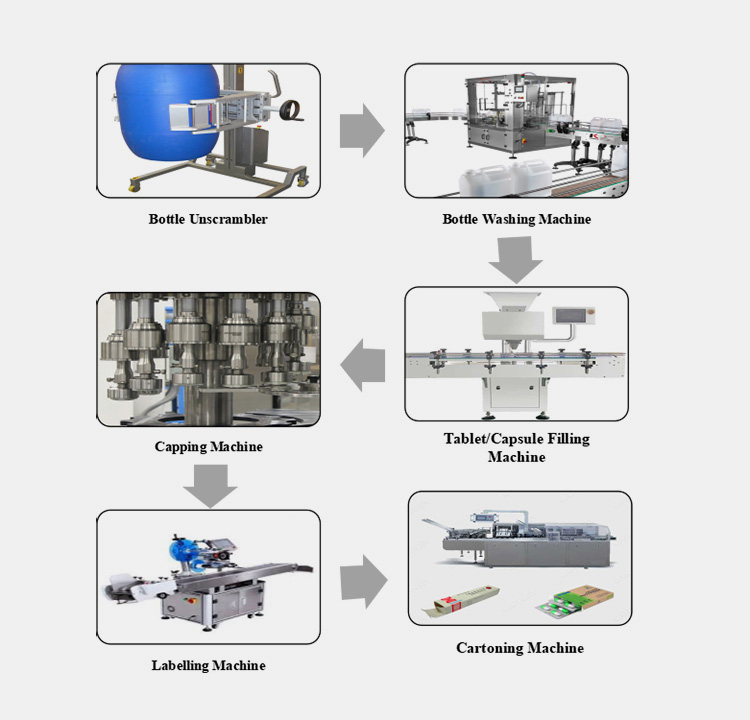

Bottle Rinsing Machine: The Complete Buying Guide in 2025

Bottle Rinsing Machine: The Complete Buying Guide in 2025

Hygiene is an important feature of any production system, especially where food and medicines are manufactured. It is obligatory to rinse and clean bottles before use to avoid contamination risk and to protect the health of consumers. Therefore, the bottle rinsing machine is a prime component of production where packaging in the bottle transpires. This machine features specialized components like a bottle gripper, roller, and, inverter that play a specific role in smooth and reliable working.

A bottle rinsing machine is an ideal addition to your business if you are looking for a solution to clean your bottles. For this, first, you must carefully go through this guide to acquire important knowledge about the bottle rinsing machine.

1.How Bottle Rinsing Machine is Defined?

Bottle Rinsing Machine

Complete cleaning of bottles before filling is essential in achieving quality standard product dispensing and averting contamination chance, therefore, bottle rising machine is prevalently found in bottle filling lines. It completely washes the exterior as well as the interior surface of bottles via washing with water, and air.

With an air blower and water washing system, the bottle rinsing machine perfectly cleans out unwanted dust, debris, contaminants and microbes. It is fitted with conveyors and rotary tables that allow this system to accomplish bottle rinsing at a fast pace.

2.What are the Useful Benefits of a Bottle Rinsing Machine?

This machine is an all-rounder solution that offers exceptional results in less time. Rapid processing businesses need this solution to maintain their quality. Some of the handy benefits of bottle rinsing machine are penned below:

Flexibility and Adaptability

Flexibility and Adaptability of Bottle Rinsing Machine- Picture Courtesy: Traktech

Productions do not have standard bottle shapes and sizes, subsequently, filling and capping all and sundry sizes and designs of bottles. A bottle rinsing machine is designed to rinse a diverse range of bottles with easily changed parts. It is a versatile equipment that saves productions from the hustle of buying new machines for different design bottles.

Thorough Cleaning

Thorough Cleaning- Picture Courtesy: Newmapak

Manual rinsing bottles one by one is bound to leave unwanted objects on the exterior of bottles, increasing unsanitary bottles that lower quality standards and often resulting in huge losses. But with a bottle rinsing machine, you can get absolute and in-depth washing and rinsing of bottles. Employment of this machine in businesses significantly improves quality standards.

Time-Saving

Time-Saving With Bottle Rinsing Machin- Picture Courtesy: GS1 UK

Cleaning bottles by hand could be tough and time-consuming. Moreover, it is impossible to completely clean all nooks and crannies of bottles. However, due to the bottle rinsing machine, this washing feat is achieved in no time. Moreover, this unit automates your production and allows you to fill a higher number of bottles.

Consistency

Consistency with Bottle Rinsing Machine- Picture Courtesy: ViSona

This machine has high-speed washing nozzles that accurately and precisely clean the bottles. It is regularly employed in medium and large-sized industries because of its consistency and no cleaning variation of any kind in different batches.

Water Conservation

Last but not least, this system is eco-conscious and it helps in the conservation of an important resource which is water. High jet pressure nozzles direct water to rinse in such a way that it cleans bottles with a minimal amount of water, subsequently saving hundreds of gallons of water that would be wasted with labour-intensive cleaning.

3.What Industrial Sectors Employ a Bottle Rinsing Machine?

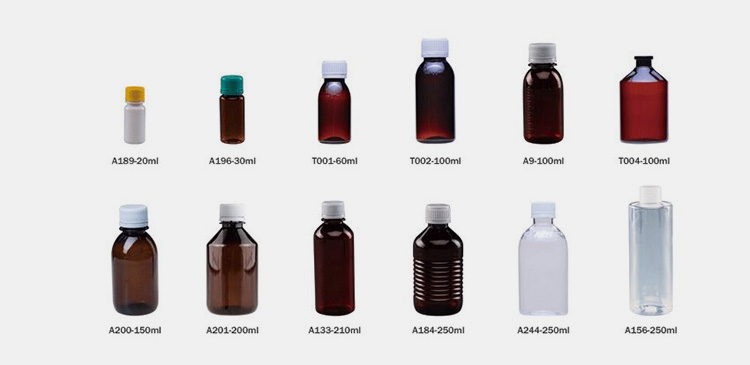

Bottles are one of the biggest packaging containers and almost every industry uses them for packaging goods. Hence, bottle rinsing machine is found in every industry. Some of the industrial applications of this handy unit are stated below:

Food Industry

Food Bottles- Picture Courtesy: Imperial Packaging

Hygiene is a must in the food industry, therefore, for ideal cleaning of food bottles, this machine is utilized in every food application sector. This machine wash and sanitize bottles of oils, sauce, dressings, condiments, syrup, and many more.

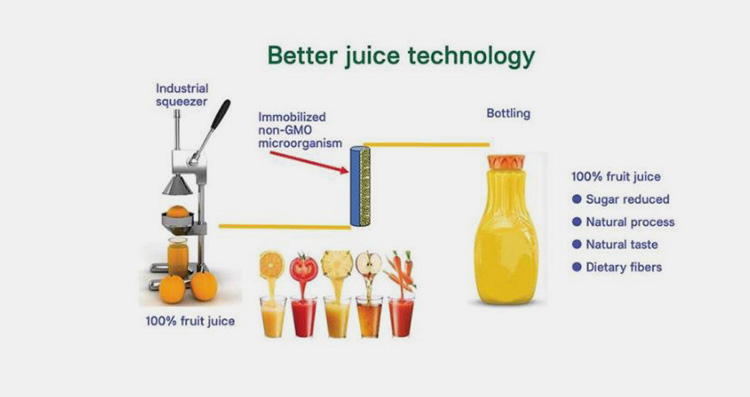

Beverage Industry

Beverage Bottles- Picture Courtesy: Dieline

This industry is the main business that utilizes huge quantities of bottles. Glass bottles are typically used for packaging sodas, juices, milk, iced tea, and coffee. So, the bottle rinsing machine is part of such production and washing these glass and plastic bottles before filling to avert cross-contamination and to eliminate impurities that could cause health risks.

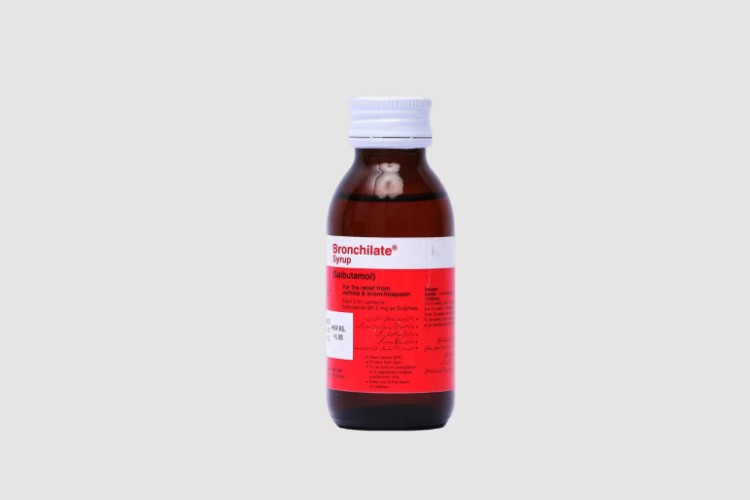

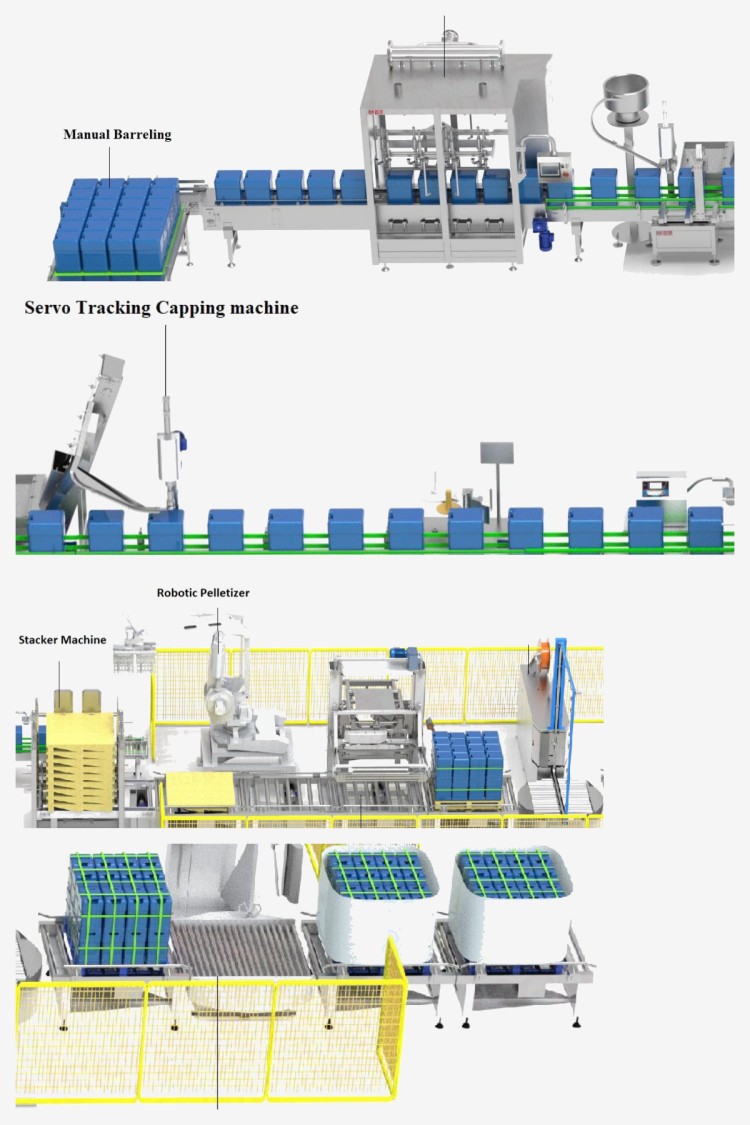

Pharmaceutical Industry

Pharmaceutical Bottles- Picture Courtesy: Pharmaceutical Technology

It is very important to de-dust and polish pharmaceutical bottles before their packing. The medicinal and supplement bottles are purified by a bottle rinsing machine for clean filling of capsules, pills, syrups, emulsions, supplements, etc.

Cosmetic Industry

Cosmetic Bottles

Aesthetic products are applied directly on the skin, so, they must be loaded inside uncontaminated and fresh cosmetic bottles that are clear of dust, debris, and other foreign objects. Bottle rinsing machine is highly regarded in this aspect as it sprays water and cleaning agents from all angles to make cosmetic bottles safe for packaging.

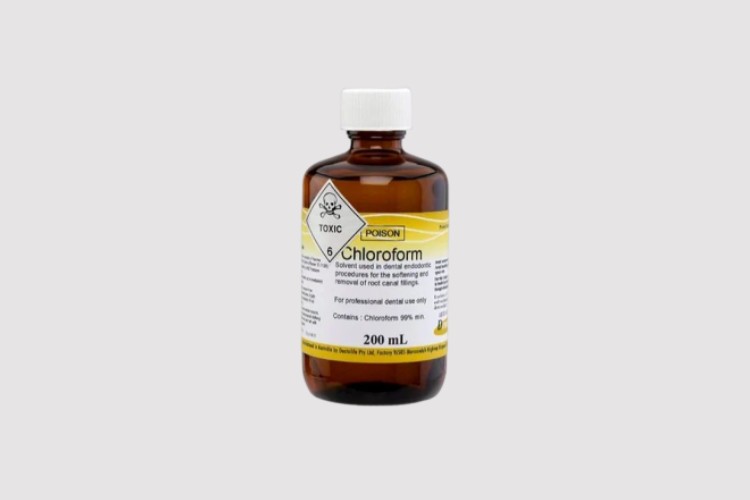

Chemical Industry

Chemical Bottles- Picture Courtesy: RCI Labscan

Generally, laboratories and large-scale industries need chemicals in their pure form, otherwise, unwanted outcomes occur in reactions. Therefore, the chemical filling industry use bottle rinsing machine for rinsing and cleaning used chemical bottles and jars.

House-Hold Industry

Household Chemical Bottles- Picture Courtesy: ThoughtCo

Bulk quantities of antiseptics, cleaning agents, detergents, soaps, bleaches, dyes, sanitisers, and many more come in stylish and elegant bottles. But these bottles must be rinsed and that is where bottle rinsing machine shows its worth to the household industry.

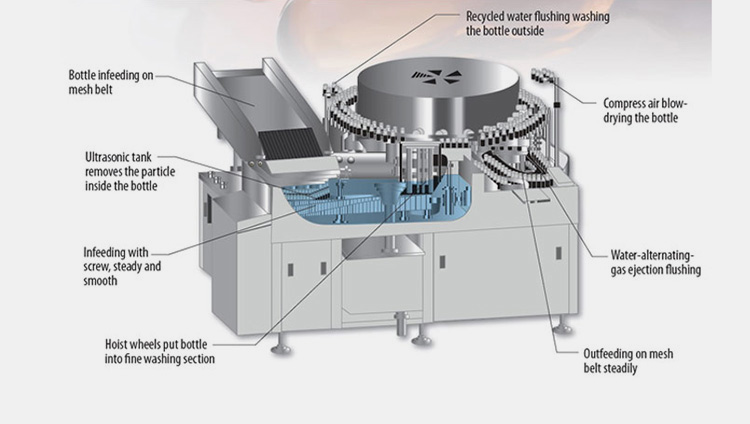

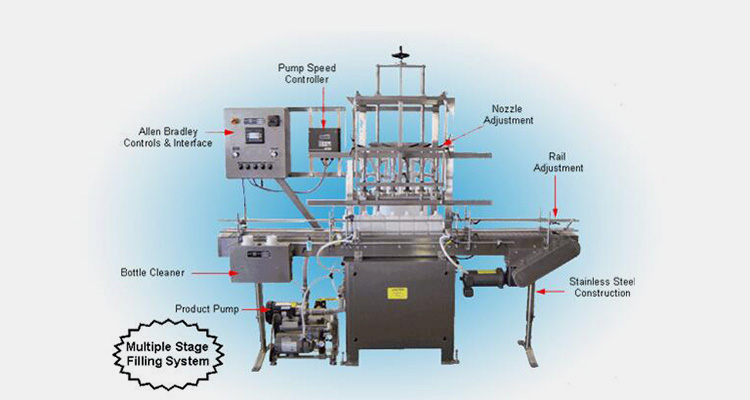

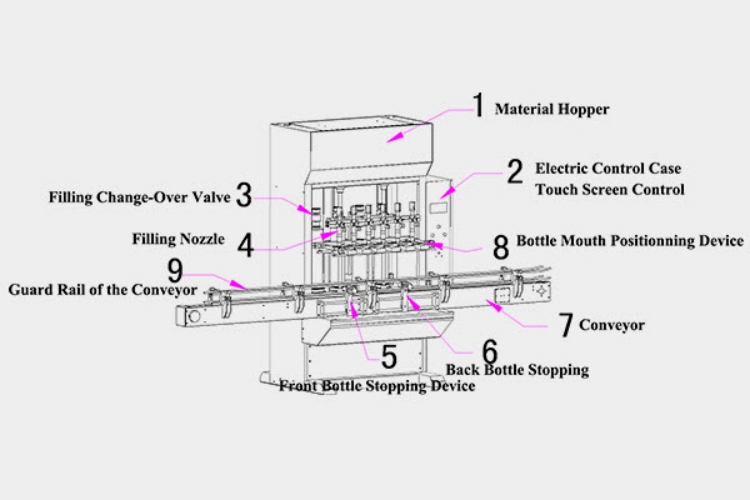

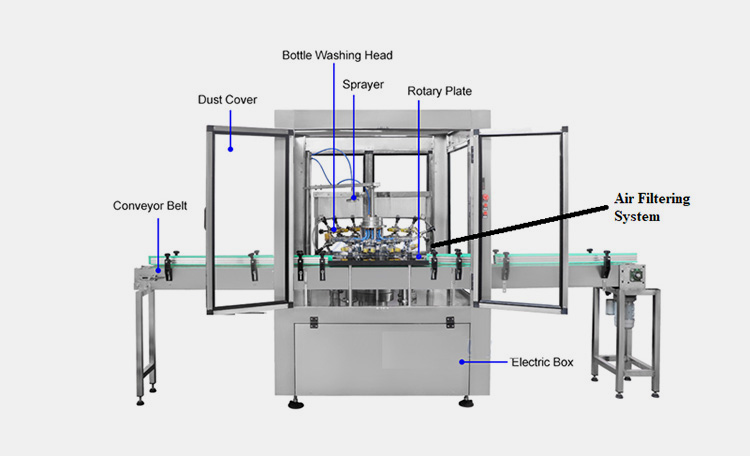

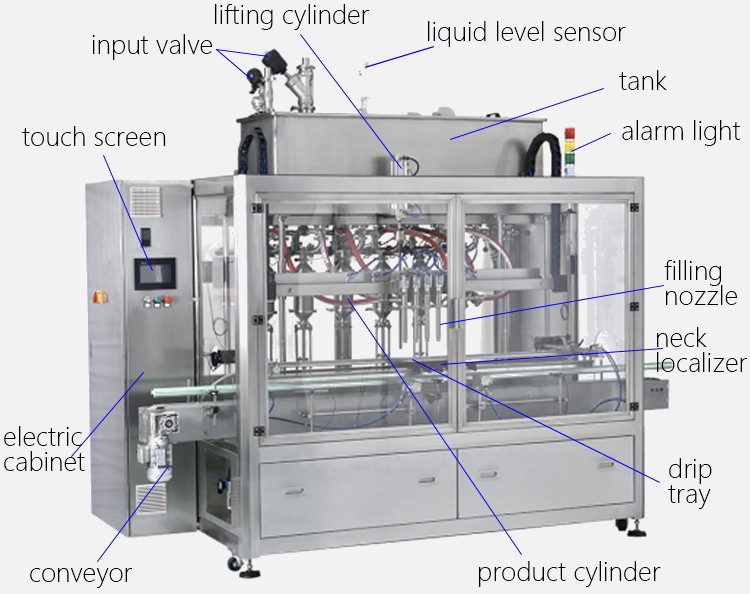

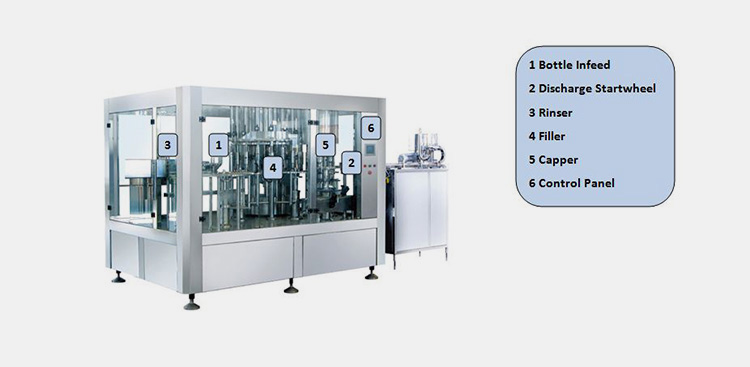

4.What are the Basic and Important Parts of a Bottle Rinsing Machine?

Parts of Bottle Rinsing Machine

This machine is comprised of different specialized parts, each having a vital role in completely rinsing and cleaning the bottles. A detailed description of these parts is given below:

| Bottle Infeed Belt | It is a chute-like structure in which large loads of bottles are placed for smooth and effortless movement of the bottle. This is equipped with a mesh belt that aids in the efficient flow of bottles. |

| Ultrasonic Tank | This is the part in which high-frequency ultrasonic waves are targeted on bottles. The sonicator device emits ultrasonic waves and this tank is commonly seen in ultrasonic bottle rinsing machines. |

| Hoist Wheels | These are lifting systems that smoothly carry the bottles and place them in the washing area. These are the cylindrical devices over which bottles are placed for their insertion in the rinser. |

| Recycled Water Flushing Station | For rinsing and washing bottles and other containers, rinsing nozzles at this station dispense heavy sprays of recycled water to wash the foreign particles from the bottles. |

| Drying Station | It is typically found in wet bottle rinsing machines. At this station, a hot blast of air is introduced over the bottles to dry off water molecules that lingered after rinsing. |

| Out Feed Chute | It is a sliding channel that removes the bottles from the machine. |

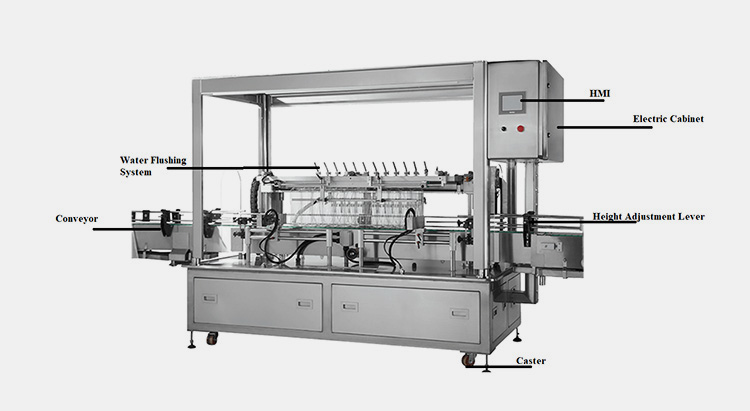

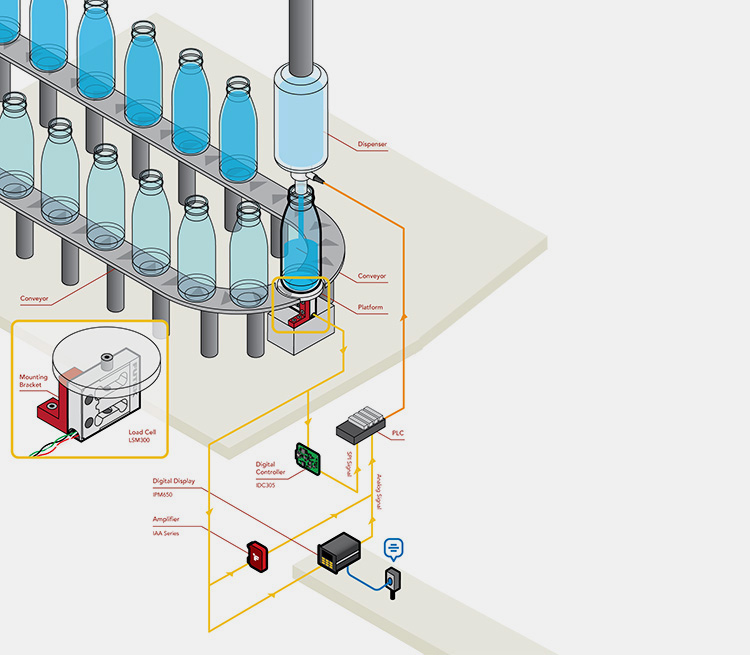

| Conveyor | A large belt-driven conveyor that supports and guides bottles through rinsing and drying stations. |

| Caster | This is a wheel-like component that rotates for easy portability of the bottle rinsing machine. |

| Height Adjustment Lever | To accommodate different-sized bottles, levers are present at the sides of the conveyor. These components are rotated to modify the height of the bottle according to the height of the container. |

| Electric Cabinet | For the safety of the workforce, different kinds of electric parts, for instance, cables, wires, relays, breakers, and power buttons are located inside the sturdy electric cabinet. It is an electricity-providing unit of the machine. |

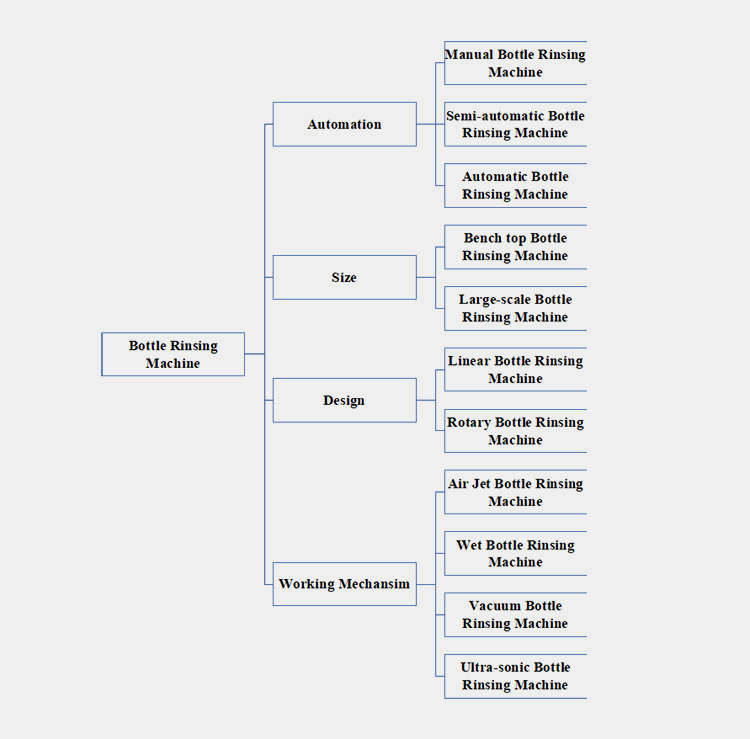

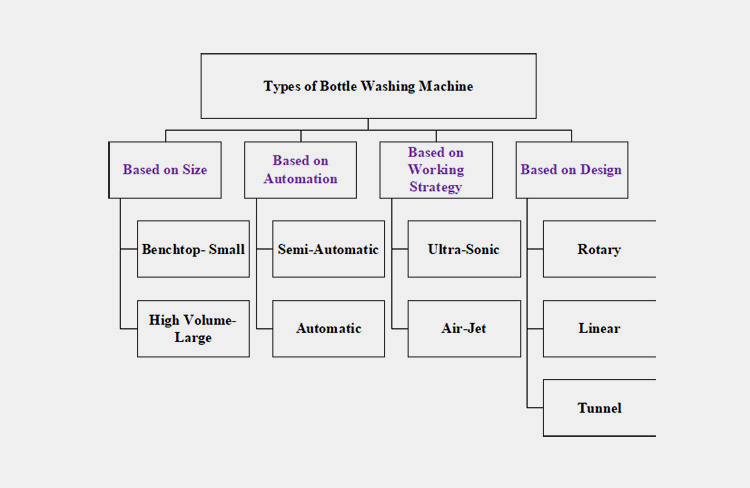

5.Can You Tell About Types of Bottle Rinsing Machine?

There are diverse makes and models of bottle rinsing machines that utilize different working principles and have different configurations as well as automation levels. A complete classification of this useful system is written below for your aid:

According to Automation

Manual Bottle Rinsing Machine

Manual Bottle Rinsing Machine- Picture Courtesy: Allma.net

It is a small machine typically, seen in small home-based settings and laboratories. It has a primitive design with a washing mould tray. The bottles are placed in the mould cavities and water is sprayed from the valves. This washing water is supplied by the hose connected to the water supply. It generally processes a limited number of bottles in one setting.

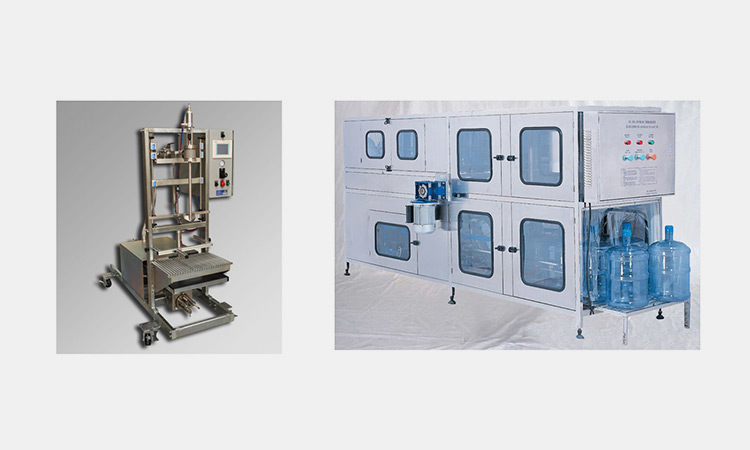

Semi-automatic Bottle Rinsing Machine

Semi-automatic Bottle Rinsing Machine- Picture Courtesy: Criveller Group

It is comparatively larger than its simple manual bottle rinsing machine. This machine is best for achieving typically larger processing capacity on a medium-sized budget. Loading of bottles is manually performed by operators on this unit while spraying of water and washing is carried out independently. It is built for rinsing diverse sizes of bottles.

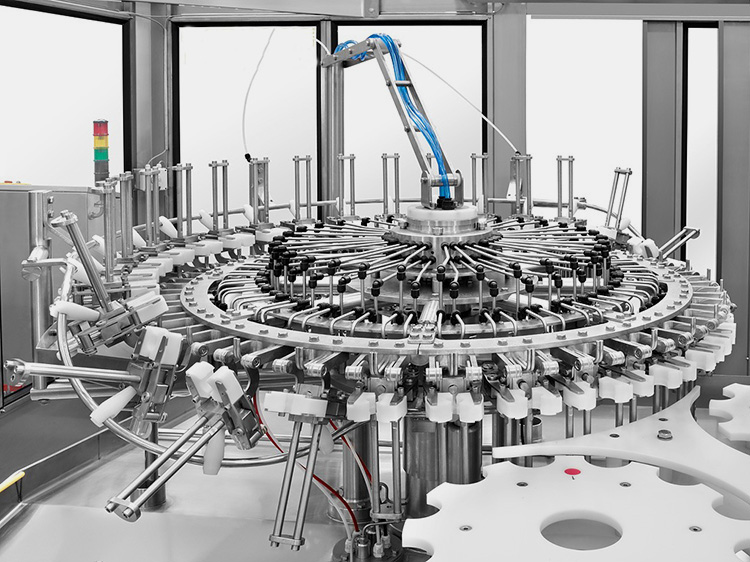

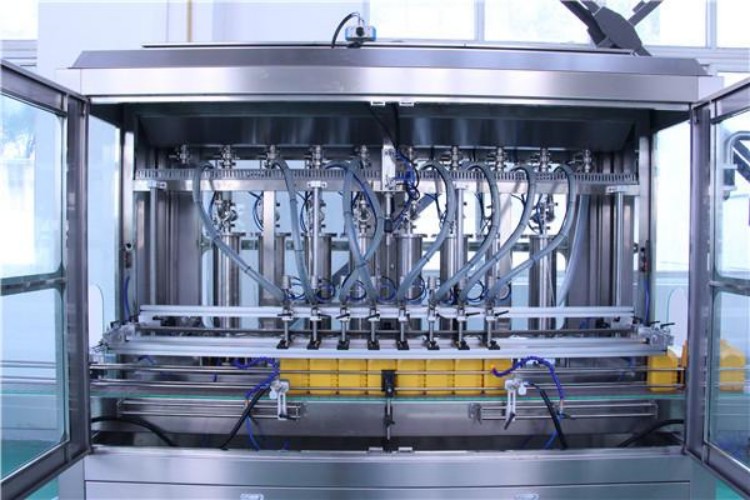

Automatic Bottle Rinsing Machine

Automatic Bottle Rinsing Machine- Picture Courtesy: IC Filling Systems

It is a modular construction made with heavy-duty materials and is best for rinsing bottles on a large scale. A large output rate is attained by rinsing hundreds to thousands of bottles in one batch. Every working stage-loading, filling, unloading- is completed by the machine with little to no human involvement. This machine features large nozzle systems and heavy air jets are used for rinsing bottles.

According to Size

Benchtop Bottle Rinsing Machine

Benchtop Bottle Rinsing Machine- Picture Courtesy: DirectIndustry

It is an ideal solution for small pharmacies and medium-sized production that have space and budget constraints. It is a cost-effective solution because of its simple automation. Benchtop bottle rinsing machine has a compact configuration and takes less room for its setup. It can treat and rinse moderate-sized batches in one wash cycle.

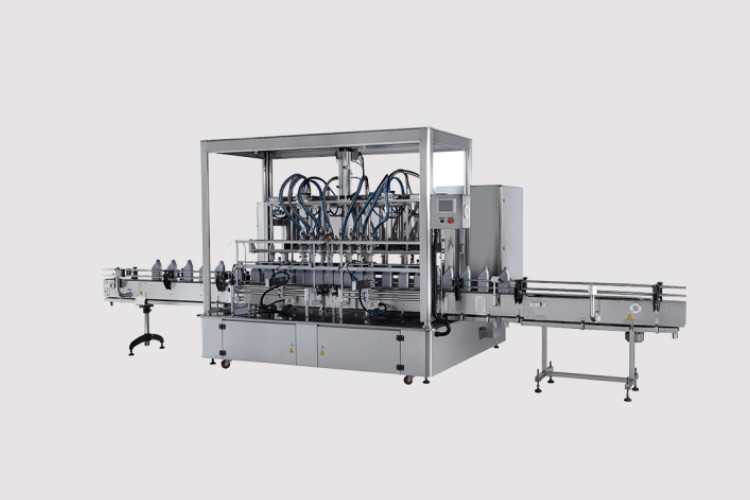

Large-scale Bottle Rinsing Machine

Large-scale Bottle Rinsing Machine- Picture Courtesy: TRAKTECH

As the name suggests, it is a gigantic assembly that gives an edge to large production because of its huge output rate. With its state-of-the-art wash nozzles, large pressure units, heavy-duty pumps, and motors, it allows efficient and instant rinsing. It is installed in larger settings that run 24/7 without stopping. It is easily integrated into the bottle processing plants.

According to Design

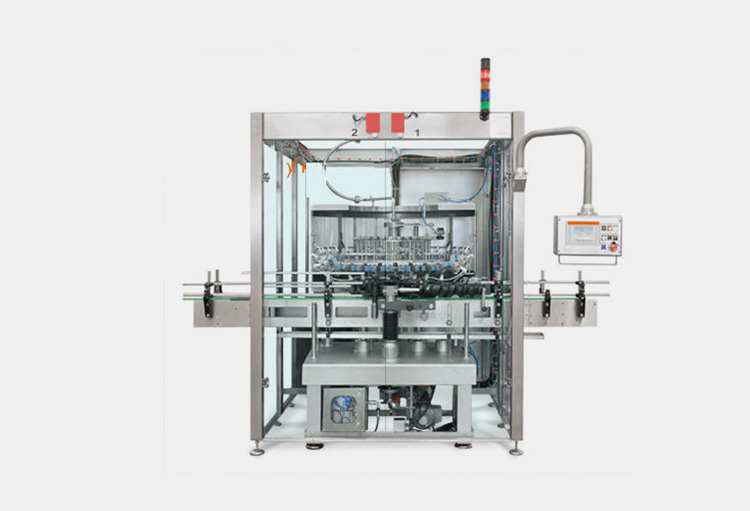

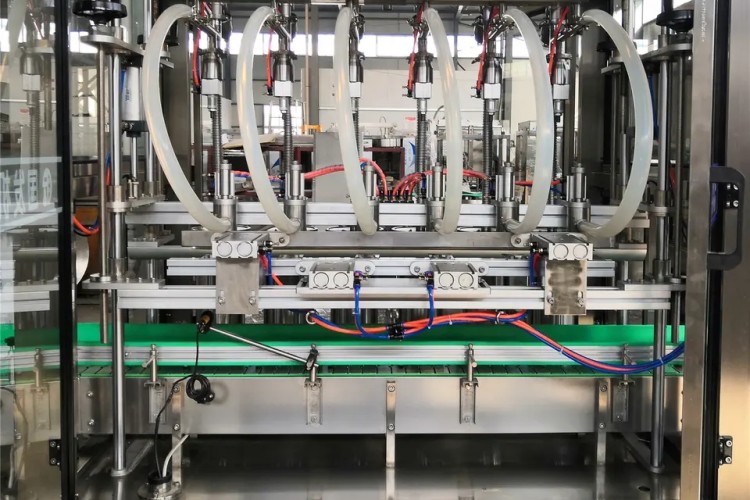

Linear Bottle Rinsing Machine

Linear Bottle Rinsing Machine- Picture Courtesy: TRAKTECH

With larger conveyors for transport, this machine type opts for a straight-line design. It has one or more washing nozzles fitted after one another for a quick wash. It is typically installed in medium-sized production due to its less processivity than its counterparts. However, it is a cost-effective system and allows for easier integration in bottle filling and capping setups.

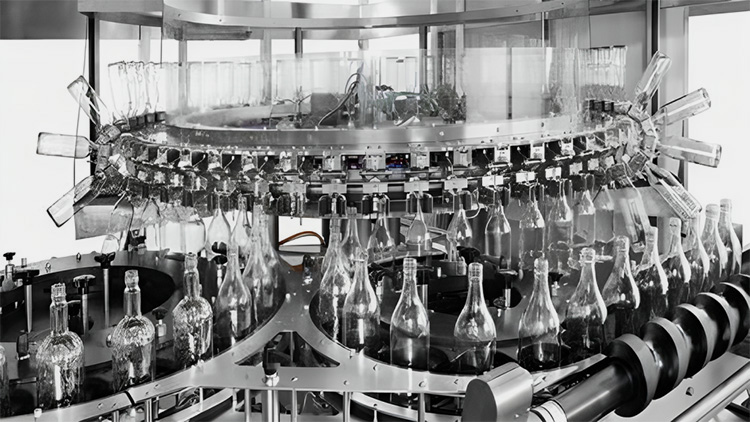

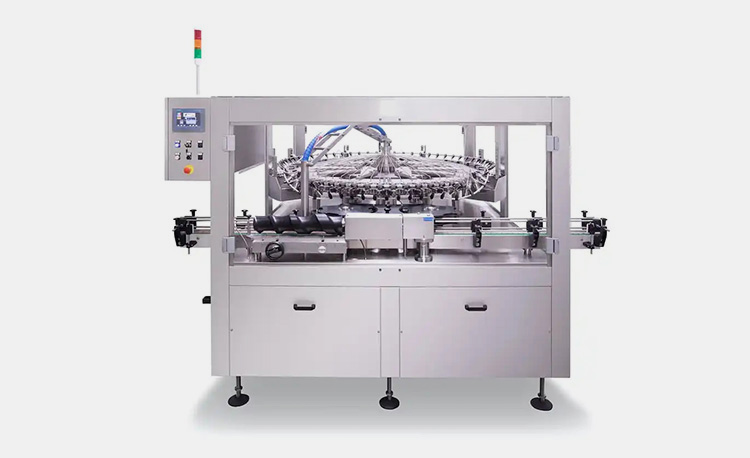

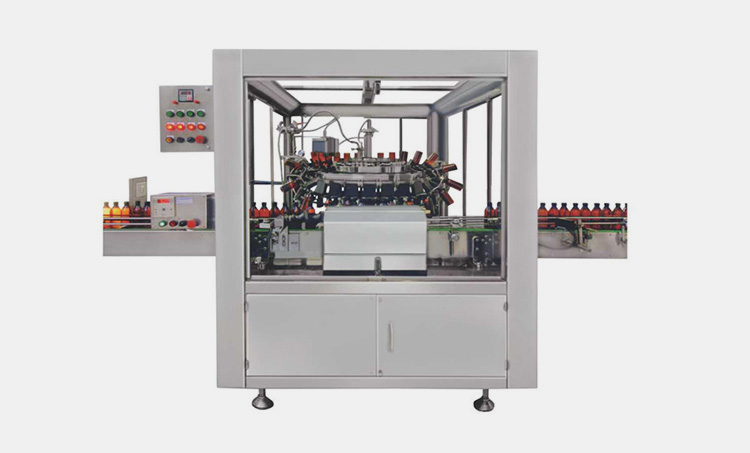

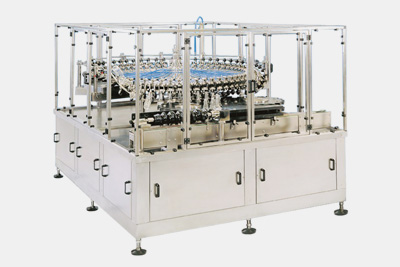

Rotary Bottle Rinsing Machine

Rotary Bottle Rinsing Machine- Picture Courtesy: IC Filling Systems

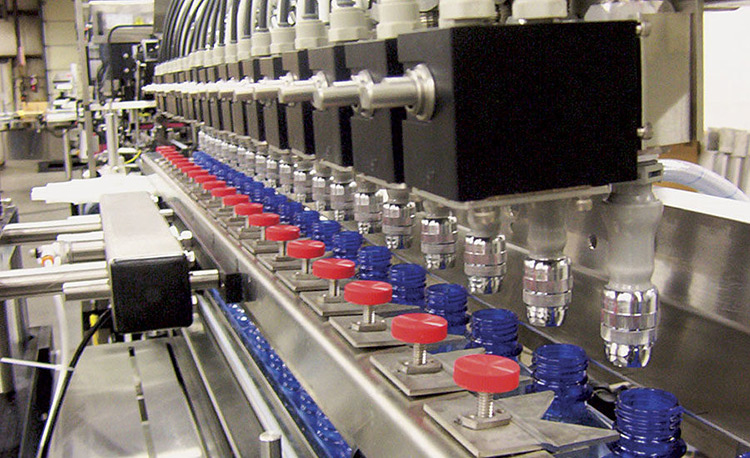

Large-sized and heavy processing businesses prefer this system because of its fast-paced rinsing, dedusting multiple batches in hours. The rotary carousel and star wheel have numerous rinsing and airing systems that swiftly wash and dry glass and plastic bottles within seconds. With the rotation of the star wheel, bottles go to different rinsing stations for absolute cleaning.

According to Working Mechanism

Air Jet Bottle Rinsing Machine

Air Jet Bottle Rinsing Machine- Picture Courtesy: vkpak

In this system, ionized air or large air jets are targeted at the bottles to remove dust or sticky residues from the interior of bottles. The clean air sucks the debris out of the bottle. It is an efficient system that lowers water wastage and is preferred by industrial sectors. With the blast of air, the foreign objects get loose and are easily removed from the bottles.

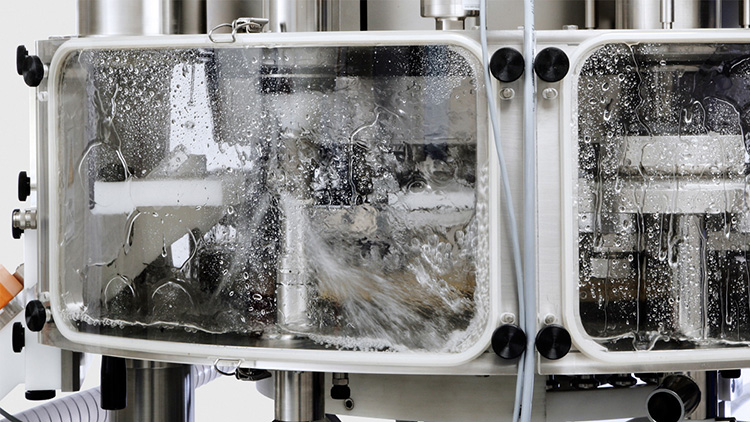

Wet Bottle Rinsing Machine

Wet Bottle Rinsing Machine- Picture Courtesy: DirectIndustry

It is the most commonly used machine that employs pressurized water to wash unwanted objects from the bottles. It uses pre-set rinsing time for rinsing bottles with water spray. Rinsing nozzles are employed for cleaning contaminants from the surface as well as inside of bottles.

Vacuum Bottle Rinsing Machine

Vacuum Bottle Rinsing Machine- Picture Courtesy: DirectIndustry

This machine employs a vacuum system to create low air pressure for eradicating bottles of undesired particles like dirt or fragments. It is a feasible solution for the uniquely shaped, twisted and heavy bottles. The containers are not inverted for cleaning instead they remain on the conveyors for the rinsing process.

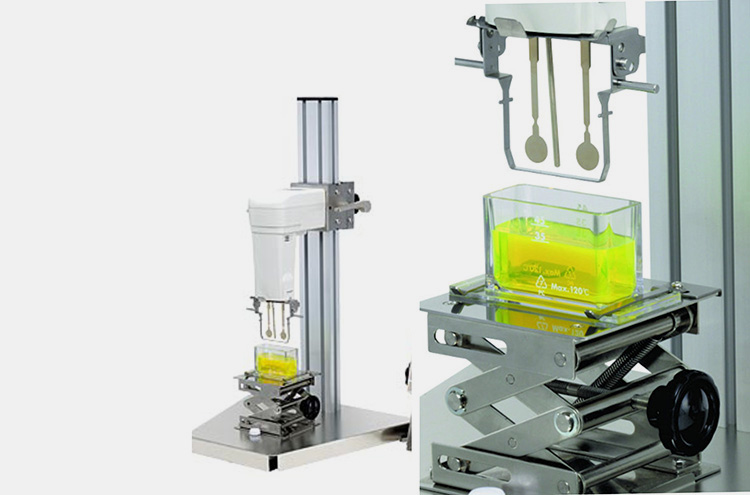

Ultra-sonic Bottle Rinsing Machine

Ultra-sonic Bottle Rinsing Machine- Picture Courtesy: Aipak

This machine uses high-power ultra-sonic waves for systematically cleaning hidden crevice bottles. These waves hit the bottles and dislodged sticky objects from the walls and base of the bottles. Ultra-sonic bottle rinsing machine is ideal for washing bottles with narrow openings and complex designs.

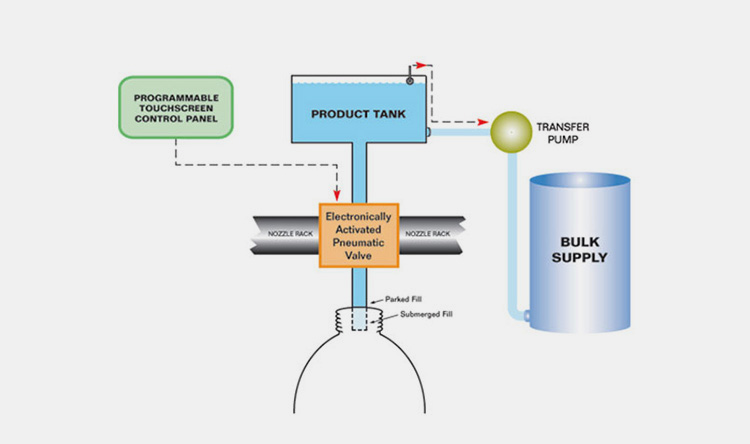

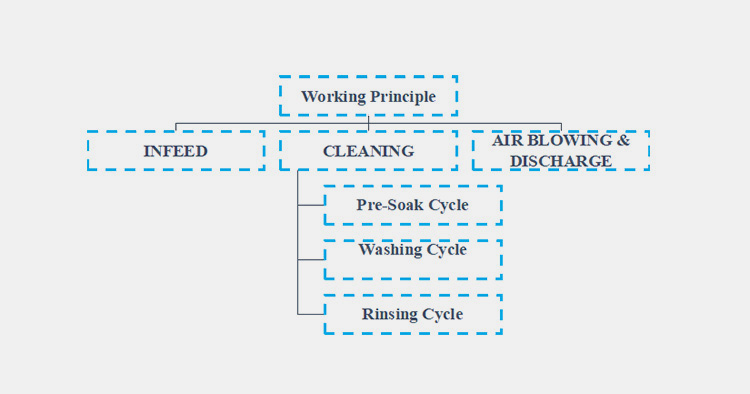

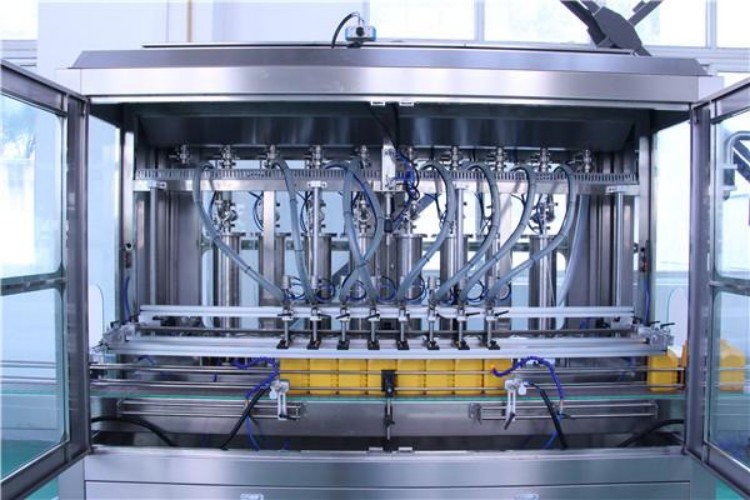

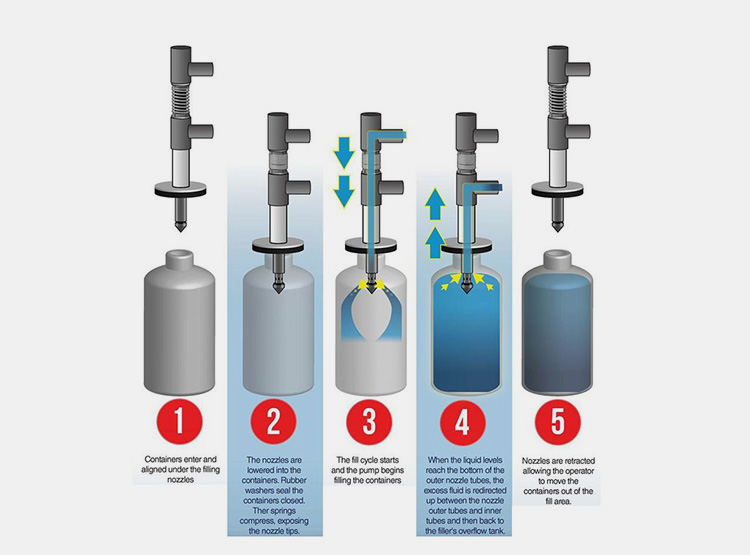

6.How Does Bottle Rinsing Machine Works?

Bottle rinsing machines work in a straightforward manner in which each step is carefully carried out under the guidance of a PLC system. The working stages are described below:

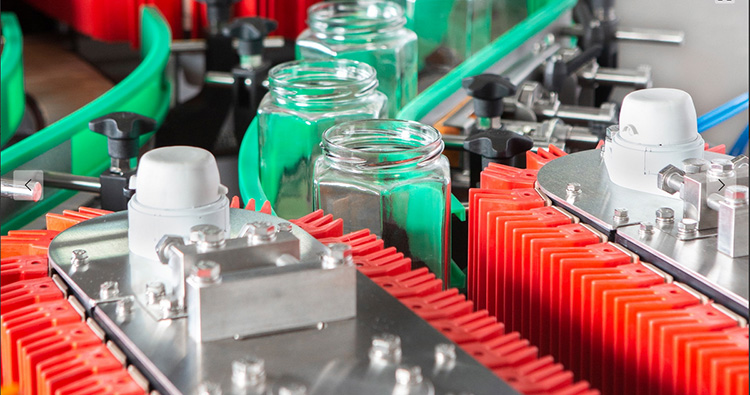

Bottle Infeed

Bottle Infeed- Picture Courtesy: TRAKTECH

First, the bottles are positioned on the conveyor either by using a bottle unscrambler that methodically places bottles after a fixed interval on the belted conveyor or by the operators. On a rotary type of bottle rinsing machine, grippers carry each bottle efficiently and place it into a star wheel receptacle. Ultimately, these bottles are received by washing or rinsing station.

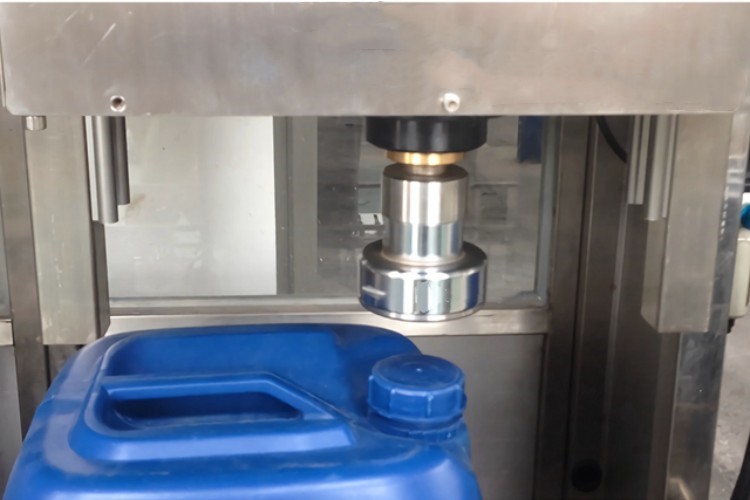

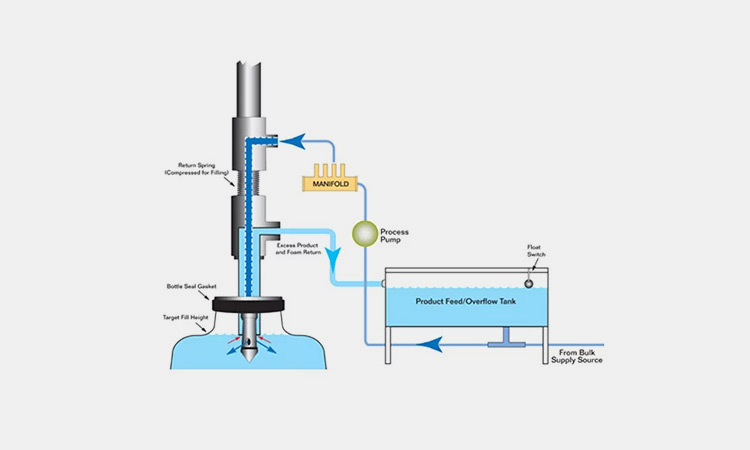

Rinsing

Bottle Rinsing- Picture Courtesy: motionarray

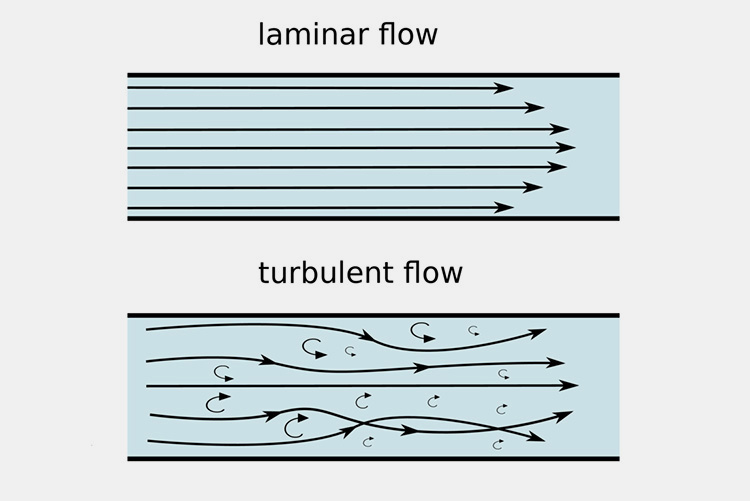

Here, different methods are employed for the rinsing of bottles, such as air, water, vacuum or ultra-sonic waves. The number of bottles indexed towards the rinsing station is determined by the number of rinsing nozzles.

On reaching the rinsing head, the soft pad gently grips the bottle and slowly inverts them onto the water basin and gushes of water are sprayed inside the bottles to loose any residues or dirt. In the case of the air rinsing machine, the first curtain of ionized air is formed first, before inverting the bottle. After inverting, the loose debris is drawn out of the bottle via a vacuum.

Drying

Bottle Drying- Picture Courtesy: NISSEI ASB MACHINE

It is an optional step performed only in a wet bottle rinsing machine. The bottles after rinsing are passed to the drying unit where clean air is blasted to vaporize excess water remaining after washing.

Bottle Unloading

Bottle Unloading- Picture Courtesy: Raconteur

After rinsing and drying, bottles are moved to the outfeed chute from where they are collected and fed to subsequent machines in the production line.

7.What Safety Practices are Adopted by a Bottle Rinsing Machine?

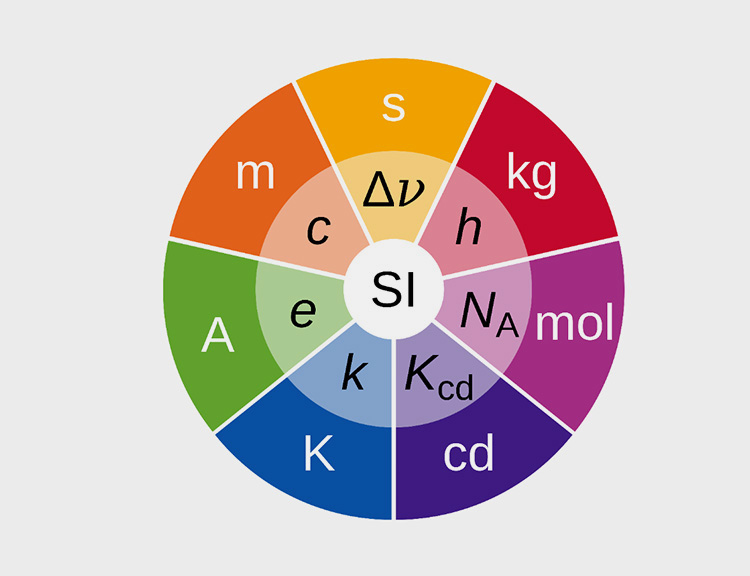

When processing bottles for pharmaceutical and food filling, the machine must fulfil strict industrial obligations such as that of the FDA, ISO, and GMP. To meet these requirements, bottle rinsing machine must have different features such as:

High-Quality Materials

High-Quality Materials- Picture Courtesy: Clearpack

This machine is constructed with high-quality and food-grade materials like stainless steel, Teflon, and rubber gaskets. The frame, spray nozzles, rotary tables, and hose pipes are fabricated with corrosion-resistant constituents. These materials are durable, non-toxic, chemical-resistant and rust-resistant.

Cleanability

Cleanability- Picture Courtesy: Syntegon

Bottle rinsing machine is assembled with easily removable parts therefore, it aids cleaning efforts. Different parts of this machine have rounded corners, for instance, processing tanks. Also, some components are welded to avoid dead hard-to-clean corners. Furthermore, the components have smooth surfaces and minimal crannies, aiding in regular cleaning and maintenance.

Safety Glass

Safety Glass in Bottle Rinsing System- Picture Courtesy: vkpak

The whole cleaning section is surrounded by a plexiglass shield cover that is resistant to elements but offers a good view of the cleaning process. This prevents the risk of contamination and ensures the safety of operators.

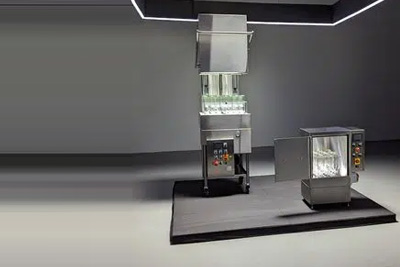

8.What is the Difference Between Bottle Rinsing Machine and Bottle Washing Machine?

Bottle Washing Machine- Picture Courtesy: Sidel

Although the terms bottle rinsing machine and bottle washing machine are interchangeably used, this is the fact that these machines have different working mechanisms and industrial usage. These differences are summarized in the table below:

| Features | Bottle Rinsing Machine | Bottle Washing Machine |

| Main Function | This machine is more suitable for the role of removing dirt, debris, or loose particles from the bottles. | Its specific role is to meticulously wash and sterilize bottles to avoid contamination and microbial growth. |

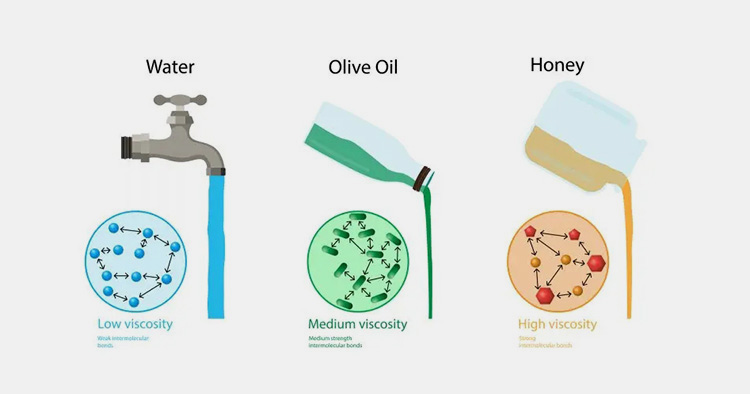

| Cleaning Medium | It uses water spray, ionized air, ultrasonic waves, and vacuum for rinsing bottles. | It normally utilizes detergents, steam, sanitisers, or all three to accomplish a high level of cleanliness. It is also equipped with brushes and scrubs to wash the machine. |

| Usage | This equipment is typically employed in low-risk settings and is usually an initial step beforehand bottle washing. | It is typically found in high-risk industries and is the main equipment to sanitize bottles for foodborne germs. |

9.How To Troubleshoot Technical Problems in Bottle Rinsing Machine?

Like other machines, technical problems may arise in the bottle rinsing machine that could lead to extensive downtimes and higher repair costs. But with simple training of operators, these downtimes can be minimized. Here are some informative tips to troubleshoot technical problems:

Insufficient Rinsing

Insufficient Rinsing- Picture Courtesy: DirectIndstry

At times, visible water marks are seen on the surface of a bottle, indicating the inadequate rinsing of bottles.

Cause

This problem may arise because of clogged rinsing heads. It could also be due to insufficient pressure of water spray.

Troubleshooting

To avoid this problem, it is recommended to maintain a proper cleaning timetable and especially clean and wipe the interior of the nozzle for best rinsing results. Adjust the water pressure to achieve adequate cleaning.

Water or Air Spray System Not Working

Water or Air Spray System Not Working- Picture Courtesy: APG Pharma

Sometimes, on starting the machine, no water or air jet is observed.

Cause

Failure in the working of the spray system is due to blocked or congested nozzles. There could be an error in the water or air pressure system. A defective solenoid valve may also affect the working of the spray system.

Troubleshooting

To remedy this problem, wash the rinsing heads with strong detergents. Moreover, fix the water and air pressure to achieve appropriate spray. Also, examine the solenoid valve for fault and repair it.

Jamming of Bottles in the Machine

Jamming of Bottles in the Machine- Picture Courtesy: Traktech

Sometimes, the bottles get stuck inside the machine parts, for instance, carousel, hoist wheel, etc.

Cause

It could be due to poor leveling and skewness of the conveyor. It could be due to hindrance and interruption on the conveyor. The hoist wheel or rotary star wheel could have some mechanical defects.

Troubleshooting

To rectify this problem, first, it is suggested to realign and properly level the conveyor system. Second, clear the obstructions from the moving pathway of bottles. Repair the mechanical faults of the hoist wheel and star wheel.

Dripping of Water After Washing

Dripping of Water After Washing

Small droplets of water drip down the nozzles after the bottle rinse.

Cause

This problem could arise because of heavy water pressure. Moreover, poor positioning of the nozzle could lead to dripping. Fault in the drain system could also cause dripping.

Troubleshooting

Adjust the water pressure. Level and align nozzles and fix the fault in the drainage system.

Poor Drying of Bottles

Poor Drying of Bottles- Picture Courtesy: Traktech

Minute droplets of water are observed in the bottles after drying.

Cause

Poor timing for drying. Defects in the drying systems especially air blowers could be the reason for this problem.

Troubleshooting

Fix the time duration for drying to solve this issue. Also, check and repair the defects in the air blowers.

10.What are Buying Consideration for Choosing Top Notch Bottle Rinsing Machine?

Generally, bottle rinsing machine has different advanced features and comes with superior specification, resulting in much higher purchase cost. Therefore, it is imperative to consider the following items when finding a bottle rinsing machine for a particular project:

Cost and Return on Investment (ROI)

Cost and Return on Investment (ROI)

First, calculate the machine cost and assess the possible ROI. Think of the machine's entire worth in terms of production, efficiency, quality, and durability. Cost is vital, but you should not compromise on bottle rinsing machine automation and work efficiency. When buying a machine, you should also need to consider the long-term advantages and how they will affect your business in addition to buying costs.

Production Rates

Higher Production Rates- Picture Courtesy: FILLEX

Another important thing is your required production rate and this is determined by the level of automation. Different types of bottle rinsing machines have varying automation. Estimating the production rate of a specific project will give you a clear idea about the automation level.

Flexibility and Versatility

Flexibility and Versatility- Picture Courtesy: The Business Journal

Also, you must check whether the bottle rinsing machine offers flexibility to accommodate future changes in bottle designs and geometries. Machines with adjustable rinsing parameters and customizable features can be adapted to different bottle sizes and shapes with a swift and simple change of filling heads and conveyor height.

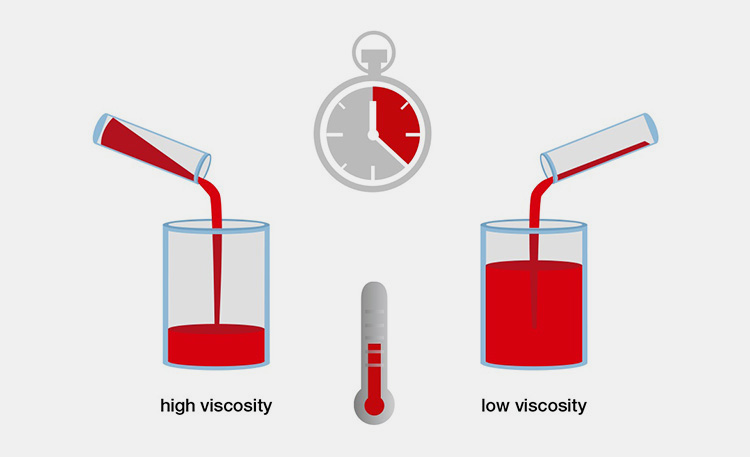

Rinse Type

Rinse Type- Picture Courtesy: Krones

A bottle rinsing machine uses different rinsing media, such as air, water, or ultrasonic waves. Wet bottle rinsing machines might have a drying chamber while air rinsing machines utilize ionized air for developing electrostatic charges to fully cleanse bottles. But rinsing type is determined by the specific needs of the project, which in turn depends on the characteristics of bottles and products.

Machine’s Long Shelf Life

Bottle Rinsing Machine- Picture Courtesy: TRAKTECH

Consider the brand quality and reputation of the manufacturer while evaluating the dependability and durability of the machine. For long-lasting service, look for a machine constructed with high-quality materials and components. Reading client feedback may provide knowledge about a machine's dependability and performance.

Conclusion

In short, a bottle rinsing machine is a must-have automation in production for sanitation and safety purposes. With rigorous water jets and air blowers featured in this machine, an absolute and fine cleaning is accomplished. Moreover, by having this solution in production, a business can gain a reputation for the safest quality standards among its customers. Keen on buying this handy equipment, then message our Allpack customer service just now. We will help you select an outclass machine for your business promptly.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Bottle Rinsing Machine: The Complete Buying Guide in 2025 Read More »