Jelly Stick Packing Machine: The Complete Buying Guide In 2025

Jelly is a dessert whose use is common in sweets like custard, cake, and pastries. Jelly is also consumed in its original form due to its delectable and refreshing taste. That's why, it is delivered in small to large packages for assisting consumers. Similarly, a Jelly Stick Packing Machine is an equipment tailored to pack jelly in stick packs.

The machine is highly effective in its performance and greatly assist in increasing production growth and packaging accuracy. You can find it in range of different types with varying automation degree as well as different structure. So, be ready for knowing this Jelly Stick Packing Machine in detail by going through this informative review!

1.What Is Jelly Stick Packing Machine?

Allpack- APK 8-480 Multilane stick packing machine for liquid

Jelly stick packing machine is a type of automatic machine designed to prepare liquid jelly for retailing by effectively packing it into stick packs also known as stick packaging. This stick packaging is a form of flexible packaging where jelly is enclosed into single serving tubular bags with 3 or 4 side sealing for greater protection and convenient handling.

The machine performs this function of jelly stick packing by keeping the jelly into a heated hopper from where it weighs the amount of jelly through weighing system. Similarly, it forms the stick pack from film and dispense the precisely measured volume of jelly into bag. In this way, the quality, taste, and color of jelly is retained, while as, its shelf life is extended.

2.Enlist The Features And Benefits Of A Jelly Stick Packing Machine?

Jelly stick packing machine has numerous features which carry wide range of benefits for your business in all the possible ways. Let's uncover some of the eminent ones!

Consistent Operation

Multiple pops stick packs- Picture Courtesy: eater.com

Contrary to manual working when labours get tired of the repetitive task, a jelly stick packing machine is automatic in functioning. It follows a smooth, consistent, and continuous operation without any break or intervals. This ultimately help you use your machine for getting optimal production rate.

Quality Performance

3 side bag forming unit- Picture Courtesy: chengyipacking.com

All the parts of machine are assigned with specified task to make sure there is no possibility for error and inconsistencies. It eventually leads to the formation of uniform and beautiful stick packs with stringent sealing which are filled with similar volume of jelly.

Enclosed Structure

Structure display of Allpack- APK 2-220 stick packing machine

The body of machine is the creation of high-quality stainless steel with anti-bacterial and corrosion resistant properties. Thus, the entire processing is carried out in a safe protected environment with zero chances for contamination. In addition, for safety observation, it has a transparent protected window from where user can examine the machine working without contacting it.

Customization

Various sizes liquid chocolate stick packs- Picture Courtesy: danpak.co

Another prominent attribute of a jelly stick packing machine is undoubtedly its adaptability to support designing creative and unique style stick packs. For instance, the machine can be used to create stick packs with different sizes, sealing designs, and cutting formats. So, it provides greater opportunity for the marketing of your products and attracting consumers towards them.

Multi-Functioning

As a jelly stick packing machine is the creation of advance technology, it accomplishes the packing of stick packs from their formation, printing, and sealing to material weighing and filling. So, all the steps are carried out in a single run.

3.What Packaging Styles Do A Jelly Stick Packing Machine Offer?

Well, jelly stick packing machine offers extensive varieties in terms of packaging styles. A brief glimpse of each has been provided below:

Stick Pack Cut Styles

Jelly stick packs with flat cutting

Stick pack cut styles refer to the packaging styles a jelly stick packing machine employ for cutting of finished stick packs. There are different cut styles which the machine can adopt such as zigzag cut for creating attractive cut on jelly stick packs, flat cut for professional appearance, and round cut for safe handling. For achieving these cutting formats, various types of cutting blades are integrated into the machine.

Stick Pack Seal Style

Stick packs with flat sealing- Picture Courtesy: danpak.com

In addition to cut styles, sealing styles also vary for jelly stick packing in order to make distinction between your goods and that of other manufacturers. Therefore, various attractive seal styles such as diamond sealing, square sealing, straight line sealing, and strips sealing is formed on jelly stick packs with the help of customized sealing jaws.

Stick Pack Shape Style

Irregular shape stick packs- Picture Courtesy: aranow.com

Jelly stick packing machine also offers diversity in the shape of stick packs. Hence, 3 side sealing in employed for making side neck shape, four side seal for enhanced protection, back side sealing for stick pillow shape, and similar other techniques are used for making irregular jelly stick packs.

Stick Pack Easy- Cut Style

Easy tear cut stick pack display- Picture Courtesy: kiskofreezies.com

Jelly stick packing machine can be used for producing different types of easy-cut styles on stick packs for the convenience of consumers. In this way, popular styles such as side tear-notch, perforation, v-cut, or dot break are added to jelly stick packs.

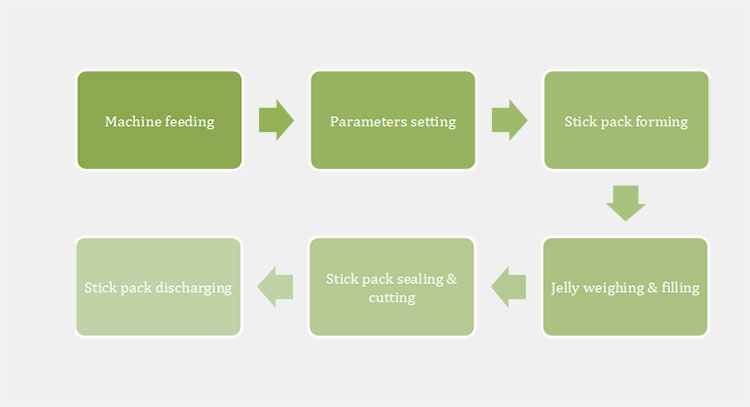

4.Explain The Working Principles Of A Jelly Stick Packing Machine?

Jelly stick packing machine follows certain principles for functioning. These working principles can be better understood by looking into the underlying steps explained for your ease:

Machine Feeding

Hopper feeding- Picture Courtesy: chengyipacking.com

Film feeding is the must-have step for operating a jelly stick packing machine. It includes the placement of a film roll stock or film reel into fixed frame and the loading of machine hopper with bulk volume of jelly. The hopper keeps the jelly at a suitable temperature to avoid jamming or cooling.

Parameters Setting

Parameters setting- Picture Courtesy: chengyipacking.com

Once the machine feeding is done, now operator is required to set the basic parameters of machine by using a control panel. Here, the important setting regarding dosage of jelly to be filled in each stick pack, the length of stick packs, temperature of hopper and sealing jaws are maintained.

Stick Pack Formation

Stick pack formation- Picture Courtesy: chengyipacking.com

From here start the actual working of machine when it is powered on. As soon as the machine is started, all the fixed setting activates various parts of machine among which the very first is stick pack formation. For this, the film begins unwinding from reel and is transported towards the bag forming station. Here, flat film is transformed into beautiful stick packs through cutting and sealing.

During this phase, if machine is equipped with printing device, then date and batch no information is printed over the film.

Jelly Weighing & Filling

Jelly filling into stick packs- Picture Courtesy: chengyipacking.com

In addition to stick pack formation, jelly weighing process goes on inside the hopper and adjoined weighing pump. Following the set parameters, filling system measures exact volume of jelly and push it towards filling nozzles. Afterwards, formed stick packs are supplied with measured jelly amount through filling nozzles.

Stick Pack Sealing & Cutting

Stick pack sealing & cutting- Picture Courtesy: chengyipacking.com

Once the filling is completed, filled stick packs are moved downward where a pair of heated sealing jaws come into contact with the upper horizontal side of filled stick packs from parallel sides. This results in the creation of stringent sealing and closure of stick packs. Similarly, the finished jelly stick packs are passed by the cutting blades which separate them from one another and add a desired cutting style to them.

Stick Pack Discharging

Stick pack discharging- Picture Courtesy: chengyipacking.com

In the end, jelly stick packs are ready for retailing. Now, they fall over a conveyor belt which takes them to a collection container or an integrated machine for secondary packaging.

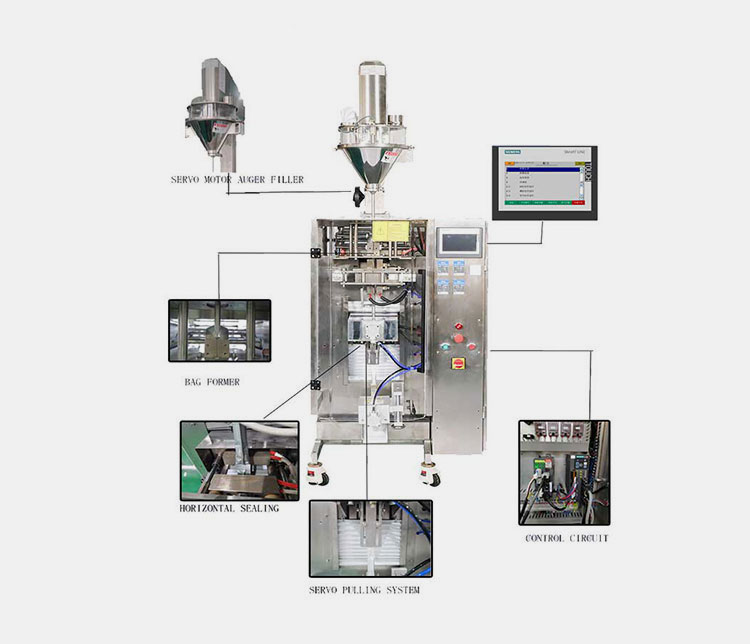

5.Describe The Structure Of A Jelly Stick Packing Machine?

The structure of a jelly stick packing machine is made up of different components. These components are explained below in detail:

Structure of 4 side sealing multi-row liquid packaging machine- Picture Courtesy: khmesindo.com

| No | Components | Function |

| 1 | Hopper | Hopper is a large size stainless steel bucket or a tank usually of round or cone shape. It is the storage room of machine where large volume of liquid jelly is poured for supplying the machine with jelly during operation. |

| 2 | Weighing pump | It is an integral part of a jelly stick packing machine whose function is to measure the amount of jelly to be filled in each pack. It is attached to the outlet of hopper. |

| 3 | Filling nozzles | Filling nozzles are small narrow tubes through which jelly is transferred from the weighing pump into the formed stick packs. |

| 4 | PLC touch screen | It refers to the programmable logic controller touch screen which is situated on the top front of machine. It is an interactive device that enable the operator to communicate necessary commands into the machine. |

| 5 | Bag unwinding unit | Bag unwinding unit is a collection of intermittently located rollers or pulleys which help in the unwinding of film from reel and guide it towards it way for bag formation. |

| 6 | Film roll | Film roll is a single sheet film rolled around a core which is often termed as rollstock. It is fitted over a reel to supply machine with inevitable material required for bags formation. |

| 7 | Bag former | Bag former is another important part of the machine characterized by forming tubes. Around these forming tubes, film is surrounded and turned into stick packs. |

| 8 | Horizontal seal | As the name indicates, horizontal seal is a pair of sealing jaws whose function is to seal the bottom and top of stick packs. |

| 9 | Cutting device | Jelly stick packing machine has a cutting device which comes into action for disjoining the finished jelly stick packs. |

| 10 | Conveyor | Conveyor is a transporting unit which takes the finished jelly stick packs from machine and discharge them into a collection container. |

| 11 | Main frame | The main frame of machine is made up of durable and sturdy stainless-steel material which support all the other parts attached to it and play its role in ensuring stable operation. |

| 12 | Control board | Control board encompasses an assembly of several knobs and switches used for controlling machine such as power button, emergency stop, and temperature regulator etc. |

| 13 | Control cabinet | Control cabinet is the electric enclosure of machine known for its purpose of encasing all the electrical wires, relays, breakers, and fuses of machine for safety purpose. |

6.What Are The Types Of A Jelly Stick Packing Machine?

There are multiple types of jelly stick packing machine, each with unique features. These are explained below in detail:

Single Lane Jelly Stick Packing Machine

Single Lane Liquid Packing Machine for Sachet & Stick Pack- Picture Courtesy: samfull.net

Single lane jelly stick packing machine is characterized by its single unit for bag forming, filling, sealing, and cutting. It can be found in both fully as well as semi-automatic technology.

Structure

Its structure is compact with only a single station. Therefore, it is easy to use, mobile, and maintain.

Operation

Its operation is extremely easy with a reel unwinding film. Similarly, the film is wrapped around a single lane bag former, turned into stick pack, loaded with jelly amount, and sealed from top followed by cutting.

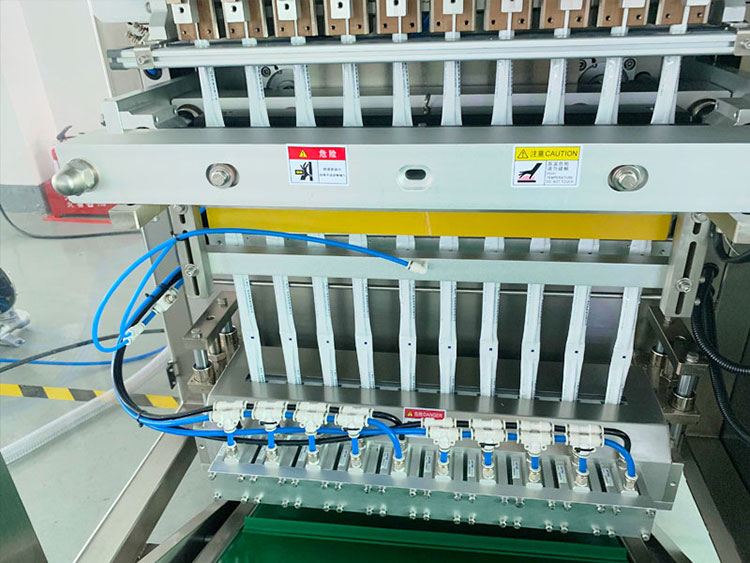

Multi-lane Jelly Stick Packing Machine

Allpack- APK 8-480 Multilane stick packing machine for liquid

Multi-lane jelly stick packing machine is an amazing machine that comes in fully automatic technology. The machine's number of lanes vary from 4-12. Therefore, it is always perfect for meeting greatest production targets. Apart from this, it supports customization in packaging styles and can be integrated with other machines for secondary packaging

Structure

The machine has a robust structure with complex body comprising numerous lanes for bags formation, sealing, and cutting. Therefore, it may require a thorough maintenance routine.

Operation

It turns the single film into multiple stick packs and then these bags are filled by with jelly using several filling heads. Once filled, stick packs are sealed, separated, and ejected from the machine simultaneously.

7.Differentiate Between A Jelly Stick Packing Machine And A Jelly Sachet Packing Machine?

Consider the table below for knowing the differences between jelly stick packing machine and jelly sachet packing machine:

| No | Features | Jelly Stick Packing Machine | Jelly Sachet Packing Machine |

| 1 | Used for | It is used for packing jelly into beautiful single serving stick packs. | It is designed for packing jelly into single dosage sachets. |

| 2 | Packing design | It can create tubular log narrow stick packs. | While as, it makes square and rectangular shape sachets. |

| 3 | Capacity | Jelly stick packing machine produce bags with little capacity for jelly. | In contrast, jelly sachet packing machine design bags with higher capacity for jelly holding. |

| 4 | Structure | Its structure is compact and vertical. | While as, the structure of jelly sachet packing machine is complex and is available in both vertical and horizontal sachet packing machine. |

| 5 | Speed | It is efficient and has high production rate. | Jelly sachet packing machine is comparatively slow because of lengthy sealing sides. |

| 6 | Application | It is suitable for low amount of liquid jelly and can be used for similar products like honey, milk shake, and juices. | On the other hand, this machine is good for delivering both liquid and solid jelly. |

| 7 | Picture |

Jelly Packaging Machine- Picture Courtesy: coretamp.com |

Allpack- APK-110 Flat Pouch Horizontal Sachet Machine |

8.What Are The Industrial Applications Of A Jelly Stick Packing Machine?

The industrial applications of a jelly stick packing machine go far beyond food and beverage industry. In this question, you will get to know about the extensive applications of a jelly stick packing machine in different industries. These include:

Confectionery Industry

Liquid chocolate stick packs presentation idea- Picture Courtesy: danpak.com

The use of a jelly stick packing machine is inevitable in confectionery industry where products like liquid chocolate, liquid cream, butter, and most importantly jelly are produced and packed every day. Therefore, the help of machine is taken to enhance production efficiency.

Seasoning Industry

Ketchup presentation idea- Picture Courtesy: Nutrition Redefined

In addition to confectionery industry, jelly stick packing machine has also a good demand and presence in seasoning industry where liquids such as soy sauce, tomato ketchup, mayonnaise, and dressings etc., are regularly produced and packed.

Beverage Industry

Fruit drink stick packs with box- Picture Courtesy: fruitfunk.com

The significance of a jelly stick packing machine cannot be underestimated when it comes to beverage industry. It is because juices are what give us energy in the hot sunny days. Therefore, whether fruit juices, milk shake, soda, or a small amount of spirit, single serving stick packs are all-time favored for sipping.

Medical Industry

Supplement stick packs- Picture Courtesy: theelixirusa.com

Now, medicines and health supplements are also delivered in small handy stick packs. That's why a hygienic and quality machine is required to maintain the sensitivity of drugs and medicines which are offered by a jelly stick packing machine due to its protected structure.

Cosmetic Industry

Stick packages for beauty care

How can cosmetic industry be left behind when the ongoing discussion is about a machine providing appealing, convenient, and safe packaging! So, what matters here is the relevance of a jelly stick packing machine in beauty care sector for its ability to pack creams, hair dyes, shampoo, moisturizers, and hand washing gel etc.

Chemical Industry

vasudevcommodity.in

Stick packing machine is highly corrosion resistant due to which its applicability extends to chemical industry as well. Therefore, it can be used for packing any kind of daily use liquid chemicals such as paint, grease, detergents, dish washing gel, and adhesives etc.

9.What Quality Standards A Jelly Stick Packing Machine Should Meet With?

Jelly stick packing machine deals with processing edible things such as jelly, chocolate, and juices etc. Here, it is pertinent that the machine must be the product of a safe and protected material. To fulfill this aim, international community has established a set of rules and regulations which must be complied by quality machines. Some of the prominent ones include:

cGMP quality standard icon- Picture Courtesy: arenasolutions.com

ISO

International Organization for Standardization is a standard crucial for ensuring the safety of jelly stick packing machine.

FDA

Food and Drug Administration is another international agency established with the aim to keep strict eye on products and machines dealing with food and drugs processing.

cGMP

Current Good Manufacturing Practices is another quality standard which specifically aims at assuring the product quality. Its major significance is that it certifies only that machine which is adhering the latest rules and regulations.

CE

Conformité Européene is a mark mandatory for all these goods and products which are meant to be sold in European Union countries.

10.How To Install And Maintain A Jelly Stick Packing Machine?

Buying a new jelly stick packing machine can positively change your business growth. However, its successful installation and maintenance can be tricky. Therefore, we have come up with few essential tips for installation and maintenance of a jelly stick packing machine. These are as follows:

Installation

Installation icon- Picture Courtesy: duaflo.co.uk

Check the suitable place for machine by looking into the size of your jelly stick packing machine.

Make sure the area is properly ventilated and free from all kinds of dirt and pollution.

The floor or surface over which machine is kept must be plan and smooth otherwise the machine may show inconsistencies during operation.

Provide adequate power supply system to the machine or it will not work and may lead to sudden power breakdown.

Maintenance

Maintenance icon- Picture Courtesy: craveyrealestate.com

Maintenance is also very important for extending the working life of a jelly stick packing machine. For this you need to follow underlying guidelines:

- Regularly clean your machine with non-acidic water and compressed air for sensitive parts to remove out all the debris and residues accumulated in the machine.

- Keep your machine well lubricated and use grease as per the requirement of machine to avoid friction and parts damage.

- Make sure to adjust all the structural components, screws, and nuts of machine for ending noise and interruption.

- Examine the machine and if found any damage part then replace it with new one or it will affect the performance and efficiency of machine.

11.Diagnose The Common Pitfalls Of A Jelly Stick Packing Machine?

While using a jelly stick packing machine, you may face spontaneous errors. However, they are easy to solve provided that you have advance knowledge about them. Some of the common errors along with their causes and solutions are as follows:

Machine does not start

Displaying electrical connection of machine- Picture Courtesy: chengyipacking.com

Cause

Inadequate power supply.

Disconnection with power.

Solution

Provide adequate power to the machine.

Make sure the machine is properly connected to electricity.

There are wrinkles on film

Encircled film unwinding- Picture Courtesy: samfull.net

Cause

Too high-tension ok film during unwinding.

Roll stock is not fixed in right location.

Solution

Reduce the film tension by adjusting film on rollers.

Fit the film roll stock in center of film reel.

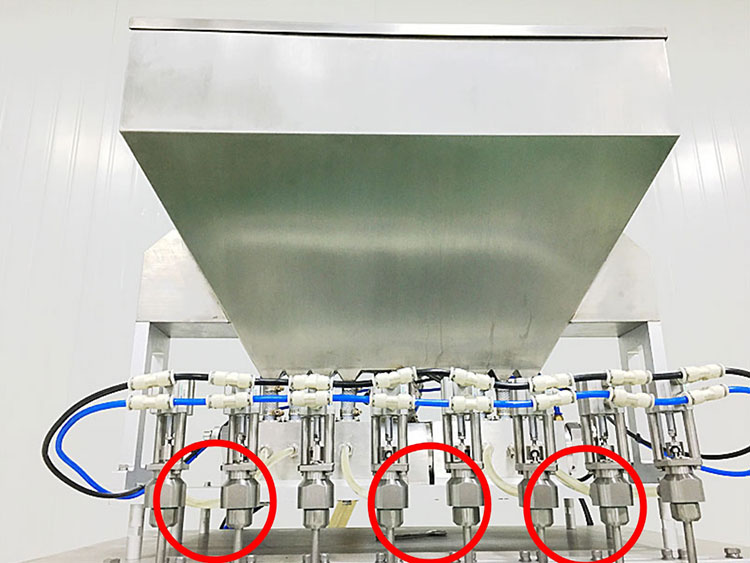

Jelly filling inconsistencies

Displaying filling nozzles blockage- Picture Courtesy: chengyipacking.com

Cause

The filling nozzles are clogged due to accumulation of jelly.

Uncleaned hopper and filling heads get dirty and does not dispense jelly evenly to stick packs.

Filling system is not rightly calibrated.

Solution

Remove the accumulated jelly from filling nozzles.

Clean the machine regularly especially hopper and filling heads for avoiding material blockage.

Make sure the filling system is rightly calibrated with the hopper on its top and filling nozzles in its bottom.

Improper bag Sealing

Encircled sealing rollers

Cause

Jaw jamming can cause weak sealing.

Too high temperature produces burned sealing.

Too little temperature causes partial sealing.

Solution

Properly setup the sealing jaws by resetting and tightening screws.

Reduce the temperature to suitable level.

Increase the temperature to suitable level.

12.Factors To Look For When Buying A Jelly Stick Packing Machine?

Some of the important factors for buying a jelly stick packing machine are written below:

Speed

Speed icon- Picture Courtesy: Freepik

Speed of a jelly stick packing machine matters a lot as you have decided to switch from manual to automatic way for packaging. Each machine has different speed, you must set your production requirements and opt for the machine by looking into its packing speed per hour.

Packaging Styles

Various design stick packs- Picture Courtesy: coretamp.com

Although, jelly stick packing machine is available in back side seal and 3 side seal packing machines, there are further categorization for shaping the stick packs through sealing and cutting. Therefore, you need to determine every aspect of stick packs style and buy the machine accordingly.

Operating Cost

With a bigger purchase of jelly stick packing machine, it's not only the initial cost which matters but also the operating cost of machine, the labor required for operation, and the maintenance cost. It means that an expensive machine may reduce your later expenses while maintaining smooth operation and automatic cleaning.

Reputable Supplier

Reputation icon- Picture Courtesy: siroistool.com

Having a trustable vendor is crucial but hard to find. For this purpose, you can check the customer feedback of that supplier, warranty policy, and after-sale services.

Conclusion

To put in a nutshell, Jelly Stick Packing Machine is the need of modern-day manufacturers. Due to its wide applications, high efficiency, and convenient operation, this machine generates high profits for businesses. It also reduces the possible wastage of jelly and packaging material. With so many benefits who will not bother to incorporate a jelly stick packing machine into their production line. Of course, no one! So, don't make any delay and contact us if you are interested in purchasing the machine!

Don't forget to share this post!

CONTACT US

Tell us your raw material and project budget to get quotations within 24 hours.

WhatsApp Us: +86 181 7101 8586

The Buyer's Guide

Tell us your material or budget, we'll reply you ASAP within 24 hours

Tell us your material or budget, we'll reply you ASAP within 24 hours