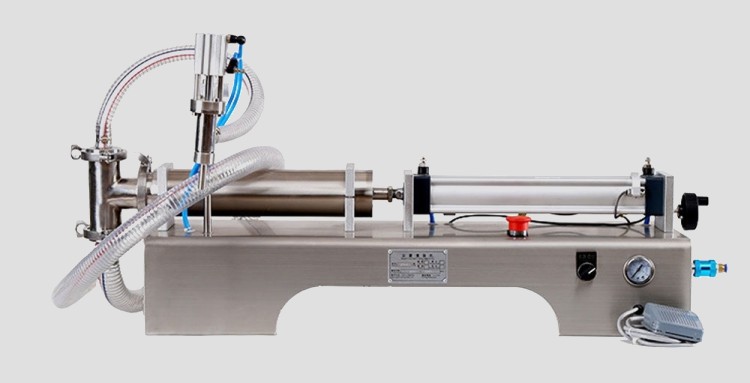

- Piston Milk Filling Machine

A piston milk filling machine involves piston operation while dispensing milk product into the packaging material. The to and fro movement of piston pushes specific volume of milk that is to be released into the containers and bottles. The machine depends upon its viscous nature and quantity.

- Overflow Milk Filling Machine

An overflow milk filling machine as its name mentioned is dependent on the overflow level of milk product. The hoppers or feed systems are filled with specific amount of milk product and the excess is overflowed out of it. Mostly the milk products that have foamy nature are filled using an overflow milk filling machine.

- Weight Milk Filling Machine

This type of milk filling machine is used where the filling amount tends to be accurate at every level without any tolerance. The machine weighs the dispensed milk product and then cuts to the set level. High level of containers and valued products are usually filled using a weight milk filling machine.

- Pneumatic Milk Filling Machine

Pneumatic type of milk filling machine uses air pressure instead of electrical signals. The shaft of cylinder is moved forward and backward for dispensing milk products and filling them in bottles, jars and containers.

- Gravity Milk Filling Machine

As the name mentions, the milk product is filled in the feed system present at the top of machine. This filled product is travelled downward through gravitational pull and no external force is applied. The gravity is also responsible for further filling the packaging material with the product dispensed from the filling nozzle.

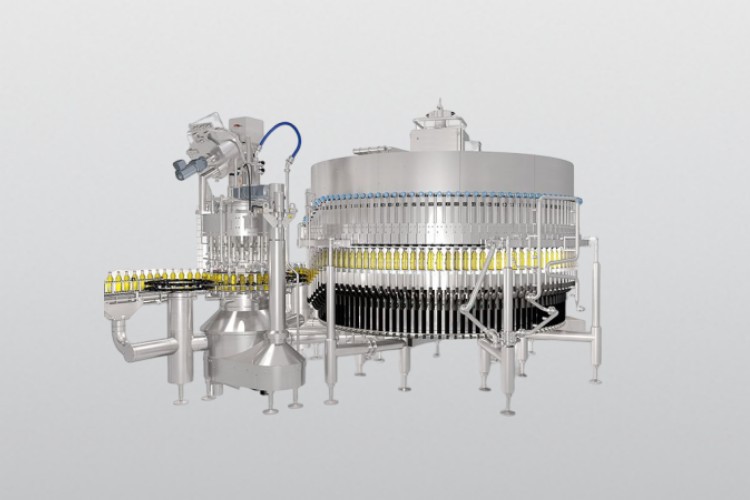

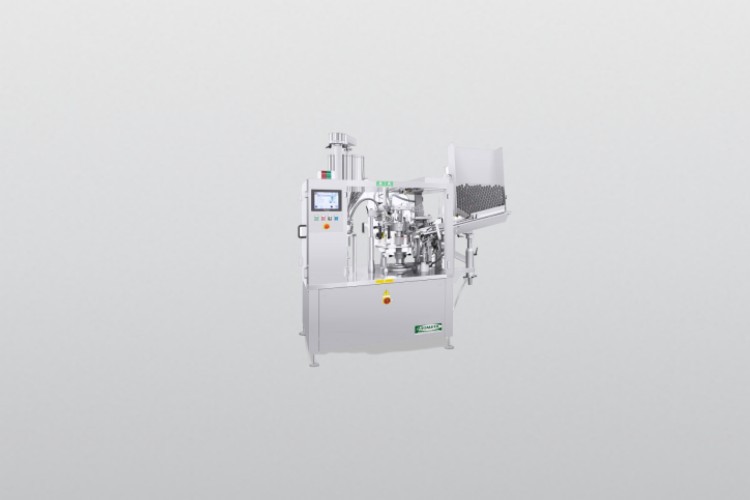

- Rotary Milk Filling Machine

A rotational carousel or a rotational turret made up of stainless is used that moves the jars, bottles in this type of milk filling machine. Once the rotational cycle passes through the filling nozzle, the nozzle releases specific amount of milk product into it. The same turret takes the filled bottle out of the system and gets an empty one into the system in a similar manner.

7. How The Level OfFilling Is Maintained In A Milk Filling Machine?

A milk filling machine contains few advanced feature that are directly involved in maintaining the filling level in it. Some of them are

- Photoelectric Sensors

One of the highly advanced technology used for maintaining the level are the photoelectric sensors. These sensors are initially used for detecting the presence of bottles or jar and then allow the system to release. Once the desired level is achieved, the height sensor detects the level of filled material and closes the filling nozzle once it’s achieved.

- Timers

The other unique components are the timers and actuators. The operator initially according to the size and shape of filling bottles sets a specific time on which the milk is to be released. The timer is directly connected with the valve of filling nozzle and allows it to open only in that set time duration. This also gives us support in maintaining the filling level of a milk filling machine.

- Volume Controller

A volume controller is used for dispensing specific amount of milk product into the packaging material. It measure the weight and volume and gives continuous output to the main controller. The system cuts when the selected range of volume and weight is achieved.

- Overflow Gauges

Overflow gauges are also used for maintaining filling levels as they detect if any of the product comes out of the bottles or the filling range gets exceeded.

- Shut-off Valve

For maintaining filling levels shut-off valves are incorporated with the solenoid of filling nozzle. This solenoid switching is used for controlling the open and close mechanism of filling nozzle. It dispenses and shuts with the help of this shut-off valve.

8. What Are The Differences Between Semi-Automatic And Fully Automatic Milk Filling Machines?

Both of the semi-automatic and fully automatic milk filling machines are distinguished on the bases of few important features. These are

- Level Of Automation

A working process of a semi-automatic milk filling machine has an involvement of both human and machine. The products are placed by the operator and the machine releases specific amount of milk product into it. Finally the operator is there for taking it out of the system.

Whereas the fully automatic milk filling machines complete relies on machines process. All the filling, packaging and labeling processes are carried out of machine in an efficient manner.

- Applications

Semi-automatic milk filling machines are mostly used is small and medium scale industries with a production capacity ranging 20 to 50 bottles per minute.

Fully automatic milk filling machines have high production volumes and are used in medium and large scale industries. The production capacity of fully automatic milk filling machine ranges in between 70 to 120 bottles per minute.

- Controls

In a semi-automatic milk filling machine the controls are available in front of an operator where he adjusts all the related parameters including speed, temperature, pressure and etc.

The operator has just to select the type packaging material and its type form the human machine interface and rest all the tasks are done by the machine itself.

9. How Can Milk Filling Machine Be Adjusted For Different Types Bottles And Different Sizes?

Most of the milk filling machines are able to fill variety of bottles, cans, containers that are different in shapes and sizes. Some of the methods to adjust these sizes are according to their

- Different Opening Sizes

The machine mainly focuses on how the packaging material is gripped before filling of milk. For this a simple mechanism of grip is adjusted from bolts and nuts that is widen according to the opening size of packaging material.

- Width Size

These packaging materials including bottles, cans, jars and containers also are different in width size. An indexing system is incorporated in a milk filling machine that holds and releases these materials. It is adjusted by a gate system that open either large or small size bottles are to be filled. Also wing nuts are present there to tight the opening at desired position.

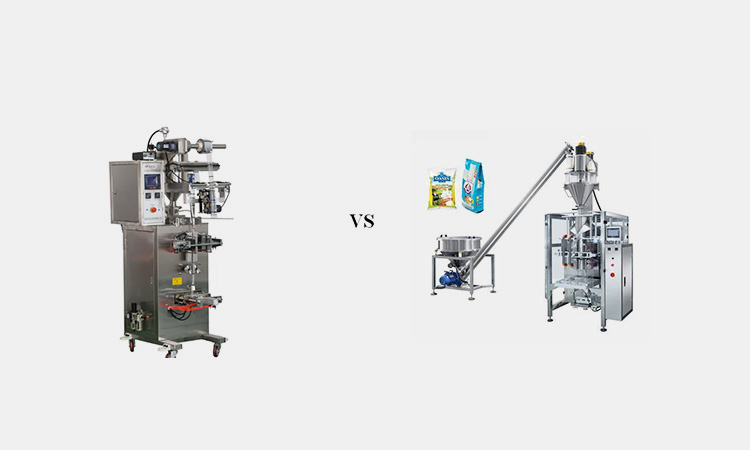

10. What Are The Differences Between Milk Filling Machine And Milk Powder Filling Machine?

Milk filling machine and milk powder filling machines are two different types of machines that are distinguished based on following reasons

- Mechanism Of Product Filling

A milk filling machine mainly depends on the nature of liquid and are used based on volumetric and gravitational type of filling procedures.

Milk powder filling machines are entirely different in there filling mechanism and rely on vacuum or auger type of filling. It depends on the type of powder used and what substances are mixed with it.

- Filling Material

A milk filling machine is usually used to package liquid materials that turn out to be dairy products like yogurt, milk, fresh creams and etc.

On the other hand milk powder filling machine is used to package powdered form of milk that are in the shape of dry milk, powder milk, protein milk, caramel milk, pharmaceutical milk and etc.

- Packaging Material

Milk filling machines are used to fill liquid products into bottles, jars, containers, pouches, cans and sometimes cartons.

Milk powder filling machines pack products into pouches, bags, cans and containers made up of plastic and steel.

- Production Capacity

Both of the machines can be used in small, medium and large scale industries depending upon the type and class of machine an industry is using.

11. What Important Factors Should Be Considered Before Buying A Milk Filling Machine?

Following are the factors that should be considered before buying a milk filling machine

- Packaging Machine Type

Before considering a milk filling machine the manufacturers should select the best suitable type of machine according to its production setup. Either semi-automatic, automatic, volume, pneumatic or overflow the machine should be select with keen research.

- Size Of Bottle

The buyer should select the best type of machine that can singly be compatible with different sizes of bottles, jars and containers. This will make the system much economical.

- Sanitation Perspective

As milk can easily be contaminated and is a perishable material, the machine with best sanitation facility should be selected so that the process may remain fresh for longer period.

- Packaging Product

The buyer should be clear with what type of products will be packed using a milk filling machine. Machines with greater filling capabilities are more suitable for any filling line production setup.

Conclusion

In the modern world, usage of milk filling machines is increasing rapidly. Industries are focus on preparing health, high quality and efficiently packed products using milk filling machine. Allpack is here to provide you variety of milk filling machines and its accessories. If there is any question in your mind you can call our representative or visit our website https://www.allpackchina.com/.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Milk Filling Machine: The Complete Buying Guide In 2024 Read More »

Company Background & Information

Company Background & Information

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

ACF-L Liquid Packaging Machine

ACF-L Liquid Packaging Machine

Mercury Liquid Packaging Machine

Mercury Liquid Packaging Machine

PHS-100 Liquid Packaging Machine

PHS-100 Liquid Packaging Machine

LINEA Liquid Packaging Machine

LINEA Liquid Packaging Machine

Before buying sauce packaging for your sauces, one must consider some factors in order to determine which packaging would the most suitable for his industry. These factors are.

Before buying sauce packaging for your sauces, one must consider some factors in order to determine which packaging would the most suitable for his industry. These factors are.

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours