Liquid Beverage Pouch Packaging Machine: The Complete Buying Guide In 2025

A sip of cold beverage can magically refresh your mood in a hot sunny day. So, what about having it all the time ready for you? This is a matter that led the think tanks of packaging world to suggest a packaging means that can provide greater ease for consumer in product handling while at the same time considering its cost and environmental effects. Eventually, they preferred flexible packaging which result in the creation of a Liquid Beverage Pouch Packaging Machine!

This machine is highly advanced and fully protected to retain the essence of all kinds of liquid beverages. Moreover, its vary features help you get utmost performance in terms of efficiency, accuracy, and versatility. So, make sure to fully understand the structure, functions, types, and working procedure of Liquid Beverage Pouch Packaging Machine and get benefits as much as possible!

1.What Is Liquid Beverage Pouch Packaging Machine?

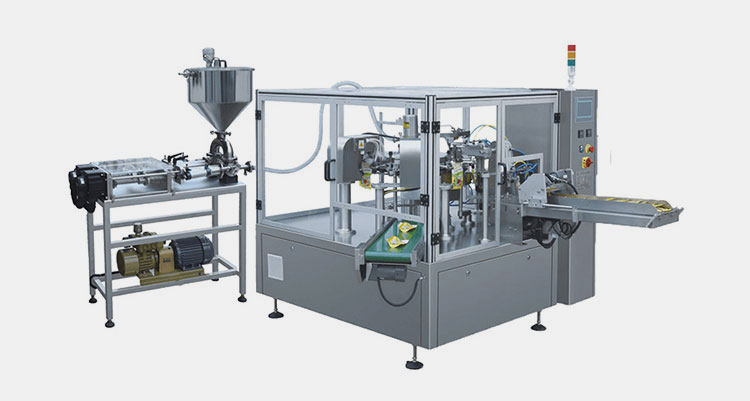

Allpack- APKRL200-Y Rotary Liquid Premade Pouch Filling Machine

The process of enclosing liquid beverages such as juice, coffee, and spirits in flexible pouches is known as liquid beverage pouch packaging. Similarly, the machine used to carry out this task of packing liquid beverages in pouches is referred to as liquid beverage pouch packaging machine.

This machine is configured with topnotch features and advanced technology to make sure the material being processed is fully protected and have fast packaging pace. It accomplishes the function of liquid beverage packaging by forming consistent pouches, filling them with accurate beverage volume, and sealing these pouches for enhancing their shelf life.

2.Explain The Benefits Of A Liquid Beverage Pouch Packaging Machine?

Bringing automation in your packaging process can greatly benefits your business. In this way, a liquid beverage pouch packaging machine hold multiple features and characteristics which together contribute to uplift your production. These are explained below:

High Consistency

Consistently packed juice pouches

Consistently packing each pouch with precise volume of liquid beverage is neither possible nor easy. However, by using a liquid beverage pouch packaging machine, you can get highly accurate packaging with machine undergoing each pouch through the same process with high consistency in terms of packaging as well as filling.

Production Efficiency

Every manufacturer wants to boost their production horizon which is not possible with hiring manual labours. So, what matters here is the ability of machine to increase its production growth. You can simply enhance its speed further by integrating the machine with conveyor belt and other machines to get uninterrupted operation.

Versatility

Customized beverage pouches

Liquid beverage pouch packaging machine display exciting versatility when it comes to process liquids of various nature by accepting the integration of different filling systems such as gravity filler, piston filler, and volumetric filler etc., for spirits, shakes, and juices.

Marketing Opportunity

Consumer holding beverage pouches

Marketing and advertising are what determines the success of new brand when it enters into market. That's why, entrepreneurs are looking forward for getting a solution that can cope up with the emerging needs and trends especially regarding customer convenience. Similarly, the machine offers myriad of packaging formats and sealing methods which will attract consumers.

Simple Handling

Handling a large heavy-duty machine is not an easy job. At the same time, it is obligatory for operator to have complete control over it. In such a scenario, liquid beverage packaging machine is highly user-friendly with intuitive human machine interface and compact, enclosed body which is both easy to control and mobilize.

3.What Packaging Formats Does A Liquid Beverage Pouch Packaging Machine Support?

A liquid beverage pouch packaging machine do support the creation and processing of wide range of pouches which are highlighted below:

Standup Pouch

Standup liquid beverage pouches

Standup pouch is a durable pouch which has the ability to stand erect on its bottom. It is also known as doypack. Such type of pouch is good for holding medium to large volume of liquid beverages and can have multiple types of convenient opening methods such as spouts and fitment etc. So, a liquid beverage pouch packaging machine can create stand-up pouches easily.

Flat Pouch

Various flat pouches of liquids

Flat pouch is another type of packaging format which a liquid beverage pouch packaging machine is capable to make. It is called flat pouch for the reason that its body is flat with no additional gussets. They either have 3 sides or 4 sides sealing, therefore, single serving liquid beverages are best delivered in them.

Stick Pouch

Liquid beverage stick pouches

Stick pouch refers to small size long, narrow pouch which is best suitable to hold single serving liquid beverages like juice, milk, and other liquids including cough syrup and shampoo etc.

Irregular Shape Pouch

Irregular fruit shape juice pouches

In addition to above mentioned regular and standard types of pouches, a liquid beverage pouch packaging machine can be employed to produce wonderful irregular shape pouches for liquid beverage packaging. Fruit shaped pouches is a common example.

Zipper Pouch

Liquid beverage pouch with zipper

It refers to the pouch having a zipper on its top for resealing. Zipper pouches are also known as press-to-close pouches for their convenient closure which can be easily resealed. Hence, a liquid beverage pouch packaging machine can pack such type of pouches.

Spout Pouch

Spouted juice pouch

Pouches having a spout on their top for safe and swift pouring of liquids is known as spouted pouches. These pouches have caps on spouts which, like bottles, can be opened and closed multiple times. Hence this machine is able to process spouted pouches.

Heat Sealed Pouch

Heat sealed juice pouches

A liquid beverage pouch packaging machine can also form, and process heat sealed pouches which are sealed through heat on the top instead of zipper or spouts. The common heat-sealed pouches include pillow pouches, single serving stick pouches, and flat pouches.

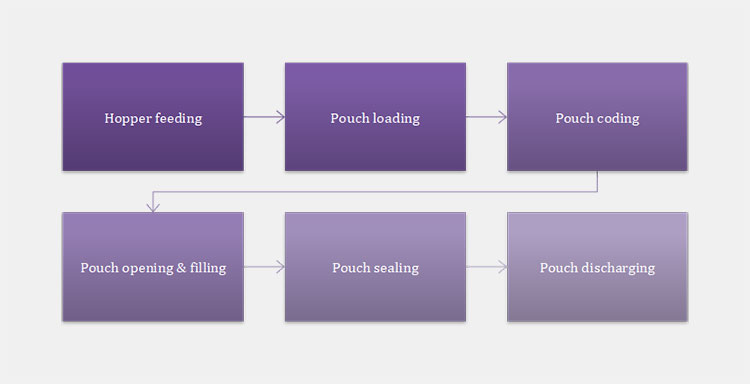

4.What Are The Working Principles Of A Liquid Beverage Pouch Packaging Machine?

To get benefited from your liquid beverage pouch packaging machine, it is necessary to operate it on right working principles. As liquid beverage pouch packaging machine is available in different types, so, each machine has its own particular way for operation. In this question, we have explained the working process of a premade liquid beverage pouch packaging machine and stick pack iquid pouch packaging machine as examples:

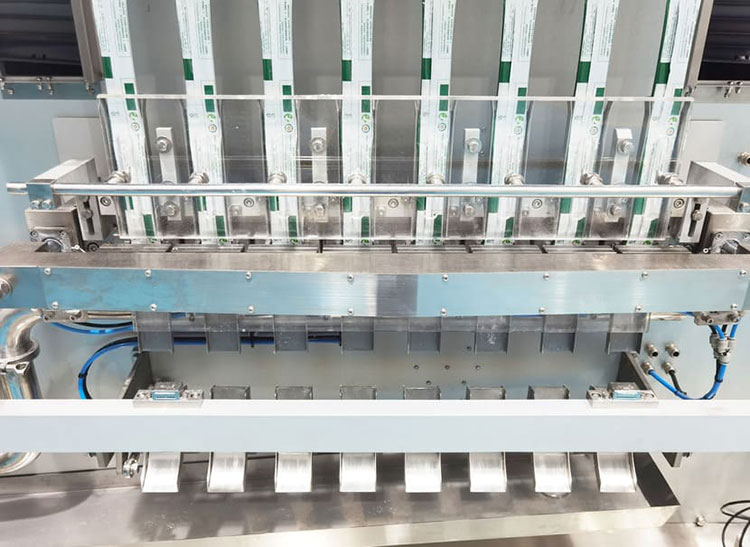

Working Principles of a Premade Liquid Beverage Pouch Packaging Machine

Hopper Feeding

Hopper loading

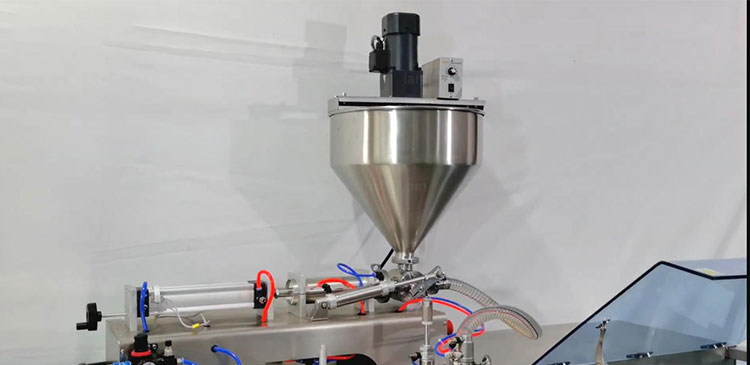

To operate the machine, first step is to feed the hopper of machine with adequate volume of any liquid beverage which you want to process. However, it is crucial that the filling system attached to the main machine must be in accordance with the nature of liquid beverage. For instance, thick liquids will require a piston filler, while as, for free-flowing liquids gravity filler will be suitable.

Pouch Loading

Pouch loading

After feeding hopper, the operator is required to load the bulk of premade pouches into machine. Moving forward, when machine is powered on, the robotic arm will come into action and will start picking and placing the pouches one by one in an automatic way.

Pouch Coding

Upon pouch loading, the optional but essential step of pouch coding will be carried out. During this phase, information regarding batch no, manufacturing data, expiration date, and price etc., is printed over pouches.

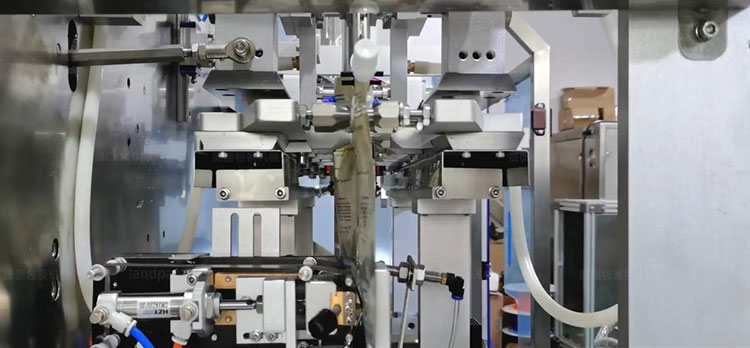

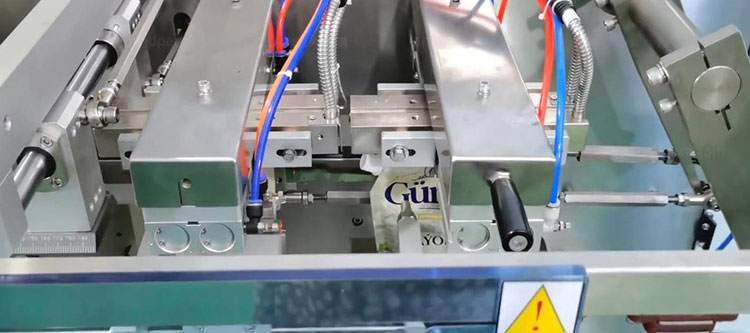

Pouch Opening & Filling

Pouch opening & filling

Proceeding further, multiple grippers grip over the pouch from opposite sides in order to open them. As the pouch gets opened, a pre-weighed dosage of liquid beverage is discharged into each passing pouch. Similarly, the filled pouch move forward and its place is taken over by the awaiting one.

Pouch Sealing

Pouch sealing

In this step, the liquid beverage filled pouches are passed through sealing process. For this, heated sealing jaws come together and create a stringent sealing on the top of pouches.

Pouch Discharging

Finally, the finished pouches are ready for output. They are discharged from the machine via discharge chute and processed for further packaging.

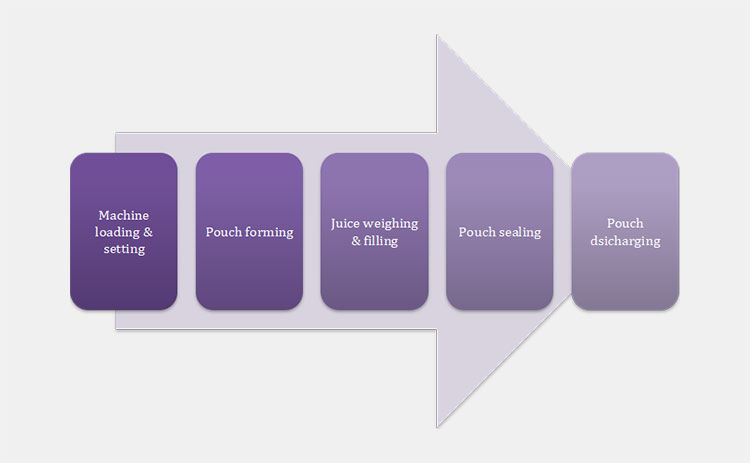

Working Principles of A Form Fill And Seal Liquid Beverage Pouch Packaging Machine

Machine Feeding & Setting

Operator setting machine

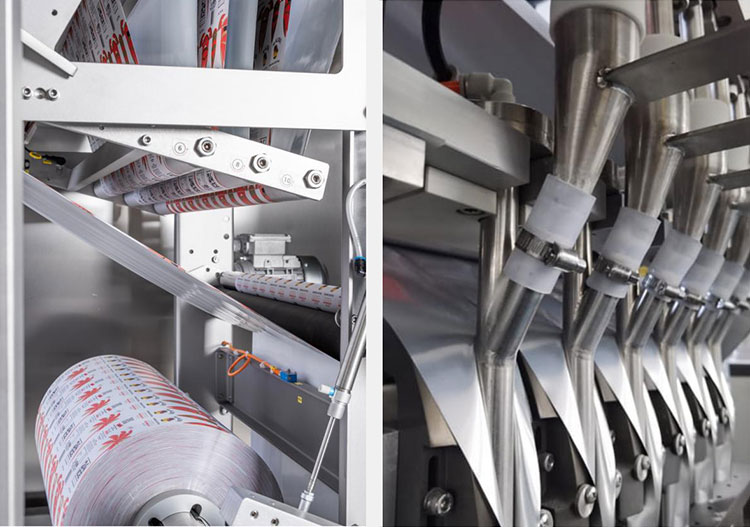

The first working principle for operating a stick pack liquid pouch packaging machine is feeding and setting. Here, the operator is required to load the hopper of machine with large volume of juice and also supply the roll stock of a film for pouch formation.

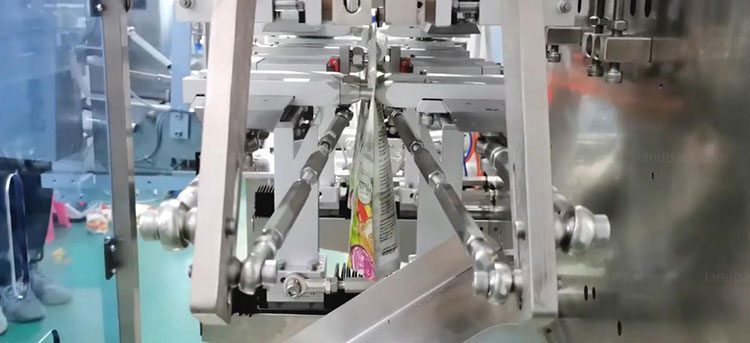

Pouch Forming

Film unwinding & pouch forming

The next step is formation of pouch. The pouch is formed as a result of film unwinding which is then wrapped around a pouch former and sealed from bottom and sides.

Juice Weighing & Filling

Juice weighing & filling

Moving forward, the formed pouches are ready to be filled with juice. However, it is very essential that the juice must be accurately weighed before filling. For this purpose, the attached filling or weighing system start measuring the amount of juice to be filled in each pouch. As the weighing process gets completed, juice is dispensed into pouches.

Pouch Sealing

Pouch sealing

Now, the loaded pouches are passed through sealing phase where the opening of pouches are hermetically closed. Afterwards, by using sharp cutting blades, the finished pouches are separated from each other.

Pouch Discharging

Pouch discharging

In the end, juice filled and packed pouches are ejected out of machine and are collected into a container.

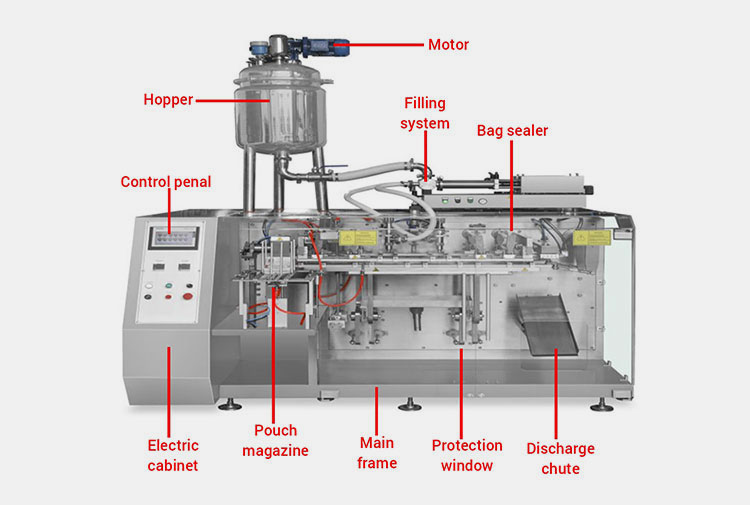

5.Describe The Structure Of A Liquid Beverage Pouch Packaging Machine?

The structure of a liquid beverage pouch packaging machine vary from one type of machine to another. However, most of their parts are common. In this question, we will be describing the structure of a premade liquid beverage pouch packaging machine.

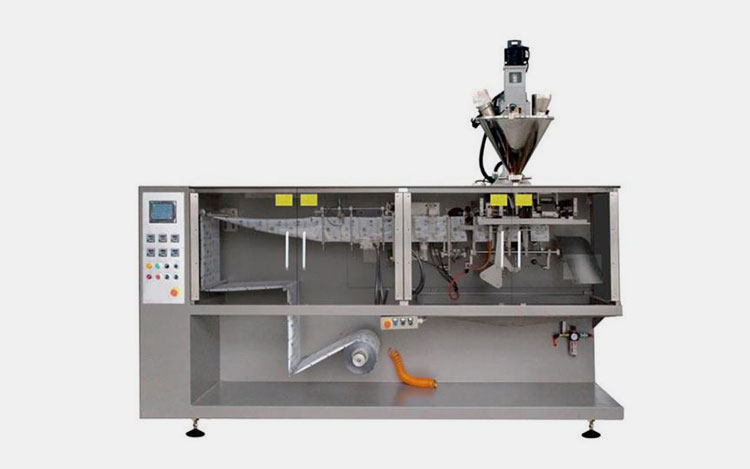

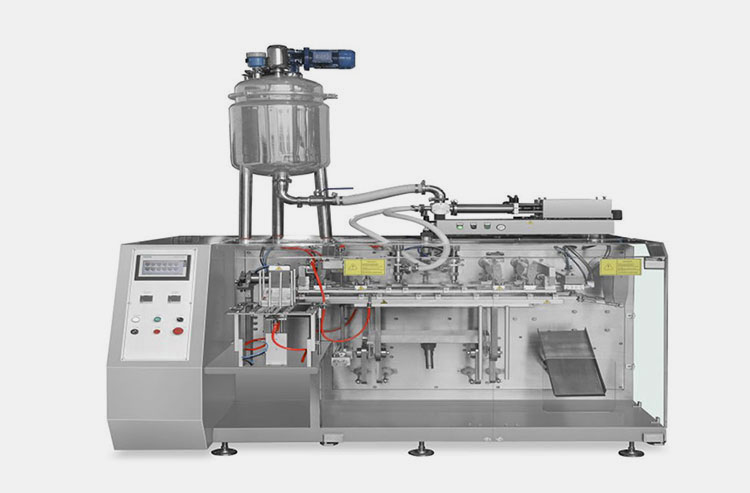

Structure of Allpack- APK-200 Automatic Horizontal Liquid Premade Pouch Filling Machine

Motor

Motor is an important component of a liquid beverage pouch packaging machine located at the top of hopper to energize the machine for begining and regulating operation.

Electric Cabinet

It is an electric enclosure where all the electrical connections of machine in form of wires, switches, and fuses are settled.

Protection Window

The machine has a transparent protection window installed outside the working area. It greatly helps in ensuring the safety of ongoing operation.

Control Panel

Control panel is one of the core components of a liquid beverage pouch packaging machine located on the top front of machine. It consists of a touch screen interface and several knobs responsible for controlling and regulating machine's functions such as amount of liquid and temperature of sealing jaws etc.

Pouch Magazine

Pouch magazine is another part of the machine used to hold bulk of premade pouches prior to operation. From here, the machine is supplied with empty pouches.

Main Frame

Main frame constitutes the overall structure of machine which is made up of 304 stainless steels With the help of main frame, all other components of the machine are attached to each other, and it greatly helps in maintaining the structural stability of machine.

Material Hopper

Liquid beverage pouch packaging machine has an empty material hopper situated on its top where large volume of liquid is poured before operation. From here the liquid is supplied to machine during operation which ensures smooth functioning.

Filling System

Filling system is an integral part of the machine. Although it is a separate device, yet it has a significant role in the machine. Each liquid beverage pouch packaging machine has different type of filling system as per the properties or requirements of material being filled. These include piston filling system, gravity filling system, and volumetric filling system.

Bag Sealer

Bag sealer is a set of heat-sealing jaws whose function is to seal the liquid filled pouch tightly before its discharging.

Discharge Chute

A stainless-steel flat device with tilted edges is known as discharge chute. It is located right under the pouch sealer and is used to discharge the finished pouches from machine into collection container.

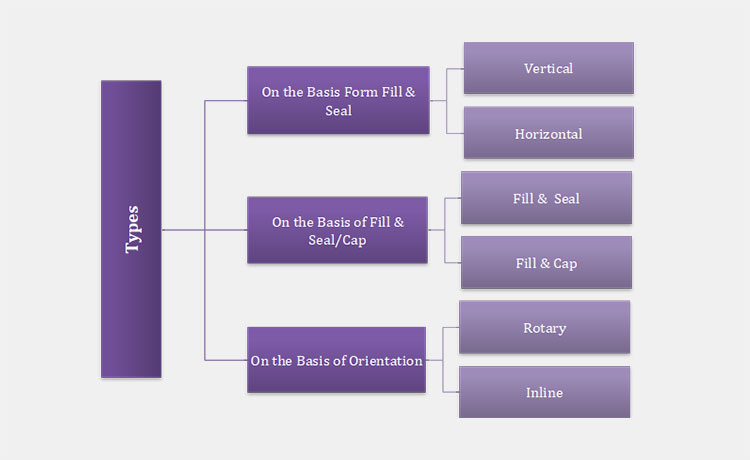

6.Explain The Types Of A Liquid Beverage Pouch Packaging Machine?

Liquid beverage pouch packaging machine is available in multiple types and each type offer substantial benefits according to its specification. Below provided information will give a valuable insight regarding all these types. So, stay tuned and keep reading!

On the Basis of Form Fill and Seal

Vertical Liquid Beverage Pouch Packaging Machine

Automatic Vertical Juice Pouch Filling & Sealing Machine

As the title illustrates, this type of liquid beverage pouch packaging machine has a vertical design to facilitate quick, smooth, and easy packaging way. The machine is multifunctional with performing triple tasks of pouch forming, filling, and sealing simultaneously. The machine can create flat, stick, and pillow pouches.

Structure

The machine is characterized by its vertical structure which is compact and cover less space. The main components include stainless steel body, a hopper, control unit, electric enclosure, and bag forming, filling, and sealing tools etc.

Working Process

It follows a simple operation that begins with unwinding film from a roll in a vertical downward position. This film is then turned into desired pouch, filled with precise volume of liquid, sealed tightly from top and then discharged from the machine.

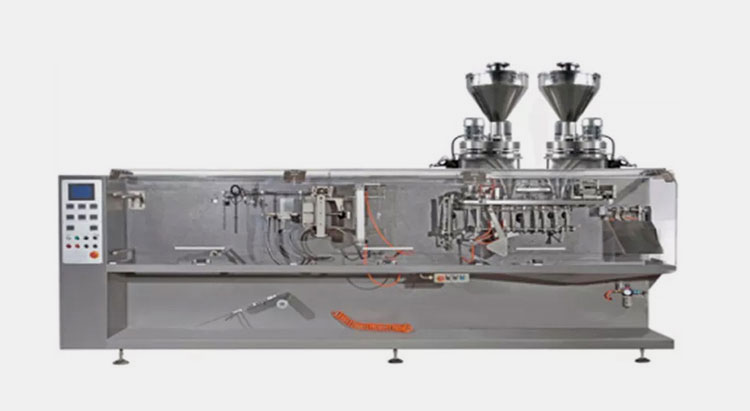

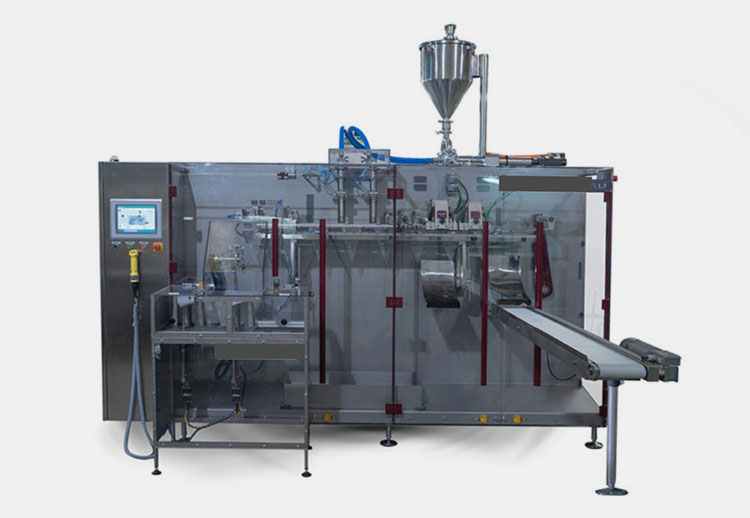

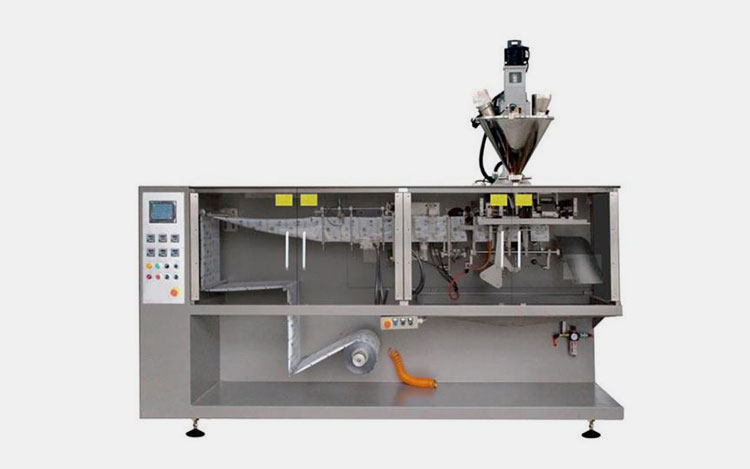

Horizontal Liquid Beverage Pouch Packaging Machine

Allpack- APK-240D Horizontal honey, juice, ketchup flat pouch sachet machine

Horizontal liquid beverage pouch packaging machine is yet another type of machine famous for its versatility and packaging efficiency. The machine is fully automatic and able to create beautiful flat, stick, and standup pouches and filling them with liquid beverages. The machine can also be integrated with other machines for enhancing productivity.

Structure

The structure of machine is horizontal and thus having a large footprint that require more working space. However, it is composed of few components including a stainless-steel main frame, filling system, pouch forming mechanism, film guiding rollers, sealer, and cutter.

Working Process

It works in a horizontal way where film is unfurled from roll and is guided through rollers located at certain intervals. Afterwards, the filling system measure the exact volume of liquid and fill it into pouch. Consequently, the filled pouches are closed through sealing, separated from each other through cutting, and ready for output.

On the Basis of Fill and Seal/ Cap

Fill & Seal Liquid Beverage Pouch Packaging Machine

Allpack- APK-200 Automatic Horizontal Liquid Premade Pouch Filling Machine

This type of liquid beverage pouch packaging machine is designed to process all kinds of readymade pouches by filling and sealing. In this way, it reduces the time spent on forming pouches and adds into production efficiency. Moreover, the machine uses a technique of heat sealing for closing pouches.

Structure

As far as the structure of machine is concerned, so, it is precise as the forming step is absent here. Apart from this, the machine is an assembly of a pouch magazine, weighing pump, storage tank, grippers, and heat-sealing jaws.

Working Process

The machine works by picking empty pouches from magazine and holding them through grippers. Then these pouches are coded with necessary data, loaded with weighed volume of liquid, and properly sealed from top. Now, they are ready for outlet.

Fill & Cap Liquid Beverage Pouch Packaging Machine

Filler/Capper monoblock for spouted doypack- Picture Courtesy: tenco.it

Fill and cap liquid beverage pouch packaging machine is unique design equipment tailored with astonishing features to intelligently pack spouted pouches. For this the machine employ filling and screw capping method. It is available in fully automatic, semi-automatic as well as manual form to meet the vary needs of industry.

Structure

The machine has a compact vertical structure which composed of two units, filling unit and capping unit. Its major parts comprise feeding rack system, filling station, pouch gripper, cap feeder, and capping device.

Working Process

The working process of machine is based on two functions which is filling and screw capping. Firstly, it grabs the premade spouted pouches from magazine rack and then fill these pouches with liquid beverage. Secondly, the filled pouches are moved ahead where caps are placed over spouts, and they are screwed. Finally, finished pouches are conveyed for discharging.

On the Basis of Orientation

Rotary Liquid Beverage Pouch Packaging Machine

Allpack- APKRL200-Y Rotary Liquid Premade Pouch Filling Machine

Rotary liquid beverage pouch packaging machine is a sophisticated machine that enable you to process your pouches in a rotary manner and get highest possible output. The machine is advanced in technology and therefore, support pouches of various types including flat pouches, stand-up pouches, and spouted pouches.

Structure

The machine is made up of quality tools and enclosed body where major components include a rotary channel for pouch opening, filling, and sealing, along with adjoined filling and feeding system.

Working Process

It has extremely convenient working process that begins with machine automatically taking pouches from magazine and supplying them to the rotary turret. Here, multiple units of rotary channel pass the pouches through coding, opening, filling, sealing, and discharging phase.

Inline Liquid Beverage Pouch Packaging Machine

Inline premade pouch packaging machine- Picture Courtesy: bartletpackaging.com

Inline liquid beverage pouch packaging machine offers fast and straight way for liquid beverage pouch packaging. The machine is capable of processing pouches with spout, zippers, and mere heat sealing. It is available in both form, fill, and seal as well as fill and seal form.

Structure

This machine has a linear body with horizontal structure where the structural and functional components are located in a linear way. These include a material storage unit, human machine interface, weighing system, filling heads, pouch sealer, and coder etc.

Working Process

It carries out the main task of liquid beverage pouch packaging by starting operation from one end and completing it on the other in a sequential manner.

7.Differentiate Between A Liquid Beverage Pouch Packaging Machine And Solid Beverage Pouch Packaging Machine?

Liquid beverage pouch packaging machine and solid beverage pouch packaging machine are two different machines with different functions. Let's explore what are these differences!

| No | Factors | Liquid Beverage Pouch Packaging Machine | Solid Beverage Pouch Packaging Machine |

| 1 | Definition | Liquid beverage pouch packaging machine is used to pack liquid beverages in pouches. | While as, solid beverage pouch packaging machine is employed to deal with solid beverage pouch packaging. |

| 2 | Filling system | It uses gravity filling system, piston filling system, and volumetric filling system for liquid filling. | On the other hand, it utilizes auger filling system, volumetric cup filling system, and basculating filling system for solid beverage filling. |

| 3 | Type of pouch | The machine can process spouted, flat, stick, and irregular shape pouches. | Contrary to that, it can pack gusseted, standup, flat, and pillow pouches. |

| 4 | Type of material | It deals with free flowing, thick, and viscous liquid beverages. | In contrast, it processes liquid beverages available in powder and granulated form. |

| 5 | Application | The machine is best suitable for packing cold drinks, juices, milk shakes, spirits, and smoothies. | It is reliable for packing juice powder, protein powder, and spirits cubes etc. |

| 6 | Picture |

Allpack- APK-200 Automatic Horizontal Liquid Premade Pouch Filling Machine |

Allpack- APK-130 Horizontal 4 side seal small salt powder granule sachet machine |

8.What Are The Applications Of A Liquid Beverage Pouch Packaging Machine?

There are many applications of a liquid beverage pouch packaging machine. Some of the prominent ones are highlighted below:

Beverage Industry

Spouted doypack pouch of juice

One of the top industries where the application of a liquid beverage pouch packaging machine can be found is the beverage industry itself. It is an area where liquid beverages such as fruit juices, pulps, soft drinks, wines, and carbonated drinks are produced and processed. Therefore, it is inevitable to securely pack these beverages in flexible packages with the help of this machine.

Seasoning Industry

Various sauces in doypacks

Oh yes! Ketchup, mayonnaise, yogurt, and sauces are what we want to have whenever sitting on a dining table or having a pizza party with friends. So, a liquid beverage pouch packaging is always considered by manufacturers' of the concerned products to keep their customers happy and satisfied by providing tantalizing seasonings in hygienic pouches.

Healthcare Industry

Energy drink pouches

The advancement in technology has a great influence on healthcare industry where the liquid mode of drug delivery has gained momentum. Therefore, now you will see the beautiful single serving to large size pouches of cough syrup, herbal pastes, energy drink, and protein shake etc., in stores. This is the result of bringing in use a liquid beverage pouch packaging machine.

Beauty Care Industry

Shampoo & conditioner twin flat pouches

As the number of living essentials increases, people, on the other hand, are trying to reduce the number of products they carry. Similar is the case with today's beauty care goods. That's why, shampoo, conditioner, hand washing gel, and hair dye are delivered in small to large light-weighted and handy flexible pouches for which a liquid beverage pouch packaging machine is necessary.

Detergent Industry

Window cleaning fluids packing

Liquid beverage pouch packaging machine can be also used in detergent industry where liquid detergent, dish washing gel, and floor cleaning fluids are packed in spouted doypack pouches.

9.How To Maintain A Liquid Beverage Pouch Packaging Machine?

Maintenance is inevitable to keep your liquid beverage pouch packaging machine at good working condition. It can reduce the possible breakdowns and also extend the working efficiency of machine. So, make sure to establish a routine maintenance schedule for your machine. In this way, below points will be helpful:

Operator maintaining machine

Cleaning:After your machine gets done with daily task of packaging, disassemble the hopper and filling nozzles and clean these components to remove out the accumulated debris. Also clean the sealing jaws, conveyor, and cutting device for proper functioning.

Inspection:It includes the examination of machine parts during operation. By doing so, it will be easy to take the notice of unusual voice or any damaged part whose timely correction or replacement is essential for maintaining the machine.

Greasing:Lack of lubrication can lead the movable parts to friction of wear and tear. To avoid such situation, it is obligatory to keep checking the conveyor, rollers and other movable parts and add recommended grease weekly and monthly.

Adjustment:It covers both the adjustment of internal parameters of machine before starting operation and also the right placement of various components after its disassembling and cleaning.

10.How To Conduct A Leakage Test For A Liquid Beverage Pouch Packaging Machine?

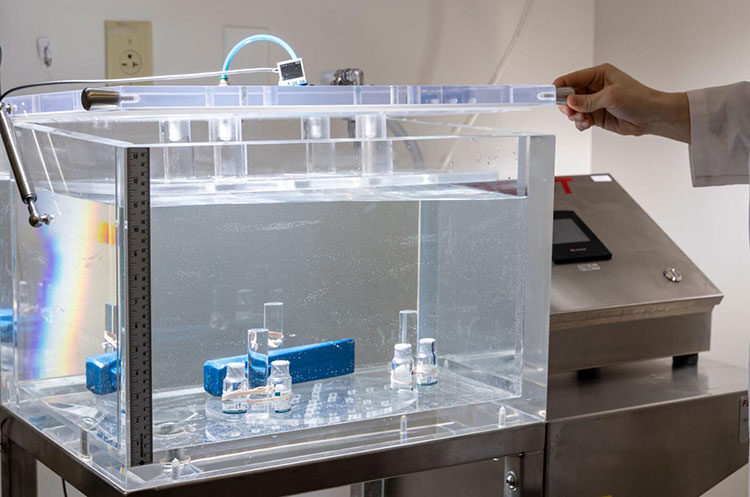

Vacuum Leak Detector

Leakage in finished liquid pouches can result in huge economic loss and it also causes product contamination. Due to this reason, a proper leak test is conducted to ensure package safety against possible leaks. In this way, vacuum leak test is one of the notable tests conducted by the users of liquid beverage pouch packaging machines.

This test includes the placement of a finished liquid beverage pouch in an enclosed leak tester having water. Now, the vacuum leak tester is powered on to remove the air present inside the chamber. During this phase, user keeps observing the change that may occur in the chamber.

If the bubble appears from package and liquid inside pouch start mixing with water, then it shows the existence of a leak. In contrast, a scenario with no occurrence of change shows that the package is fully protected against leaks.

11.What Quality Standards Should A Liquid Beverage Pouch Packaging Machine Meet With?

Every liquid beverage pouch packaging machine must adhere to certain quality standards recognized by the national and international authorities to be called as quality machines. These are as follows:

Certification stamp

ISO:A liquid beverage pouch packaging machine must comply the rules and regulations established by International Organization for Standardization.

FDA:Food and Drugs Administration is an agency created to keep a strict eye on goods and machines related to food and drugs. Hence, a liquid beverage pouch packaging machine should meet these principles.

GMP:Another eminent quality standard is Good Manufacturing Practices which particularly deals with the construction material of machine. Thus, your machine should be certified by GMP.

CE:CE is a certification mark only significant for machines which are either produced in European Union or which are meant to be sold or used in these countries.

12.Tips For Choosing The Best Liquid Beverage Pouch Packaging Machine?

To choose the best liquid beverage pouch packaging machine, it is crucial to have considered some of the important tips including those enumerated below:

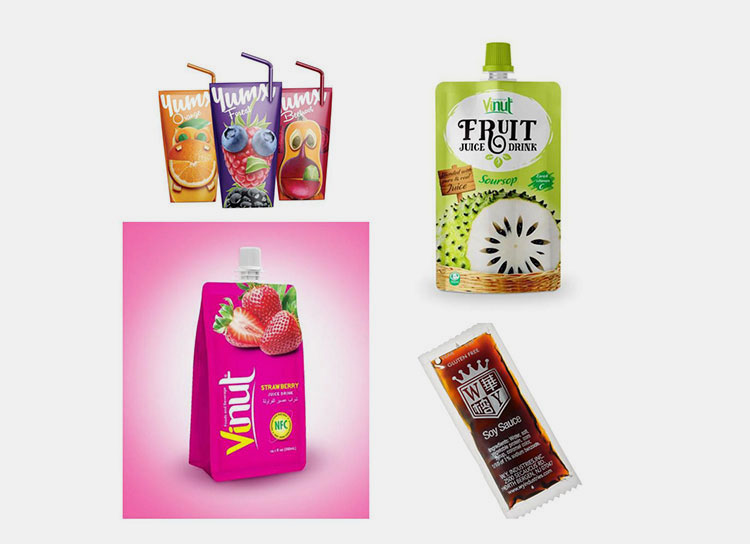

Type of Packaging Format

Various types of juice packaging formats

What type of packaging formats you want to process by a liquid beverage pouch packaging machine? Is it flat pouch, stick pouch, standup pouch, or irregular shape pouch? Answering this will enable you to determine the type of machine you require.

Working Space

As discussed above, liquid beverage pouch packaging machine comes in different structure and design. So, what you need to do is to have a look towards your production line and the available space for machine and then opt for the right one.

Speed

Various juice filled pouches

Speed matters a lot when talking about a packaging machine. However, as each machine has different capacity rate, you have to check its current speed ratio and its adaptability for further scalability in accordance with changing needs.

Cost

Cost accounting

Another valuable tip is to look your financial status and calculate the collective expenditure that will be brought by a liquid beverage pouch packaging machine. If purchasing new machine is expensive for you then considering a secondhand machine from reputable supplier is a worthy decision.

Conclusion

We are about to conclude this detailed buying guide about a Liquid Beverage Pouch Packaging Machine with a positive gesture that it has been helpful for you. This machine can transform your business provied that you make its best use by taking help from above explained tips, working procedure, and its features. Moreover, regular maintenance is very important for keeping your machine active. So, if you have understood all these points, the next step is to make a purchase. For this we will recommend you to consider Allpack for its effective services and machines with long lasting performance. For further information please visit our website!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide