Your Best Lab Coating Pan Supplier

- Multiple uses&Coating&Coloring&Drying&Mixing

- Uniform Atomization&Fine Particles

- Touch Type Human Computer Interaction Interface

Lab Coating Pan

Allpack Lab coating pan is mainly used for pharmaceutical, food research&development or University teaching to add the transducer,external heating,temperature controlling,spraying system,based on original sugar coating machine at a small scale production of film coating. Through the lab coating pan , the tablets will have bright surface, which can prevent oxidation, damp or volatilization and can also cover the uncomfortable taste. This make medicine can be easily identified by body parts and ease dissolution. The pipe of the blower stretches into pot for an evenly heating distribution while the coating pan is rotating. With adjustable coating pan and LED display, all stainless steel 316 construction to meet the GMP standard.The lab coating pan is easy to operate, clean, excellent performance and simple maintenance.

Allpack Lab Coating Pan

Pharmaceutical And Food Research&Development University Teaching Lab Coating Pan

Allpack Lab coating pan is mainly used for making pellet, film coating on tablets. This lab coating pan can also be used for making ball shape products or granules, mixing, and polishing, etc.Such as:chocolate polishing, peanut coating, sugar coating,seasoning, producing tapioca pearls, porcelain ball making, etc. All Allpack lab coating pans consist of main body, worm wheel box, coating pan, heating device,hot air&common blower, electrical equipment, etc. The transmission process that the motor drive the worm wheel and worm via triangle belt to make the coating pan rotate.

Multiple uses, coating, coloring, drying, mixing

Suitable for spraying small and medium areas, uniform atomization, fine particles

Touch-type human-computer interaction interface

The Buyer's Guide

Lab Coating Pan: The Complete Buying Guide In 2025

We restore our body physiology by using solid dosage forms like tablets, capsules, granules, or pills; have you ever wondered how they are protected? This is a coating that not only keeps your medicine safe and improved but offers several benefits.

This article has a piece of basic information about the equipment, its utilization, its parts, and how you can facilitate the best possible benefits from it.

We have tried our best to deliver extensive detail about the lab coating pan and ensure you that by the end you will be able to learn to select the right machine, its working principle, relevant troubleshooting with common problems, and much more. Let’s read the article and enjoy the expert suggestions.

1.What is a lab coating pan?

Lab Coating Pan

This is a device that allows you to facilitate the process of coating over different oral solid dosage forms such as granules, tablets, capsules, and pills, by a consistent circular motion of the pan and constant spraying of desirable coating material.

Well, this is the very general definition of a lab coating pan, but if you see an insight picture, we would like to tell you from the very initial when the tablets were invented for example around 1500 BCE and it was known as pills and ancient Egyptian pills were prepared by hand made dough, oil, honey.

Later, it was coated with a slippery substance obtained from plants. For example, psyllium seeds provide an extensive coating to mask the bitter taste of medicines.

This is quite surprising that everything is coated pills with silver and sometimes gold.

2.Where is a lab coating pan utilized in the industrial sector?

A lab coating pan is a versatile solution that is not only utilized in laboratories for the procedure of coating, but it offers you a broad industrial utilization for the manufacturing of various products that we have discussed below.

Pharmaceutical Industry

Medicinal Manufacturing Industry- Picture Courtesy: The Pharma Machinery

The pharmaceutical industry is the hub of making and providing medication in every corner of the world. Here, in this case, you can refer to solid dosage forms that are comprised of a large spectrum of medications that need coating.

You can find sugar-coated tablets, film-coated tablets, enteric-coating tablets, sustain release, immediate release, and so on. All are based on the application of coating relevant to the respective criteria, and the particular need for manufacturing depending on the specific type of population that needs certain medications.

Nutraceutical Industry

Nutraceutical Items- Picture Courtesy: Mediusa

Nutraceutical products mainly aim to improve your lifestyle and health by fulfilling the basic requirements and the deficiencies present inside your body.

For example, you can see that many nutraceutical products are helpful to make your appearance youthful, reducing the complications or the risk of progressing the disease such as anemia, falling of hair, sleep problems, weakness of nails, bleeding of gums, and so much more.

Therefore, nutraceutical manufacturing industries aim to produce their products in a way that can meet your body’s needs and make you capable of tolerating physical challenges effectively.

The most important factor for coating items is to give a good flavor and a taste when you consume them, therefore all health-conscious individuals willingly pick those tablets that are not only beneficial, offering no side effects but presented with attractive colorful pills, gummies, or capsules.

Food Industry

Food Products- Picture Courtesy: The Daily Meal

You have seen candies, gummies, confectionery products, and so many other beverage goods that have shiny and smooth appearance. How do you get it? Of course, it is all about the application of lab coating pan in the food industry.

This is the constant protocol used before finalizing the product as it gives a consistent and uniform look to your product with rich flavor and taste. Therefore food manufacturing industry always looks forward to having lab coating pans in their facilities in order to produce a uniform production and making the confidence of their consumers when picking their products.

Veterinary Industry

Pet Related Products

This industry also deals with the production of pet-related medications that are mostly available in capsules, tablets, or, oral solid dosage form. How do they look different from one another and how are they available in different colors? This is all about the lab coating pan that gives a distinguished identity to the vet medication and makes the user compliant when it comes to picking the particular product with the help of a unique color.

Research and Development

Research and Development- Picture Courtesy: SEPPIC

This is the department where the initiation of any product takes place first. If the product is approved then it goes for the clinical trials and related formalities till its marketing.

The lab coating pan is equally important when it comes to research and development tasks as it is used to improve potency, release, and modulate the releasing action of the active potential ingredients and evaluate its action on the physiological system.

Cosmetic Industry

Cosmetic Products

Different cosmetics products require surface coating for their attractive appearance as the finest coating of the particular material, for example, if your product represents coca it will be coated with a chocolate layer that will not only grab consumer attention but it give a beautiful aroma and color.

Similarly, there are various aesthetic products such as nails, serums, oils, powders in capsules, small pellets, and granules all of them are subjected to the coating before it reach you.

Decorative Production Industry

Decorative Products

You have seen various decorative products that are lustrous and shining in presence such as kids’ toys and stationery products, household decorative items, ornaments, etc, are required to deal with lab coating pan.

3.How a lab coating pan is useful?

You know a lab coating pan is considered a ‘must-have’ tool in your facility, the reason behind its popularity is described below:

Prevent stickiness & Improve mechanical strength

No stickiness

If an uncoated solid formulation is damped, it forms stickiness. Therefore, a lab coating pan treatment is required before it finishes. The reason is that the coating layers act as a protective layer that prevents molecules from interacting or stickiness and therefore improves stability than before.

Moreover, when a coating surface of polymers is surrounded by your product, it ultimately offers enhanced mechanical strength thus medicines are more capable of dealing with harsh environments.

Masking the bitter taste

Improved taste- Picture Courtesy: Garden remedies

This is a very common use of a lab coating pan that provides all flavorful and colorful properties to your solid dosage form which not only makes it attractive but offers masking of taste with flavors, so the patient couldn't resist taking it.

Dosage identification

Medicines with prints- Picture Courtesy: Ackley machine

You have seen many products that are designed with logos, identification, or any printable information, over them. Before this action, you need a smooth surface to offer printing, a lab coating pan hence performs a remarkable job in making tablets or capsules entirely special.

Regulating releasing action

Controlled release medication- Picture Courtesy: justdial

Pharmaceutical sciences keep striving to bring more advancement related to drug release. When using a lab coating pan, you can make your medicines controllable in terms of releasing them inside your body. By coating, sustained release, immediate release, enteric coating, etc, you can ensure the patient that the following medicines are safe to use and can be released at the specific site.

Preventing your GIT

GIT safe- Picture courtesy: Lubrizol

Let me give you an easy example when you take an uncoated aspirin it can be directly released into your body system and can affect your gastric lining, ultimately causing erosion of the stomach and GI ulcers.

Whereas, when you take film-coated aspirin, it does not interact with an acidic environment and makes your stomach and entire GIT pretty safer.

4.How many types of lab coating pan are there?

The types of lab coating pans are described below:

Standard lab coating pan

Standard lab coating pan- Picture Courtesy: Hoopman equipment and engineering

This is also known as a conventional coating pan which is composed of a hollow pot for coating material inside. It is typically available in size ranges from measurements 6 to 80 inches. If you see the diagram, you will understand that it is positioned in a tilted direction with the help of a supporting stand that helps in the revolution of the pan with the help of a driven motor.

Now let’s talk about inside the pan, here you can find an atomizer spray that distributes the coating spray over the tablet bed which is continuously tumbling over one other to get deep and even coating.

When coating is done, traditionally dry air is subjected to the coating bed to enhance the hot air blowing that improves the evaporation of volatile oils present in the coating solution and makes drying of the coating layer.

However, this method was not adequate to attain proper drying therefore insufficient exposure to air was provided. So different devices were introduced in lab coating pans to improve the drying process. For example:

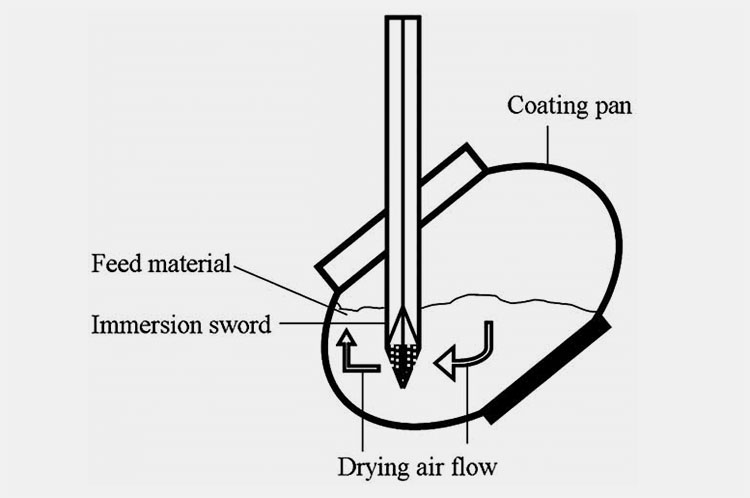

The Immersion sword lab coating pan

Immersion sword lab coating pan- Picture Courtesy: Resrarchgate

This is the type of coating pan that is facilitated with sword-like pipe which is immersed in the coating bed and is designed with two ducts that are meant for supplying as well as for removing exhaust air. Once the material is sprayed over the coating bed the dry air is accelerated over the bed in a way exhausted air is evacuated.

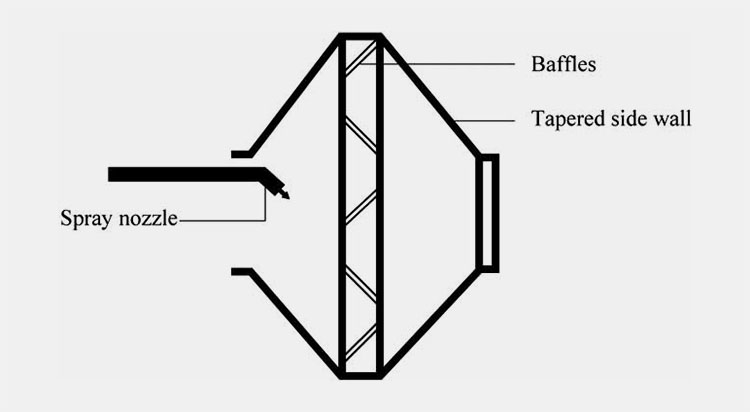

Pellegrini lab coating pan system

Pellegrini lab coating pan- Picture Courtesy: Researchgate

This is known as a baffled or diffuser pan which by name depicts that it allows the distribution of hot air over the coating bed in order to have a diffusive effect so the particles of heated air can cause evenly drying. This is recommended for the sugar coating method as for the film coating procedure, the Pellegrini lab coating pan is hooked to certain limitations.

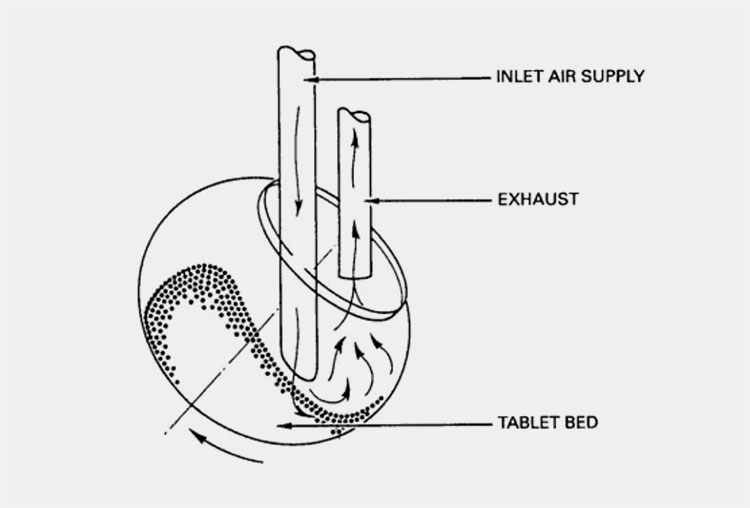

Immersion tube lab coating pan system

Immersion tube lab coating pan- Picture courtesy: Pharmaapproach

It is composed of a tube structure that is capable of being immersed in the coating bed and causes the generation of hot air from the spray nozzle to ensure the drying of the coating bed effectively.

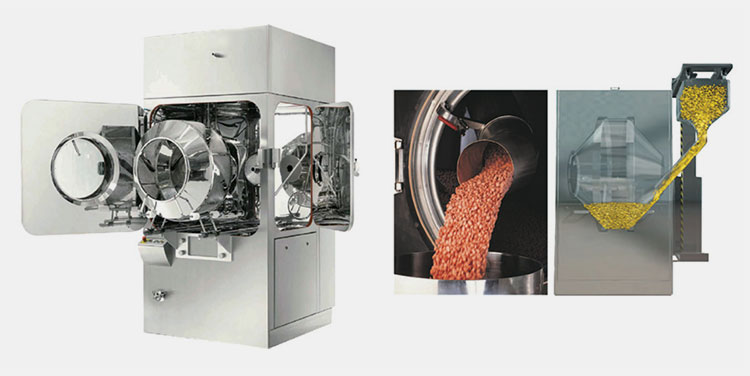

Perforated Lab Coating Pan

Perforated lab coating pan- Picture Courtesy: cimaindustry

This is a highly advanced solution for coating purposes where the machine is presented with an enclosed frame with a partial and fully perforated coating drum that ensures a circular movement over the horizontal axis.

The entire component such as the drum, spray nozzle, dryer, etc is facilitated inside the confined chamber. This machine is a good solution for coating than conventional machines as it allows better coating and excellent drying in a limited time.

A perforated lab coating pan itself is divided into the two main types:

AccelaCota Lab Coating Pan

AccelaCota lab coating pan

This machine is designed with a perforated coating drum ensuring the blowing of warm air that revolves all around the drum following upward and downward directions. The unit is made up in a way that ensures that exhausted air cannot stay inside the unit.

The presence of a baffle is required for the tumbling force of the coating bed and facilitates you with complete coating and drying.

Dria Coater Lab Coating Pan

Dria lab coating pan

This machine also gives similar working, designing, and output as Accela Cota. Here, the incoming air and exhausted airflow channels are joined with a wall of the drum. The whole process is taken place simply by the revolving of the drum.

The flow of air is accompanied by a downward direction towards the upward side. Also, the exhausted air is discharged from the back side of the machine.

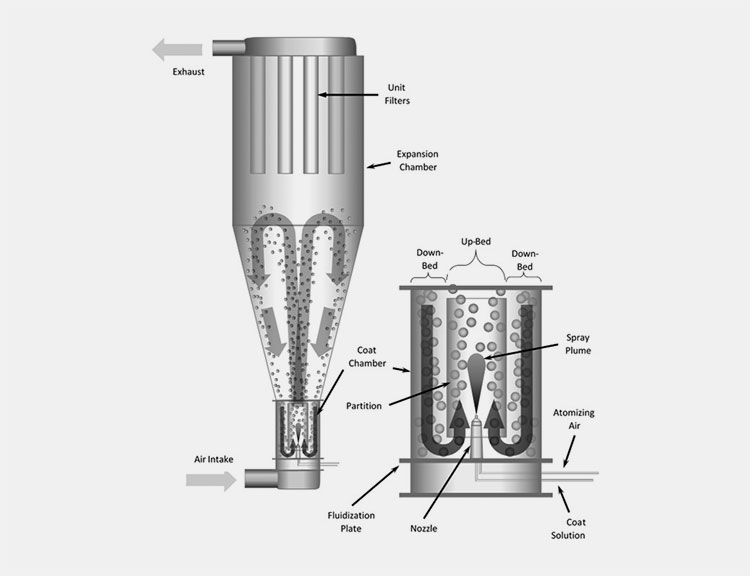

Fluidized Bed/Air Suspension Lab Coating Pan

Fluidized bed/air suspension lab coating pan- Picture Courtesy: ScienceDirect

As its name refers, the coating method is taken by inducing a fluidization state on your raw items to be coated. The machine is composed of a vertical chamber where inside high air flows have induced that flow from the downward to the upward direction to produce a fluidization state to the tablet bed.

The flow of tablets or any coating materials goes in a way that it moves upward and then downwards by re-entry of the air stream. At the bottom of the chamber the spray nozzle generates coating spray, the same method is used from the upper location of the chamber. This means the machine is designed with two spray nozzles.

Here you can find its working is based on two major principles, first a high-pressure airless system that mainly ranges between 1.7 & 20 MPa from a very tiny orifice that is typically of 0.02 and 0.2 mm diameter and is responsible for tiny spray droplets.

Secondly, a low pressurized air atomized system where the spray material is generated from a large orifice that typically ranges between 0.05 and 2.5 mm in diameter produces very low pressure of 35 to 350 kPa over the top of the atomizer.

5.What are parts of the lab coating pan?

Lab coating pan

| Air Duct Supply | During the process, when coating spray is applied over the coating bed, the air duct supply provides hot air to dry the coating layer. |

| Coating Pot | This is also known as a coating drum which is constructed in a way that allows continuous rotation of the drum where the inside presence of the coating bed of the materials tumbles and ensures evenly distribution of sprayed solution as well as uniform drying. |

| Spray Gun | The optimized concentration of formulation is showered over the coating bed by a spray gun. |

| Coating Liquid Cylinder | This unit ensures a constant supply of coating solution. |

| Liquid Spray Device | The coating solution is stored in the store in liquid spray device that ensures the proper supply of material till its spray nozzle. |

| Baffle | A long tube which is facilitates adequate mixing by the formation of cascade movement to the materials of the coating. |

| Control Panel and Electric Cabinet | What should be the revolution per minute of the coating pan? How much should be coating speed? The drying temperature, as well as so many variables, are regulated by using of control panel of the system.

However, the electric cabinet is responsible for holding electrical components. |

| Internal Heat | The unit is responsible for generating the warmth or heat required for drying the coating solution. |

| External Heat Device | This is also known as a fume exhaust blower used to eliminate inside fumes and heat. |

6.How does a lab coating pan work?

The step-by-step working principle of a lab coating pan is discussed as:

Stage 1

Material loading

Whatever the batch size, the formulation of the coating solution, production size, temperature, and relevant information is designed and implemented in this stage, the coating solution is loaded inside the storage or hopper for uninterrupted supply throughout the process.

The materials to be coated are loaded inside the machine either with automatic devices or manually.

Stage 2

Coating- Picture Courtesy: HAVX

Before the application of the coating solution, it is essential to warm up the inside environment which is mainly recommended at stabilizing around 50°C or 122 F.

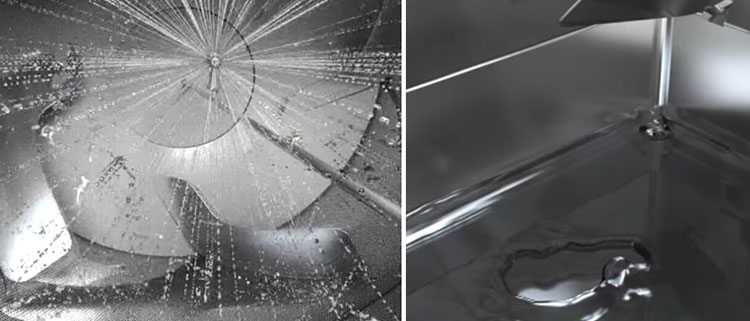

Once all the parameters are under control, the atomization of the coating solution takes place inside the lab coating pan with the help of the spray nozzle of the spray gun. The system of spraying is maintained by the utilization of a peristaltic pump that ensures the finest burst of the solution over the coating bed.

The entire process subtly takes place and is maintained with heating temperature ranges from 70 to 90°C or from 158 to 194 F.

Stage 3

Drying

The coating solution is composed of polymers, plasticizers, and flavorings, and all of them are formulated in the solvents that are possibly evaporated once the coating is done. For that reason, the drying is carried out with the utilization of hot air that ranges in temperature from 40 to 60 °C or 158 to 194 F.

To get a smooth and uniformity of coating solution, the repetition of the same procedure takes place.

Stage 4

Cooling- Picture Courtesy: Biogrund

Under room temperature, the rotation of the coating pan is maintained to ensure the cooling of the coating bed and prevent the clumping of the coating layers applied over the materials. Once it is achieved, it is now discharged from the lab coating pan.

7.What types of coating processes are there?

It is so surprising that a lab coating pan can produce more than one type of coating. What are those? For that please see our below discussion.

| Film coating

|

This is the most popular and highly utilized form that not only reduces the chances of coating errors but also helps you attain physiologically better effects.

For example, film coating is a great way to get your desired therapeutic effects at a desirable time. This is a very thin and delicate layer of polymer all over your product. Therefore it is considered as an ideal form of coating that produces an elegant appearance. |

| Sugar Coating

|

This is a conventional form of coating that has a sugary and sweet taste. The sugar coating itself comprises several steps, such as sealing which is used to protect material against moisture.

However, subcoating, smoothing and coloring, finishing and drying and polishing are the series of coating steps that are applied and yield a professional product. As the procedure involves so many coating steps therefore you will be required with technical skills. |

| Enteric Coating

Picture Courtesy: Biogrund |

This is a specialized coating and is named enteric as it mainly focuses on the release of medication inside the enteric or small intestine.

You know that your stomach is surrounded by an acidic environment, therefore many patients who are suffering from acidity or problems related to the stomach are prescribed enteric coating medication that resists stomach acidity and does not disintegrate medicines with stomach juices. |

8.How to clean the lab coating pan?

When it comes to cleaning a lab coating pan; it is highly recommended to use strict cleaning protocols. The reason behind this is that a lab coating pan is mainly subjected to dealing with the material used in medicines, foods, nutraceuticals, etc.

That’s why unhygienic practices may result in poor-quality production batches as well as batch failures.

Cleaning With Hot Water & Detergent

Lab coating pan- Picture Courtesy: GMP-machine

This is pretty sure that washing a lab coating pan is not a one-time job, because you can not clean invisible particles just by rinsing it with water. Therefore it is recommended to clean it with hot water incorporated with alkaline detergent, so it can vanish the chances of leaving over any stubborn particles or sticky molecules. If manual scrubbing is required, it is done with soapy water.

Once the step one cleaning is done, you can again rinse the equipment with hot water to ensure the inside surface is cleaned.

Sterilization in Place (SIP) and Cleaning in Place (CIP)

CIP & SIP washing system

The above types of lab coating pans are also included with advanced machines that are constructed with an embedded or enclosed coating pan. These machines are mainly cleaned by utilization of SIP or CIP processes that clean the equipment without disassembling them.

The following methods are described with the induction of high-temperature water supply inside the system which helps in the loosing and elimination of coating solution. This system carries out the cleaning procedure by implementing multiple washing steps including pre-rinsing, rinsing, washing, etc hence it minimizes the chances of any leftovers.

9.What are the main problems and solutions of lab coating pan?

Along with so many benefits, there are some minor flaws that are associated with a lab coating pan. Dnt worry! For every problem, there is a technical and easy hack. We have described them just right below:

| Problem | Description | Solution |

| Blistering

Picture courtesy: Dulux |

A tablet, capsule, or any material with coating sometimes swells and forms a blister that is easily removable and manifests poor quality. This problem mainly takes place when you induce a greater temperature during the procedure.

You might have heard about air bubbles; similarly, the air gases mainly entrap between the coating layer and the product. |

You should design an appropriate protocol for the formulation of coating materials as well as the temperature, and pressure of air spray, and should maintain the correct setting for coating, therefore, blistering can be avoided. |

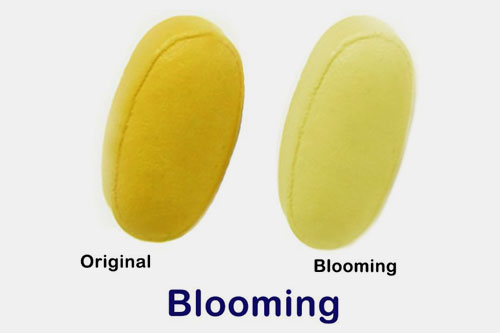

| Blooming or Dull Coating

|

Blooming is also known as a dull coating where a high temperature or prolonged storage under unfavorable conditions results in blooming or color fading. | It is a problem that can be caused if you’ve added a high concentration or low percentage of plasticizers. Try to design an optimized protocol with an average concentration of ingredients to prevent blooming. |

| Blushing

Picture Courtesy: Biogrund |

The coating material is when surrounded by whitish unwanted spots, this is known as blushing. | When ingredients in your formulation are precipitated that can be occurred when you are using poor solvents. It results in blushing when your materials are exposed to high temperatures. Moreover, it is recommended to provide the right drying time. |

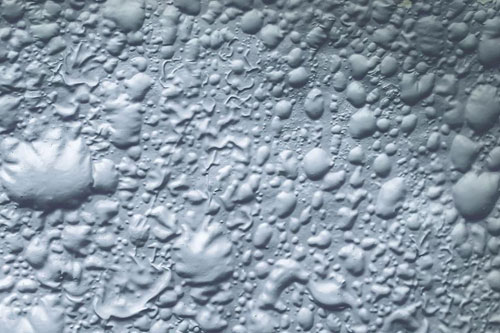

| Cratering

Picture Courtesy: Pharmascience |

This is a typical coating defect where a crater appears over the surface of the coating layer that represents a volcanic-like structure. | Due to insufficient drying time, it can induce cratering and may disintegrate the base. Regulate the spray rate, modulate the drying time, and provide a regulated concentration of solution viscosity. |

| Twinning

Picture Courtesy: Pharmaeducation |

This occurs when two tablets join together and is commonly observed in gelatin capsules. | This is corrected by regulating your lab coating pan speed and you can alter the tooling so it can be avoided. |

| Mottling

|

When there’s an uneven distribution of coating materials over your product, you can see light and dark patches. | It is suggested to use an appropriate mixing of the coating solution prior to applying it over the material. |

10.What are the recent advancements in lab coating pan?

New lab coating pan techniques- Picture Courtesy: European Pharmaceutical

With time, you can see various new implementations in the lab coating pan technique. Let's have a short look at them.

Aqueous coating technology

This is a new technology used to produce glossiness and innovative coating which is mainly formulated by the implementation of natural solvents. For example, methylene chloride, and by this way problems like adhesion, bridging, and hardness, are prevented.

Electrostatic dry coating

This technology is introduced where electrostatic dry powder charging particles are utilized that are sprayed with high voltage with a spray gun in a lab coating pan. The prime purpose of this technique is to gain a smooth and even coating which can be attained by specific solvents.

Super-cell coating technology

This is a super technique that is designed to cater to many coating-related problems. The process is associated with supercell technology that grinds off the edges of the materials which is exactly not coated with the same thickness when using rotary pan coating and airflow for drying is also not considered.

Conclusion

In conclusion, a lab coating pan is a promising piece of equipment offering you wonderful benefits to your products. With time, you can observe various amazing developments in the lab coating pan technique that gives an elegant appearance and offers a flexible way to operate the coating procedure. For your requirements, such as type of coating, number of batches, production capacity, disintegration properties, releasing site, etc., a lab coating pan is an ideal solution. If you are still confused; we would recommend contacting our team. Allpack is the one-stop solution related to providing you wide series of lab coating pans and related guidance. Why not try us? Please message us now!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp:+86 18171018586