Ketchup Oyster Sauce Bottling Line: The Complete Buying Guide

Ketchup oyster sauce stands alone! Just shake a bottle and layer it in stir-fry stuff. Yet- what is this magical ketchup oyster sauce? If you’re a fan of Asian food, then probably the ketchup oyster sauce bottles must be in your kitchen. But do you know how it can be a good one for longer? How is it packed and how it can deploy a tremendous role in your business?

This blog is all about you need to know its packaging! The ketchup oyster sauce bottling line is everything to must know when taking action on installing a new setup, be sure to have a thorough look at this guide for knowledge.

1.What is ketchup oyster sauce?

Ketchup Oyster Sauce

A ketchup oyster sauce is a saltish and savory product used for the best taste in your food nowadays. It is mainly intended for all meats, especially poultry. An oyster sauce comes from spicy horseradish which is combined with tomato sauce and served as a topping or in little cup servings.

Interestingly, how oyster sauce came into the culinary world absolutely by coincidence, in 1888 by Mr. Lee Kum Sheung who was a restauranteur from south China, who forgot a boiling pot of oyster soup that turned into a thick gravy with irresistible delicious taste and flavor and it was sold as an oyster sauce.

This sauce is popular all over the world but most commonly used in American cuisines, where it is commonly known as a "horseradish sauce" which looks like ketchup due to more reddish colors of tomatoes and is served with meats.

2.What is the ketchup oyster sauce bottling line?

This is a production system that is composed of a series of equipment altogether in a huge field to fill and pack the ketchup oyster sauce formulation into each bottle and make them suitable for further marketing process.

A specialized system with integrated types of machinery where an absence of one unit can affect the overall production.

This is included with very basics from bottle orientation to its final labeling and quality testing of finished bottles combined to work faster and way more tremendously free from errors. The following series is popular in every large industry for not only ketchup oyster sauce but also for various other liquids that we discussed in further sections of this article.

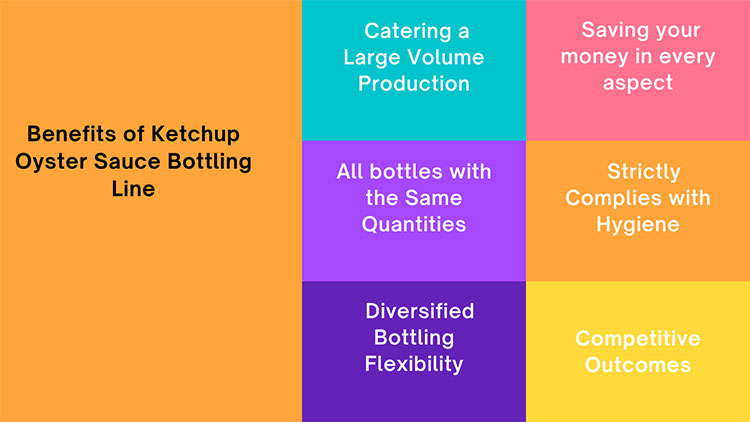

3.Why ketchup oyster sauce bottling line is a good investment?

Reason For Ketchup Oyster Sauce Bottling Line Popularity

Investing in ketchup oyster sauce bottling is ever smartest choice for various reasons:

Catering a Large Volume Production

Huge production

The ketchup oyster sauce bottling line is an automatic unit of multiple machines. So, this helps in the running of the production line without any hassle and can cater to a large volume of filling jobs quickly. Therefore, it improves your working efficiency and capability to meet your market production demands on time.

Saving your money in every aspect

Save your money- Picture courtesy: Epicurious

It is just about spending money and time on the initial setting up of types of machinery.

Once it is done; then the game will be played by the ketchup oyster sauce bottling line as it will save your time, saving your labor costs, reduce chances of product spillage, and minimize the chances of human mishandling and error because machines are equipped with modern PLCs system where no room for blunders.

All bottles with the Same Quantities

Accurate filling- Picture Courtesy: Chinese sourcing company

Using a ketchup oyster bottling line is a stress-free job! You can expect errors or inconsistencies with this excellent setup. And, this is the major reason every customer assumes a good brand. This unit promises you accurate and proper catering of packing bottles with greater satisfaction.

Strictly Complies with Hygiene

Safe- Picture Courtesy: White stone oyster

One of the modern bottling lines is designed to meet high levels of cleanliness and consumer safety as it is made up of ultra-hygienic materials such as food-grade stainless steel which is absolutely easy to clean and avoids compilation or stickiness of product residues. This is easy to clean and offers lesser chances of cross-contamination; therefore it is highly recommended for specifically foods and medicals related sectors where your safety comes first.

Diversified Bottling Flexibility

Greater filling diversities- Picture Courtesy: Aussie Seafood House

Many types and sizes of bottles can be subjected to ketchup oyster sauce bottling lines easily providing manufacturers with flexible options to fill and pack materials without installing new equipment or new tools.

Competitive Outcome

Handsome profit- Picture Courtesy: Caroline cooking

The main reason for its high demand is offering competitive outcomes in terms of high productivity and faster throughput to your formulation. So what are you waiting for? You’re lucky to be offered by ketchup oyster sauce bottling line to manage such a complex task flexibly.

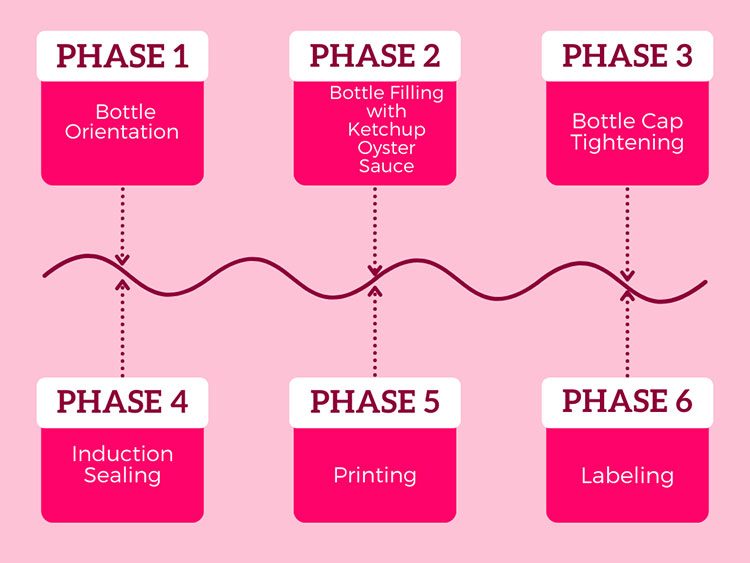

4.How ketchup oyster sauce bottling line work?

The working of ketchup oyster sauce bottling is mainly based on the following easy and subtle phases. The reliable system really carries on all the functions significantly perfectly. We’ve categorized the bottling line steps one by one below:

Working steps of ketchup oyster sauce bottling line

Phase 1: Bottle Orientation

Bottle orientation- Picture Courtesy: ACASI Machinery

The first phase of the bottling line is to adjust and set the chaotic pile-up of bottles into the finest orientation for proper and correct filling. you can not ignore the initial step of organizing bottles; this is because it prevents jamming and providing wrong positioning of filling material hence you can achieve streamlined processing.

Phase 2: Bottle Filling with Ketchup Oyster Sauce

Bottles Filling

In this phase, a precise and pre-determined volume of ketchup oyster sauce is filled in each bottle. Whether it is thick or with different viscosities; the bottling line is significantly tremendous to carry the filling procedure effectively without spillage. This phase ensures that the product is consistently and uniformly filled without worrying about wastage or spillage.

Phase 3: Bottle Cap Tightening

Caps Tightening

After filling of ketchup oyster sauce, it is now transferred to the capping section for proper securing of your product and ensuring that it is safe against leakage and preserving the quality. Therefore, it is a very crucial step and never to be ignored in the bottling line.

Phase 4: Induction Sealing

Bottle sealing- Picture Courtesy: convertacor

The working of the bottling line continues for another significant step where a layer of foil is sealed around the neck of each bottle to preserve ketchup oyster sauce and helps to extend its shelf life by preventing it from external unwanted factors. For example, oxidation, temperature, or humidity. This is typically known as an induction sealing section where intentional sealing is induced as an important part of the bottling line when it comes to packing ketchup oyster sauce to keep it fresh.

Phase 5: Printing

Printing of Details

Towards the final steps, where essential details about the products, such as the manufacturing date, expiration date, storage conditions, and relevant information are printed using a printer integrated into the bottling line. This is primarily done to enhance the branding and communication with your customers.

Phase 6: Labeling

Applications of labels

If labels are printed; then these steps are deployed with their applications over each bottle without any errors, bubbles, or wrinkling. Once it is done, your product is now ready for final processing such as quality testing.

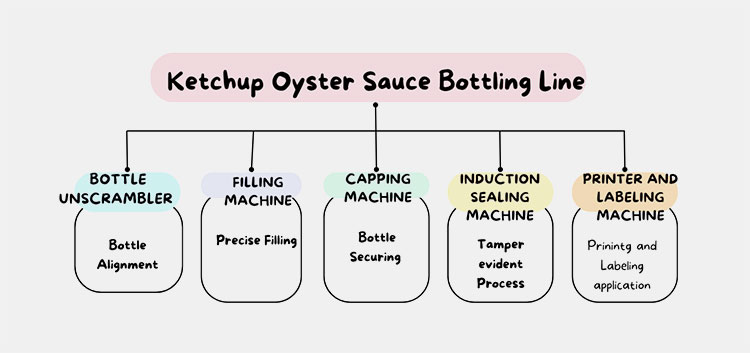

5.What are the machines of the ketchup oyster sauce bottling line?

Thinking about the ketchup oyster sauce bottling line might fret you; in reality, this is set of a simple integrated machines that are capable of bringing challenging tasks in a smoother way. There are a number of machines used to make ketchup oyster sauce bottling lines. For example:

List of machines involved in the Ketchup Oyster Sauce Bottling Line

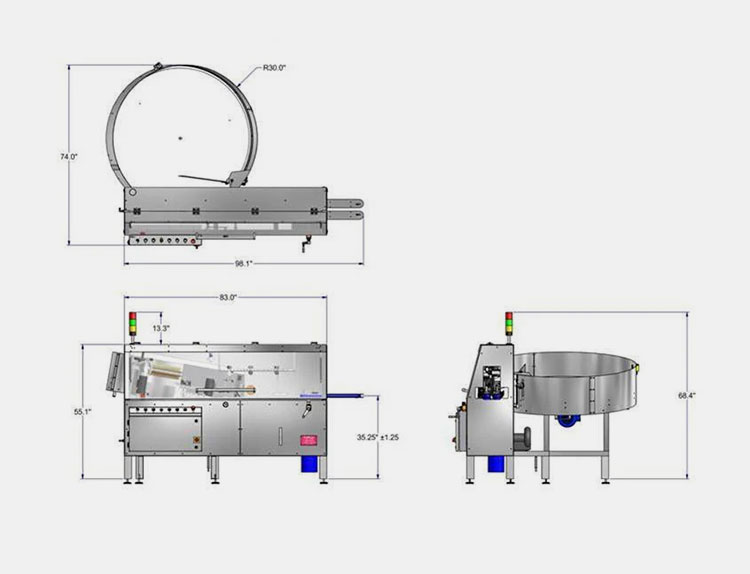

Machine 1: Bottle Unscrambler

Bottle Unscrambler machine- Picture courtesy: Shineben

This machine serves to organize the bottles just like receiving jumbles of bottles in an unorganized form and it makes them completely sorted just by using the mechanism of vibratory disc and high frequency blower.

These two mechanisms allow random sets of bottles to super-organize and acquire a uniform direction toward the next machine i.e. filling machine. remember if you want an uninterrupted and fast filling of ketchup oyster sauce. Don’t forget to integrate this machine into the ketchup oyster sauce bottling line.

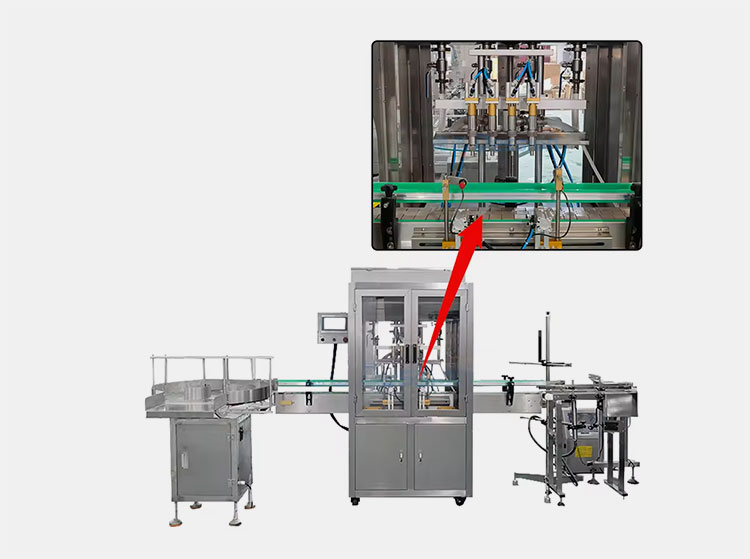

Machine 2: Bottle Filling Machine

Ketchup oyster sauce filling machine

This is the chef machine where the main task of filling happens by accurately pouring ketchup oyster sauces into each bottle. This machine mainly works when it receives a bottle at its filling station. The presence of sensors indicates the system and it sends signals to dispense the pre-determined volume of solution.

If there’s no bottle- there’s no filling job. Therefore, the machine is quite promising in terms of accurate filling and no chances of error or spillage. This means it ensures that consistent batches are delivered if treated with bottle bottle-filling machine. moreover, it is ideal for various flowability solutions quickly. The machine is available in various automations and various models allowing you an effective result.

Machine 3: Bottle Capping Machine

Ketchup oyster sauce capping machine

As per our expertise, no production line is completed if you ignore the capping machines in it. The answer is very simple, it ensures that your product is safe and free from interacting with external environment and easy to transport.

This machine is available in various types and automation. However, it is responsible for tightening the caps over the neck of bottles at the right level and ensuring you safety and security of bottles. The working of the machine involves grippers which pick and tighten the cap using torque and making sure that each cap is twisted properly.

Machine 4: Bottle Induction Sealing Machine

Induction sealing machine- Picture Courtesy: Shipu

We have talked about the purpose of induction sealing above which is used to provide an extra barrier for your materials. To achieve this layer, an induction sealing machine is utilized which exerts electromagnetic radiation and its action melts the layer of caps or inner seal. It becomes harder once it is cooled down and surprisingly it turns into a tight bond formation which is helpful to ensure that the product is original till you tear it. This airtight sealing can ultimately extend the product’s shelf life and maintain the quality of it till the end user.

Machine 5: Bottle Printer Machine

Bottle printing machine- picture courtesy: Gulmen digital

This is a kind of printer integrated with a ketchup oyster sauce bottling line that prints the labels once receives signals from the control panel. This can be an inkjet printer, laser printer, thermal or 3-D printer, etc.,

Machine 6: Bottle Labeling Machine

Labeling machine

The filled, capped, and induction-sealed bottles of ketchup oyster sauces are fed to the labeling machine with the help of a conveyor belt. The machine senses the presence of bottles and applies the labels using applicators and presser rollers over the surface for proper application without the formation of wrinkles or any bubbles. This machine ensures that your bottles are quickly treated with greater automation and fast production of batches. No matter what size and shape of bottles are subjected to it, you can feed the right information into the machine’s system and yes work can be perfectly done by it.

6.Where ketchup oyster sauce bottling line is worthwhile?

Nevertheless, the ketchup oyster sauce bottling line is indeed a worthwhile addition to your business no matter if you belong to a particular formulation. Today, the same unit is applicable in various industries across the globe. You might be one of them!

Food and Beverage Industry

Beverage and food- Picture courtesy: CSC Dubbo

The world's biggest companies such as Heinz, Hunt’s, Del Monte, Pepsi, and other utilizes a ketchup oyster sauce bottling line for faster and consistent results in every batch. It includes unscrambler, filling till final labeling which gives an ultimate professional presentation. Here, products like sauces, soft drinks, pastes, and many other items can be subjected to preparation and packaging.

Pharmaceutical Industry

Calamine lotion

This manufacturing and preparatory sector is always in high demand and safety, and accuracy with high-level hygiene is its priority. The filling and packing of products like topical lotions, syrups, topical solutions, anti-biotics, and anti-septics solutions are day-to-day preparation and packing items in the medicine industry. Therefore, the ketchup oyster sauce bottling line is used for bringing the following tasks under high sterility and automation.

Cosmetics Industry

Skin moisturizer and repairing lotion

A largely exercised field where several kinds of cosmetics products are introduced, manufactured, packaged, and marketed. In the easy words, this is a never-ending production field and the most demandable too.

A ketchup oyster sauce bottling line is an important unit that plays a significant role in filling products like lotions, serums, moisturizers, shampoos, conditioners, body washes, facewashes, perfumeries, and a never-ending products list ranges from haircare to foot care.

Chemical Industry

Sulfuric acid bottles- Picture Courtesy: Carl Roth

Have you heard about organic and inorganic solvents in bottles? These are the commonly used products in research and prepared in the chemical industry. These companies mainly deal with products that contain harsh chemicals (bleaches, acids, alkaline solutions, cleaners) and that’s why accuracy really matters as it can affect further reactions if not packed correctly. Therefore, a ketchup oyster sauce bottling line is an ideal setup for the management of chemicals in this industry and you can see larger setups with similar machines.

Automotive Industry

Automotive oils- Picture Courtesy: Garahm Packaging

Products like engine oils, motor oil, brake oil, anti-freezing solutions, shiners, cleaners, distil water, and others are precisely filled and dispensed till their final form by using a ketchup oyster sauce bottling line for ideal marketing.

7.What types and sizes of bottles can be employed with the ketchup oyster sauce bottling line?

There are various types and sizes of bottles but determining the unique and right one takes expertise and capabilities. The ketchup oyster sauce bottling line is a tailor-made packing line that dispenses efficiencies in the entire procedure and supply chain. The final result is a professional and consumer-appealing product with five-star satisfaction. the standard types and sizes run by this unit are:

Types of Ketchup Oyster Sauce Bottles Used in Bottling Line

Plastic Bottles

Plastic bottles

You normally see ketchup oyster sauce in plastic bottles; in fact, this is the most conventional mode of packing used for very long. These are now available in squeezable options too and they are food-grade plastic materials that are normally BPA-free and very safe to store for formulation. Instead, there are certain limitations with plastic bottles that you can't microwave or provide heat to them or never store hot liquid in them

Glass Bottles

Glass Bottles

This is a very popular and commonly used material for ketchup oyster sauce bottling line and various food services distributors prefer this mode of storage. The reason is mainly assumed that glass bottles are the best source for preserving the freshness and taste of ingredients. However, the history of glass bottles for ketchup oyster sauce is also very rich which is considered as hard to coax out.

Sizes of Ketchup Oyster Sauce Bottles used in Bottling Line

Small Bottles

Small bottles

If your bottle sizes are 100 to 200 ml then the ketchup oyster sauce bottling line is suitable for catering them and filling product precisely. The current size bottles are mainly used for promotions, traveling, or single-serving packing such as restaurant

Medium Bottles

Medium size bottles

Firstly, you see the regular bottles in your refrigerator of ketchup oyster sauce that are normally storing 250 to 500 ml of the product known as medium-sized bottles. They’re available in plastic and glass packaging and are preferable in many sectors of packaging.

Large Bottles

Large size bottles

These are mainly capable of storing ketchup oyster sauce with 700 to 1000ml of formulation and are lovable among heavy or frequent users consuming ketchup oyster sauce.

Bulk Bottles or Jerry Can

Bulk bottles or Jerrycan

This is mainly required in restaurants, food-based businesses, and catering. This is capable of storing products in more than 2 litres and the ketchup oyster sauce bottling line is ideal in terms of packing bottles of bulk size as well.

8.What should you know about filler types in the ketchup oyster sauce bottling line?

You should know that in the ketchup oyster sauce bottling line, the filler types are very important. Because it directly relates to the viscosity or flow rate of the product. Therefore when selecting the unit you should know the type of filler you should opt for.

Piston Fillers

Piston filler- Picture Courtesy: APACK

This type of filler is mostly employed for thick and viscous products like ketchup oyster sauce, mayonnaise, etc. because it utilizes pistons to pressure or push the product inside the bottles. The piston allows an accurate and exact concentration of the product without any leakage.

Gravity Fillers

Gravity Filler

I know you have guessed right! Yes, the force of gravity is responsible for filling of product into each bottle. This type of filler is ideal for a non-viscous solution or with a slightly low viscosity. It is quite a simple machine and easy to operate.

Pump Fillers

Pump Filler- Picture Courtesy: APACK

In this type of filler, a pump is responsible for dispensing ketchup oyster sauce by adding a slight push. It is suitable for thick or viscose solutions.

9.What should you know about fluid types in the ketchup oyster sauce bottling line?

Ketchup oyster sauce filling machine- picture courtesy: Ibottling

Setting up the ketchup oyster sauce bottling line also requires knowledge about the flowability ratio of your product. Remember it is very essential to understand that there are three major groups that fully describe the viscosity state:

Flowing Liquid

Flowable liquids- picture courtesy: Ox studio

This is mainly considering those liquids that are entirely non-viscous and possess high flowability. For example, alcohol, water, perfumes, etc.,

Semi- Viscous Liquid

Semi-viscous- Picture Courtesy: Lab manager

Those liquids that possess non-flowing properties or show thickness are known as semi-viscous liquids such as syrups, honey, maple syrups, oils, etc.,

Viscous Liquids

Viscous liquids- picture courtesy: Upya

This includes paste, gels, and products that aren’t capable of moving easily. Therefore, it requires specialized filler for smooth filling.

That’s why sciences have given it a specific term known as ‘centipoise’ whose value is very important when dealing with liquids filling. It allows one to measure its technical sound via a viscometer. If the value is low viscosity rating means high flowability and vice versa which is denoted by ‘cp’.

| Name of Fluid | Centipoise Rate |

| Peanut Butter | 250,000 – Highly Viscous |

| Tomato Ketchup Oyster Sauce | 190,000 – Highly Viscous |

| Petroleum Jelly | 64,000- Viscous |

| Ink Paste | 45,000-Highly Viscous |

| Shampoo | 800-1000- Viscous |

| Hand/Body Lotions | 700- Semi-Viscous |

| Plastisol | 700- Semi-Viscous |

| Varnish | 420- Semi Viscous |

| Soya Bean Oil | 160- Semi Viscous |

| Maple Syrup | 144- Semi-Viscous |

| Liquid Ink | 25- Semi- Viscous |

| Perfume | 1-7- Non-Viscous |

| Water | 1- Non-Viscous |

| Sulfuric Acid | 0.2- Non-Viscous |

10.What quality testing you should do for the ketchup oyster sauce bottling line?

Ketchup oyster sauce bottling line

Every quality product that reaches you is always passed through various steps such as manufacturing, packing, and quality assessments. There are several quality tests and equipment available that tell the packed product is ready for final transportation.

Vacuum Leak Test

This is a very common quality test where a ketchup oyster sauce bottle is placed in a vacuum chamber to estimate the pressure drops. If it is decreased, shows the presence of leakage in the bottle.

Bottle Burst Test

A highly precise and quality test is used for the ketchup oyster sauce bottling line where pressure is subjected to bottles to assess how long it takes time to collapse. The purpose of the test is to ensure that bottles are safe enough to withstand against progression of internal pressure.

Bottle Cap Torque test

It is an essential test used in worldwide laboratories and industrial testing to assess the closing and opening of the ketchup oyster sauce bottles. The testing machine not only tells the integrity of closing bottles but also helps in maintaining the quality and freshness of the sample. There are digital and motorized torque testers that can ensure large batches of cap evaluation and prevent leaks.

Secure Seal Test for Bottle

The machine is responsible for detecting gas leakage instead of liquid in glass or plastic bottles. This is an accurate test as gas detection is more sensitive than liquids. An air-increased pressure is used to detect the leakage with the help of a pressure-controlled gauge which detects changes in case of leakage and tells you about the sealing quality of the bottling line.

11.How long your product is fresh when filled by ketchup oyster sauce bottling line?

Fresh ketchup oyster sauce- Picture courtesy: lifegetbetter

An unopened ketchup oyster sauce can have preserved freshness for one to two years or more if the bottling line is done properly and carefully.

Because the chances of it going bad remained minimized by proper handling. Besides this, the acidic nature of your product also prevents the process of oxidation and can longer the shelf life.

Also, with time the thickness of ketchup oyster may be affected but it is still safe to use. For taste, it will be slightly affected too over time that’s why it is recommended to keep it at a lower temperature.

12.How to maintain the hygiene and performance of the ketchup oyster sauce bottling line?

Ketchup oyster sauce bottling line- Picture Courtesy: Sunter

To deliver quality and safe filling the ketchup oyster sauce bottling line must be sanitized completely on a regular basis. In case of negligence can affect the effectiveness of the whole batch and your brand identity too.

For the machines like unscrambler, capping, induction sealing, and labeling; the regular cleaning involved a dry cloth and a slight spray of disinfectant 70% ethanol or Isopropyl alcohol.

For filling machines, a careful method for sanitation is required for promising cleaning with stress-free results.

Cleaning In Place (CIP) Programs

CIP unit- Picture Courtesy: TMX flow

The CIP cleaning can help to wash away any sticky particles or products that are leftover inside the filling machine. it is included with proper cleaning of every internal circulatory part of the machine. The steps involved are:

| Pre-Rinse

Here excessive water is flushed through the pipelines and internal circulatory system of the filling machine to clear the sticky particles. This is mainly done with hot water usually 80°C for 30 minutes. Detergent Wash To wash dirt and particles completely, detergent wash is done. Acid Rinse To clear stubborn particles, an acid rinse is done mostly with citric acid. Final rinse The final rinsing is done with water to clean or flush any residual chemicals inside the machine. |

Conclusion

In summary, the ketchup oyster sauce bottling line offers a broad range of filling machines that are flexible to carry out filling tasks in every stage effectively. Whether it is unscrambler, filling, or any machine, all are integrated to bring the challenging task accurately and rapidly. For medium to large production companies, installing this line would make a worthwhile addition to meet your production demand smoothly. If you’re in the market for a ketchup oyster sauce bottling line and want to know more information, Allpack welcomes you to contact us for guidance and to know our series of tremendous ketchup oyster sauce bottling lines up your budget and needs.

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours