Vodka Whiskey Alcohol Bottling Line: The Complete Buying Guide In 2025

Vodka Whiskey Alcohol Bottling Line: The Complete Buying Guide In 2025

Do you intend to increase the production of your vodka or whiskey? Are you trying to find strategies to guarantee constant product quality while streamlining your bottling process? Establishing a bottling line can play a crucial role in the growth of your beverage business, but it may not be an easy and inexpensive venture.

Picture Courtesy: Bloomberg

Creating unit for vodka, whiskey, or other alcoholic drinks is a substantial expenditure that needs to be planned and thought out carefully. In alcoholic beverages, the bottling line must ensure the product’s safety, integrity, and quality while satisfying the production needs.

A well-selected bottling line may simplify your business processes, save labor expenses, and preserve the purity and uniformity of your product. However, choosing the best bottling line might be difficult given the abundance of alternatives available.

This article ‘vodka whiskey alcohol bottling line’ attempts to assist you in navigating the intricate process by outlining the important elements and aspects to consider while investing in it.

1.What is a vodka whiskey alcohol bottling line?

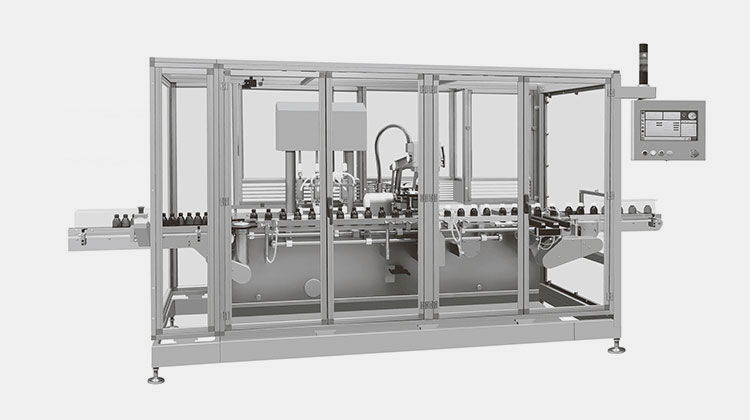

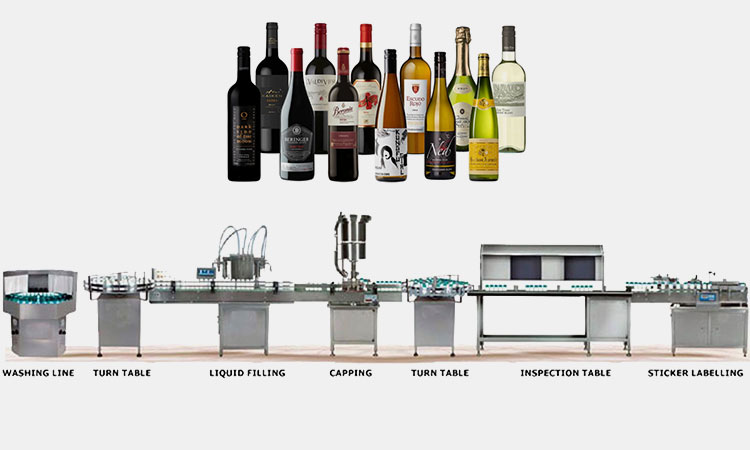

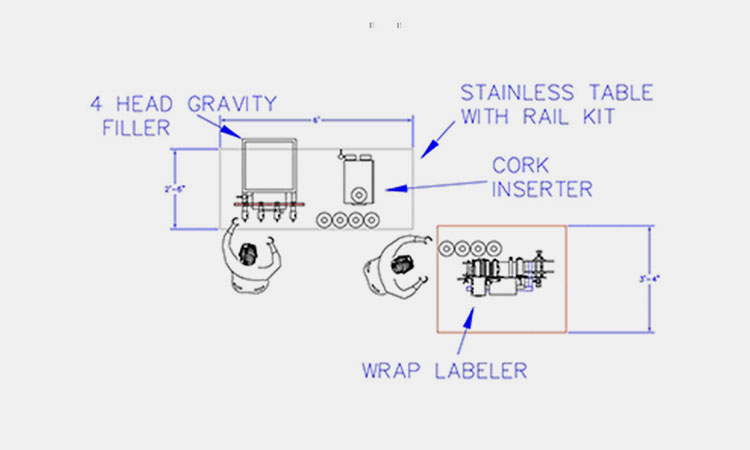

Vodka Whiskey Alcohol Bottling Line – Picture Courtesy: VKPAK

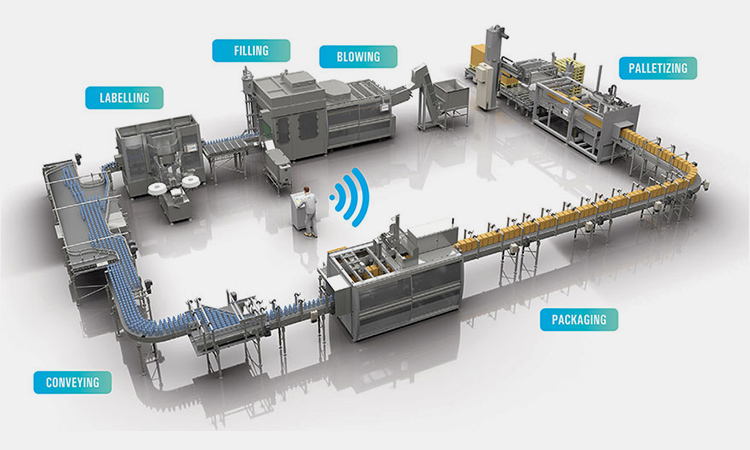

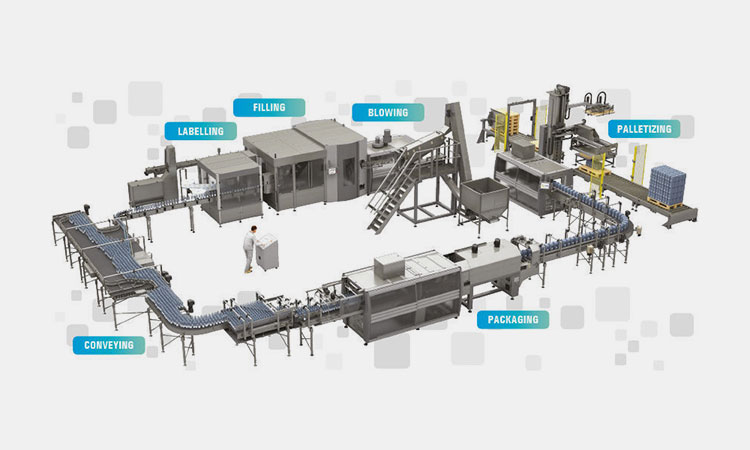

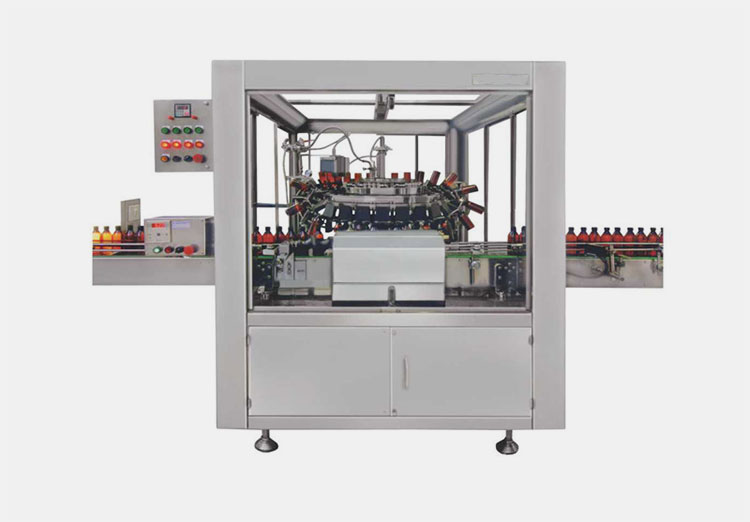

A vodka whiskey alcohol bottling line is an integrated system designed to fill bottles with liquid products, such as alcoholic beverages like wine, vodka, whiskey, scotch, and other liquids, seal them, label them, and prepare them for distribution.

It is an intricate production line specifically engineered for efficient packaging of various forms of liquid beverages in multiple bottles. The line consists of several interlinked devices that manage the whole bottling operation, ensuring precise filling with the right amount of liquid, tight sealing, and accurate labeling of every bottle.

2.How installing a vodka whiskey alcohol bottling line can be a worthy investment?

Installing a vodka whiskey alcohol bottling line in your industry can be a worthy investment. It will bring greater value to your business, offering numerous benefits, including maximizing production output, efficiency, cost savings, and rapid processing.

Some of the fundamental benefits provided by a vodka whiskey alcohol bottling line are discussed here:

Increased Production Output

Increased Production Output

The vodka whiskey alcohol bottling line encompasses upgraded equipment technology. These gadgets ensure that everything runs smoothly and automatically, eliminating the need for human connectivity and ultimately resulting in increasing the overall production output.

Enhanced Processing Efficiency

Enhanced Processing Efficiency

The vodka whiskey alcohol bottling line automates the bottling process using digitally advanced equipment. It reduces the manual interaction and enhances the processing efficiency, benefitting the business growth and profits.

Precise Filling and Effective Capping

Precise Filling and Effective Capping

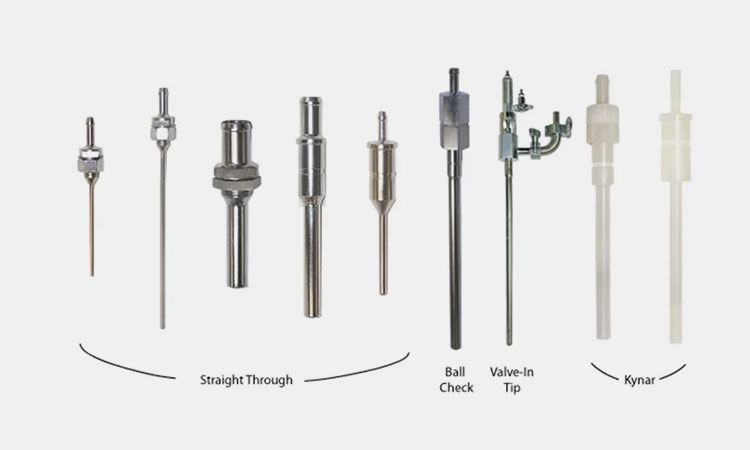

The filling precision is essential in the majority of industries. The vodka whiskey alcohol bottling line ensures precision in filling bottles by employing various filling mechanisms, such as pneumatic pumps, piston cylinders, and vacuum filling.

Moreover, the bottling line also aids in the automatic capping of bottles, offering more rapid and effective results than traditional methods.

Improved Product Quality and Brand Image

Improved Product Quality and Brand Image

The overall efficiency, precision, and secure processing of the vodka whiskey alcohol bottling line enhances the product quality. It also preserves the liquid’s inherent characteristics, leading to more customer satisfaction, brand building, and eventually more revenue generation.

Long-Term Cost Benefits

Long-Term Cost Benefits

It is understood that investing in the vodka whiskey alcohol bottling line requires a considerable amount of money. However, the value it provides in the long run makes it a worthy investment. The bottling line maximizes the throughput and accuracy and maintains the product’s safety and integrity.

It automates the entire production process and thus minimizes labor expenses and time consumption.

Consistency and Versatility

Consistency and Versatility

The vodka whiskey alcohol bottling line is a reliable production line, offering accurate results consistently and effective handling options for various liquids and container sizes, making it an indispensable component of most industries.

3.Which industries can employ a vodka whiskey alcohol bottling line?

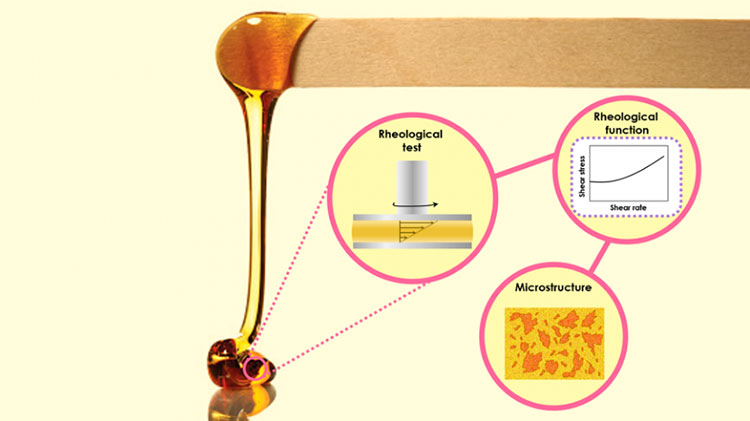

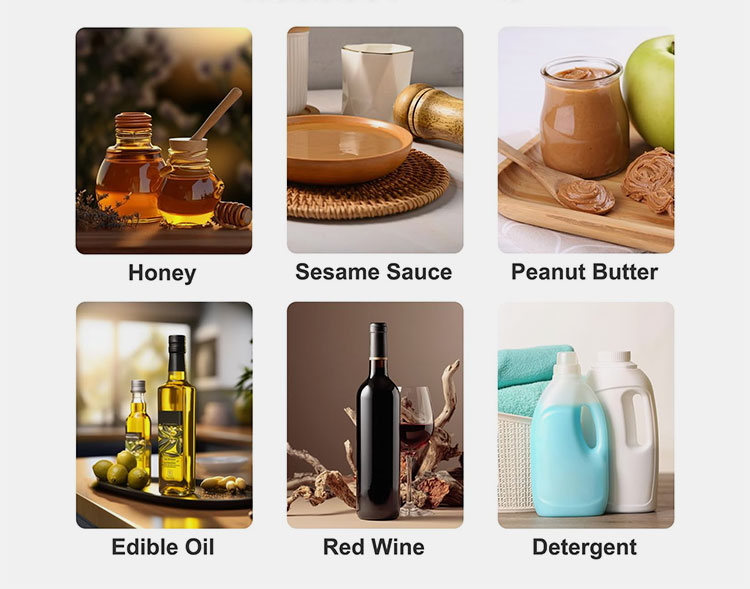

The vodka whiskey alcohol bottling line is a renowned liquid production line widely adopted across industries due to its tremendous benefits of the effective and safe packaging of various liquid items, including all sorts of viscous and non-viscous liquids.

Some of the key industries that have employed the vodka whiskey alcohol bottling line are highlighted below:

Beverage Industry

Applications of Vodka Whiskey Alcohol Bottling Line in the Beverage Industry

It is the primary sector where a vodka whiskey alcohol bottling line is used. The line is employed for securely packaging various alcoholic and non-alcoholic beverages, such as wine, whiskey, vodka, scotch, gin, coffee, juices, soft drinks, and energy drinks.

It is used for bottling these liquids in various suitable containers.

Food Industry

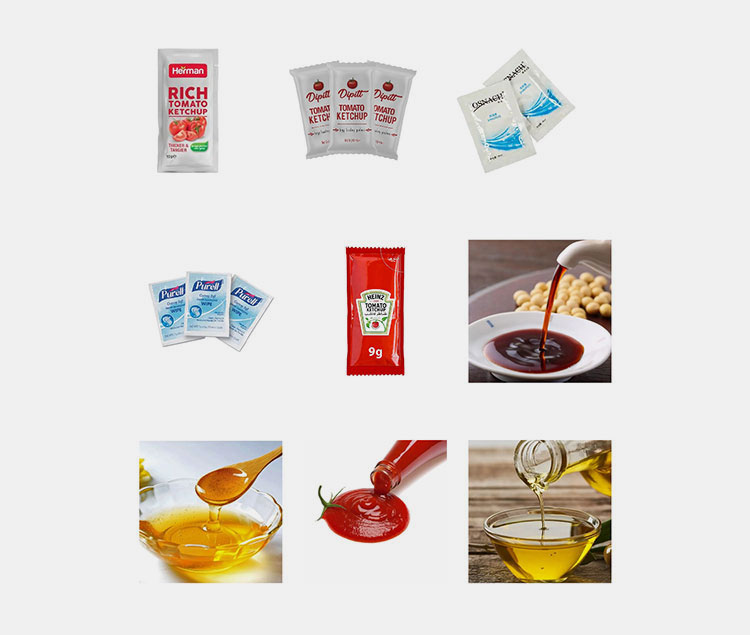

Applications of Vodka Whiskey Alcohol Bottling Line in the Food Industry – Picture Courtesy: Gravel & Dine

As the vodka whiskey alcohol bottling line can handle all sorts of viscous and non-viscous liquids effectively, it has wide applications in multiple industries, including the food industry. It can efficiently package several liquid food items, like ketchup, sauces, vinegar, oils, and honey.

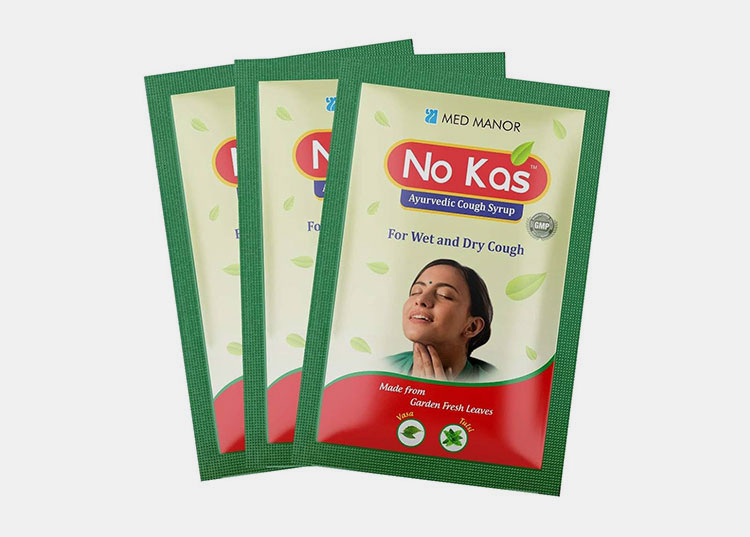

Pharmaceutical Industry

Applications of Vodka Whiskey Alcohol Bottling Line in the Pharmaceutical Industry

In the healthcare industry, precision is paramount. The vodka whiskey alcohol bottling line is therefore employed for its precise, effective, secure filling and bottling. Several medical products, such as syrups, suspensions, elixirs, enemas, and other liquid drugs, are bottled efficiently using a vodka whiskey alcohol bottling line.

Chemical Industry

Applications of Vodka Whiskey Alcohol Bottling Line in the Chemical Industry

Numerous liquid chemicals, including detergents, disinfectants, and pesticides, are securely bottled and capped using a vodka whiskey alcohol bottling line to avoid leakage.

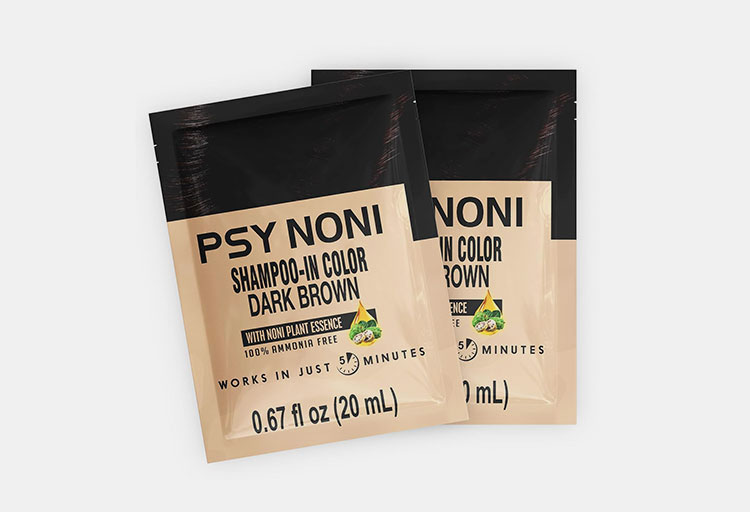

Cosmetics Industry

Applications of Vodka Whiskey Alcohol Bottling Line in the Cosmetics Industry

In the cosmetics industry, the vodka whiskey alcohol bottling line is utilized for packaging various beauty care products.

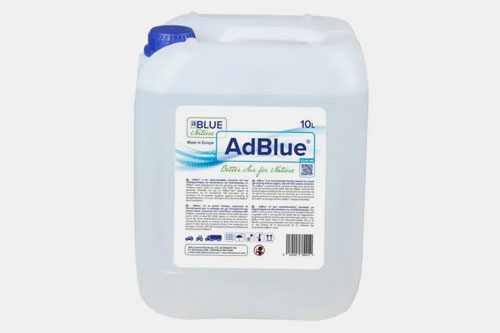

Automobile Industry

Applications of Vodka Whiskey Alcohol Bottling Line in the Automobile Industry

In the automobile and automotive care industry, the vodka whiskey alcohol bottling line can package diverse products, such as mobile oils, battery acids, and windshield washer fluid.

Treated Water Supply Industry

Applications of Vodka Whiskey Alcohol Bottling Line in the Treated Water Supply Industry

Various water supply sectors in the market supply treated and clean water to many household and commercial customers. These industries have adopted the vodka whiskey alcohol bottling line for efficient results.

4.What types of bottles can be supported by the vodka whiskey alcohol bottling line?

The vodka whiskey alcohol bottling line is a sophisticated production line that can handle a variety of containers effectively. It offers personalized system options for each type of container with varied sizes, shapes and each liquid with varied density and viscosity.

Here are discussed some common container types used for liquid packaging in a vodka whiskey alcohol bottling line:

| Glass Bottles

These are the primary bottles used for alcoholic beverages. They can be of various shapes and sizes, designed for specific purposes. They are also used for containing medical syrups. |

|

| Plastic Bottles

These are other popular container types for containing liquid products, such as juices, coffee, drinks, water, vinegar, and sauces. The most common polymers used to fabricate these bottles are HDPE (High-density Polyethylene) and PET (Polyethylene Terephthalate). |

|

| Metal Cans

There are small cans made up of several metals, particularly tin cans, used for packaging several single-use products, such as soft drinks and energy drinks. |

|

| Jugs

These are large containers usually made of plastics and utilized for bottling bulk quantities of products. They have a capacity ranging from 5 liters to 5 gallons. |

|

| Jerry Cans

They are adaptable receptacles made for safe transportation and storage of sensitive liquids, such as mobile oils, kerosene oils, and petrol. |

|

| Drums/Barrels

These are large containers for storing, stocking, and supplying liquids in huge quantities. They are typically made up of HDPE polymer. Their capacity ranges from 50 to 220 liters. |

|

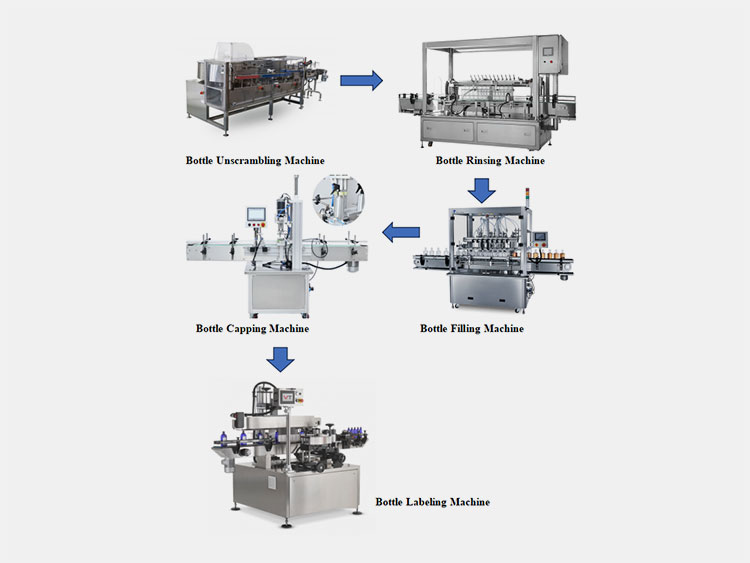

5.What devices are included in a vodka whiskey alcohol bottling line?

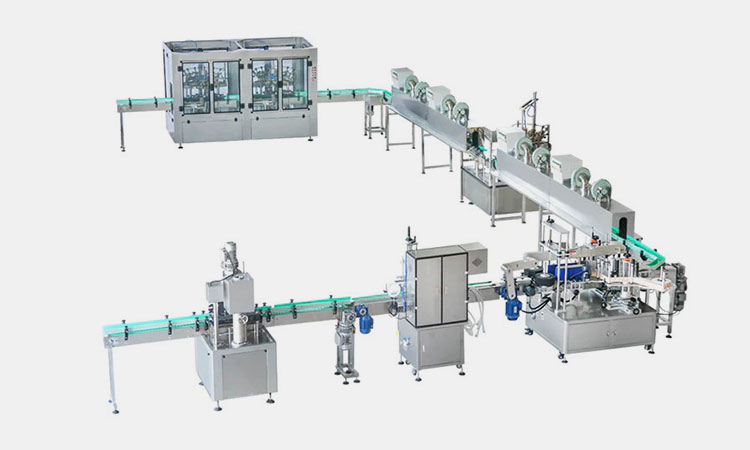

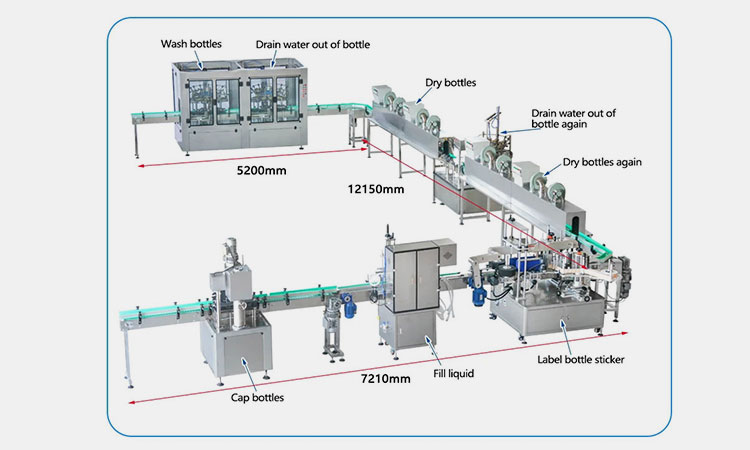

The vodka whiskey alcohol bottling line comprises several interconnected devices. Each device is designed specifically for its respective function. These devices are described under:

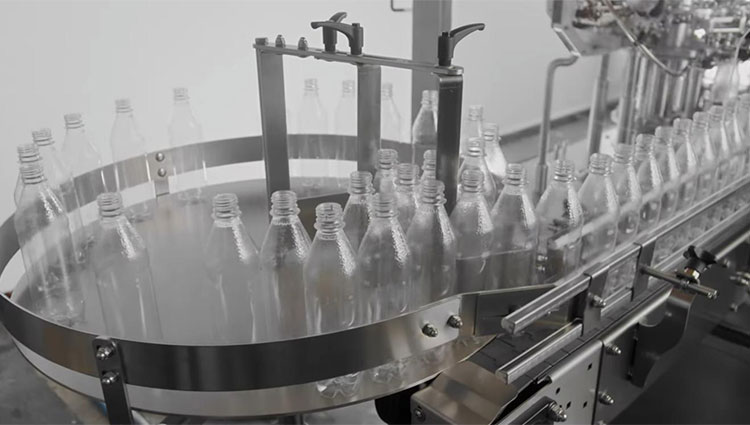

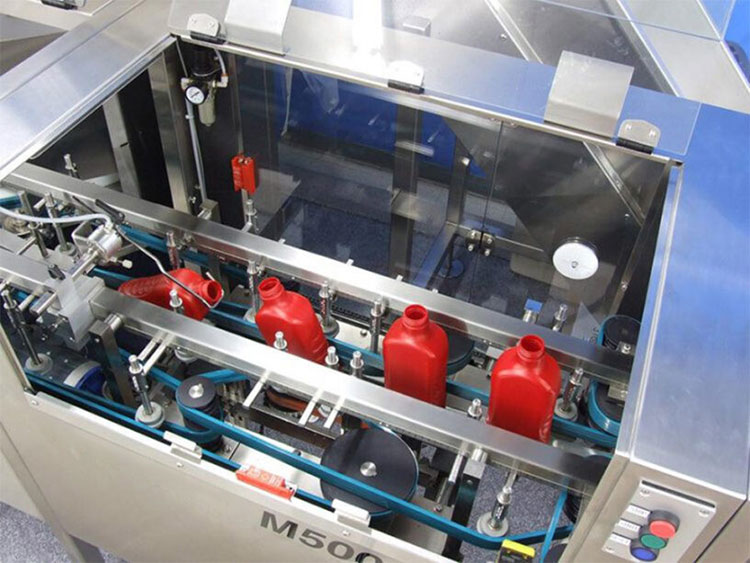

Infeed and Outfeed Bottle Unscrambler

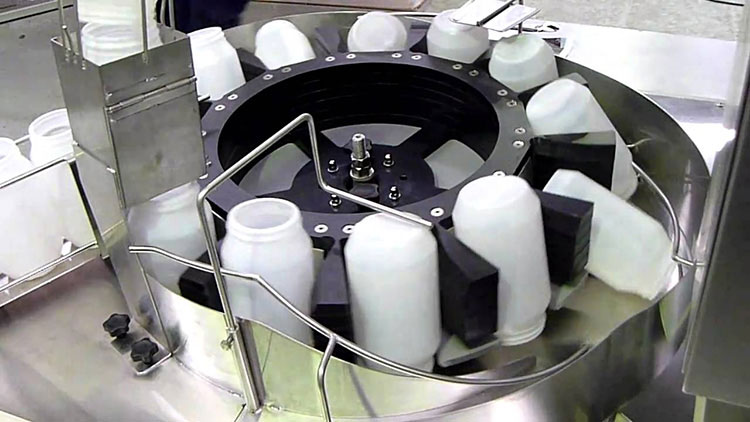

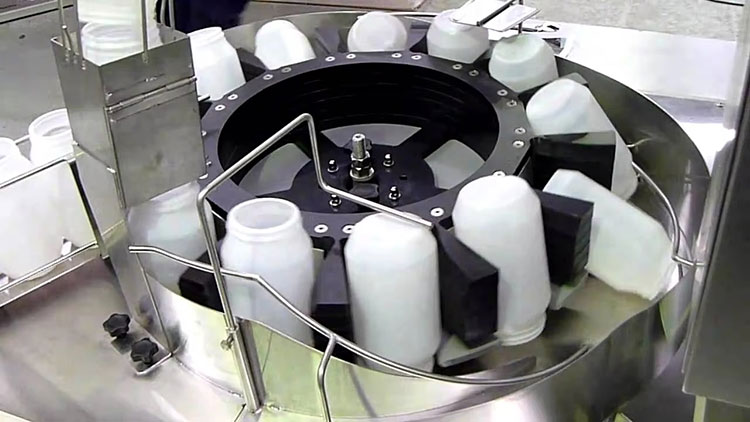

Automatic Infeed and Outfeed Bottle Unscrambler – Picture Courtesy: APACKS

These are the pair of devices positioned at the beginning and terminal of the vodka whiskey alcohol bottling line. They are automated units

having a rotating table that revolves and guides the empty bottles toward the rinsing station (infeed unscramble) or directs the finished bottles for further processing (outfeed unscramble).

The infeed device ensures a steady supply of bottles while keeping them in order. The outfeed device has the same function of precisely ejecting the bottles from the line.

Bottle Rinsing Device

Automatic Bottle Rinsing Device

The automatic bottle rinsing device is a vital component of the bottling line and is responsible for cleaning the containers before filling them with liquids. The bottles might be contaminated with particles or dust and thus must be cleaned to preserve the product’s integrity and safety.

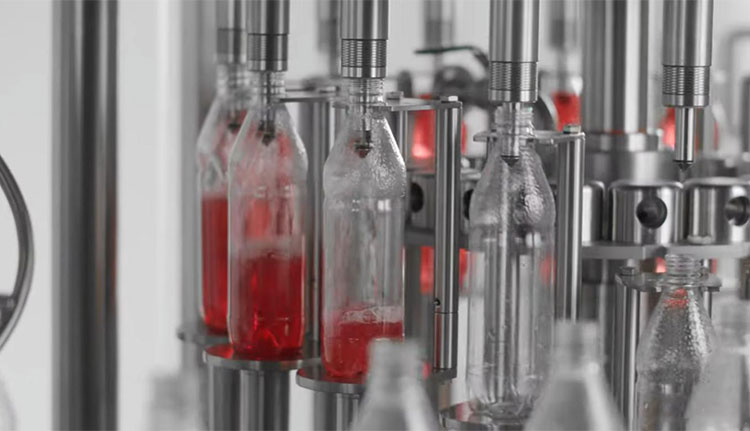

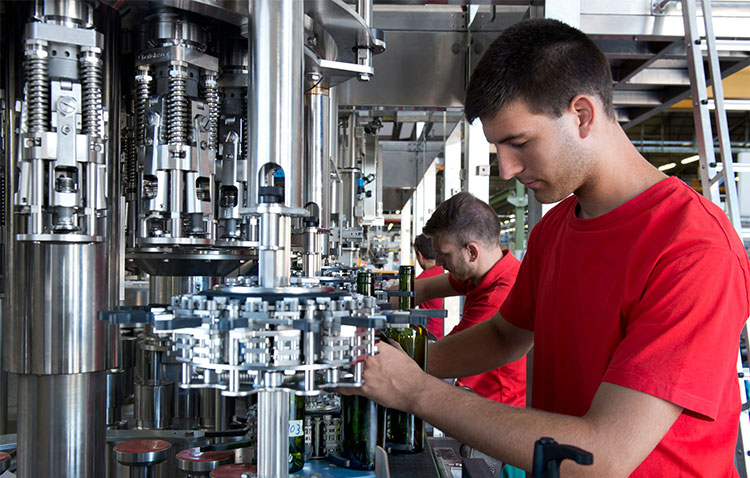

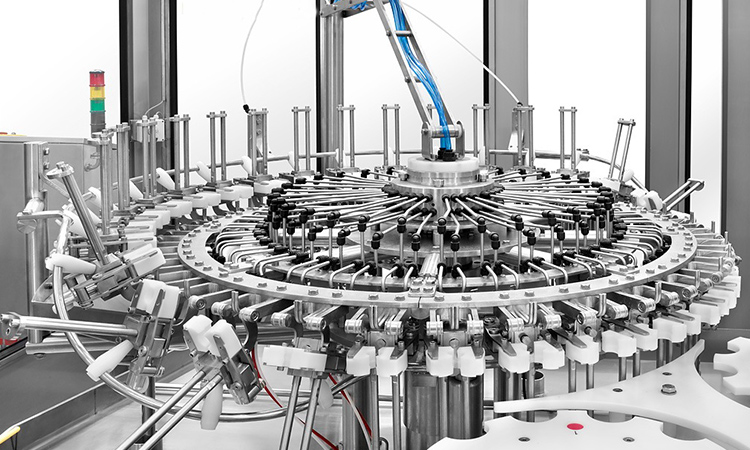

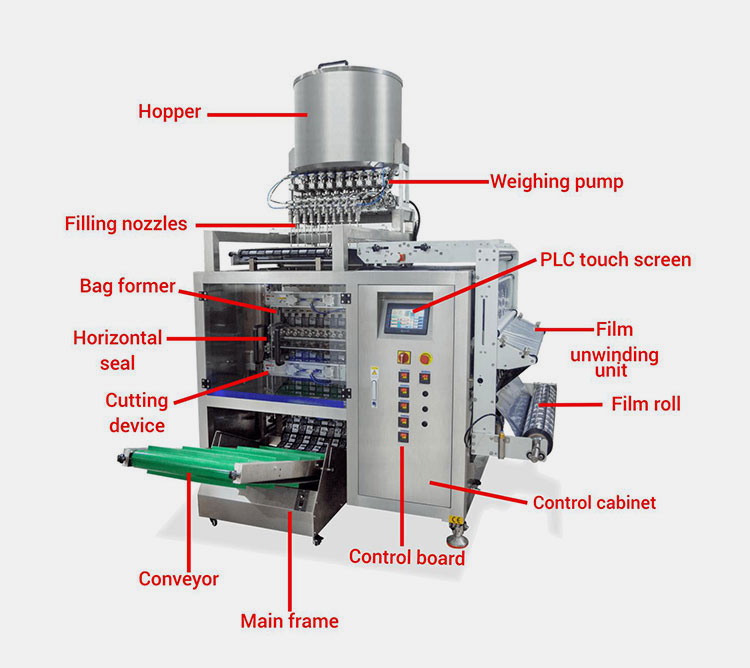

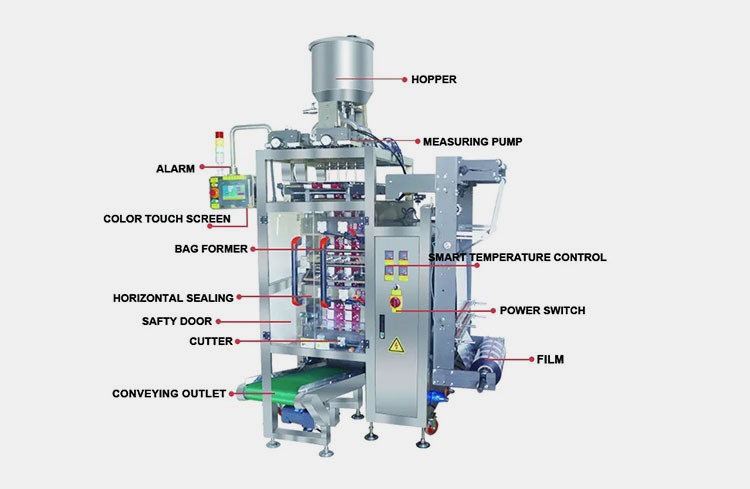

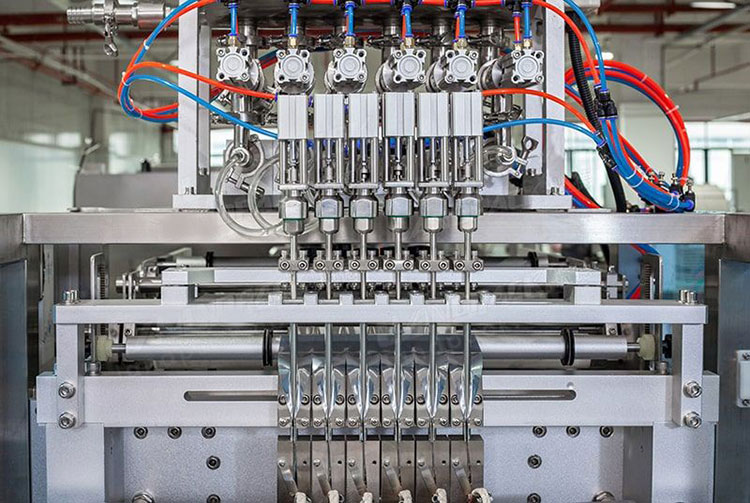

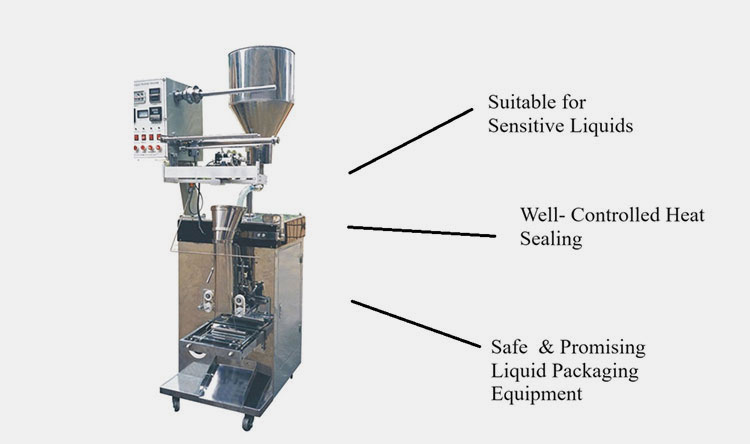

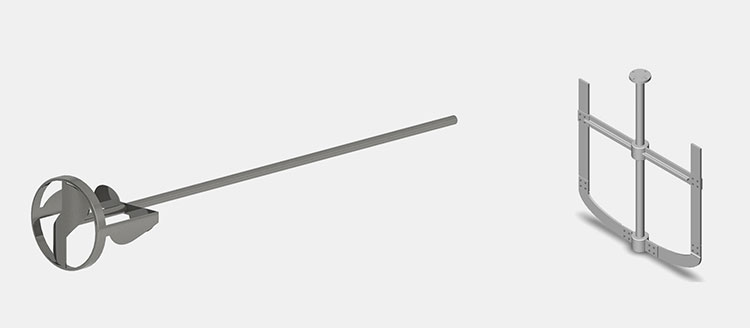

Liquid Filling Device

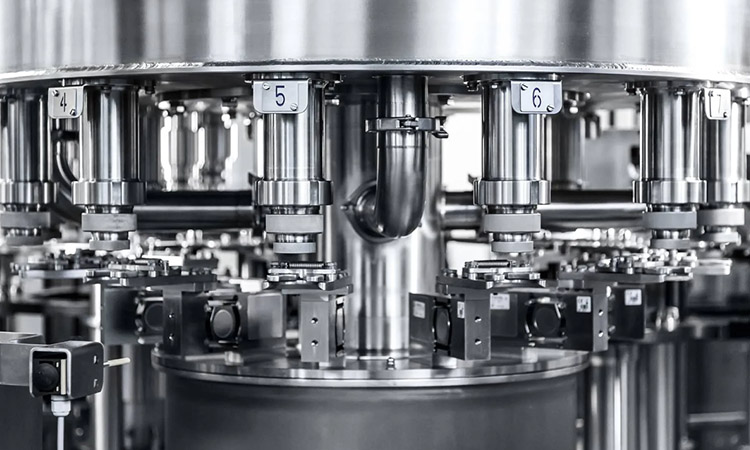

Automatic Liquid Filling Device – Picture Courtesy: Pack leader

The liquid-filling device is an indispensable part of the line. There are various forms of devices available that can be chosen as per desired features and product attributes. Each variant has a unique filling mechanism suitable for particular liquids. The device precisely measures and dispenses the required volume of liquids into each bottle.

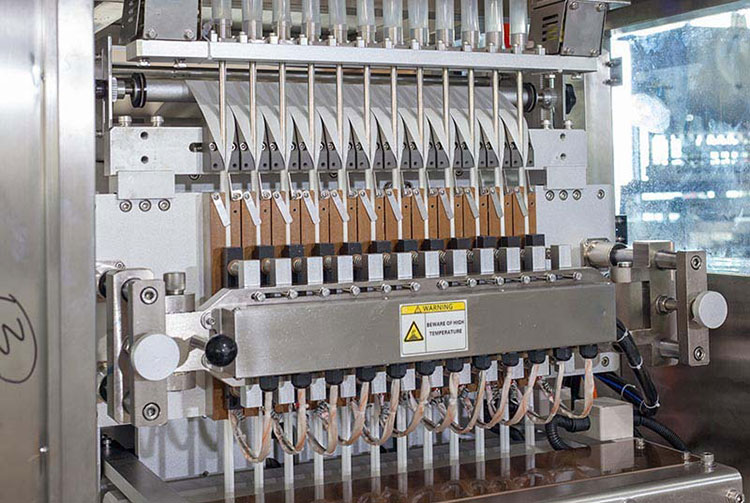

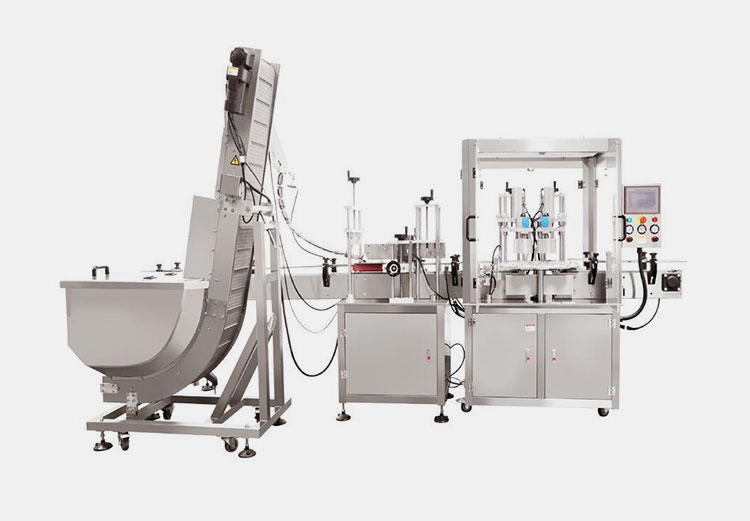

Bottle Capping Device

Automatic Bottle Capping Device

Following the bottle filling, the bottles must be securely capped to avoid leaks and spills. For this purpose, an automatic bottle capping device is integrated into the vodka whiskey alcohol bottling line. The device can be customized for particular bottles and apply various closures, like plastic and metal caps.

The typical capping device uses a screw-on capping mechanism for closing the bottles.

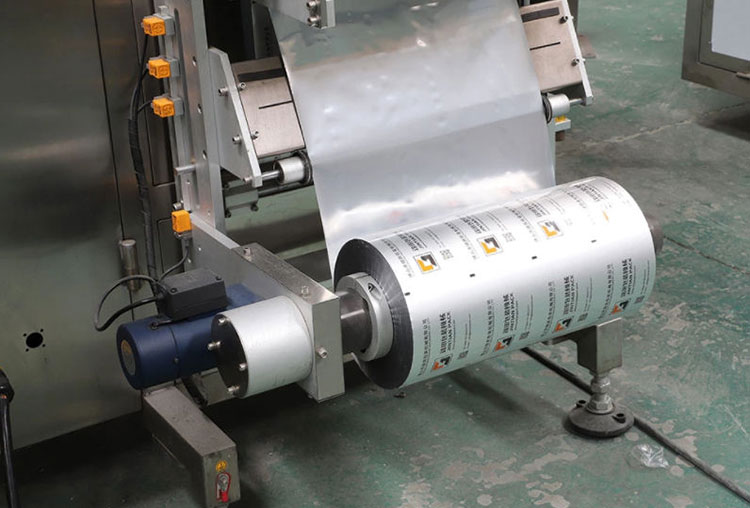

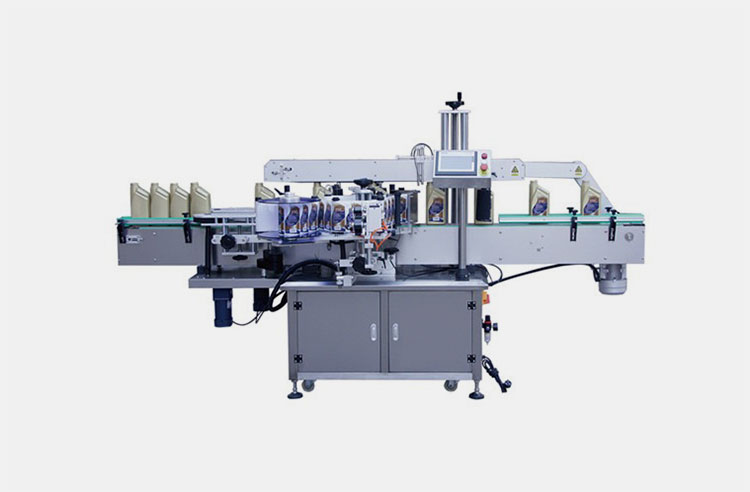

Bottle Labeling Device

Automatic Bottle Labeling Device – Picture Courtesy: VKPAK

The automatic bottle labeling device posts informatory labels on the containers. It may be stationed before or after the liquid-filling device. Two types of labels can be affixed, pre-made labels or direct imprinting on the container’s surface.

The labels usually have the necessary information, including the ingredients, manufacturing and expiry dates, bar codes, and other provisionary information.

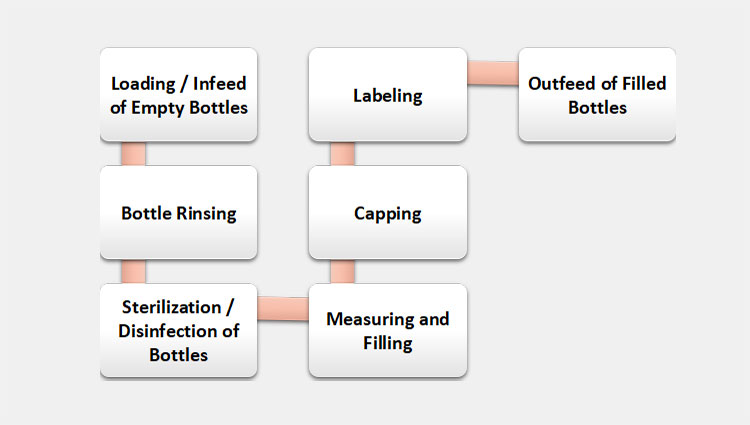

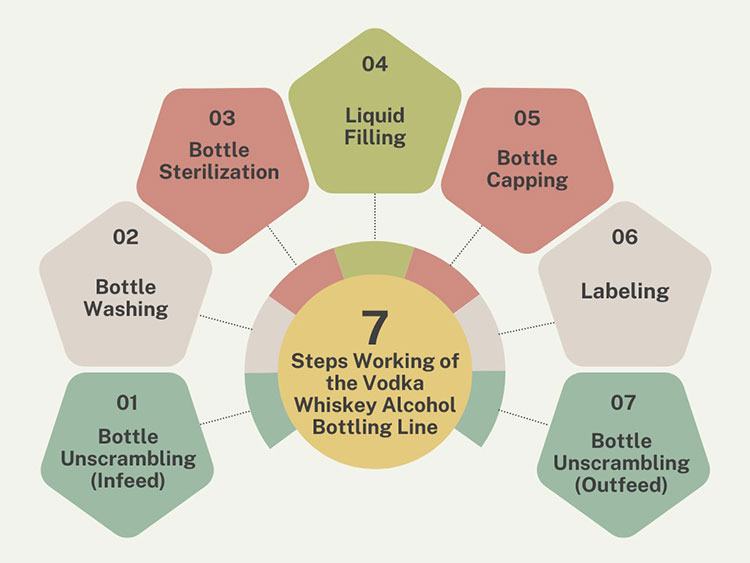

6.Describe the series of steps involved in the working of the vodka whiskey alcohol bottling line.

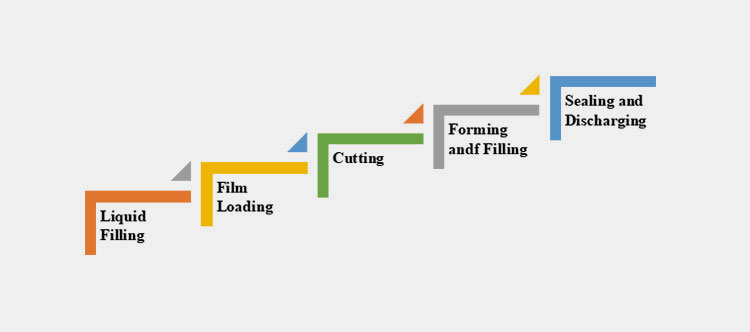

There are a series of integrated devices in the vodka whiskey alcohol bottling line, each performing its function efficiently to optimize the packaging operation. Following are the steps involved in the bottling of liquids:

| Step: 1 Bottle Unscrambling (Infeed)

At the start, loads of empty bottles are placed on the infeed bottle unscramble. The device orients and guides the bottles through rotational movements toward the rinsing station. The unscrambling is done automatically and it is guaranteed to have an uninterrupted supply and streamlined operation. |

| Step: 2 Bottle Washing/Rinsing

Each bottle will be washed by the automatic bottle rinsing device to ensure a clean container. The device blows water into each container to terminate the external particles and dust. |

| Step: 3 Bottle Sterilization

The sterilization of bottles is an elective step. An automatic bottle sterilizer is used for this purpose. Some industries, such as the medical industry, deal with sensitive content. Therefore, the containers must be sterilized for the safety of products and customers. Several sterilization mechanisms are used, such as ionized air, high-pressure heated air, etc. |

| Step: 4 Liquid Filling

After the bottles are cleaned, liquids are precisely determined and dispensed into bottles by a liquid-filling machine. The filling of a single or multiple bottles in each cycle depends on the specific design of the device. |

| Step: 5 Bottle Capping

The filled bottles are then securely capped by the automatic bottle capping device. The device has torque sensors that aid in the air-tight leakage-free closure of the bottles. |

| Step: 6 Labeling

This step can be done before filling or after capping. The bottles are labeled with pre-made labels or direct imprinting using a labeling machine. |

| Step: 7 Bottle Unscrambling (Outfeed)

Finally, securely filled, capped, and labeled bottles are directed in proper order for further processing by an automatic unscrambling device. |

7.What are the differences between a semi-automatic and a fully automatic vodka whiskey alcohol bottling line?

There are two types of vodka whiskey alcohol bottling lines based on automation. They are differentiated by some key differences that are noted down here:

Semi-Automatic Vodka Whiskey Alcohol Bottling Line

Fully Automatic Vodka Whiskey Alcohol Bottling Line

| Semi-Automatic Vodka Whiskey Alcohol Bottling Line | Fully Automatic Vodka Whiskey Alcohol Bottling Line |

| In this type of bottling line, some of the steps are performed manually using manual tools. | In this type of bottling line, the entire production process is performed automatically using automatic devices. |

| It has limited productivity and efficiency. | It has greater productivity and efficiency. |

| It is suitable for small to medium-scale businesses. | It is recommended for large-scale industries with high production demands. |

| It requires more labor force to operate. | It automates the processing and does not require much of the manual interaction. |

| It is economical comparatively and can be afforded by small industries for efficient results. | It is an advanced level of the bottling line and is expensive, requiring a huge investment. |

8.Are there specific quality standards or regulations that a vodka whiskey alcohol bottling line must comply with?

Yes, there are several international quality standards that a vodka whiskey alcohol bottling line must comply with to ensure product safety and integrity. These quality standards are as follows:

Food & Drug Administration (FDA)

The FDA is an international organization that has made certain quality standards for products and equipment that are connected with food and medical items. The regulations emphasize public health and safety.

International Organization for Standardization (ISO)

It is an autonomous global organization founded to set regulatory standards and guarantee the safety and quality of goods and equipment.

Good Manufacturing Practices (GMP)

These regulations are part of quality assurance that guarantees products are regularly manufactured and inspected to meet the quality standards stipulated in the product specs and are suitable for their considered purpose.

European Conformite (CE)

CE marking appears on many goods and equipment commercially sold in the EEA (European Economic Area). It indicates that the product complies with the European health and safety standards.

9.How will you maintain and clean the vodka whiskey alcohol bottling line?

Every manufacturer desires long-term optimum working conditions for their industrial equipment. It can be fulfilled only by keeping up with their regular cleaning and maintenance. The same applied to the vodka whiskey alcohol bottling line.

Each device in the bottling line needs to be routinely maintained to preserve its lifelong working condition. Here are a few maintenance tips to follow for your bottling line.

Cleaning and Sanitization

Cleaning and Sanitization

Regularly cleaning every device’s components must be done to avoid residue and dust accumulation. Schedule a deep cleaning program for the bottling line by disassembling each device to prevent liquid buildup and microbial contamination.

Furthermore, sanitize the components that are in direct contact with the product, such as the hopper, nozzles, and pipes.

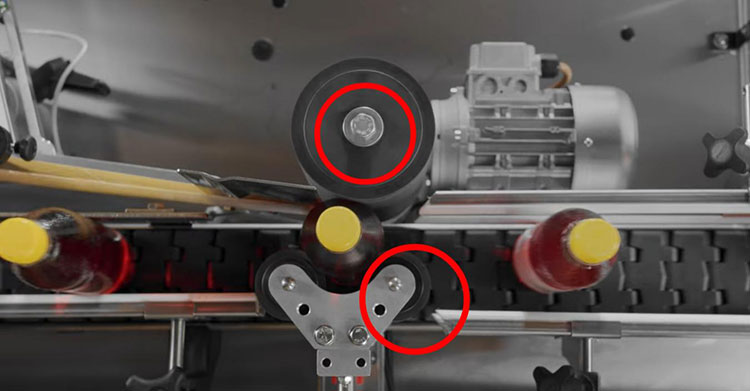

Lubrication and Polishing

Lubrication and Polishing – Picture Courtesy: Tekwell

Lubricate all the dynamic segments of each device in the bottling line. Lubricating these parts reduces the abrasiveness caused by continuous working. These parts include conveyor belts, gearboxes, and electric motors. Moreover, polish all the components after cleaning regularly for better precision outcomes.

Inspection and Changeovers

Inspection and Changeovers

It is advised to inspect parts of each device for damage and tear. Consider timely repair or replacement (as the case may be) of damaged components to avoid major incidents or lengthy breakdowns.

Calibration and Adjustments

Calibration and Adjustments

Calibrate the components after maintenance and if liquids of varied characteristics are being processed to preserve consistency. Check the performance of sensors. Update the software regularly. Fasten all the nuts and bolts.

10.Describe how to troubleshoot a vodka whiskey alcohol bottling line.

You may encounter certain problems while working with a vodka whiskey alcohol bottling line. They may arise for several reasons, the major one being neglecting maintenance schedules. You may avoid them by knowing the root cause and immediately resolving them.

Here we will discuss some commonly encountered problems, their potential causes, and their remedies.

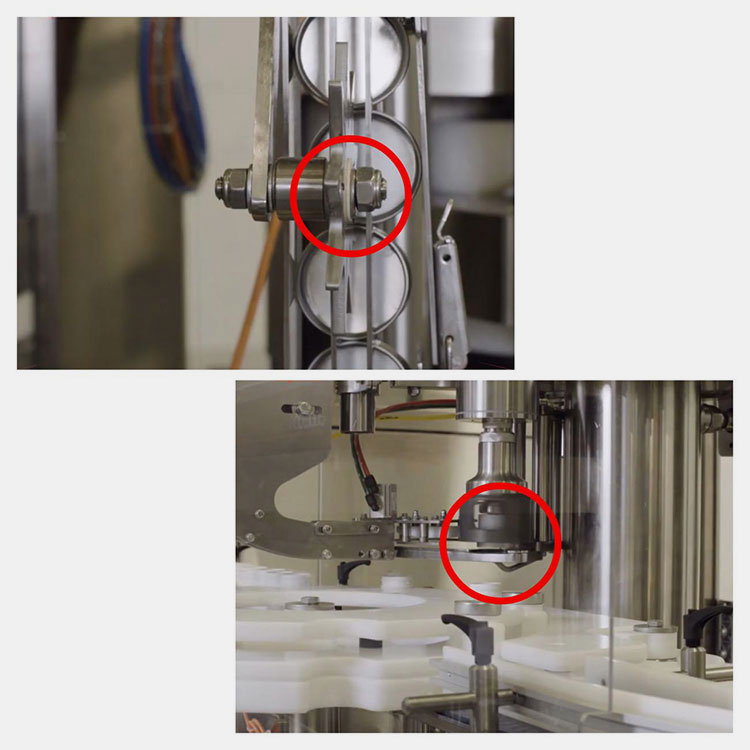

Jamming of Unscrambling Disc

Jamming of Unscrambling Disc – Picture Courtesy: CVC Technologies

The bottle unscrambling disc can be jammed due to the impaired friction plate or transmission gear. It can result in the interruption of bottle feed or improper arrangement of supplying bottles.

Solution: adjust the specifications of the transmission gear. Repair or change the friction plate.

Jamming of Conveyor

Jamming of Conveyor

The machine conveyors can be stuck for several reasons, such as high-speed processing and damaged or eroded conveyor belts. The conveyor’s jamming results in inconsistent processing, bottle slipping, and reduced efficiency.

Solution: regulate the operational speed. Immediately replace or lubricate conveyor belts.

Non-Uniform Filling

Non-Uniform Filling – Picture Courtesy: Ridge Vineyards

Precise filling is one of the essential features of the vodka whiskey alcohol bottling line. The inconsistency in filling can reduce the product’s quality and customer satisfaction. It may be because of the obstruction in the feeding path, inaccurate calibration, damaged or clogged dispensing nozzles, or incorrect operational settings.

Solution: check for any obstruction in the liquid feeding path and clear it. Replace the torn nozzles or wash out the blocked ones. Properly calibrate the components, particularly after the maintenance. Always cross-check the process parameters.

Improper Capping

Capping Defects

If there is any problem with the capping step, it may result in the product spills or leaks. Improper capping may result from damaged bottle heads, impaired spindle clamp, or inappropriate capping methods for a particular bottle type.

Solution: check the bottle heads and consider replacement, if necessary. Replace the spindle clamp. Use the appropriate capping method for the respective container.

11.What are the key considerations when buying a vodka whiskey alcohol bottling line?

Buying a single piece of industrial equipment might be relatively easy, but shopping for multiple devices for a production line can be daunting.

Manufacturers are inclined toward the devices' efficient processing and compliance with strict quality guidelines to ensure the preservation of products’ quality. Therefore, it is crucial to consider certain factors before investing in a vodka whiskey alcohol bottling line for your business.

Some major factors are highlighted below:

Production Requirements

Production Requirements

When investing in the vodka whiskey alcohol bottling line, it is important to ascertain the production size. You must choose the gadgets that can best meet your current needs as well as your future goals for the line to run more efficiently.

Evaluation of your production needs is crucial in deciding the level of automation you need for your business. For example, if the production demands are high and you opt for a semi-automatic line, it will be a waste of your money as such a line will not be able to satisfy your demands efficiently.

Equipment Capacity

Equipment Capacity

The processing capacity of the equipment to be integrated into the vodka whiskey alcohol bottling line is critical. Opt for the gadgets with the desired durability and ability to respond to higher production demands.

Finances

Financial Evaluation

Estimate your finances carefully and invest in an affordable bottling line that can effectively meet your demands. The cost of the bottling line is determined by the degree of automation. Smaller and medium-sized businesses can consider investing in manual or semi-automatic bottling lines.

Large-scale industries with huge production sizes should opt for the automatic vodka whiskey alcohol bottling line for better results. Although it is expensive with the initial investment and operational plus maintenance costs, it will prove to be a worthy investment in the long run.

Compatibility of Devices

Compatibility of Devices

Purchasing a single device could be simple, but finding several devices for a manufacturing line might be challenging. Selecting devices that are compatible with one another is necessary to attain the best possible performance results consistently.

Adaptability of Devices

Adaptability of Devices

If you want to expand your business in the future, you must opt for adaptable devices with easy changeovers that can handle multiple items effectively.

Warranty and Maintenance Support from Vendor

Warranty and Maintenance Support from Vendor

Every manufacturer desires the long-term functioning of their production equipment with minimal breakdowns. A significant warranty and reliable technical support can be beneficial and relaxing. Therefore, always buy equipment for your production lines from reputable vendors, offering the necessary support.

Conclusion

To conclude this comprehensive buying guide about the ‘vodka whiskey alcohol bottling line’, we believe to have covered all the necessary facts you need to know. This line can enhance your product quality and improve your existing production efficiency. You may potentially grow your company to the maximum level by adhering to the previously listed rules and explanations of the setup, operation, and maintenance of the vodka whiskey alcohol bottling line. Despite having the pertinent information, there may still be questions that need to be answered. You can contact the Allpack, you will be guided better!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Vodka Whiskey Alcohol Bottling Line: The Complete Buying Guide In 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours