Lab Vacuum Dryer: The Complete Buying Guide In 2025

Drying is an integral step in the preparation of different ingredients, especially solid dosage forms. Vacuum drying has significance in drying raw material by lowering the temperature of solvents, leading to energy conservation. Isn’t that sustainable? How vacuum drying is carried out?

The lab vacuum dryer is a dynamic device that quickly and uniformly dries different ingredients- from pharmaceuticals to foodstuff. What are its pros? What are its types? Several questions confuse operators and manufacturers alike. So, we have compiled this guide to improve your understanding of this promising instrument. Let’s enlighten your minds!

1.What is a lab vacuum dryer?

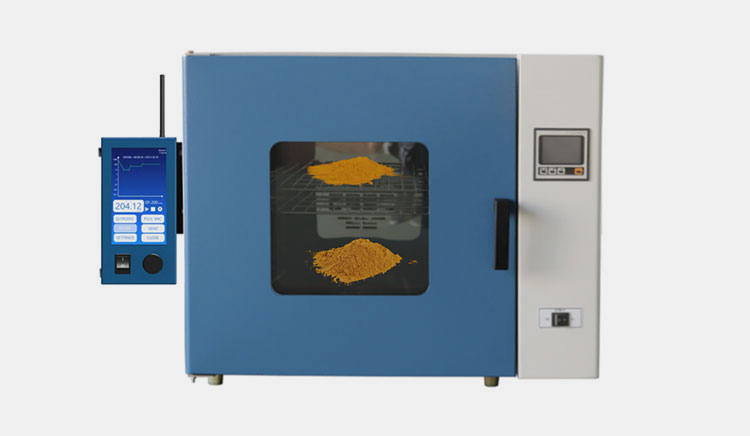

Lab Vacuum Dryer- Picture Courtesy: Labec

A lab vacuum dryer is a specialized category of equipment that effectively vaporizes chemicals, gases, moisture, or watery content from the feed without oxidizing material or causing undesired reactions in it.

It works on the principle of the formation of a vacuum to reduce the vessel pressure below the solvent vapor pressure, resulting in its boiling. The solvent molecules travel to the surface of the feed and vaporize owing to decreased pressure.

It is an integral device utilized in laboratories and manufacturing units for drying, curing, and heat treatment procedures under low-pressure settings. It has higher drying proficiency because of enhanced heat transfer.

2.What are the benefits of a lab vacuum dryer in different manufacturing units?

A lab vacuum dryer is an innovative and cutting-edge machine that has a plethora of features to provide manufacturers and researchers with financial and industrious benefits. A few significant advantages of lab vacuum dryer include:

Improved Product Stability

Improved Product Stability- Picture Courtesy: Homesteading Family

Water content plays a major part in microbial growth. Manufacturers and developers use a lab vacuum dryer to remove moisture content, consequently inhibiting microbial growth. Moreover, by regulating the amount of moisture in the products, this device is essential in preserving product integrity and averting alterations that could affect their functionality and stability.

High Product Quality

High Product Quality- Picture Courtesy: Somafina

Conventional drying techniques tend to damage heat-sensitive materials, resulting in the loss of their structural integrity. The lab vacuum dryer is specially designed to handle heat-sensitive fragile items with its low-temperature drying. Furthermore, there are no issues such as the development of hard and leathery crusts in a lab vacuum dryer, which are quite common with traditional dryers. Therefore, it retains the quality, appearance, and potency of pharmaceutical and food items.

High Product Shelf Life

High Product Shelf Life- Picture Courtesy: 100% Chef

The materials dried with a lab vacuum dryer exhibit longer shelf life because the latter lowers the likelihood of oxidation and hydrolysis. The chemical reactions in the product and their oxidation promote spoilage and degradation chances, leading to a short life shelf.

Rapid Drying Time

Rapid Drying Time- Picture Courtesy: RAYPA

The low pressure due to the vacuum decreases the boiling points of solvents, as a result, the vaporization procedure is accelerated and drying occurs in a short time. Rapid drying times contribute to higher process productivity and throughput in the manufacturing units. This is particularly important in industries- requiring quick movement of products.

Increased Energy Efficiency

Increased Energy Efficiency

Since the lab vacuum dryer minimizes the required drying temperature and time, so this device uses less energy than other standard dryers. Lower energy consumption translates into reduced utility bills, making drying processes in a lab vacuum dryer more eco-friendly and financially viable for manufacturers.

More Product Uniformity

More Product Uniformity- Picture Courtesy: Soln Pharma

Drying in the lab vacuum dryer occurs in controlled settings of temperature and pressure, leading to uniform vaporization across samples. This reduces variances in drying throughput and delivers constant and reproducible outcomes.

Higher Product Yield

Higher Product Yield

The lab vacuum dryer operates at significantly lower temperature situations, so is effective in keeping products safe from overheating in turn preventing their degradation and minimizing wastage. The mild drying conditions decrease product deterioration, contributing to higher proportions of feasible products.

Versatility

Versatility

Lab vacuum dryer is frequently used for drying multitudes of materials- from slurries to solids, powders to liquids- because it can effortlessly process a wide range of materials and is adjusted to accommodate diverse drying needs.

Low Safety Risks

Low Safety Risks- Picture Courtesy: New York Weekly

By using a lab vacuum dryer, productions minimize the safety risks to the operators. There is no formation of vented fumes and particles in the lab vacuum dryer. These undesired drying products are inhaled by operators, making them sick. However, ventilation does not happen in a lab vacuum dryer, so operators managing this device are safer.

3.Where does a lab vacuum dryer find its use?

A lab vacuum dryer has a huge deal of significance in manufacturing fields because of its potential to safely process materials. Let’s discuss various platforms in which lab vacuum dryer is routinely found:

Pharmaceutical Industry

Tablets and Powders- Picture Courtesy: Bluebird Provisions

Lab vacuum dryer has a major role during the drug formulation process, as it delicately removes solvents from active ingredient materials, maintains properties of sensitive material, and does not change the chemical profile of excipients and drug components. So, this instrument is pivotal in increasing productivity for pharmaceuticals, such as orally disintegrating tablets, camphor, and lactose granules.

Chemical Industry

Chemical Resins- Picture Courtesy: Siegwerk Druckfarben

Sometimes, chemicals severely lose their physical attributes and chemical structure on drying with conventional drying approaches. Therefore, a lab vacuum dryer has a key part in the drying of polymers, resins, and fabricated materials because it ascertains product propriety and quality.

Life Sciences Industry

Cell Culture- Picture Courtesy: Pawitra Biotek

Lab vacuum dryer is a part of recurrent biological research protocols to prepare life samples, for example, proteins, enzymes, cell culture, microbes (bacteria), and tissues. It proficiently dries biological materials while upholding their quality and biological activity.

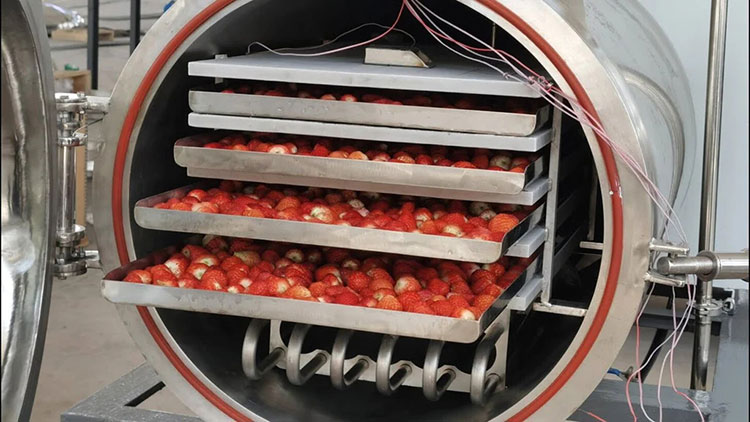

Food and Beverage Industry

Dried Fruits

Lab vacuum dryer dries food products, for instance, fruits, vegetables, spices, herbs, and coffee. It upholds their nutritional quality, color, texture, delicacy, taste, and aroma. This equipment is involved in the dehydration and curing of different types of food products, such as baby powder, milk powder, flavoring, and protein powder.

Cosmetic and Personal Care Industry

Cosmetic and Personal Care Powders

Cosmetic preparations usually deal with botanical and herbal extracts and their potency and integrity are compromised on processing with standard drying methods. Hence, cosmetic preparations like creams, gels, powders, and lotions make use of a lab vacuum dryer, as it gently handles cosmetic products and decreases their likelihood of clumping due to moisture.

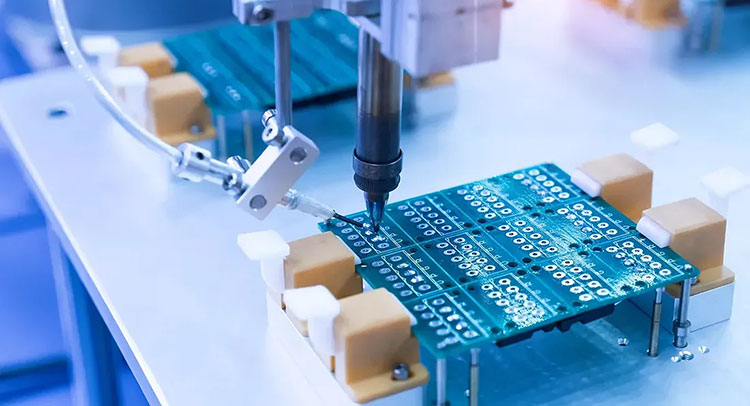

Electronic Industry

Semiconductors- Picture Courtesy: Keyence

Oven and hot air drying exert thermal stress on electronic components like semiconductors, circuit boards, and batteries, leading to their cracking and melting. Therefore, manufacturers prefer to use a lab vacuum dryer for the removal of moisture from electrical components, consequently averting the risk of short-circuiting, corrosivity, and other electrical issues.

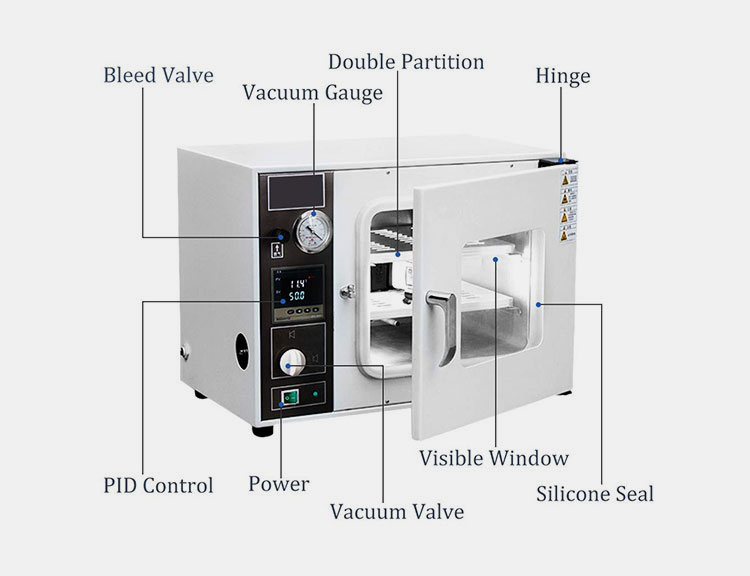

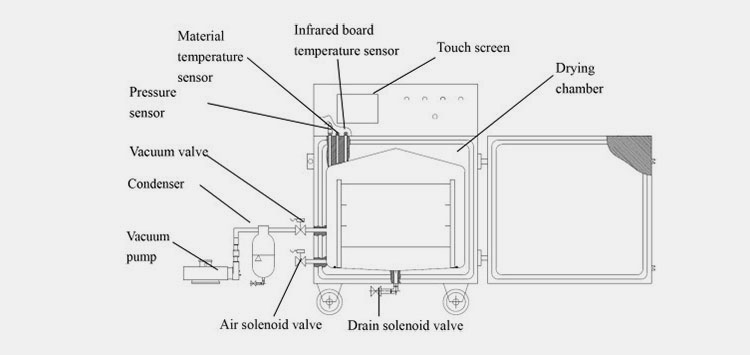

4.What is the structural design of a lab vacuum dryer?

A lab vacuum dryer consists of several integral components having unique functionalities. Here is a complete list of parts featured in a lab vacuum dryer:

Structural Design of Lab Vacuum Dryer- Picture Courtesy: ResearchGate

| Bleed Valve | It is known by terms, such as vent or pressure relief valve. It aids in pressure equalization by reintroducing the gaseous molecule inside the chamber. It gradually restores air concentration, thereby, preventing the immediate air influx, which may degrade the end product. |

| PID Control | It is a typical type of feedback control mechanism to manage different inputs, such as temperature, pressure, and time. It continuously estimates the difference between the preprogrammed and actual values and controls process parameters, and hence, stabilizes drying conditions. |

| Vacuum Gauge | The users can easily adjust and control the vacuum level in the lab vacuum dryer by scrutinizing the vacuum level through a vacuum gauge. |

| Power Button | The basic purpose of the power button is to start and turn off the machine. It powers different electronic parts and safely shuts off heating and vacuum systems. |

| Double Partition | It is a structural design attribute, consisting of two layers of partition to increase heating efficiency by uniformly dispensing heat across every corner of the chamber. It provides an insulation barrier to decrease heat deficit. |

| Vacuum Valve | This valve is essential in regulating the air diffusion in and out of the vacuum chamber. It produces a vacuum, maintains it, and releases the said vacuum upon complete drying. |

| Hinge | It is located at the side of the doors and allows gentle opening and closing of the door. It secures the seal and provides accessibility and safety to operators. |

| Visible Window | It is a transparent window and is produced from tempered glass. Users can observe the functioning of the device through the visible window without accessing the sealed chamber and disrupting the vacuum environment. |

| Silicon Seal | This seal is routinely installed in a lab vacuum dryer to ensure the airtightness of the vacuum chamber by averting the leakage of gas in or out of the chamber. There are diverse types of silicon seals, for instance, O-rings, gasket seals, etc. |

| Material Temperature Sensor | This sensor is pivotal in controlling the temperature of the sample being dried. It offers real-time temperature data and aids in safeguarding thermolabile materials. |

| Pressure Sensor | It verifies that the desired pressure range is maintained in the chamber. The pressure sensor delivers feedback to the control system and operator by examining pressure changes inside the vacuum vessel. |

| Condenser | It is usually found in the lab vacuum dryer manufactured for solvent recovery. This device collects and condenses the vaporized solvent chamber with the help of its cooling mechanism (consisting of cold water or refrigerants). |

| Vacuum Pump | There are several kinds of vacuum pumps in the lab vacuum dryer, for instance, rotary vane or diaphragm pump, which establish a low-pressure environment in the drying chamber by eradicating gaseous components from the chamber. It is located outside the drying vessel and has integrated pipes for maintaining the vacuum inside the chamber. |

| Air Solenoid Valve | It is an electromagnetic valve that works on signaling by electricity and regulates the flow of incoming and exhaust air. Thus, it keeps the vacuum level in a chamber under the desired threshold. |

| Infrared Temperature Sensor | It gauges the temperature range of material or component by examining the amount of infrared radiation released from it. This sensor does not come in direct contact with the object but allows the scrutinizing of real-time temperature alterations during the drying process. |

| Touch Screen | It is an intelligent screen to configure the drying process by programming desired inputs. It is a simple control screen to modify the parameter settings. It stores pre-saved drying recipes to quickly operate the lab vacuum dryer. |

| Drain Solenoid Valve | It regulates the movement of moisture or vapors to a drainage mechanism. It manages the offloading of condensate materials and other fluids produced while drying and ensures the stability and efficiency of the compartment environment. |

| Drying Chamber | It is a core component of a lab vacuum dryer in which a vacuum is maintained for drying. It is manufactured from corrosion-tolerant material to resist low-pressure conditions and avert the risk of contamination. It comes with airtight secure safety interlocking doors to uphold vacuum stability. This compartment is typically insulated to prevent temperature fluctuations. |

5.What are the working stages of a lab vacuum dryer?

By learning about a lab vacuum dryer, you can gain insight into its working and methodologies, which are fruitful in effective moisture vaporization and high expiry period of products. Therefore, we are discussing the working stages of a lab vacuum dryer for scientists, developers, and engineers, who are inquisitive about details regarding this device:

Loading of Material

Loading of Material” Picture Courtesy: VACUUBRAND

At the start, the samples are gently introduced inside the drying compartment. After loading, the vacuum chamber is completely and securely sealed to establish a closed atmosphere for vacuum drying.

Vacuum Creation and Product Heating

Vacuum Creation and Product Heating: Picture Courtesy: KNF

The vacuum pump is activated which in turn begins decreasing the pressure inside the drying compartment by creating a vacuum. With the pressure drop, the vaporization of the solvent becomes easier. As soon as a vacuum is set up inside the chamber, a controlled heating source is utilized to accelerate moisture evaporation.

Evaporation

Evaporation

The solvents are converted into vapors at lower temperatures and are consistently removed from the drying vessel using a vacuum pump. This prevents vapors from transforming back into moisture. Some lab vacuum dryers are equipped with condensers, where solvents are condensed and recovered.

Cooling and Unloading of Product

Cooling and Unloading of Product

The temperature of materials is decreased inside the drying chamber for their cooling, once the solvent evaporation is completed. The product is kept inside the vacuum for a short interval for stabilization. On successful cooling, the vacuum is slowly discharged to allow re-entry of air in the chamber.

After the restitution of pressure, the door of the lab vacuum dryer is opened and then the dried and moisture-free product is slowly offloaded from the chamber for next-in-line processing.

6.What are the available categories of a lab vacuum dryer?

There exists a diversity in the types of a lab vacuum dryer, including:

Static Lab Vacuum Dryer

Static Lab Vacuum Dryer- Picture Courtesy: News-Medical

It is a kind of lab vacuum dryer in which original products stay immobile on the trays or other holders in the drying chamber. It is easier to maintain and operate because of the lack of moving parts. In the static lab vacuum dryer, the heat is uniformly transferred to every surface of the vacuum chamber, resulting in regulated and even vaporization of moisture.

The rate of drying is slow, especially for thicker products, because of the absence of agitation. Moreover, static lab vacuum dryers have restricted space, consequently limiting the processing volumes of materials.

Its further categorization includes:

Tray Lab Vacuum Dryer

Tray Lab Vacuum Dryer- Picture Courtesy: PharmaChem Cosmetics Industries

It is composed of stationary trays that house products for drying. It has a simple design and is popular for lab, pilot, and small-scale drying due to its precise temperature control. The trays are vertically housed in the rectangular kind of cabinets. It utilizes low-pressure conditions to boost the drying rate.

The minimal volume and ergonomic design increase energy conservation by decreasing the quantity of heating liquid needed.

Lab Vacuum Oven Dryer

Lab Vacuum Oven Dryer- Picture Courtesy: Digivac

It is a type of static lab vacuum dryer and follows the same working principle- dielectric heating principle- as that of a standard oven. However, the lab vacuum oven dryer runs in a vacuum environment to reduce boiling points and boost drying.

The high-frequency electromagnetic radiations interact with molecules of materials, causing them to heat. Lab vacuum oven dryer is different from other static lab vacuum dryers because in the former heat is produced by the transformation of electromagnetic energy into kinetic energy. So, materials are dried from deep within, resulting in quicker drying.

Lab Vacuum Shelf Dryer

Lab Vacuum Shelf Dryer- Picture Courtesy: Labquip

It features a cylindrical or rectangular shape drying vessel in which shelves are stacked over one another. The materials are put on the shelves for drying via conduction. Shelves have their specific heating plates for improved heat transmission and maintenance of accurate temperature across drying planes.

Drying is much more rapid and uniform in the lab vacuum shelf dryer in comparison with the tray lab vacuum dryer.

7.What are the technical problems and troubleshooting relevant to a lab vacuum dryer?

A lab vacuum dryer is state-of-the-art equipment with long lists of handy benefits, however, now and then, it faces some unfortunate issues that potentially halt its operativity, resulting in a loss of profit margins. Nevertheless, there is no need to worry, as these problems are rectified by implementing the following suggestions:

Vacuum Leakage

Vacuum Leakage- Picture Courtesy: Waldner

Sometimes, there is leakage in the air pressure, resulting in a lower drying rate and longer drying cycles. Materials are also subjected to air or moisture, affecting their physical structure and other properties.

Cause

This issue is due to several reasons, for instance, faulty sealing components, broken glass windows, and unsecured connection in the drying chamber or vacuum hoses.

Troubleshooting

To rectify this problem, you should thoroughly check the working condition of O-rings, gaskets, and other seals. Replace damaged seals if required. Inspect the window for cracks and substitute it if broken. Examine connectivity between hoses and tighten all flanges. Pressure drop in the drying vessel can be checked by a vacuum gauge.

Uneven Heating

Uneven Heating- Picture Courtesy: Holland Green Science

It is observed that some product sections remain wet while others are heavily dried and degraded due to uneven heating in a lab vacuum dryer.

Cause

This problem stems from worn-out heating bars, incorrect positioning of trays or products, or inadequate airflow.

Troubleshooting

It is advised to check the functioning of heating bars and substitute malfunctioning ones. Reload the products evenly in the drying chamber without overloading. Reposition incorrectly placed trays and provide adequate air circulation for uniform heat distribution.

Longer Drying Cycle

Longer Drying Cycle- Picture Courtesy: Lab Manager

The problem of longer drying time arises in a lab vacuum dryer, unsettling the smooth workflow of lab operations.

Cause

The issue of longer drying cycles is due to inadequate vacuum settings, low-temperature ranges, and incorrect placement of materials.

Troubleshooting

First, alter the settings of the vacuum pump to attain a low-pressure range, Secondly, optimize the temperature inputs, so that the heating process becomes faster. Reintroduce samples inside the vacuum chamber and ensure the sample load is below the working capacity of a lab vacuum dryer.

Moisture Condensation

Moisture Condensation- Picture Courtesy: Pella Windows

The issue of moisture condensation is encountered occasionally in the device, resulting in vapors on chamber walls liquifying to solvents. This may contribute to the reabsorption of moisture in the dried sample.

Cause

The reasons for this problem are poor heating, inadequate vacuum level, or leftover moisture that has not completely evaporated.

Troubleshooting

It is solved by increasing the temperature in the drying chamber so that it can fully evaporate moisture. Inspect leakage in the vacuum pumps to fix the faults in vacuum levels. Complete moisture evaporation must be observed using suitable temperature and vacuum conditions.

Loss of Product Integrity

Loss of Product Integrity-Picture Courtesy: Freeman Technology

Sometimes, the samples being dried may lose their physical structure, efficacy, or flavor. These materials may be discolored in a lab vacuum dryer.

Cause

The factors that contribute to this predicament are high heat and inadequate vacuum settings that degrade the thermos-sensitive samples.

Troubleshooting

To resolve this predicament, it is important to minimize the temperature to a certain value that is ideal for drying materials. Modify the vacuum level to lower the boiling temperatures of solvents. Heat exposure to samples can be minimized by using a shorter drying cycle in which materials are satisfactorily dried.

Conclusion

In summary, a lab vacuum dryer is an extraordinary machine capable of drying a wide array of samples- ranging from fresh fruits to sensitive drugs. It is a need of today’s green world because it conserves energy. Procuring this instrument is extremely advantageous for labs and small-scale industries, as it opens new arenas of success. For purchase-related queries, you are more than welcome to contact Allpack. We have a wide portfolio of high-quality lab vacuum dryers, customized to fulfill your unique drying requirements.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide