Agricultural Chemical Packaging: The Complete FAQ Guide in 2025

Agricultural Chemical Packaging: The Complete FAQ Guide in 2025

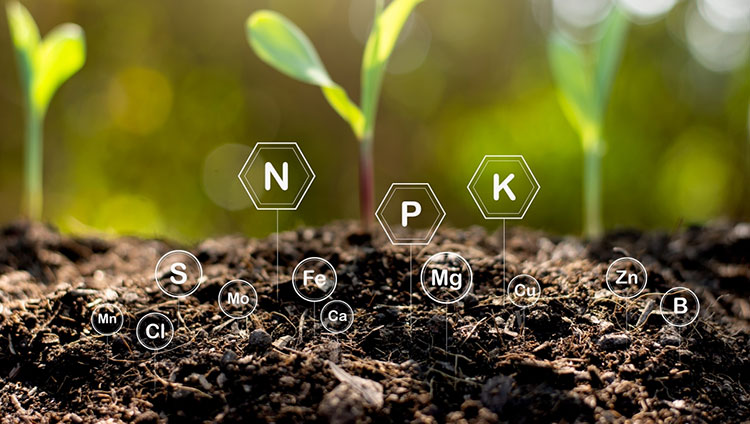

Have you ever considered how agrochemicals, like herbicides, pesticides, and fertilizers, reach us in optimal condition, ready to protect crops and increase yield? The answer lies in agricultural chemical packaging, which plays a crucial part in the safe storage, transportation, and handling of these products.

If you don’t ensure proper packaging, chemicals could leak, contaminate, degrade, and, most importantly, pose serious hazards to humans, animals, and the environment. Various techniques and materials designs are used in agricultural chemical packaging to maintain the product's integrity while reducing environmental hazards.

Modern agricultural chemical packaging involves flexible packaging options that withstand chemical interactions. With the increasing demand for sustainability, the industry is switching toward biodegradable packaging, smart tracking systems, and tamper-evident designs.

This article is a comprehensive guide to help you understand the key aspects addressing the most important questions about agricultural chemical packaging. Let's dive into:

1.What’s meant by agricultural chemical packaging?

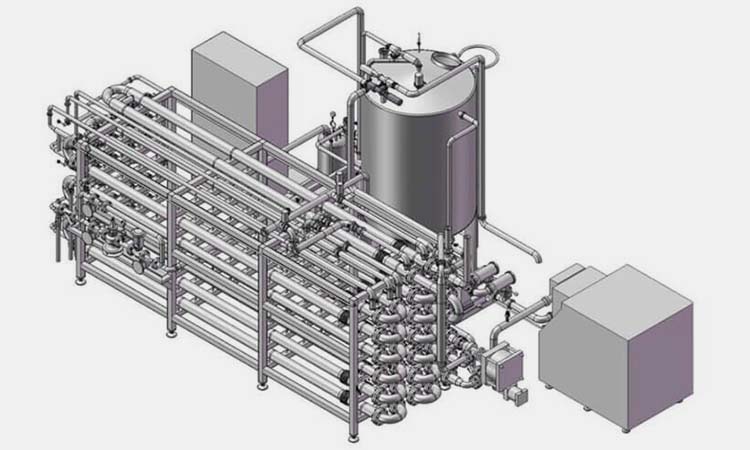

Agricultural Chemical Packaging- Picture Courtesy: Filltech Packaging Machines

Agricultural chemical packaging refers to materials and methods designed to preserves the chemical’s integrity, safe storage, safe transportation, and application of agricultural chemicals.

The advanced packaging solutions provide stability to agrochemical products by protecting them from environmental factors that could compromise their chemical composition. These factors include moisture, air, and sunlight.

Proper chemical packaging is necessary to ensure safe handling, avoid spills or exposure during the packaging process and to meet the regulatory standards to prevent health hazards.

2.Why is agricultural chemical packaging important in the agriculture industry?

Significance of Agrochemicals Packaging

In an agriculture field agricultural chemical packaging is important since crop productivity directly impacts global food production and supply. These packaging containers are responsible for maintaining the compound’s effectiveness and the safety of the workers during the agriculture process.

Stability

Agrochemicals Stability- Picture Courtesy: Omega

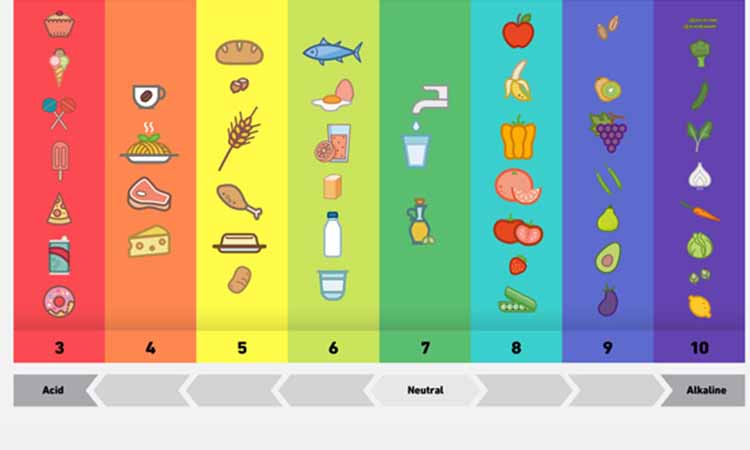

One of the important aspects of these packaging materials is the preservation of the chemicals’ potency and stability. Since agrochemicals are sensitive to sunlight, air, or moisture. The agricultural chemical packaging offers UV-resistant coatings or moisture barriers (desiccants) to maintain the effectiveness and integrity of these products,

User’s Safety

Safety of Workers from Agrochemicals

The agrochemicals, especially in powdered form, can impose health hazards, so the safety of individuals working in agriculture fields is a priority. The précised packaging securely contains these products with tamper-evident and child-resistant caps, reducing the risk of accidental exposure, spillage, or poisoning. Proper labeling prevents improper use by farmers and workers.

Environmental Safety

Pesticides Harm Drinking Water- Picture Courtesy: Friends of Earth Melbourne

Utilizing leak-proof and biodegradable packaging solutions reduces the possibility of chemical spillage and minimizes pollution, thereby protecting soil, water bodies, and surrounding environments.

Optimized Storage and Transport

Compact Storage of Chemicals

Optimized agricultural packaging provides compact and space-saving solutions, allowing improved stacking and storage in warehouses or farms. The durable and lightweight packaging solutions reduce waste, safe handling, and transportation while minimizing costs.

Regulatory Conformance

Proper Disposal of Agricultural Chemical Containers- Picture Courtesy AG WEB

When agricultural chemical packaging adheres to international safety and environmental standards set by organizations such as FAO (Food and Agriculture Organization) and ISO (International Organization for Standardization), it ensures safe use, storage, and disposal.

3.What do you know about the types of agricultural chemical packaging?

Varity of Agricultural Chemical Packaging- Picture Courtesy: United Caps

Various packaging solutions exist in the market, which can be selected based on the nature of chemicals (such as powder, liquid, or granules), regulatory conditions, and sustainability.

These are the various types of agricultural chemical packaging:

Plastic Containers

HDPE Plastic Containers for Agrochemicals

These containers are widely used for liquid chemicals because they are lightweight, strong, and non-corrosive. The commonly used material is high-density polyethylene (HDPE).

Drums and Barrels

Agrochemical Drums

These large-capacity plastic or metal drums are suitable for storing and transporting large volumes of liquid chemicals. They ensure safety by preventing accidental spills.

Sacks and Bags

Agricultural Bag

Sacks and bags are suitable for solid or powder agrochemicals. They are commonly made from woven propylene or multi-layered materials, which give strength and resistance to tearing.

Intermediate Bulk Containers (IBC)

IBC for Bulk Storage

Intermediate bulk containers are ideal for transporting and storing bulk quantities of liquid and powder. They are reusable and durable, reduce waste, and are suitable for long-term storage.

Pouches and Sachets

Fertilizer Pouch

Some industries often use pouches or sachets for small quantities of agrochemicals. These are lightweight, convenient, and provide accurate dosing.

Water-Soluble Packaging

Water Soluble Packaging Film- Picture Courtesy: Polyva

These are good options when precise applications and doses are required. These packs dissolve in water, reducing exposure during handling.

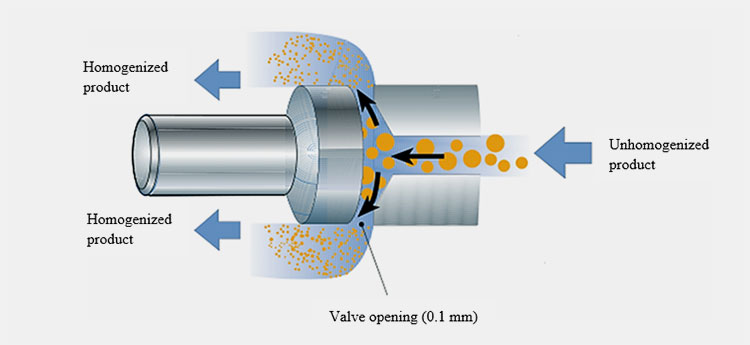

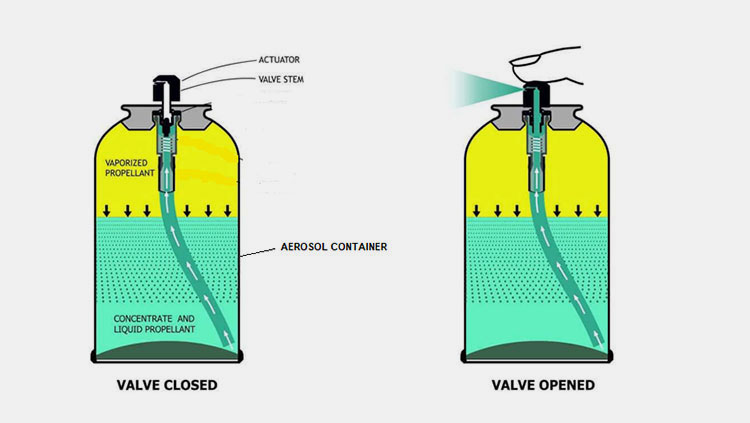

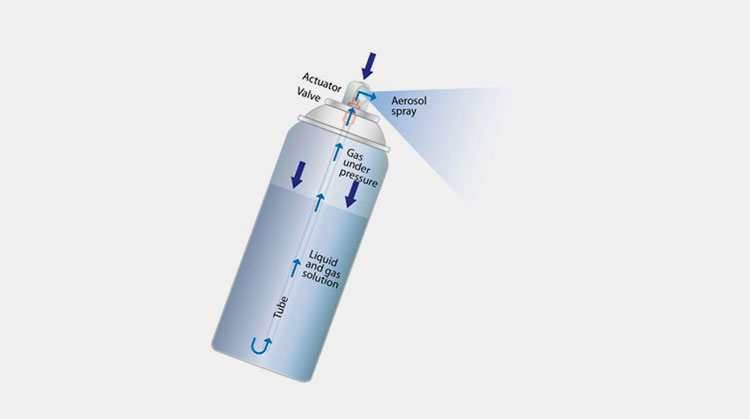

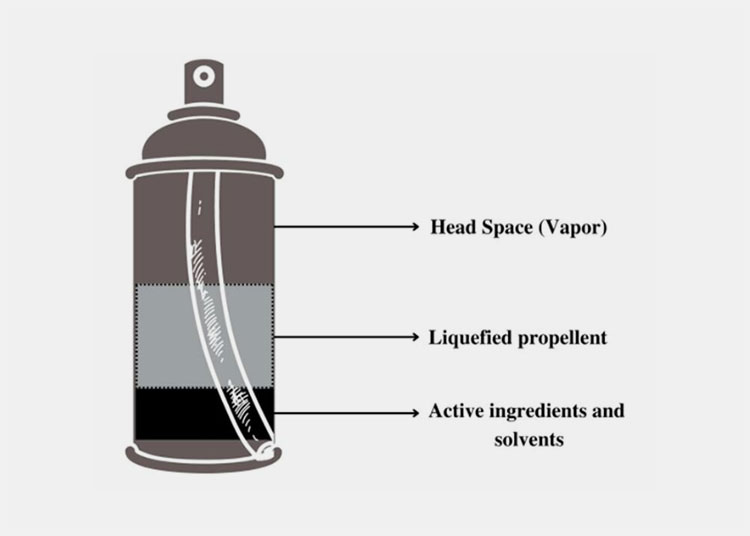

Aerosol Containers

Aerosol Spray

Due to its controlled spray application, aerosol containers are often used for pesticide formulation. One thing that should be considered when using these cans is that they require specialized disposal.

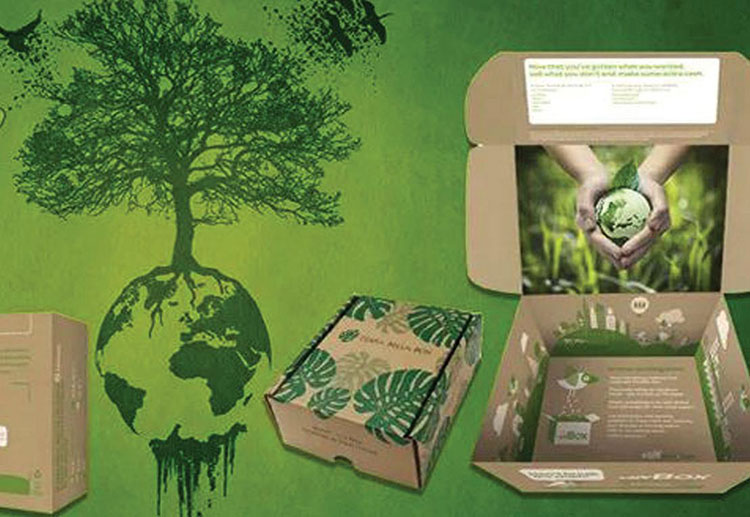

Biodegradable Packaging

Eco-Friendly Packaging- Picture Courtesy: Arka Packaging

Some agrochemical industries are now using biodegradable or recyclable materials to align with the emerging focus on sustainability.

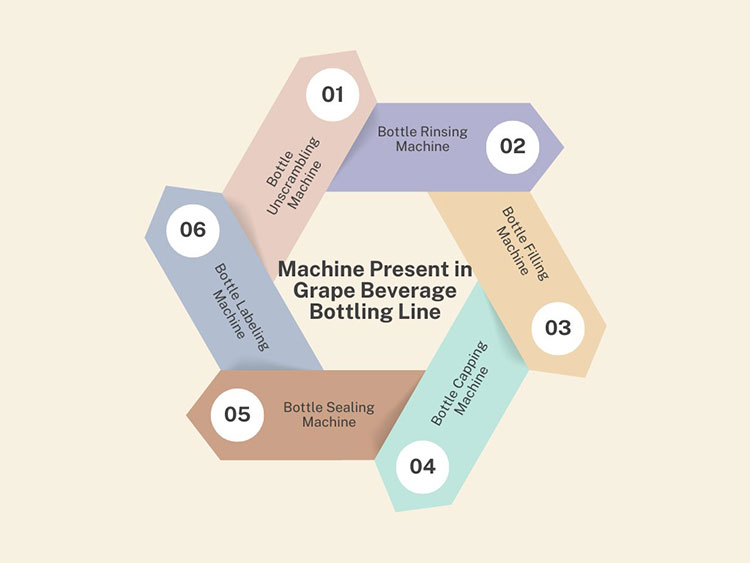

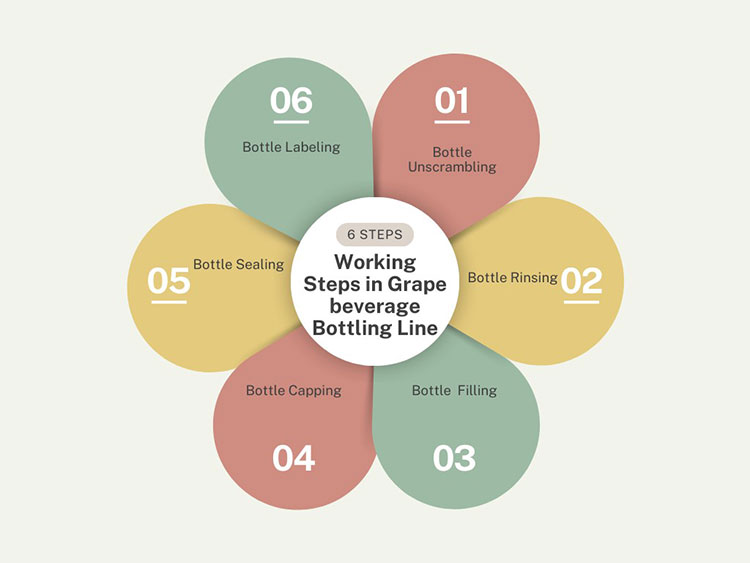

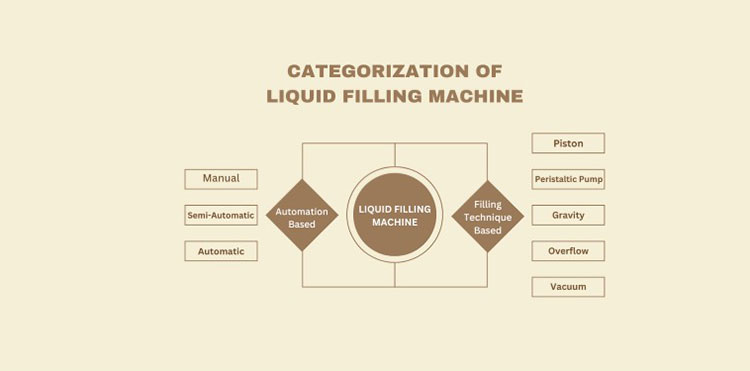

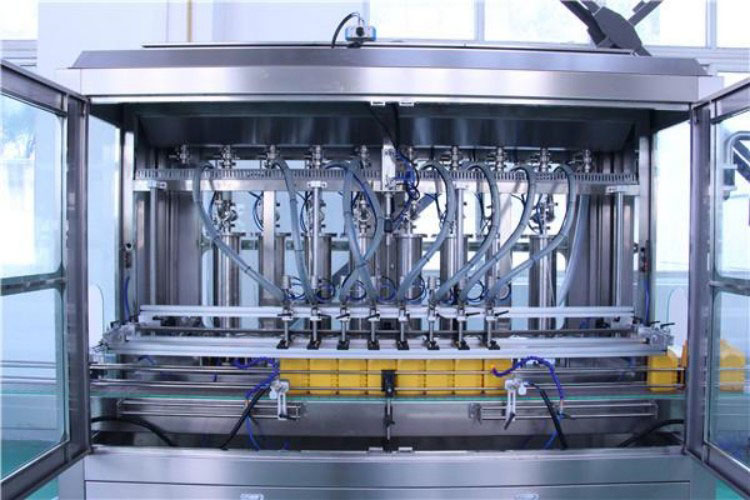

4.What equipment is used for agricultural chemical packaging?

Agricultural Chemical Filling- Picture Courtesy: KWT Machine Systems

Investing in the right equipment is essential for protecting agricultural chemicals, minimizing health risks, and optimizing production. Advanced automation improved consistency and accelerated the process. Let’s discuss the types of equipment utilized for different agricultural chemical packaging:

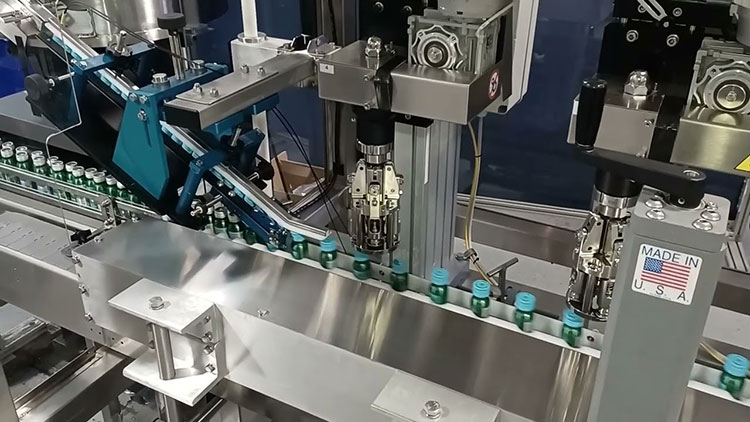

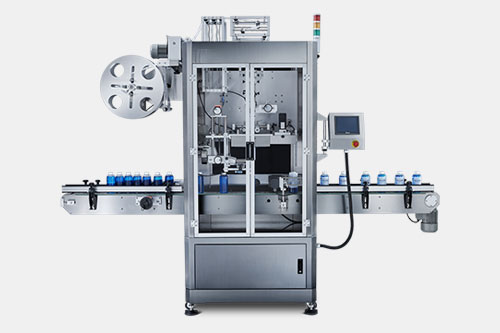

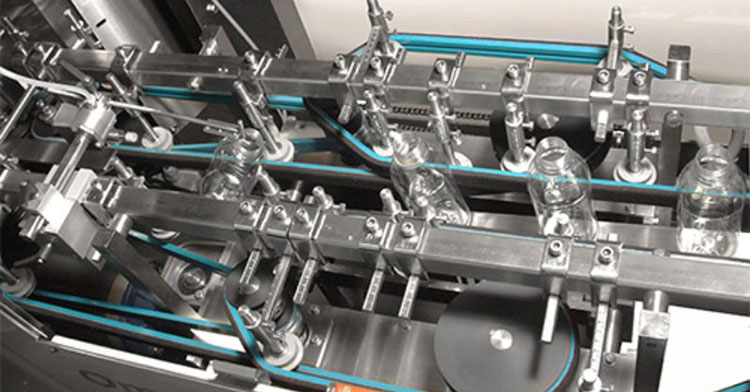

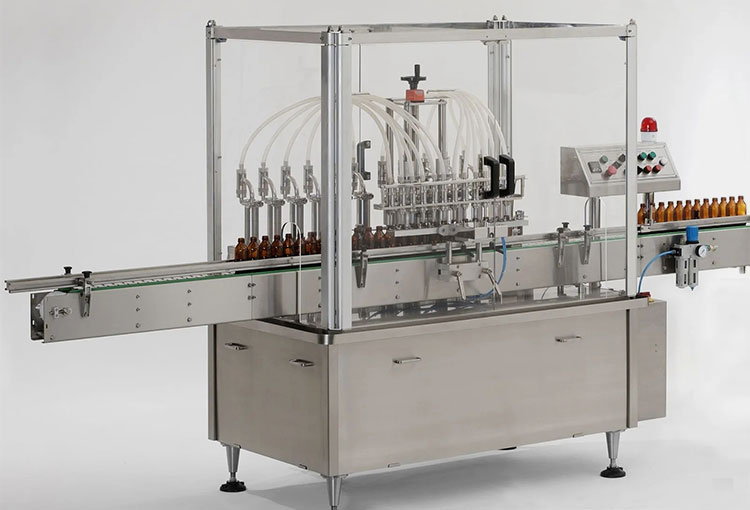

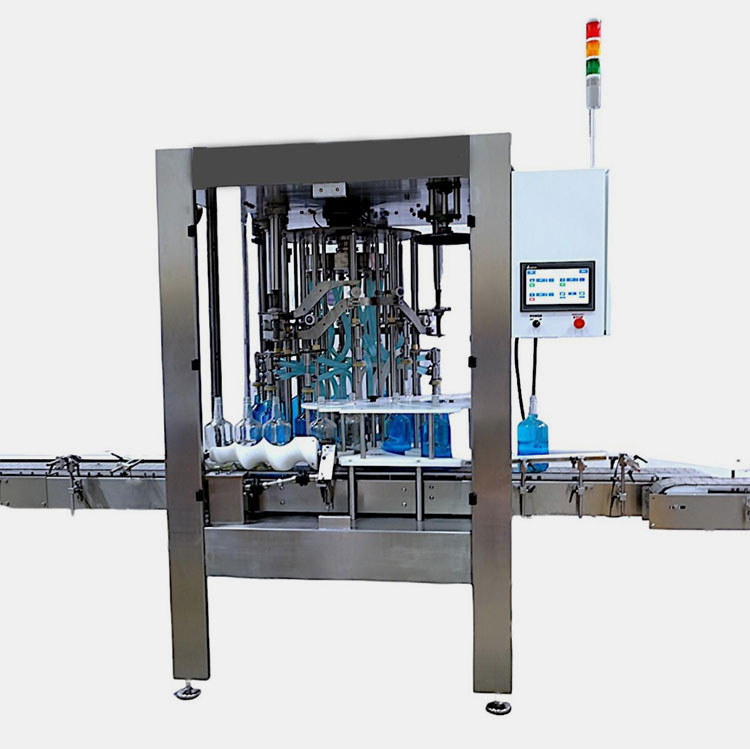

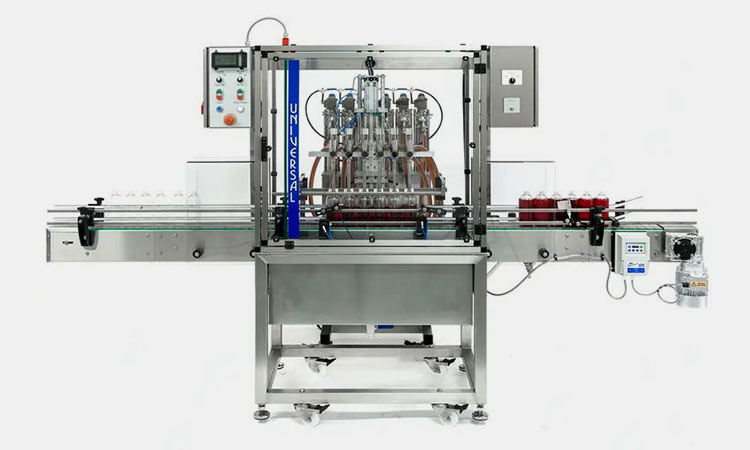

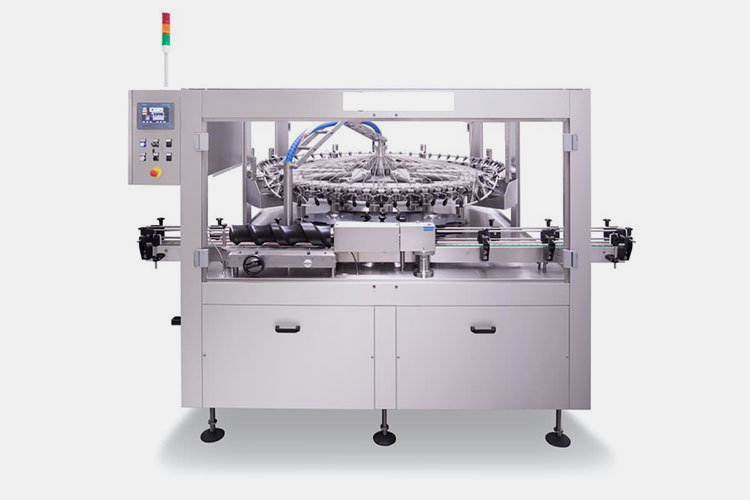

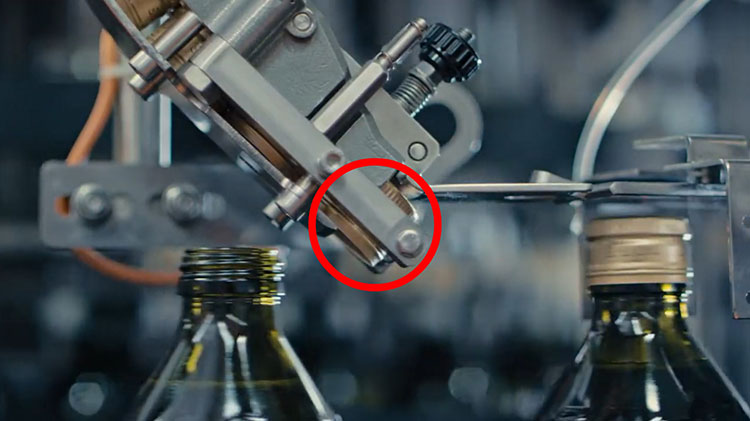

Bottle Filling Machine

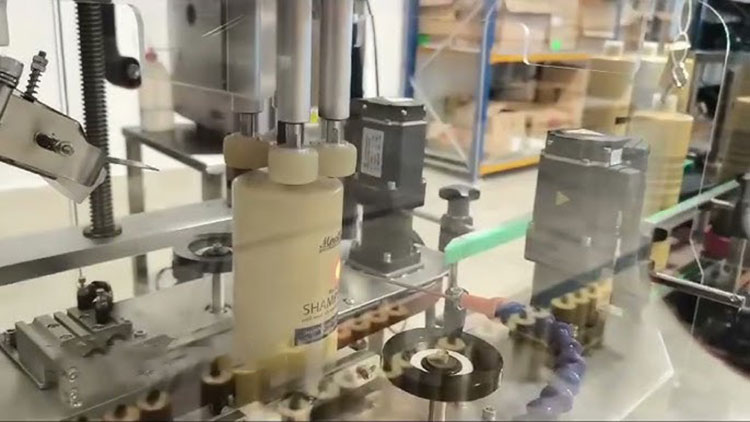

Bottle Filling Machine for Various Containers- Picture Courtesy: PACK’R

The bottle-filling machine is designed for accurately dispensing liquid agrochemicals into plastic or glass bottles while preventing spills, leakage, and accidental exposure. The machine can be semi-automatic or fully automatic. The equipment often has features of an automatic capping and labeling system.

The bottle filling machines are of various types that can be chosen according to chemical properties and production needs, such as:

Gravity Bottle Filling Machine

Automatic Gravity Bottle Filling Equipment- Picture Courtesy: APACKS

This machine deals with chemical liquids with free-flowing properties and less viscosity. These time-based automatic filling machines use the volumetric time gravity filling method and fill the bottles with precise volume. These are best for non-foaming liquids.

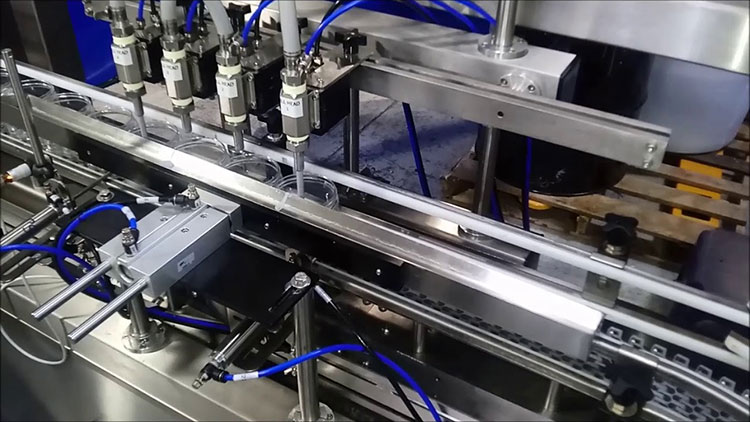

Piston Bottle Filling Machine

Automatic Piston Bottle Filling Equipment with Six head Filling

This machine is widely used for filling high-viscosity viscous liquid agrochemicals, such as concentrated fertilizers. The emulsion and suspension form liquids can be filled. These machines offer volumetric filling, having a piston to push and dispense liquid chemicals into the bottles. They fill the bottles with precise volume, even for denser liquid chemicals.

Overflow Bottle Filling Machine

Automatic Overflow Bottle Filling Equipment- Picture Courtesy: ACCUTEK

Some agrochemicals are foamy, and they require visually consistent fill levels. The overflow bottle filling machines provide uniform fill levels regardless of slight variations in volume. Once the bottle is filled at a desired level, excess product overflows back to the reservoir.

These machines have control of the pressure pump speed to reduce foam. Commonly used for transparent bottle packaging of agrochemicals for a neat appearance.

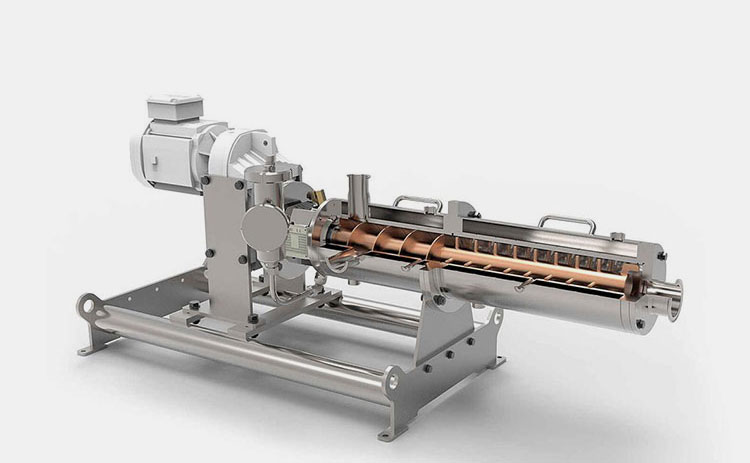

Peristaltic Pump Bottle Filling Machine

Automatic Peristaltic Pump Bottle Filling Equipment- Picture Courtesy: N.K. Industries

These machines are best suited for corrosive and sensitive agrochemical solutions. The benefit of these machines is that they provide highly precise filling of agrochemicals, even in very small volumes. The machine pumps liquid by using flexible tube and rollers.

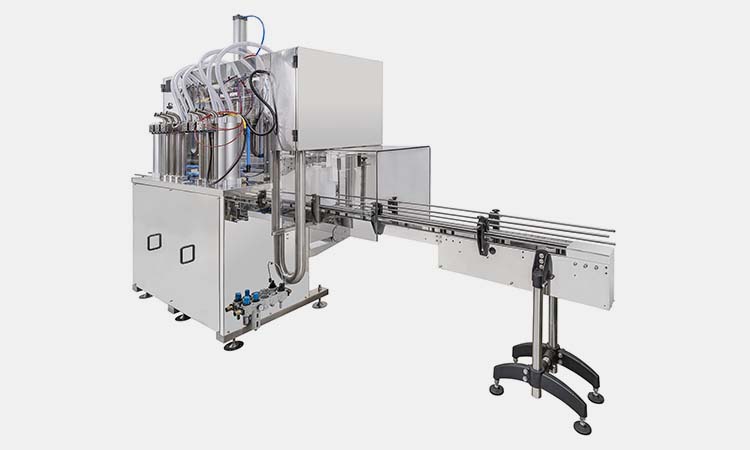

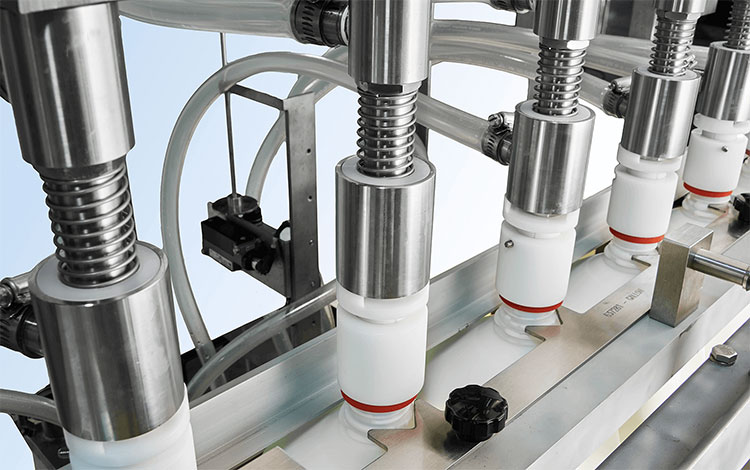

Servo-Driven Bottle Filling Machine

Servo-Driven Bottle Filling Equipment

These machines use servo motors for highly-precise volumetric filling of liquid. The machine is highly programmable and adjustable, handling various liquid viscosities, including aqueous, foamy, and semi-viscous solutions.

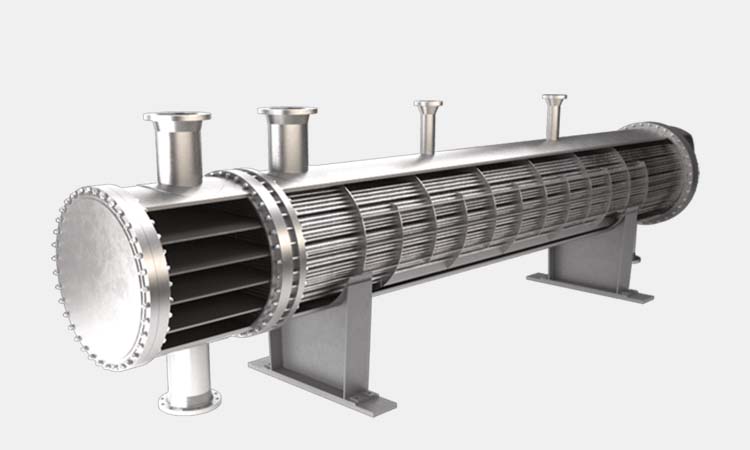

Drums and IBC Filling Machine

Semi-Automatic Drum Filling Machine

These machines come in semi-automatic and fully-automatic options, ensuring accurate filling of large-capacity drums and IBCs for storing liquid agrochemicals. They are often used in agrochemical industries to fill the bulk liquid of fertilizers and pesticides. Multiple options are available, depending on production needs, liquid viscosity, and required level of automation.

Weight-Based Filling Machine

Automatic Weighing-Based Filling Equipment for IBSs and Drums

These machines fill drums and IBCs by placing them on a weighing platform, the liquid is dispensed into the containers according to the desired weight. The sensors track the filling process and stop the flow automatically when the target weight is achieved. Various models come with foam-controlling nozzles to prevent splashing in case of foamy agrochemicals.

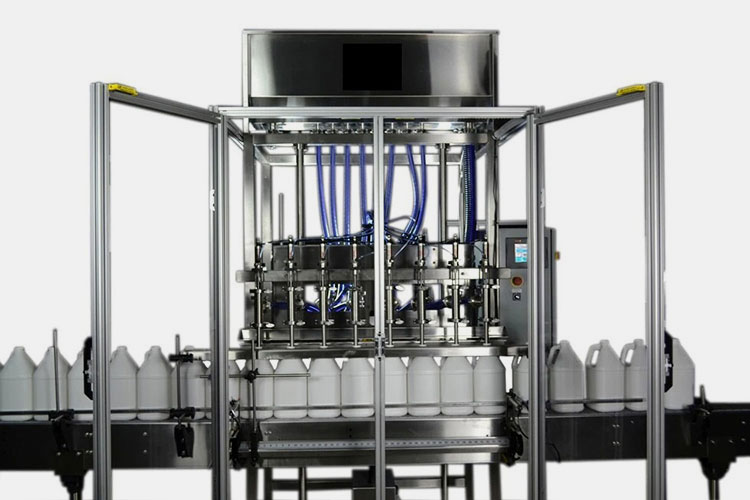

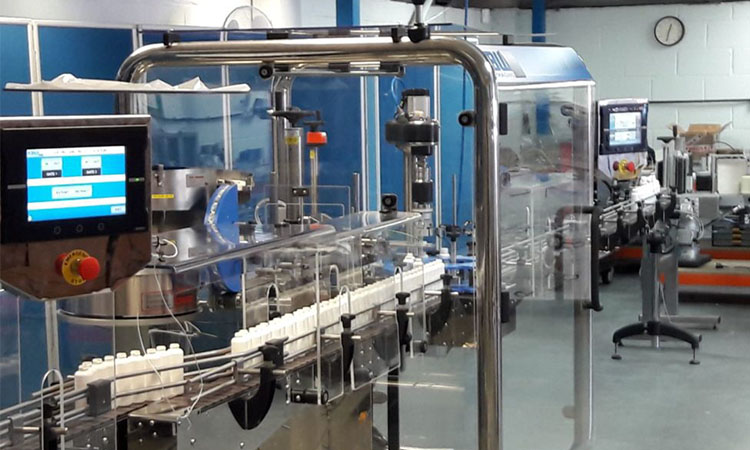

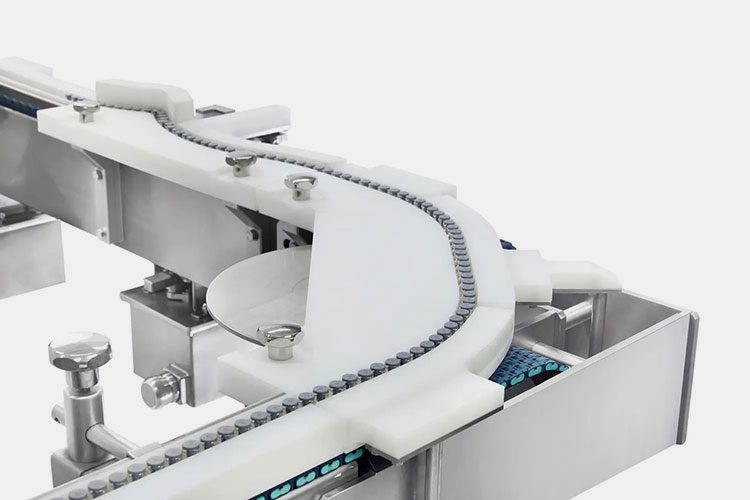

Automatic Filling Lines

Fully Automatic Filling System for Drums and IBCs- Picture Courtesy: Aicrov

These fully automatic systems are ideal for large-scale agrochemical production requiring high-speed operation. These filling lines integrate conveyors, sensors, and programmable filling units.

The containers travel on the conveyor belt to the filling station, where sensors adjust the filling nozzle by sensing the container size. These filling lines use a volumetric or weighing mechanism to dispense a predetermined volume of liquid. After filling, the nozzle withdraws, and the container proceeds to the next stage for capping and sealing.

Semi- Automatic Pump Based Filling machine

Semi-Automatic Filling Equipment- Picture Courtesy: AF Advantech

These machines are ideal for moderate production volumes and provide a cost-effective and efficient solution. The operator manually positions the drum or IBC under the filling nozzle, where the pump dispenses the liquid. Filling is manually controlled or automatically stopped via sensors once the desired volume is reached.

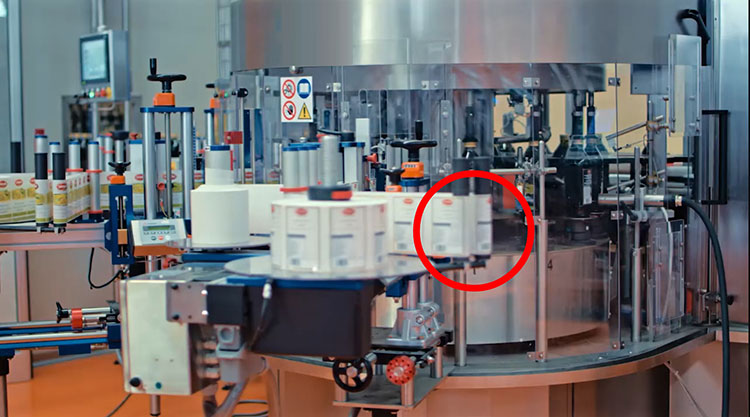

Pouch and Sachet Filling Machine

Automatic Pouch Filling

Multiple options are available for filling liquid or powdered agrochemicals into small, single-use sachets or pouches. The choice depends on the desired packaging (i.e., sachets or pre-made pouches), speed, and dosing.

Vertical Form Fill Seal (VFFS) Machines

VFFS Equipment or Pouch and Sachet Filling- Picture Courtesy: UNIFIELD FLEX

VFFS equipment is ideal for filling agrochemicals with high-speed operation and less material wastage. The forming of sachets or pouches, filling, and sealing of sachets take place in a single process.

In a vertical filling system, a continuous film roll forms pouches or sachets, accurately fills them with agrochemicals, and seals them automatically.

Horizontal Pouch Filling Equipment

AIPAK Automatic Horizontal Pouch Filling Equipment

These machines accurately fill pre-made pouches, including stand-up, spouted, and flat pouches. The empty pouch is picked up by the machine, filled with the product, and then sealed tightly to avoid leakage.

Bag Filling Machines

Weighing and Bagging Machine

Automatic Bag Filling Machine- Picture Courtesy: Tinsley Company

These machines are designed for filling and packaging powdered agrochemicals, including fertilizers, pesticides, and soil conditioners. The bags are made of paper, plastic, or woven material. These machines use net or gross weighing systems for accurate filling. The machines work for multiple bag types, including open-mouth, valve, and bulk bags. The machine offers accurate weight distribution and robust packaging.

Double Scale Net Weigher Bagger

Double Scale Net Weighing and Bagging Machine

The equipment is suitable for bulk product packaging. It provides precise weighing and filling, ensuring accuracy in product quantity and preventing under-filling or overfilling. These are crucial for maintaining consistency while meeting regulatory standards.

The machine weighed the product before filling it into the bag using a pre-weighing hopper. This machine offers high-speed operation by weighing the next batch while the previous one is being filled.

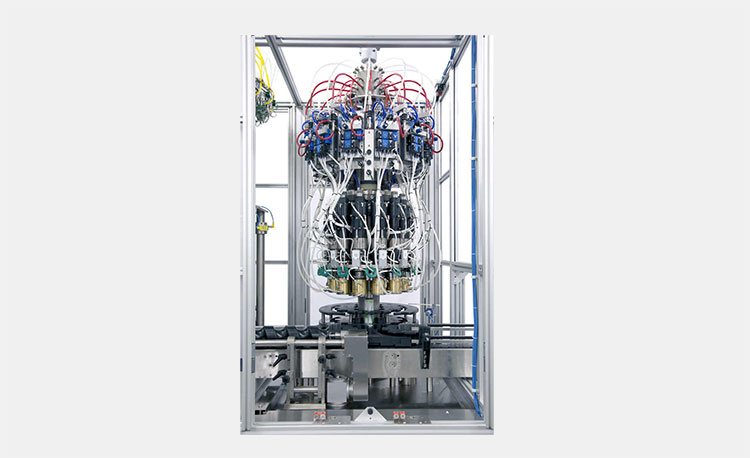

Aerosol can Filling Machine

Aerosol Can Filling Equipment

These machines are used to fill pressurized pesticide sprays in aerosol metal cans. The aerosol can fill is accomplished by filling the liquid pesticide formulation into metal cans by an aerosol filling machine. After that, pressurized gas (such as nitrogen, propane, or butane) is injected by a propellant injection machine to create the aerosol spray effect.

5.How does agricultural chemical packaging take place?

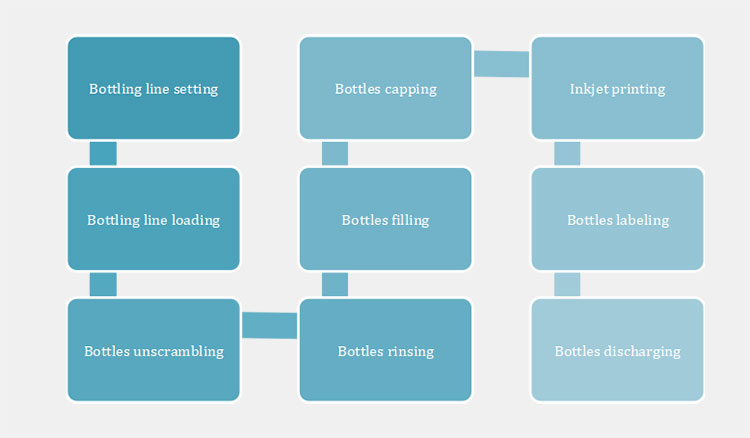

Steps of Agricultural Chemical Packaging

The agricultural chemical packaging is a process designed to ensure secure containment and handling of agrochemicals. Let’s discuss how the process takes place in the agriculture industries:

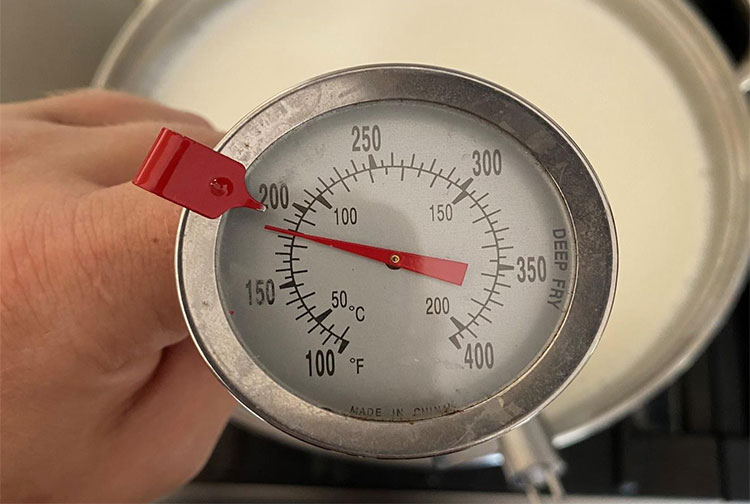

Step # 1: Formulation

Agrochemical Formulation Development- Picture Courtesy: ChemLinked

First you have to developed correct formulation and perform quality checks to verifies chemical composition for consistency, effectiveness, and stability before packaging.

Step # 2: Material Selection

Packaging Selection According to Chemical Form.

Then you have to select the right packaging material according to chemical types.

You can choose plastic or glass bottles, drums, and IBCs for liquid agrochemicals.

Opt for plastic, paper, or woven bags packaging for powder or granule agrochemicals.

You have to select pressurized metal cans for aerosol.

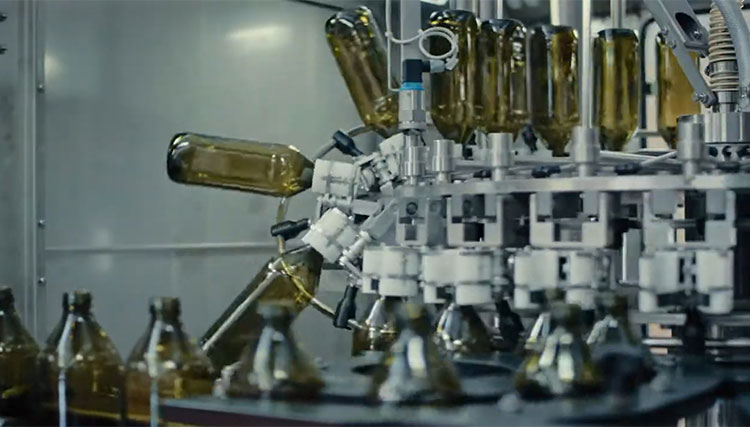

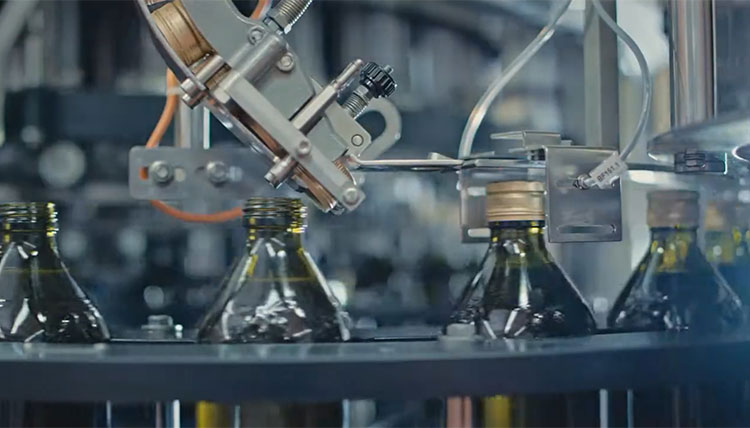

Step # 3: Filling

Bottles Are Filling with Agrochemicals

The agrochemicals are filled into containers using advanced filling machines. There are multiple options for each chemical type, and they are selected accordingly. For liquid chemical filling, you can select gravity, piston, and volumetric filling machines according to the chemical properties of the liquid.

While, for powder chemical filling, auger or weighing-based bagging machines are best suited. Aerosol chemical filling is performed by aerosol filling machines that fill liquid chemicals followed by propellant injection to develop gas pressure.

After filling the containers, they are capped, sealed tightly, and labeled with details including chemical composition, hazard symbols, handling, storage conditions, and disposal method.

Step # 4: Secondary Packaging

Reusable Secondary Packaging for Agrochemicals- Picture Courtesy: Packaging Strategies

The agrochemical packed containers are then packed in cartons, shrink-wrapped, or cased for bulk transport and storage.

Step # 5: Final Inspection

Quality Inspection- Picture Courtesy: Paramount Global

You have to assure that each batch has passed through quality inspection for leak testing, weight verification, and seal integrity to ensure safety standards are met.

Step # 6: Storage

Warehouse for Agrochemicals Storage- Picture Courtesy: Royal Chemicals

The packaged products are stored in a regulated warehouse under controlled temperature and ventilation before transportation. Avoid unauthorized access to storage areas.

6.What are the latest advancements in sustainable agricultural chemical packaging?

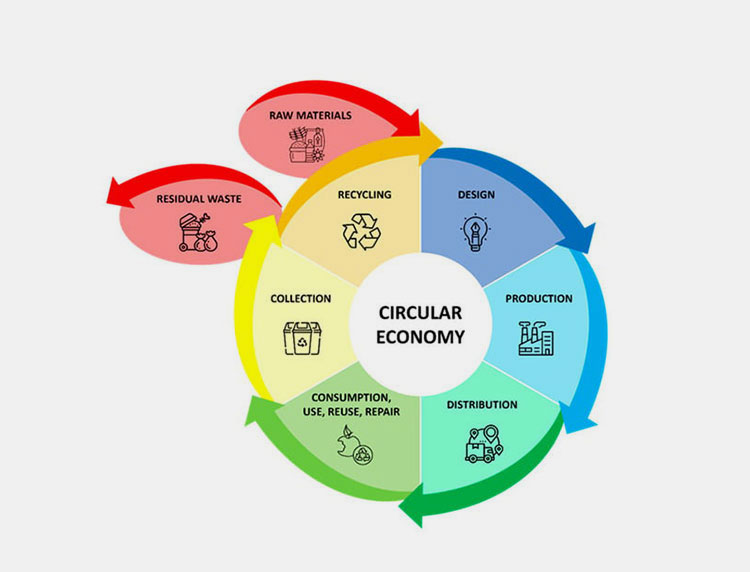

Emphasis on Circular Economy- Picture Courtesy: MDPI

Have you ever thought how sustainable and eco-friendly agricultural chemical packaging significantly helps to minimize environmental effects and promote sustainable practices? Let’s discuss some of the measure developments:

Biodegradable Packaging

Biodegradable Packaging- Picture Courtesy: Magzter

Do you know the conventional plastic materials used in agricultural chemical packaging (such as petrochemical-derived plastics) result in an environment where they persist for centuries? Therefore, agrochemical industries are shifting to biodegradable materials from renewable sources, such as the most favored bioplastic, polylactic acid (PLA). These materials reduce pollution and help to create a circular bioeconomy by decomposing naturally.

Recyclable Packaging

Sustainable Packaging- Picture Courtesy: Packing Pigeon

The U.S. Environmental Protection Agency (EPA) emphasizes sustainable materials management to minimize environmental harm. They emphasized lightweight or efficient packaging materials to reduce waste generation and encourage recycling, keeping packaging materials out of landfills.

Nanotechnology

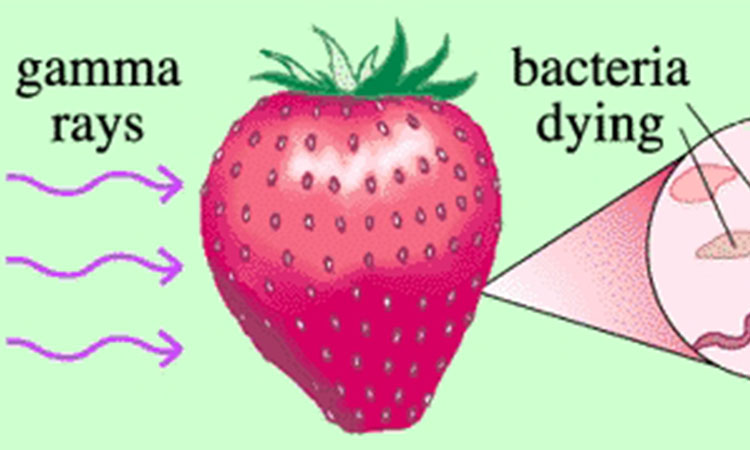

Eco-friendly Pest Control Management- Picture Courtesy: Gumtree Traps

We all are aware that nanotechnology is rapidly emerging across various industries. Nanotechnology provides environmentally safe solutions for agricultural pest management. Extensive research is focused on replacing chemical pesticides, including developing pheromone-loaded nanostructures encapsulated by graphene oxide for pest control management.

7.What are the important regulations governing agricultural chemical packaging?

Regulated Agrochemical Packaging- Picture Courtesy: Farmonaut

Agricultural chemical packaging is strictly regulated locally and globally to ensure user safety, environmental protection, and compliance with international standards. Some of the important regulatory bodies governing the agricultural chemical packaging are discussed below:

| Environmental Protection Agency (EPA) – FIFRA (USA)

Ensures child-resistant and tamper-evident packaging with proper hazard labeling and a safe disposal method. |

Food and Agriculture Organization (FAO)

Sets global guidelines for durability, leak-resistant packaging, and proper labeling to prevent environmental harm. |

| European Union (EU) – CLP Regulations

Standardizes hazard symbols and risk labeling for user safety. |

United Nations (UN) – Transport & Safety Regulations

Set guidelines on safe transport standards to prevent leaks and exposure. |

| ISO Standards (International Organization for Standardization)

ISO 16103 promotes recyclable and reusable packaging. ISO 14001 promotes sustainable packaging materials and production processes. |

Hazardous Materials Regulations (HMR) – U.S. Department of Transportation (DOT)

HMR controls safe agricultural chemical packaging, labeling, and transportation to avoid spillage and contamination. |

| Global Harmonized System (GHS) of Classification and Labeling of Chemicals

The GHS harmonizes chemical labeling and classification worldwide to ensure clear communication of hazards for safer handling and use. |

|

8.Do you know about safety measures that should be followed for agricultural chemical packaging?

Safety Measures for Agrochemicals Packaging- Picture Courtesy: NOBOWA

As we discussed earlier, many organizations worldwide provide strict guidelines for the secure packaging, handling, storage, and disposal of chemicals. By following certain safety measures, you can ensure secure agricultural chemical packaging. Let’s explore them:

Approved Packaging Materials

HDPE Packaging for Agrochemicals

The manufacturer should use that packaging be made of strong, unbreakable, leak-proof, and non-corrosive material, such as high-density polyethylene (HDPE), which is resistant to degradation.

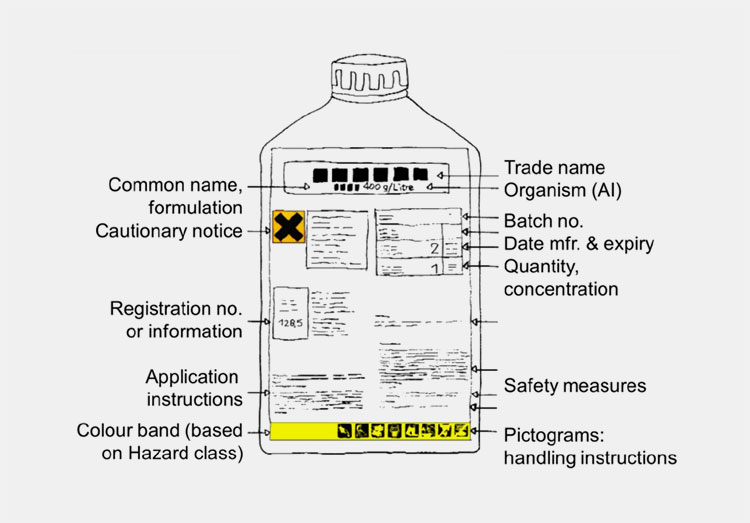

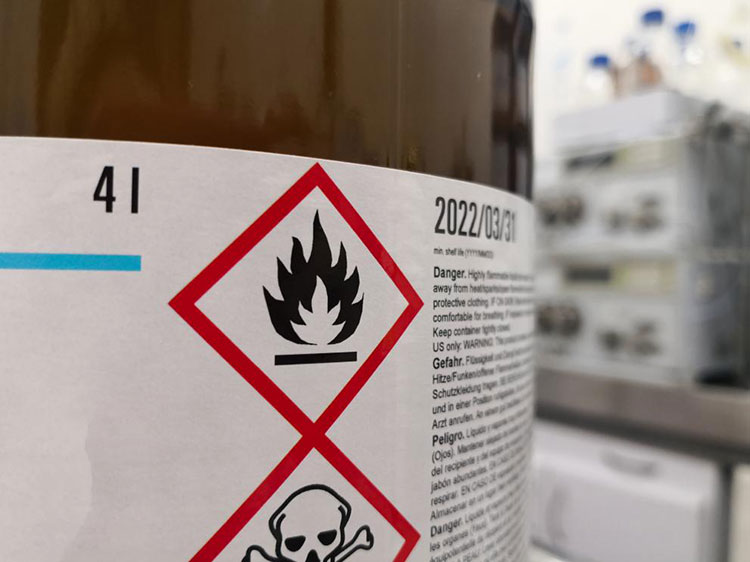

Hazard Communication

Packaging with Proper Labeling- Picture Courtesy: ResearchGate

The manufacturer should ensure that the packaging contains proper labeling, including chemical composition, hazard warnings, handling instructions, and correct disposal methods Color-coded labels and pictograms make it easier to identify hazards for safe handling.

Child-Resistant & Tamper-Evident Seals

Tamper-Evident Packaging- Picture Courtesy: Industrial Packaging

The manufacturer must use child-resistant and tamper-evident seals to prevent accidental exposure and unauthorized access.

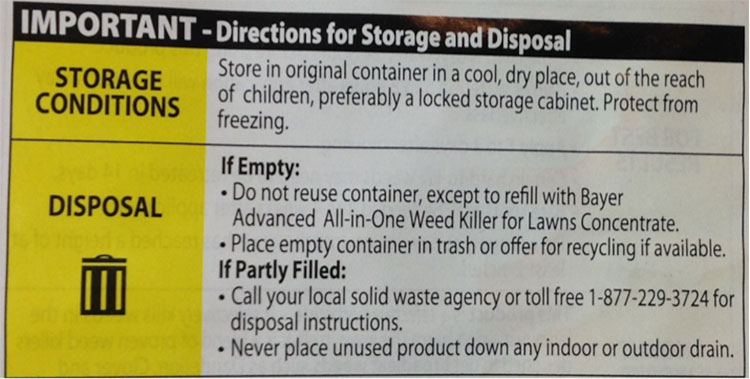

Safe Storage

Optimized Storage Conditions for Agrochemicals- Picture Courtesy: Citrus Industry

The chemicals must be kept in cool, dry, and well-ventilated areas and away from heat and direct sunlight. Containers must be kept upright and securely closed to avoid leaks and contamination. chemicals must be kept in their original well-labeled containers.

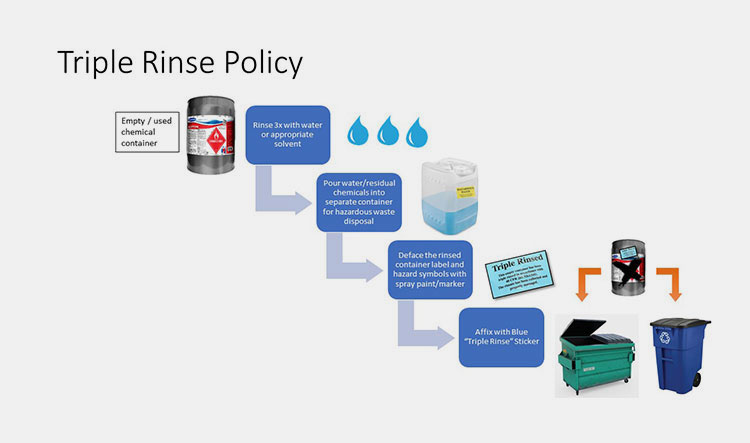

Disposal Protocols

Triple-Rinsing of Agro Containers- Picture Courtesy: ACRC

The containers should be disposed of according to EPA and FAO guidelines to minimize soil and water contamination. It’s instructed to use the triple rinsing method for empty containers and participate in the recycling program.

Transport Regulation Compliance

Packaging Compliance with UN Guidelines for Transportation

Hazardous chemicals packaging must comply with UN Recommendations for Transport of Dangerous Goods for safe transit. Spill-proof secondary containments further prevent leaks during transportation.

9.Why is labeling important for agricultural chemical packaging?

Significance of Labeling of Agricultural Chemical Packaging- Picture Courtesy: Cropia

Labeling is an important part of agricultural chemical packaging; therefore, regulatory bodies establish strict guidelines to harmonize labeling for hazardous chemicals. Here are some important points that highlight the importance of labeling in agricultural chemical packaging.

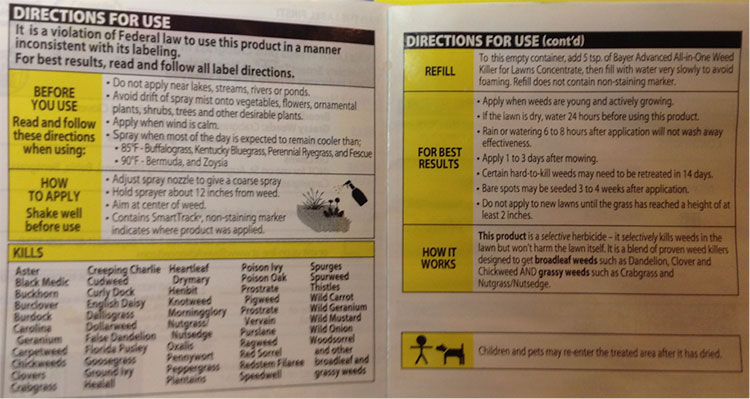

Instructions for Handling

Usage Instructions on Label- Picture Courtesy: Ohioline

Proper labeling provides instructions for the safe handling, mixing, and application of agricultural chemicals. It also helps the user to take the necessary precautions to prevent contamination and health risks.

Hazards Warnings

Proper Labeling of Hazardous Chemicals

Standardized pictograms, single words, and hazard statements are used to alert users of potential risk. Hence, it prevents accidental exposure, poisoning, and misuse of these chemicals.

Provided Emergency Response

Safe Disposal of Agrochemical Containers

Labels contain first-aid measures and emergency contact numbers for accidental exposure management. It contains information on spill management and safe disposal protocols.

Guides Proper Storage

Instruction for Storage on Label- Picture Courtesy: Ohioline

Labels contain proper storage conditions that help maintain chemical effectiveness and prevent deterioration.

Prevents Counterfeiting

Counterfeit Identification- Picture Courtesy: Authentic Vision

By using unique identification codes and security features on labels, one can easily differentiate between original products and counterfeits. It helps to prevent the sale of unauthorized agricultural chemicals.

10.Do you know the proper disposal and recycling guidelines for agricultural chemical packaging?

Disposal of Empty Containers- Picture courtesy: Farm Progress

Do you know what happens to empty agricultural chemical containers once they’re used? If you don’t follow the proper disposal method, it can lead to pollution and cause potential health risks. That’s why it’s necessary to follow proper guidelines for the disposal and recycling of agricultural chemical packaging.

Triple-Rinsing Method

Steps of Triple-Rinsed Method- Picture Courtesy: Binghamton University

The empty containers should be triple rinsed with a solvent (water, acetone, etc.) to remove chemical residues then remove the label, and a blue “triple-rinsed” sticker should be affixed. Rinse water should be kept for the next agrochemical application to reduce waste. This method makes the container safe for disposal and recycling.

Recycling Program

Recycling of Agrochemical Containers- Picture Courtesy: Clanfarms

The user can participate in recycling program offers by many countries where they accept properly cleaned agrochemical containers. In that way, recycled plastic can be re-utilized for non-food-related products.

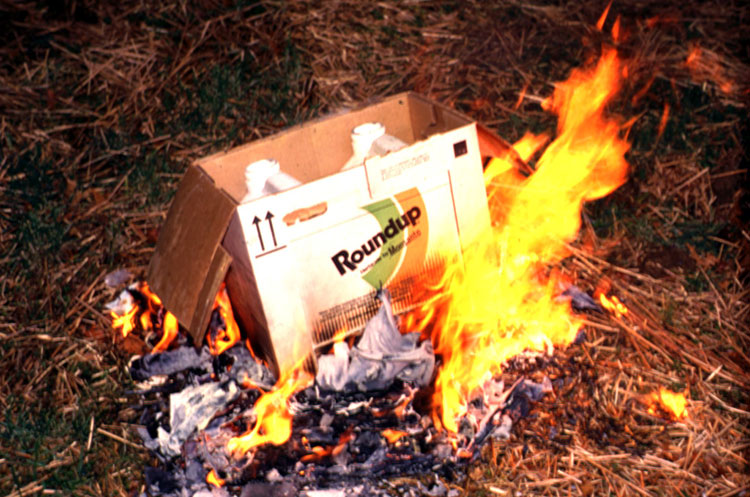

Disposal Protocol for Non-Recyclable Containers

Avoid Burning of Containers

Local guidelines for the disposal of hazardous waste should be followed in case of non-recyclable containers. To prevent re-use for food or water storage, containers should be punctured or crushed. Don’t burn or bury containers because it can lead to poisonous emissions and soil contamination.

Disposal of Bulk Containers

Bulk Containers- Picture Courtesy: Storemasta Blog

The empty bulk containers should be sent back to manufacturers if they are returnable so that they can use them for re-use or recycling.

11.What do you know about the best practices for handling and storing agricultural chemical packaging?

Labeled Storage Area- Picture Courtesy: Citrus Industry

The following are some of the best practices for handling and storing agricultural chemical packaging to avoid any consequences:

| Keep in proper storage conditions. |

| Always store it away from food, water sources, and livestock. |

| The storage area should be secured and labeled and should restrict unauthorized access. |

| Keep the containers in an upright position and properly sealed. |

| Always keep secondary containment trays for extra protection from accidental spills. |

| Carefully read and follow the instructions on the label about handling, storage, and disposal. |

| Before handling containers, wear protective gear, including gloves, a mask, and goggles. |

| Always store different agrochemicals separately from each other to prevent cross-contamination. |

| In case of flammable chemicals, keep them away from oxidizers and combustible materials. |

| Always check containers for leaks, corrosion, or damage before use. |

| In case of damaged or expired containers, dispose of them according to standard guidelines. |

| Always maintain emergency safety measures in the storage area, like equipping them with spill kits, fire extinguishers, and first-aid supplies. |

Conclusion

Agricultural chemical packaging demands secure containment of chemicals inside the container without deterioration, spillage and contamination while meeting the international standards. ALLPACK offers you advanced packaging machinery, including bag weighing and filling, liquid bottle filling, and pouch and sachet filling machines that improve efficiency and secure handling of agrochemicals. With ALLPACK packaging solutions, the manufacturer can enhance durability, efficiency, and safety in agricultural chemical packaging.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Agricultural Chemical Packaging: The Complete FAQ Guide in 2025 Read More »

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours